Development of Transparent Conducting Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TCB Glass Background and Objectives

Transparent conducting borosilicate (TCB) glass represents a significant advancement in materials science, combining the optical transparency of traditional borosilicate glass with electrical conductivity. This innovative material has its roots in the development of transparent conducting oxides (TCOs) in the mid-20th century, which revolutionized display technologies and solar cells. The evolution of TCB glass aims to address the limitations of conventional TCOs, such as indium tin oxide (ITO), by offering a more robust and versatile alternative.

The primary objective in developing TCB glass is to create a material that maintains the excellent thermal and chemical resistance of borosilicate glass while introducing electrical conductivity without compromising optical transparency. This unique combination of properties opens up a wide range of potential applications across various industries, from advanced electronics to energy-efficient architecture.

The technological trajectory of TCB glass is closely aligned with the growing demand for smart and multifunctional materials in the modern era. As industries push towards more integrated and efficient systems, the need for materials that can serve multiple purposes simultaneously has become increasingly apparent. TCB glass aims to meet this demand by offering a solution that can function as both a structural component and an active electronic element.

One of the key drivers behind the development of TCB glass is the pursuit of sustainability in technology. Traditional TCOs often rely on rare and expensive elements like indium, which raises concerns about long-term supply and environmental impact. By utilizing borosilicate glass as the base material, TCB glass offers a more abundant and potentially more sustainable alternative, aligning with global efforts to develop eco-friendly technologies.

The development of TCB glass also seeks to address the limitations of current transparent conductors in terms of durability and flexibility. Borosilicate glass's inherent strength and resistance to thermal shock make it an ideal candidate for applications requiring robust transparent conductors, such as in harsh environmental conditions or high-temperature operations.

Looking ahead, the objectives for TCB glass development include enhancing its electrical conductivity while maintaining high optical transparency, improving its manufacturability for large-scale production, and expanding its applicability across diverse fields. Researchers are exploring various doping techniques and nanostructure modifications to fine-tune the material's properties and achieve an optimal balance between transparency and conductivity.

As the field progresses, the ultimate goal is to position TCB glass as a versatile, high-performance material that can revolutionize industries ranging from electronics and energy to aerospace and architecture. By combining the best properties of borosilicate glass with advanced conductive capabilities, TCB glass aims to enable new technological innovations and contribute to the development of more efficient, durable, and multifunctional devices and structures.

The primary objective in developing TCB glass is to create a material that maintains the excellent thermal and chemical resistance of borosilicate glass while introducing electrical conductivity without compromising optical transparency. This unique combination of properties opens up a wide range of potential applications across various industries, from advanced electronics to energy-efficient architecture.

The technological trajectory of TCB glass is closely aligned with the growing demand for smart and multifunctional materials in the modern era. As industries push towards more integrated and efficient systems, the need for materials that can serve multiple purposes simultaneously has become increasingly apparent. TCB glass aims to meet this demand by offering a solution that can function as both a structural component and an active electronic element.

One of the key drivers behind the development of TCB glass is the pursuit of sustainability in technology. Traditional TCOs often rely on rare and expensive elements like indium, which raises concerns about long-term supply and environmental impact. By utilizing borosilicate glass as the base material, TCB glass offers a more abundant and potentially more sustainable alternative, aligning with global efforts to develop eco-friendly technologies.

The development of TCB glass also seeks to address the limitations of current transparent conductors in terms of durability and flexibility. Borosilicate glass's inherent strength and resistance to thermal shock make it an ideal candidate for applications requiring robust transparent conductors, such as in harsh environmental conditions or high-temperature operations.

Looking ahead, the objectives for TCB glass development include enhancing its electrical conductivity while maintaining high optical transparency, improving its manufacturability for large-scale production, and expanding its applicability across diverse fields. Researchers are exploring various doping techniques and nanostructure modifications to fine-tune the material's properties and achieve an optimal balance between transparency and conductivity.

As the field progresses, the ultimate goal is to position TCB glass as a versatile, high-performance material that can revolutionize industries ranging from electronics and energy to aerospace and architecture. By combining the best properties of borosilicate glass with advanced conductive capabilities, TCB glass aims to enable new technological innovations and contribute to the development of more efficient, durable, and multifunctional devices and structures.

Market Analysis for TCB Glass Applications

The market for Transparent Conducting Borosilicate (TCB) Glass is experiencing significant growth, driven by the increasing demand for advanced display technologies and smart devices. TCB glass combines the excellent thermal and chemical properties of borosilicate glass with the electrical conductivity of transparent conducting materials, making it an attractive option for various applications.

In the display industry, TCB glass is gaining traction as a potential replacement for traditional Indium Tin Oxide (ITO) coated glass. The market for display technologies, including smartphones, tablets, and large-format displays, continues to expand, with a projected compound annual growth rate (CAGR) of over 3% in the coming years. TCB glass offers advantages such as improved durability, better optical performance, and potentially lower production costs, which are driving its adoption in this sector.

The automotive industry represents another significant market for TCB glass applications. With the increasing integration of advanced driver assistance systems (ADAS) and the trend towards autonomous vehicles, there is a growing need for smart glass solutions. TCB glass can be used in heads-up displays, touch-sensitive controls, and heated windshields, contributing to improved safety and user experience. The automotive smart glass market is expected to grow substantially, presenting a lucrative opportunity for TCB glass manufacturers.

In the building and construction sector, TCB glass is finding applications in smart windows and energy-efficient building facades. The ability to control light transmission and heat transfer makes TCB glass an attractive option for sustainable building designs. The global smart glass market in construction is projected to expand rapidly, driven by increasing awareness of energy conservation and the adoption of green building practices.

The solar energy industry also presents a potential market for TCB glass. As the efficiency of solar panels continues to improve, there is a growing interest in integrating photovoltaic cells into building materials. TCB glass could serve as a substrate for thin-film solar cells, offering both transparency and electrical conductivity. This market segment is still in its early stages but shows promise for future growth.

Geographically, Asia-Pacific is expected to be the largest and fastest-growing market for TCB glass applications, driven by the region's dominant position in electronics manufacturing and rapid urbanization. North America and Europe are also significant markets, particularly in the automotive and construction sectors.

While the market potential for TCB glass is substantial, challenges such as high initial production costs and competition from established technologies like ITO need to be addressed. However, ongoing research and development efforts are likely to improve the cost-effectiveness and performance of TCB glass, further expanding its market opportunities across various industries.

In the display industry, TCB glass is gaining traction as a potential replacement for traditional Indium Tin Oxide (ITO) coated glass. The market for display technologies, including smartphones, tablets, and large-format displays, continues to expand, with a projected compound annual growth rate (CAGR) of over 3% in the coming years. TCB glass offers advantages such as improved durability, better optical performance, and potentially lower production costs, which are driving its adoption in this sector.

The automotive industry represents another significant market for TCB glass applications. With the increasing integration of advanced driver assistance systems (ADAS) and the trend towards autonomous vehicles, there is a growing need for smart glass solutions. TCB glass can be used in heads-up displays, touch-sensitive controls, and heated windshields, contributing to improved safety and user experience. The automotive smart glass market is expected to grow substantially, presenting a lucrative opportunity for TCB glass manufacturers.

In the building and construction sector, TCB glass is finding applications in smart windows and energy-efficient building facades. The ability to control light transmission and heat transfer makes TCB glass an attractive option for sustainable building designs. The global smart glass market in construction is projected to expand rapidly, driven by increasing awareness of energy conservation and the adoption of green building practices.

The solar energy industry also presents a potential market for TCB glass. As the efficiency of solar panels continues to improve, there is a growing interest in integrating photovoltaic cells into building materials. TCB glass could serve as a substrate for thin-film solar cells, offering both transparency and electrical conductivity. This market segment is still in its early stages but shows promise for future growth.

Geographically, Asia-Pacific is expected to be the largest and fastest-growing market for TCB glass applications, driven by the region's dominant position in electronics manufacturing and rapid urbanization. North America and Europe are also significant markets, particularly in the automotive and construction sectors.

While the market potential for TCB glass is substantial, challenges such as high initial production costs and competition from established technologies like ITO need to be addressed. However, ongoing research and development efforts are likely to improve the cost-effectiveness and performance of TCB glass, further expanding its market opportunities across various industries.

TCB Glass Development Status and Challenges

The development of Transparent Conducting Borosilicate (TCB) Glass has made significant strides in recent years, yet it still faces several challenges that hinder its widespread adoption. Currently, the technology is at a crucial juncture where researchers and industry players are working to overcome these obstacles and unlock its full potential.

One of the primary challenges in TCB glass development is achieving the optimal balance between transparency and conductivity. While borosilicate glass inherently possesses excellent optical properties, the incorporation of conductive elements often compromises its transparency. Researchers are exploring various methods to enhance conductivity without significantly reducing light transmission, including the use of novel dopants and advanced deposition techniques.

Another significant hurdle is the scalability of production processes. Laboratory-scale successes have been achieved, but translating these into large-scale, cost-effective manufacturing remains a challenge. The industry is grappling with issues related to uniformity in conductivity and transparency across larger glass sheets, which is crucial for applications in areas such as smart windows and solar panels.

Durability and long-term stability of TCB glass are also areas of ongoing research. The conductive properties of the glass must remain stable under various environmental conditions, including exposure to heat, humidity, and UV radiation. Developing coatings or treatments that can protect the conductive elements without affecting the glass's optical properties is a key focus area.

The integration of TCB glass into existing manufacturing processes and products presents another set of challenges. Industries such as electronics and automotive are exploring ways to incorporate this technology into their products, but issues related to compatibility with other materials and assembly processes need to be addressed.

From a geographical perspective, research and development in TCB glass technology are primarily concentrated in North America, Europe, and East Asia. These regions host major research institutions and companies at the forefront of this technology. However, there is a growing interest in emerging markets, particularly in developing countries looking to leapfrog traditional technologies in areas like energy-efficient buildings and renewable energy.

In terms of technological distribution, there is a notable divide between academic research and industrial applications. While universities and research institutes are pushing the boundaries of what's possible with TCB glass, translating these advancements into commercially viable products remains a challenge for many companies in the field.

One of the primary challenges in TCB glass development is achieving the optimal balance between transparency and conductivity. While borosilicate glass inherently possesses excellent optical properties, the incorporation of conductive elements often compromises its transparency. Researchers are exploring various methods to enhance conductivity without significantly reducing light transmission, including the use of novel dopants and advanced deposition techniques.

Another significant hurdle is the scalability of production processes. Laboratory-scale successes have been achieved, but translating these into large-scale, cost-effective manufacturing remains a challenge. The industry is grappling with issues related to uniformity in conductivity and transparency across larger glass sheets, which is crucial for applications in areas such as smart windows and solar panels.

Durability and long-term stability of TCB glass are also areas of ongoing research. The conductive properties of the glass must remain stable under various environmental conditions, including exposure to heat, humidity, and UV radiation. Developing coatings or treatments that can protect the conductive elements without affecting the glass's optical properties is a key focus area.

The integration of TCB glass into existing manufacturing processes and products presents another set of challenges. Industries such as electronics and automotive are exploring ways to incorporate this technology into their products, but issues related to compatibility with other materials and assembly processes need to be addressed.

From a geographical perspective, research and development in TCB glass technology are primarily concentrated in North America, Europe, and East Asia. These regions host major research institutions and companies at the forefront of this technology. However, there is a growing interest in emerging markets, particularly in developing countries looking to leapfrog traditional technologies in areas like energy-efficient buildings and renewable energy.

In terms of technological distribution, there is a notable divide between academic research and industrial applications. While universities and research institutes are pushing the boundaries of what's possible with TCB glass, translating these advancements into commercially viable products remains a challenge for many companies in the field.

Current TCB Glass Fabrication Methods

01 Composition of transparent conducting borosilicate glass

Transparent conducting borosilicate glass can be created by incorporating specific elements or compounds into the glass composition. These additives enhance both the transparency and conductivity of the glass while maintaining its borosilicate structure. The composition may include elements such as indium, tin, or fluorine-doped materials to achieve the desired properties.- Composition of transparent conducting borosilicate glass: Transparent conducting borosilicate glass can be created by incorporating specific elements or compounds into the glass composition. These additives enhance both the transparency and conductivity of the glass. The composition may include elements such as indium, tin, or fluorine-doped tin oxide to achieve the desired properties.

- Surface treatment techniques for improved conductivity: Various surface treatment methods can be applied to borosilicate glass to enhance its conductivity while maintaining transparency. These techniques may include coating the glass surface with conductive materials, ion implantation, or chemical vapor deposition. Such treatments create a thin conductive layer on the glass surface without significantly affecting its optical properties.

- Nanostructure incorporation for enhanced properties: Incorporating nanostructures into borosilicate glass can significantly improve both its transparency and conductivity. These nanostructures, such as carbon nanotubes or metallic nanoparticles, can be dispersed within the glass matrix or applied as a thin film on the surface. The resulting composite material exhibits enhanced electrical conductivity while maintaining high optical transparency.

- Heat treatment processes for optimizing properties: Specific heat treatment processes can be employed to optimize the transparency and conductivity of borosilicate glass. These processes may involve controlled heating and cooling cycles, annealing, or tempering. Such treatments can modify the glass structure, reduce defects, and improve the overall performance of the transparent conducting borosilicate glass.

- Multilayer structures for enhanced performance: Developing multilayer structures using borosilicate glass and other materials can result in improved transparency and conductivity. These structures may consist of alternating layers of glass and conductive materials or gradient compositions. The multilayer approach allows for fine-tuning of optical and electrical properties while maintaining the overall transparency of the glass.

02 Surface treatment methods for improving conductivity

Various surface treatment methods can be applied to borosilicate glass to enhance its conductivity while preserving transparency. These techniques may include coating the glass surface with transparent conductive oxides, applying conductive films, or using ion implantation processes. Such treatments create a conductive layer on the glass surface without significantly affecting its optical properties.Expand Specific Solutions03 Nanostructure incorporation for enhanced properties

Incorporating nanostructures into borosilicate glass can significantly improve both its transparency and conductivity. These nanostructures, such as carbon nanotubes or metallic nanoparticles, can be dispersed within the glass matrix or applied as a thin film on the surface. The nanoscale features allow for high conductivity while maintaining optical clarity.Expand Specific Solutions04 Heat treatment and annealing processes

Specific heat treatment and annealing processes can be employed to optimize the transparency and conductivity of borosilicate glass. These thermal processes can help in restructuring the glass network, reducing defects, and improving the distribution of conductive elements within the glass. Controlled cooling rates and temperature profiles are crucial for achieving the desired properties.Expand Specific Solutions05 Doping techniques for conductivity enhancement

Doping borosilicate glass with specific elements or compounds can significantly enhance its electrical conductivity while maintaining transparency. Common dopants include transition metals, rare earth elements, or conductive oxides. The doping process can be achieved through various methods such as ion exchange, sol-gel techniques, or melt doping during glass formation.Expand Specific Solutions

Key Players in TCB Glass Industry

The development of transparent conducting borosilicate glass is in a growth phase, with increasing market demand driven by applications in electronics, solar energy, and advanced optics. The global market size for this technology is expanding, estimated to reach several billion dollars by 2025. Technologically, the field is advancing rapidly, with major players like SCHOTT AG, Corning, Inc., and AGC, Inc. leading innovation. These companies are investing heavily in R&D to improve conductivity, transparency, and durability of borosilicate glass. Emerging players such as LG Chem Ltd. and Nippon Electric Glass Co., Ltd. are also making significant strides, particularly in specialized applications. The technology's maturity varies across different applications, with some areas nearing commercialization while others remain in early development stages.

SCHOTT AG

Technical Solution: SCHOTT AG has developed a pioneering approach to transparent conducting borosilicate glass using their CONTURAN® technology. This process involves applying a transparent conductive coating to borosilicate glass, resulting in a product with excellent optical and electrical properties. The coating is typically composed of indium tin oxide (ITO) or fluorine-doped tin oxide (FTO), which are deposited using advanced sputtering techniques[1]. SCHOTT's method ensures uniform conductivity across the glass surface while maintaining high transparency, with visible light transmission rates exceeding 90%[2]. The company has also focused on enhancing the durability of the conductive coating, making it resistant to environmental factors and repeated cleaning processes, which is crucial for applications in harsh environments or touchscreen devices[3].

Strengths: High optical transparency, uniform conductivity, and excellent durability. Weaknesses: Potential high cost due to the use of rare materials like indium, and limitations in flexibility compared to some polymer-based alternatives.

Corning, Inc.

Technical Solution: Corning has made significant strides in the development of transparent conducting borosilicate glass, leveraging their expertise in glass technology. Their approach involves a proprietary ion-exchange process that introduces conductive elements into the glass structure itself, rather than relying solely on surface coatings[4]. This method results in a more integrated and durable conductive layer. Corning's technology allows for the creation of ultra-thin borosilicate glass sheets with conductive properties, achieving thicknesses as low as 0.1mm while maintaining structural integrity[5]. The company has also developed a unique etching process that creates microscopic channels in the glass surface, enhancing conductivity without significantly impacting transparency. This innovation has led to sheets with sheet resistance as low as 10 ohms/square while maintaining over 85% visible light transmission[6].

Strengths: Ultra-thin glass capability, integrated conductivity, and high durability. Weaknesses: Potentially higher production costs and limitations in achieving very large sheet sizes.

Core Innovations in TCB Glass Technology

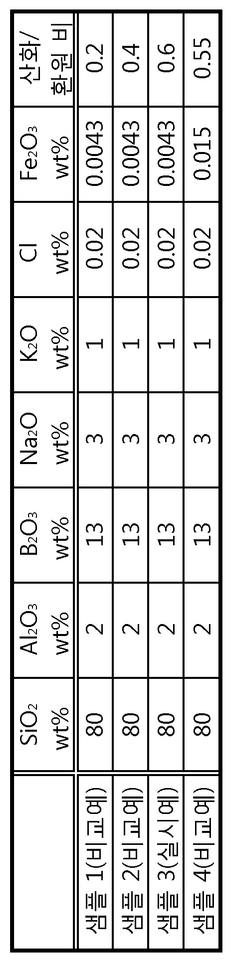

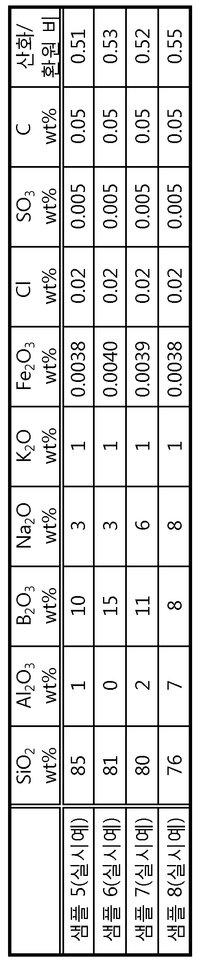

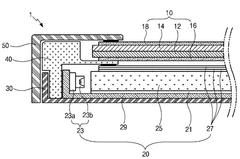

Borosilicate glass, light guide plate comprising same, and method for manufacturing same light guide plate

PatentWO2017191913A1

Innovation

- Development of borosilicate glass with specific compositions, including SiO2, B2O3, Al2O3, and R2O, with controlled oxidation/reduction ratios and low iron content, which is used to manufacture a light guide plate that replaces polymer materials and metal frames, offering improved mechanical strength and optical properties.

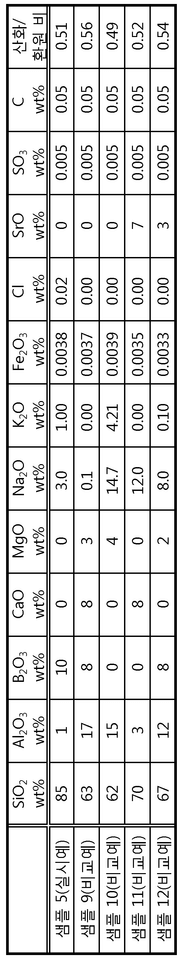

Low boric acid borosilicate glass and its use

PatentInactiveEP0699636A1

Innovation

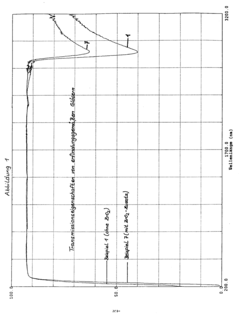

- Developing new borosilicate glass compositions with specific ratios of SiO2, B2O3, Al2O3, Li2O, Na2O, K2O, MgO, CaO, BaO, ZnO, ZrO2, and other oxides, ensuring high alkali resistance (LBK 1), low thermal expansion (4.0-5.3 x 10^-6 K^-1), and high UV transmission, while maintaining mechanical and thermal strength through chemical and thermal toughening.

Environmental Impact of TCB Glass Production

The production of Transparent Conducting Borosilicate (TCB) Glass has significant environmental implications that warrant careful consideration. The manufacturing process involves energy-intensive procedures and the use of various chemicals, which can contribute to environmental degradation if not managed properly.

One of the primary environmental concerns is the high energy consumption associated with glass production. The melting of raw materials to form borosilicate glass requires temperatures exceeding 1500°C, typically achieved through the use of fossil fuels. This process results in substantial greenhouse gas emissions, contributing to climate change. However, advancements in furnace technology and the integration of renewable energy sources in glass production facilities have the potential to mitigate these impacts.

The extraction and processing of raw materials for TCB glass production also pose environmental challenges. Mining operations for boron, silica, and other components can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. Additionally, the production of conductive coatings often involves rare earth elements or precious metals, which have their own set of environmental concerns related to extraction and processing.

Chemical usage in TCB glass production presents another environmental consideration. The etching and cleaning processes typically employ acids and solvents, which can be harmful if released into the environment. Proper waste management and recycling systems are crucial to minimize the ecological footprint of these chemicals. Some manufacturers have begun implementing closed-loop systems to recycle and reuse chemicals, reducing overall waste and environmental impact.

Water consumption is a significant factor in TCB glass production, particularly in cooling and cleaning processes. In water-stressed regions, this can put additional pressure on local water resources. Implementation of water-efficient technologies and water recycling systems can help address this issue, reducing the overall water footprint of production facilities.

The disposal of TCB glass at the end of its lifecycle presents additional environmental challenges. While glass is generally recyclable, the conductive coatings and specialized compositions of TCB glass may complicate recycling processes. Developing effective recycling methods for TCB glass is crucial for promoting a circular economy and reducing the environmental impact of electronic waste.

Despite these challenges, TCB glass offers potential environmental benefits in its applications. Its use in energy-efficient windows and solar panels can contribute to reduced energy consumption in buildings and increased renewable energy production, potentially offsetting some of the environmental costs associated with its manufacture.

One of the primary environmental concerns is the high energy consumption associated with glass production. The melting of raw materials to form borosilicate glass requires temperatures exceeding 1500°C, typically achieved through the use of fossil fuels. This process results in substantial greenhouse gas emissions, contributing to climate change. However, advancements in furnace technology and the integration of renewable energy sources in glass production facilities have the potential to mitigate these impacts.

The extraction and processing of raw materials for TCB glass production also pose environmental challenges. Mining operations for boron, silica, and other components can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. Additionally, the production of conductive coatings often involves rare earth elements or precious metals, which have their own set of environmental concerns related to extraction and processing.

Chemical usage in TCB glass production presents another environmental consideration. The etching and cleaning processes typically employ acids and solvents, which can be harmful if released into the environment. Proper waste management and recycling systems are crucial to minimize the ecological footprint of these chemicals. Some manufacturers have begun implementing closed-loop systems to recycle and reuse chemicals, reducing overall waste and environmental impact.

Water consumption is a significant factor in TCB glass production, particularly in cooling and cleaning processes. In water-stressed regions, this can put additional pressure on local water resources. Implementation of water-efficient technologies and water recycling systems can help address this issue, reducing the overall water footprint of production facilities.

The disposal of TCB glass at the end of its lifecycle presents additional environmental challenges. While glass is generally recyclable, the conductive coatings and specialized compositions of TCB glass may complicate recycling processes. Developing effective recycling methods for TCB glass is crucial for promoting a circular economy and reducing the environmental impact of electronic waste.

Despite these challenges, TCB glass offers potential environmental benefits in its applications. Its use in energy-efficient windows and solar panels can contribute to reduced energy consumption in buildings and increased renewable energy production, potentially offsetting some of the environmental costs associated with its manufacture.

TCB Glass Standards and Certifications

The development of Transparent Conducting Borosilicate (TCB) Glass has necessitated the establishment of rigorous standards and certifications to ensure quality, safety, and performance across various applications. These standards play a crucial role in guiding manufacturers, researchers, and end-users in the production, testing, and implementation of TCB glass.

One of the primary standards for TCB glass is the International Electrotechnical Commission (IEC) 61646, which outlines the requirements for thin-film terrestrial photovoltaic modules. This standard is particularly relevant for TCB glass used in solar panel applications, ensuring that the material meets specific electrical and mechanical performance criteria.

The American Society for Testing and Materials (ASTM) has developed several standards applicable to TCB glass. ASTM C1036 provides specifications for flat glass, while ASTM E2141 focuses on the durability of advanced glazing systems. These standards help in evaluating the optical and structural properties of TCB glass.

For environmental considerations, the RoHS (Restriction of Hazardous Substances) directive is crucial. TCB glass manufacturers must ensure their products comply with RoHS standards, particularly regarding the use of lead and other potentially harmful substances in the production process.

The International Organization for Standardization (ISO) has also contributed to TCB glass standards. ISO 9050 provides a method for determining light transmittance, solar direct transmittance, and related glazing factors, which are essential for assessing the performance of TCB glass in various lighting and energy-efficient applications.

Certification processes for TCB glass often involve third-party testing laboratories. These facilities conduct rigorous tests to verify compliance with relevant standards. The Underwriters Laboratories (UL) certification is widely recognized and sought after, particularly for TCB glass used in electronic displays and touchscreens.

In the automotive sector, TCB glass must meet specific standards set by organizations such as the Society of Automotive Engineers (SAE). These standards address issues like impact resistance, optical clarity, and electromagnetic compatibility, which are critical for heads-up displays and smart windshields.

As the technology evolves, new standards and certifications are being developed to address emerging applications of TCB glass. For instance, the development of flexible and wearable electronics has prompted the need for standards that can assess the durability and performance of TCB glass under bending and folding conditions.

One of the primary standards for TCB glass is the International Electrotechnical Commission (IEC) 61646, which outlines the requirements for thin-film terrestrial photovoltaic modules. This standard is particularly relevant for TCB glass used in solar panel applications, ensuring that the material meets specific electrical and mechanical performance criteria.

The American Society for Testing and Materials (ASTM) has developed several standards applicable to TCB glass. ASTM C1036 provides specifications for flat glass, while ASTM E2141 focuses on the durability of advanced glazing systems. These standards help in evaluating the optical and structural properties of TCB glass.

For environmental considerations, the RoHS (Restriction of Hazardous Substances) directive is crucial. TCB glass manufacturers must ensure their products comply with RoHS standards, particularly regarding the use of lead and other potentially harmful substances in the production process.

The International Organization for Standardization (ISO) has also contributed to TCB glass standards. ISO 9050 provides a method for determining light transmittance, solar direct transmittance, and related glazing factors, which are essential for assessing the performance of TCB glass in various lighting and energy-efficient applications.

Certification processes for TCB glass often involve third-party testing laboratories. These facilities conduct rigorous tests to verify compliance with relevant standards. The Underwriters Laboratories (UL) certification is widely recognized and sought after, particularly for TCB glass used in electronic displays and touchscreens.

In the automotive sector, TCB glass must meet specific standards set by organizations such as the Society of Automotive Engineers (SAE). These standards address issues like impact resistance, optical clarity, and electromagnetic compatibility, which are critical for heads-up displays and smart windshields.

As the technology evolves, new standards and certifications are being developed to address emerging applications of TCB glass. For instance, the development of flexible and wearable electronics has prompted the need for standards that can assess the durability and performance of TCB glass under bending and folding conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!