Borosilicate Glass-Supported Photocatalysts

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Photocatalysis Background

Borosilicate glass-supported photocatalysts represent a significant advancement in the field of environmental remediation and sustainable energy production. This technology combines the robust properties of borosilicate glass with the photocatalytic capabilities of various materials, primarily titanium dioxide (TiO2). The development of these composite materials stems from the need for more efficient and durable photocatalytic systems that can be easily integrated into existing infrastructure.

The journey of borosilicate glass in photocatalysis began in the late 20th century when researchers recognized its potential as a stable and transparent support for photocatalytic materials. Borosilicate glass, known for its excellent thermal and chemical resistance, provides an ideal substrate for anchoring photocatalysts. This combination addresses several limitations of traditional powder-based photocatalysts, such as difficulty in separation and recovery after use.

The evolution of this technology has been driven by the growing demand for water and air purification solutions, as well as the push for renewable energy sources. Photocatalysis offers a promising approach to these challenges, utilizing light energy to drive chemical reactions that can degrade pollutants or split water for hydrogen production. The integration of photocatalysts with borosilicate glass has opened new avenues for applications in self-cleaning surfaces, water treatment systems, and solar fuel generation.

Recent years have seen a surge in research focused on enhancing the performance of borosilicate glass-supported photocatalysts. This includes efforts to improve the adhesion of photocatalytic materials to the glass surface, increase the surface area for catalytic reactions, and extend the light absorption range of the photocatalysts. Innovations in nanotechnology have played a crucial role, enabling the development of nanostructured coatings that significantly boost the efficiency of these systems.

The technological trajectory of borosilicate glass photocatalysis is closely aligned with global sustainability goals. As environmental regulations become more stringent and the need for clean energy solutions intensifies, the demand for advanced photocatalytic materials is expected to grow. This has spurred ongoing research into novel synthesis methods, composite materials, and surface modification techniques to further enhance the capabilities of borosilicate glass-supported photocatalysts.

Looking ahead, the field is poised for further advancements, with researchers exploring the integration of plasmonic materials, quantum dots, and other cutting-edge nanomaterials to push the boundaries of photocatalytic efficiency. The ultimate goal is to develop highly active, stable, and cost-effective photocatalytic systems that can be readily scaled for industrial applications, contributing significantly to environmental protection and sustainable energy production.

The journey of borosilicate glass in photocatalysis began in the late 20th century when researchers recognized its potential as a stable and transparent support for photocatalytic materials. Borosilicate glass, known for its excellent thermal and chemical resistance, provides an ideal substrate for anchoring photocatalysts. This combination addresses several limitations of traditional powder-based photocatalysts, such as difficulty in separation and recovery after use.

The evolution of this technology has been driven by the growing demand for water and air purification solutions, as well as the push for renewable energy sources. Photocatalysis offers a promising approach to these challenges, utilizing light energy to drive chemical reactions that can degrade pollutants or split water for hydrogen production. The integration of photocatalysts with borosilicate glass has opened new avenues for applications in self-cleaning surfaces, water treatment systems, and solar fuel generation.

Recent years have seen a surge in research focused on enhancing the performance of borosilicate glass-supported photocatalysts. This includes efforts to improve the adhesion of photocatalytic materials to the glass surface, increase the surface area for catalytic reactions, and extend the light absorption range of the photocatalysts. Innovations in nanotechnology have played a crucial role, enabling the development of nanostructured coatings that significantly boost the efficiency of these systems.

The technological trajectory of borosilicate glass photocatalysis is closely aligned with global sustainability goals. As environmental regulations become more stringent and the need for clean energy solutions intensifies, the demand for advanced photocatalytic materials is expected to grow. This has spurred ongoing research into novel synthesis methods, composite materials, and surface modification techniques to further enhance the capabilities of borosilicate glass-supported photocatalysts.

Looking ahead, the field is poised for further advancements, with researchers exploring the integration of plasmonic materials, quantum dots, and other cutting-edge nanomaterials to push the boundaries of photocatalytic efficiency. The ultimate goal is to develop highly active, stable, and cost-effective photocatalytic systems that can be readily scaled for industrial applications, contributing significantly to environmental protection and sustainable energy production.

Market Analysis for Glass-Supported Catalysts

The market for glass-supported catalysts, particularly those utilizing borosilicate glass as a substrate for photocatalysts, has been experiencing significant growth in recent years. This trend is driven by the increasing demand for sustainable and efficient catalytic processes across various industries, including environmental remediation, energy production, and chemical manufacturing.

The global market for glass-supported catalysts is projected to expand at a compound annual growth rate (CAGR) of over 6% during the forecast period of 2021-2026. This growth is primarily attributed to the rising awareness of environmental issues and the need for cleaner production processes. Borosilicate glass-supported photocatalysts, in particular, are gaining traction due to their superior chemical and thermal stability, transparency, and ability to enhance catalytic performance.

One of the key drivers for market growth is the increasing focus on water and air purification technologies. Glass-supported photocatalysts have shown promising results in the degradation of organic pollutants and the removal of harmful substances from water and air. This has led to a surge in demand from municipal water treatment plants, industrial wastewater management facilities, and air purification system manufacturers.

The energy sector is another significant contributor to market growth. With the global push towards renewable energy sources, glass-supported photocatalysts are being extensively researched for their potential applications in solar fuel production and artificial photosynthesis. These technologies could play a crucial role in addressing the world's growing energy needs while reducing carbon emissions.

In the chemical manufacturing industry, glass-supported catalysts are gaining popularity due to their ability to improve reaction efficiency and selectivity. This has led to increased adoption in the production of fine chemicals, pharmaceuticals, and specialty materials. The transparency of borosilicate glass also allows for real-time monitoring of catalytic reactions, which is particularly valuable in research and development settings.

Geographically, Asia-Pacific is expected to dominate the glass-supported catalyst market, driven by rapid industrialization, stringent environmental regulations, and increasing investments in research and development. North America and Europe are also significant markets, with a strong focus on sustainable technologies and advanced materials research.

However, the market faces challenges such as high initial costs associated with the development and production of glass-supported catalysts. Additionally, competition from alternative catalyst support materials, such as ceramics and polymers, may impact market growth. Despite these challenges, ongoing research and development efforts are expected to lead to more cost-effective production methods and improved catalytic performance, further driving market expansion in the coming years.

The global market for glass-supported catalysts is projected to expand at a compound annual growth rate (CAGR) of over 6% during the forecast period of 2021-2026. This growth is primarily attributed to the rising awareness of environmental issues and the need for cleaner production processes. Borosilicate glass-supported photocatalysts, in particular, are gaining traction due to their superior chemical and thermal stability, transparency, and ability to enhance catalytic performance.

One of the key drivers for market growth is the increasing focus on water and air purification technologies. Glass-supported photocatalysts have shown promising results in the degradation of organic pollutants and the removal of harmful substances from water and air. This has led to a surge in demand from municipal water treatment plants, industrial wastewater management facilities, and air purification system manufacturers.

The energy sector is another significant contributor to market growth. With the global push towards renewable energy sources, glass-supported photocatalysts are being extensively researched for their potential applications in solar fuel production and artificial photosynthesis. These technologies could play a crucial role in addressing the world's growing energy needs while reducing carbon emissions.

In the chemical manufacturing industry, glass-supported catalysts are gaining popularity due to their ability to improve reaction efficiency and selectivity. This has led to increased adoption in the production of fine chemicals, pharmaceuticals, and specialty materials. The transparency of borosilicate glass also allows for real-time monitoring of catalytic reactions, which is particularly valuable in research and development settings.

Geographically, Asia-Pacific is expected to dominate the glass-supported catalyst market, driven by rapid industrialization, stringent environmental regulations, and increasing investments in research and development. North America and Europe are also significant markets, with a strong focus on sustainable technologies and advanced materials research.

However, the market faces challenges such as high initial costs associated with the development and production of glass-supported catalysts. Additionally, competition from alternative catalyst support materials, such as ceramics and polymers, may impact market growth. Despite these challenges, ongoing research and development efforts are expected to lead to more cost-effective production methods and improved catalytic performance, further driving market expansion in the coming years.

Current Challenges in Photocatalyst Support

Despite the promising potential of photocatalysts in various applications, several challenges persist in the development and implementation of effective photocatalyst support systems. One of the primary issues is the stability and durability of the support material under harsh reaction conditions. Borosilicate glass, while offering excellent thermal and chemical resistance, may still be susceptible to degradation over extended periods of use, particularly in highly acidic or alkaline environments.

Another significant challenge is the optimization of the interface between the photocatalyst and the borosilicate glass support. Achieving strong adhesion and uniform distribution of the catalyst on the glass surface remains a complex task. Inadequate interfacial contact can lead to reduced catalytic efficiency and potential catalyst leaching, compromising the overall performance and longevity of the system.

The light transmission properties of borosilicate glass also present a challenge in photocatalyst support design. While borosilicate glass generally offers good transparency, ensuring optimal light penetration to activate the photocatalyst throughout the entire supported structure can be difficult, especially in scaled-up systems or those with complex geometries.

Surface area optimization is another critical challenge. Maximizing the available surface area for catalyst loading while maintaining the structural integrity and transparency of the borosilicate glass support requires careful engineering. Techniques such as etching or the creation of porous structures must be balanced against the potential weakening of the glass substrate.

The thermal management of borosilicate glass-supported photocatalysts poses additional challenges. Although borosilicate glass has a low coefficient of thermal expansion, localized heating during photocatalytic reactions can still induce thermal stress, potentially leading to cracking or deformation of the support structure over time.

Scalability and cost-effectiveness remain significant hurdles in the widespread adoption of borosilicate glass-supported photocatalysts. Developing economically viable manufacturing processes that can produce large-scale, uniform, and defect-free supported catalyst systems is crucial for industrial applications.

Lastly, the environmental impact and recyclability of borosilicate glass-supported photocatalysts need to be addressed. While glass is generally recyclable, the presence of catalyst materials may complicate the recycling process. Developing effective methods for catalyst recovery and glass recycling at the end of the system's life cycle is essential for ensuring the sustainability of this technology.

Another significant challenge is the optimization of the interface between the photocatalyst and the borosilicate glass support. Achieving strong adhesion and uniform distribution of the catalyst on the glass surface remains a complex task. Inadequate interfacial contact can lead to reduced catalytic efficiency and potential catalyst leaching, compromising the overall performance and longevity of the system.

The light transmission properties of borosilicate glass also present a challenge in photocatalyst support design. While borosilicate glass generally offers good transparency, ensuring optimal light penetration to activate the photocatalyst throughout the entire supported structure can be difficult, especially in scaled-up systems or those with complex geometries.

Surface area optimization is another critical challenge. Maximizing the available surface area for catalyst loading while maintaining the structural integrity and transparency of the borosilicate glass support requires careful engineering. Techniques such as etching or the creation of porous structures must be balanced against the potential weakening of the glass substrate.

The thermal management of borosilicate glass-supported photocatalysts poses additional challenges. Although borosilicate glass has a low coefficient of thermal expansion, localized heating during photocatalytic reactions can still induce thermal stress, potentially leading to cracking or deformation of the support structure over time.

Scalability and cost-effectiveness remain significant hurdles in the widespread adoption of borosilicate glass-supported photocatalysts. Developing economically viable manufacturing processes that can produce large-scale, uniform, and defect-free supported catalyst systems is crucial for industrial applications.

Lastly, the environmental impact and recyclability of borosilicate glass-supported photocatalysts need to be addressed. While glass is generally recyclable, the presence of catalyst materials may complicate the recycling process. Developing effective methods for catalyst recovery and glass recycling at the end of the system's life cycle is essential for ensuring the sustainability of this technology.

Existing Borosilicate Glass Support Methods

01 Borosilicate glass as a support for photocatalysts

Borosilicate glass is used as a support material for photocatalysts due to its chemical stability, transparency, and thermal resistance. The glass provides a suitable surface for the deposition or immobilization of photocatalytic materials, enhancing their effectiveness and durability in various applications.- Borosilicate glass as a support for photocatalysts: Borosilicate glass is used as a substrate for photocatalytic materials due to its thermal stability, chemical resistance, and transparency. The glass provides a stable surface for the deposition or immobilization of photocatalysts, enhancing their effectiveness and durability in various applications.

- Preparation methods for borosilicate glass-supported photocatalysts: Various techniques are employed to prepare borosilicate glass-supported photocatalysts, including sol-gel methods, dip-coating, spray pyrolysis, and chemical vapor deposition. These methods allow for the controlled deposition of photocatalytic materials onto the glass surface, optimizing their performance and adhesion.

- Applications of borosilicate glass-supported photocatalysts: Borosilicate glass-supported photocatalysts find applications in water and air purification, self-cleaning surfaces, antimicrobial coatings, and energy conversion systems. The combination of the glass support and photocatalytic material enables efficient light utilization and catalytic activity in various environmental and industrial processes.

- Enhancement of photocatalytic activity on borosilicate glass: Researchers have developed methods to enhance the photocatalytic activity of materials supported on borosilicate glass. These include surface modification techniques, doping with metal ions, creation of nanostructured surfaces, and incorporation of plasmonic materials to improve light absorption and charge separation.

- Characterization and performance evaluation of borosilicate glass-supported photocatalysts: Various analytical techniques are used to characterize and evaluate the performance of borosilicate glass-supported photocatalysts. These include spectroscopic methods, microscopy, and photocatalytic activity tests under different light sources and environmental conditions to assess their efficiency and stability.

02 Preparation methods for borosilicate glass-supported photocatalysts

Various techniques are employed to prepare borosilicate glass-supported photocatalysts, including sol-gel methods, dip-coating, spray pyrolysis, and chemical vapor deposition. These methods allow for the controlled deposition of photocatalytic materials onto the glass surface, optimizing their performance and adhesion.Expand Specific Solutions03 Applications of borosilicate glass-supported photocatalysts

Borosilicate glass-supported photocatalysts find applications in water and air purification, self-cleaning surfaces, antimicrobial coatings, and energy conversion systems. The transparency of the glass allows for efficient light transmission to activate the photocatalysts, making them suitable for various environmental and industrial uses.Expand Specific Solutions04 Enhancement of photocatalytic activity

Researchers have developed methods to enhance the photocatalytic activity of borosilicate glass-supported catalysts. These include doping with metal ions, creating nanostructured surfaces, and incorporating plasmonic materials to improve light absorption and charge separation efficiency.Expand Specific Solutions05 Durability and reusability of borosilicate glass-supported photocatalysts

The use of borosilicate glass as a support material enhances the durability and reusability of photocatalysts. The strong adhesion between the glass and the photocatalytic material, combined with the chemical stability of borosilicate glass, allows for repeated use and easy regeneration of the catalysts, making them more economical and environmentally friendly.Expand Specific Solutions

Key Players in Photocatalysis Industry

The research on borosilicate glass-supported photocatalysts is in a developing stage, with growing market potential due to increasing environmental applications. The global market for photocatalysts is expanding, driven by demand for water and air purification technologies. Major players like SCHOTT AG, Corning, Inc., and LG Chem Ltd. are investing in R&D to improve the efficiency and durability of borosilicate glass-supported photocatalysts. Academic institutions such as Wuhan University of Technology and Dalian University of Technology are contributing to technological advancements. The technology's maturity is progressing, with companies like Nippon Electric Glass Co., Ltd. and FUJIFILM Corp. exploring commercial applications, though further optimization is needed for widespread adoption.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass-supported photocatalysts for environmental applications. Their approach involves incorporating titanium dioxide nanoparticles into the borosilicate glass matrix, creating a durable and efficient photocatalytic surface. The company has optimized the synthesis process to achieve a high surface area and uniform distribution of the photocatalyst[1]. SCHOTT's technology allows for the production of large-scale photocatalytic glass panels that can be used for air and water purification in various settings, including buildings and industrial facilities[2]. The photocatalytic activity is enhanced by the unique properties of borosilicate glass, which provides excellent chemical resistance and thermal stability[3].

Strengths: High durability, scalability for large-scale applications, and excellent chemical resistance. Weaknesses: Potential limitations in light absorption range and need for UV light activation.

Corning, Inc.

Technical Solution: Corning has developed a proprietary borosilicate glass-supported photocatalyst technology called "Corning® Gorilla® Glass with Antimicrobial Corning® Gorilla® Glass". This innovative solution incorporates silver ions into the glass matrix, which provides both photocatalytic and antimicrobial properties[1]. The photocatalytic activity is enhanced by the unique surface structure of the glass, which increases the effective surface area for reactions[2]. Corning's technology allows for the production of thin, lightweight, and durable photocatalytic surfaces that can be integrated into various devices and architectural elements. The company has also developed methods to enhance the visible light absorption of their photocatalysts, improving efficiency under indoor lighting conditions[3].

Strengths: Dual functionality (photocatalytic and antimicrobial), thin and lightweight design, improved visible light absorption. Weaknesses: Potential higher cost due to silver content, limited to specific applications.

Innovations in Glass-Catalyst Interfaces

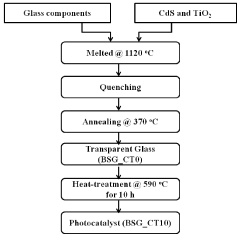

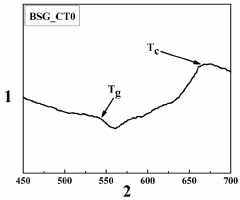

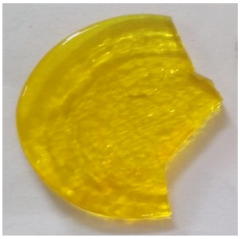

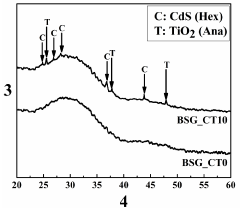

Borosilicate glass composition embedded with cds/tio2 composites for indigo carmine dye degradation

PatentInactiveIN202121000610A

Innovation

- A borosilicate glass composition embedded with CdS/TiO2 composites is developed, using a melt quenching technique to create stable, reusable photocatalysts that can effectively degrade organic pollutants under both UV and visible light, with optimized glass components and heat treatment to enhance semiconductor nanocrystal growth.

Reverse photocromic borosilicate glasses

PatentActiveEP3424888A1

Innovation

- Development of borosilicate glass compositions with specific chemical compositions (66-76% SiO2, 0-8% Al2O3, 10-18% B2O3, 0-4% Li2O, 0-12% Na2O, 0-12% K2O, 1-1.5% Ag, 1.5-2.5% Cl-, and 0.01-0.06% CuO and NiO) that exhibit reverse photochromic and thermally darkenable properties, remaining effective after ion-exchange strengthening and being substantially free of Li2O and Br-, allowing for enhanced durability and stability.

Environmental Impact Assessment

The environmental impact assessment of borosilicate glass-supported photocatalysts is a crucial aspect of their development and implementation. These advanced materials offer promising solutions for environmental remediation, but their production and use also carry potential environmental implications that must be carefully evaluated.

One of the primary environmental benefits of borosilicate glass-supported photocatalysts is their ability to degrade pollutants in water and air. By harnessing solar energy, these materials can effectively break down organic contaminants, reducing the need for harsh chemical treatments in water purification processes. This can lead to a significant reduction in the release of harmful byproducts into the environment, contributing to cleaner water sources and improved ecosystem health.

However, the manufacturing process of borosilicate glass-supported photocatalysts requires careful consideration. The production of borosilicate glass involves high-temperature processes that consume substantial energy, potentially contributing to greenhouse gas emissions if not managed properly. Additionally, the synthesis of photocatalytic materials often involves the use of chemicals that may pose environmental risks if not handled and disposed of correctly.

The long-term durability of these photocatalysts is another important factor in their environmental impact assessment. Borosilicate glass offers excellent chemical and thermal stability, which can extend the lifespan of the photocatalysts. This increased durability reduces the frequency of replacement and, consequently, the overall environmental footprint associated with production and disposal.

When considering the end-of-life phase, the recyclability of borosilicate glass-supported photocatalysts presents both opportunities and challenges. While borosilicate glass itself is recyclable, the presence of photocatalytic coatings may complicate the recycling process. Research into effective separation and recycling techniques for these composite materials is essential to minimize waste and promote a circular economy approach.

The potential for leaching of photocatalytic materials into the environment during use or disposal must also be thoroughly investigated. While borosilicate glass is known for its low leaching properties, the interaction between the glass support and the photocatalytic coating under various environmental conditions needs to be studied to ensure long-term environmental safety.

In conclusion, the environmental impact assessment of borosilicate glass-supported photocatalysts reveals a complex balance of benefits and potential risks. Their ability to address environmental pollution through sustainable remediation techniques offers significant positive impacts. However, careful consideration of manufacturing processes, material durability, end-of-life management, and potential leaching effects is crucial to maximize their environmental benefits while minimizing any negative consequences.

One of the primary environmental benefits of borosilicate glass-supported photocatalysts is their ability to degrade pollutants in water and air. By harnessing solar energy, these materials can effectively break down organic contaminants, reducing the need for harsh chemical treatments in water purification processes. This can lead to a significant reduction in the release of harmful byproducts into the environment, contributing to cleaner water sources and improved ecosystem health.

However, the manufacturing process of borosilicate glass-supported photocatalysts requires careful consideration. The production of borosilicate glass involves high-temperature processes that consume substantial energy, potentially contributing to greenhouse gas emissions if not managed properly. Additionally, the synthesis of photocatalytic materials often involves the use of chemicals that may pose environmental risks if not handled and disposed of correctly.

The long-term durability of these photocatalysts is another important factor in their environmental impact assessment. Borosilicate glass offers excellent chemical and thermal stability, which can extend the lifespan of the photocatalysts. This increased durability reduces the frequency of replacement and, consequently, the overall environmental footprint associated with production and disposal.

When considering the end-of-life phase, the recyclability of borosilicate glass-supported photocatalysts presents both opportunities and challenges. While borosilicate glass itself is recyclable, the presence of photocatalytic coatings may complicate the recycling process. Research into effective separation and recycling techniques for these composite materials is essential to minimize waste and promote a circular economy approach.

The potential for leaching of photocatalytic materials into the environment during use or disposal must also be thoroughly investigated. While borosilicate glass is known for its low leaching properties, the interaction between the glass support and the photocatalytic coating under various environmental conditions needs to be studied to ensure long-term environmental safety.

In conclusion, the environmental impact assessment of borosilicate glass-supported photocatalysts reveals a complex balance of benefits and potential risks. Their ability to address environmental pollution through sustainable remediation techniques offers significant positive impacts. However, careful consideration of manufacturing processes, material durability, end-of-life management, and potential leaching effects is crucial to maximize their environmental benefits while minimizing any negative consequences.

Scalability and Industrial Applications

The scalability and industrial applications of borosilicate glass-supported photocatalysts represent a crucial aspect of their potential for widespread adoption and commercial viability. As research in this field progresses, the focus on scaling up laboratory-scale processes to industrial levels becomes increasingly important.

One of the primary advantages of borosilicate glass-supported photocatalysts is their potential for large-scale production. The manufacturing process for borosilicate glass is well-established in industry, providing a solid foundation for scaling up the production of these photocatalysts. This existing infrastructure can be leveraged to produce large quantities of the support material, which can then be functionalized with photocatalytic materials.

The durability and chemical resistance of borosilicate glass make it an ideal candidate for use in various industrial applications. These properties ensure that the photocatalysts can withstand harsh operating conditions, including exposure to corrosive chemicals and high temperatures. This resilience is particularly valuable in industries such as wastewater treatment, air purification, and chemical manufacturing, where the photocatalysts may be subjected to challenging environments.

In terms of industrial applications, borosilicate glass-supported photocatalysts show promise in several key areas. Water treatment is a significant potential market, where these photocatalysts can be used to degrade organic pollutants and remove contaminants from industrial effluents. The transparency of borosilicate glass allows for efficient light penetration, enhancing the photocatalytic activity in water purification systems.

Air purification is another promising application, with the potential for these photocatalysts to be integrated into HVAC systems or standalone air purifiers. The ability to coat borosilicate glass surfaces with photocatalytic materials opens up possibilities for self-cleaning surfaces in various industries, from construction to automotive.

However, challenges remain in scaling up the production and application of these photocatalysts. Ensuring uniform coating and distribution of the photocatalytic material on large glass surfaces is a technical hurdle that needs to be addressed. Additionally, optimizing the light exposure and reaction conditions in large-scale systems requires careful engineering and design considerations.

The economic feasibility of large-scale production and implementation is another critical factor. While borosilicate glass is relatively inexpensive, the overall cost of producing and deploying these photocatalysts at an industrial scale needs to be competitive with existing technologies to ensure market adoption.

As research continues, addressing these scalability challenges and exploring new industrial applications will be key to realizing the full potential of borosilicate glass-supported photocatalysts. Collaboration between academic researchers and industry partners will be crucial in bridging the gap between laboratory discoveries and practical, large-scale implementations.

One of the primary advantages of borosilicate glass-supported photocatalysts is their potential for large-scale production. The manufacturing process for borosilicate glass is well-established in industry, providing a solid foundation for scaling up the production of these photocatalysts. This existing infrastructure can be leveraged to produce large quantities of the support material, which can then be functionalized with photocatalytic materials.

The durability and chemical resistance of borosilicate glass make it an ideal candidate for use in various industrial applications. These properties ensure that the photocatalysts can withstand harsh operating conditions, including exposure to corrosive chemicals and high temperatures. This resilience is particularly valuable in industries such as wastewater treatment, air purification, and chemical manufacturing, where the photocatalysts may be subjected to challenging environments.

In terms of industrial applications, borosilicate glass-supported photocatalysts show promise in several key areas. Water treatment is a significant potential market, where these photocatalysts can be used to degrade organic pollutants and remove contaminants from industrial effluents. The transparency of borosilicate glass allows for efficient light penetration, enhancing the photocatalytic activity in water purification systems.

Air purification is another promising application, with the potential for these photocatalysts to be integrated into HVAC systems or standalone air purifiers. The ability to coat borosilicate glass surfaces with photocatalytic materials opens up possibilities for self-cleaning surfaces in various industries, from construction to automotive.

However, challenges remain in scaling up the production and application of these photocatalysts. Ensuring uniform coating and distribution of the photocatalytic material on large glass surfaces is a technical hurdle that needs to be addressed. Additionally, optimizing the light exposure and reaction conditions in large-scale systems requires careful engineering and design considerations.

The economic feasibility of large-scale production and implementation is another critical factor. While borosilicate glass is relatively inexpensive, the overall cost of producing and deploying these photocatalysts at an industrial scale needs to be competitive with existing technologies to ensure market adoption.

As research continues, addressing these scalability challenges and exploring new industrial applications will be key to realizing the full potential of borosilicate glass-supported photocatalysts. Collaboration between academic researchers and industry partners will be crucial in bridging the gap between laboratory discoveries and practical, large-scale implementations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!