Pore Structure Influence on Borosilicate Glass Properties

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Pore Structure Research Objectives

The research on pore structure influence on borosilicate glass properties aims to comprehensively understand the relationship between the microscopic pore structure and the macroscopic properties of borosilicate glass. This study is crucial for advancing the development and application of borosilicate glass in various industries, including optics, electronics, and nuclear waste containment.

The primary objective is to elucidate how different pore characteristics, such as size distribution, shape, connectivity, and spatial arrangement, affect the physical, chemical, and mechanical properties of borosilicate glass. By establishing these correlations, researchers seek to optimize glass performance for specific applications and enhance overall material quality.

One key focus is investigating the impact of pore structure on thermal properties. Understanding how pore configuration influences thermal conductivity, expansion, and shock resistance is essential for applications in high-temperature environments or those requiring precise thermal management.

Another critical aspect is the examination of pore structure effects on mechanical strength and durability. Researchers aim to determine how pore-related parameters contribute to fracture toughness, elastic modulus, and long-term stability of borosilicate glass under various stress conditions.

The study also encompasses the influence of pore structure on chemical durability and ion exchange processes. This is particularly relevant for applications in corrosive environments or where controlled release of ions is desired, such as in bioactive glasses or nuclear waste immobilization.

Optical properties are another area of interest, with researchers investigating how pore characteristics affect light transmission, refraction, and scattering in borosilicate glass. This knowledge is crucial for optimizing the material's performance in optical devices and photonic applications.

The research objectives extend to developing advanced characterization techniques for precise pore structure analysis. This includes refining existing methods and exploring novel approaches to accurately quantify and visualize the three-dimensional pore network within borosilicate glass.

Ultimately, this research aims to establish a comprehensive framework for predicting and tailoring borosilicate glass properties based on pore structure manipulation. The findings will contribute to the design of next-generation borosilicate glasses with enhanced performance and expanded applications across various technological domains.

The primary objective is to elucidate how different pore characteristics, such as size distribution, shape, connectivity, and spatial arrangement, affect the physical, chemical, and mechanical properties of borosilicate glass. By establishing these correlations, researchers seek to optimize glass performance for specific applications and enhance overall material quality.

One key focus is investigating the impact of pore structure on thermal properties. Understanding how pore configuration influences thermal conductivity, expansion, and shock resistance is essential for applications in high-temperature environments or those requiring precise thermal management.

Another critical aspect is the examination of pore structure effects on mechanical strength and durability. Researchers aim to determine how pore-related parameters contribute to fracture toughness, elastic modulus, and long-term stability of borosilicate glass under various stress conditions.

The study also encompasses the influence of pore structure on chemical durability and ion exchange processes. This is particularly relevant for applications in corrosive environments or where controlled release of ions is desired, such as in bioactive glasses or nuclear waste immobilization.

Optical properties are another area of interest, with researchers investigating how pore characteristics affect light transmission, refraction, and scattering in borosilicate glass. This knowledge is crucial for optimizing the material's performance in optical devices and photonic applications.

The research objectives extend to developing advanced characterization techniques for precise pore structure analysis. This includes refining existing methods and exploring novel approaches to accurately quantify and visualize the three-dimensional pore network within borosilicate glass.

Ultimately, this research aims to establish a comprehensive framework for predicting and tailoring borosilicate glass properties based on pore structure manipulation. The findings will contribute to the design of next-generation borosilicate glasses with enhanced performance and expanded applications across various technological domains.

Market Analysis for Advanced Borosilicate Glass

The advanced borosilicate glass market has been experiencing significant growth in recent years, driven by increasing demand across various industries. This specialized glass, known for its exceptional thermal resistance, chemical durability, and optical clarity, has found applications in diverse sectors such as laboratory equipment, pharmaceutical packaging, solar energy, and high-end cookware.

The global borosilicate glass market size was valued at approximately $4.5 billion in 2020 and is projected to reach $6.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.3% during the forecast period. This growth is primarily attributed to the expanding pharmaceutical and healthcare industries, which require high-quality glass containers for drug storage and delivery systems.

In the laboratory glassware segment, borosilicate glass remains the material of choice due to its resistance to thermal shock and chemical corrosion. The increasing focus on research and development activities in both academic and industrial settings is driving the demand for laboratory equipment, consequently boosting the market for borosilicate glass.

The solar energy sector presents a promising growth opportunity for advanced borosilicate glass. As the world shifts towards renewable energy sources, the demand for solar panels and concentrated solar power systems is rising. Borosilicate glass, with its low coefficient of thermal expansion and high light transmittance, is ideal for these applications.

Geographically, Asia Pacific dominates the borosilicate glass market, accounting for over 40% of the global market share. This can be attributed to the rapid industrialization, growing healthcare sector, and increasing investments in research and development in countries like China and India. North America and Europe follow closely, with strong demand from the pharmaceutical and laboratory sectors.

The market landscape is characterized by the presence of several key players, including SCHOTT AG, Corning Inc., and Nippon Electric Glass Co., Ltd. These companies are investing heavily in research and development to enhance the properties of borosilicate glass, particularly focusing on improving its pore structure to further enhance its performance characteristics.

However, the market faces challenges such as the high production costs associated with borosilicate glass and the growing competition from alternative materials like plastics in certain applications. Despite these challenges, the unique properties of borosilicate glass and its expanding applications in emerging technologies continue to drive market growth and innovation in this sector.

The global borosilicate glass market size was valued at approximately $4.5 billion in 2020 and is projected to reach $6.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.3% during the forecast period. This growth is primarily attributed to the expanding pharmaceutical and healthcare industries, which require high-quality glass containers for drug storage and delivery systems.

In the laboratory glassware segment, borosilicate glass remains the material of choice due to its resistance to thermal shock and chemical corrosion. The increasing focus on research and development activities in both academic and industrial settings is driving the demand for laboratory equipment, consequently boosting the market for borosilicate glass.

The solar energy sector presents a promising growth opportunity for advanced borosilicate glass. As the world shifts towards renewable energy sources, the demand for solar panels and concentrated solar power systems is rising. Borosilicate glass, with its low coefficient of thermal expansion and high light transmittance, is ideal for these applications.

Geographically, Asia Pacific dominates the borosilicate glass market, accounting for over 40% of the global market share. This can be attributed to the rapid industrialization, growing healthcare sector, and increasing investments in research and development in countries like China and India. North America and Europe follow closely, with strong demand from the pharmaceutical and laboratory sectors.

The market landscape is characterized by the presence of several key players, including SCHOTT AG, Corning Inc., and Nippon Electric Glass Co., Ltd. These companies are investing heavily in research and development to enhance the properties of borosilicate glass, particularly focusing on improving its pore structure to further enhance its performance characteristics.

However, the market faces challenges such as the high production costs associated with borosilicate glass and the growing competition from alternative materials like plastics in certain applications. Despite these challenges, the unique properties of borosilicate glass and its expanding applications in emerging technologies continue to drive market growth and innovation in this sector.

Current Challenges in Pore Structure Control

Despite significant advancements in borosilicate glass manufacturing, controlling the pore structure remains a formidable challenge. One of the primary obstacles is achieving precise control over pore size distribution. The current manufacturing processes often result in a wide range of pore sizes, which can lead to inconsistent material properties and performance. This variability makes it difficult to predict and optimize the glass's mechanical, thermal, and optical characteristics.

Another major challenge lies in maintaining pore stability during the glass formation process. As the glass transitions from a molten state to a solid, the pores can undergo significant changes in shape and size. This dynamic behavior can result in unintended structural modifications, potentially compromising the desired properties of the final product. Researchers are actively seeking methods to stabilize pores during the cooling and solidification stages.

The interconnectivity of pores presents yet another hurdle in pore structure control. While some applications benefit from interconnected pore networks, others require isolated pores. Achieving the desired level of pore connectivity while maintaining other critical properties of the glass remains a complex balancing act. Current techniques often struggle to provide precise control over this aspect of the pore structure.

Surface chemistry and pore wall properties also pose significant challenges. The interaction between the pore surfaces and the surrounding glass matrix can greatly influence the overall material properties. Controlling the surface characteristics of the pores, including their chemical composition and roughness, is crucial for tailoring the glass's performance for specific applications. However, current methods for modifying pore surface properties are often limited in their precision and scalability.

Furthermore, the integration of pore structure control with other desirable properties of borosilicate glass presents a multifaceted challenge. For instance, maintaining high optical transparency while incorporating a specific pore structure can be particularly demanding. Balancing these competing requirements often necessitates compromises in either the pore structure or other material properties.

Lastly, the scalability of pore structure control techniques from laboratory to industrial production remains a significant hurdle. Many promising methods for pore structure manipulation demonstrated at small scales face substantial challenges when scaled up to meet commercial production demands. This gap between research findings and practical implementation continues to be a major focus area for both academic and industrial researchers in the field of borosilicate glass development.

Another major challenge lies in maintaining pore stability during the glass formation process. As the glass transitions from a molten state to a solid, the pores can undergo significant changes in shape and size. This dynamic behavior can result in unintended structural modifications, potentially compromising the desired properties of the final product. Researchers are actively seeking methods to stabilize pores during the cooling and solidification stages.

The interconnectivity of pores presents yet another hurdle in pore structure control. While some applications benefit from interconnected pore networks, others require isolated pores. Achieving the desired level of pore connectivity while maintaining other critical properties of the glass remains a complex balancing act. Current techniques often struggle to provide precise control over this aspect of the pore structure.

Surface chemistry and pore wall properties also pose significant challenges. The interaction between the pore surfaces and the surrounding glass matrix can greatly influence the overall material properties. Controlling the surface characteristics of the pores, including their chemical composition and roughness, is crucial for tailoring the glass's performance for specific applications. However, current methods for modifying pore surface properties are often limited in their precision and scalability.

Furthermore, the integration of pore structure control with other desirable properties of borosilicate glass presents a multifaceted challenge. For instance, maintaining high optical transparency while incorporating a specific pore structure can be particularly demanding. Balancing these competing requirements often necessitates compromises in either the pore structure or other material properties.

Lastly, the scalability of pore structure control techniques from laboratory to industrial production remains a significant hurdle. Many promising methods for pore structure manipulation demonstrated at small scales face substantial challenges when scaled up to meet commercial production demands. This gap between research findings and practical implementation continues to be a major focus area for both academic and industrial researchers in the field of borosilicate glass development.

Existing Methods for Pore Structure Characterization

01 Chemical composition and thermal properties

Borosilicate glass is characterized by its unique chemical composition, primarily consisting of silica and boron oxide. This composition contributes to its low thermal expansion coefficient, making it highly resistant to thermal shock. The glass can withstand sudden temperature changes without cracking, making it suitable for various applications in laboratory and kitchen equipment.- Chemical composition and thermal properties: Borosilicate glass is characterized by its unique chemical composition, primarily consisting of silica and boron oxide. This composition contributes to its low thermal expansion coefficient, making it highly resistant to thermal shock. The glass can withstand sudden temperature changes without cracking, making it suitable for various applications in laboratory and kitchen equipment.

- Optical properties and transparency: Borosilicate glass exhibits excellent optical properties, including high transparency and clarity. It has a low refractive index and low dispersion, making it ideal for use in optical instruments and lenses. The glass also offers good transmission of both visible and ultraviolet light, enhancing its versatility in various optical applications.

- Mechanical strength and durability: Borosilicate glass possesses high mechanical strength and durability compared to conventional soda-lime glass. It demonstrates improved resistance to scratching, impact, and chemical corrosion. These properties make it suitable for use in laboratory glassware, pharmaceutical packaging, and other applications requiring robust materials.

- Electrical insulation properties: Borosilicate glass exhibits excellent electrical insulation properties, making it suitable for use in various electrical and electronic applications. It has a low dielectric constant and low electrical conductivity, allowing it to effectively insulate electrical components and prevent current leakage.

- Chemical resistance and biocompatibility: Borosilicate glass demonstrates high chemical resistance to a wide range of substances, including acids, alkalis, and organic solvents. This property makes it ideal for laboratory glassware and chemical storage containers. Additionally, its biocompatibility and low ion release make it suitable for medical and pharmaceutical applications, such as drug packaging and implantable devices.

02 Optical properties and transparency

Borosilicate glass exhibits excellent optical properties, including high transparency and clarity. It has a low refractive index and low dispersion, making it ideal for use in optical instruments and lenses. The glass also has good UV and infrared transmission characteristics, enhancing its versatility in various optical applications.Expand Specific Solutions03 Mechanical strength and durability

Borosilicate glass possesses high mechanical strength and durability compared to conventional soda-lime glass. It demonstrates improved resistance to scratching, impact, and chemical corrosion. These properties make it suitable for use in laboratory glassware, cookware, and industrial applications where durability is crucial.Expand Specific Solutions04 Electrical insulation properties

Borosilicate glass exhibits excellent electrical insulation properties, making it suitable for use in various electrical and electronic applications. It has a low dielectric constant and low electrical conductivity, which contribute to its effectiveness as an insulator in high-voltage equipment and electronic components.Expand Specific Solutions05 Chemical resistance and biocompatibility

Borosilicate glass demonstrates high chemical resistance to a wide range of substances, including acids, alkalis, and organic solvents. This property makes it ideal for laboratory glassware and chemical storage containers. Additionally, its biocompatibility and low leaching characteristics make it suitable for pharmaceutical packaging and medical devices.Expand Specific Solutions

Key Players in Borosilicate Glass Industry

The research on pore structure influence on borosilicate glass properties is in a mature stage, with established players and ongoing innovation. The market for borosilicate glass is substantial, driven by applications in pharmaceuticals, electronics, and laboratory equipment. Key players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. have advanced technological capabilities in this field. These companies, along with others such as AGC, Inc. and Hoya Candeo Optronics Corp., are continuously improving glass properties through pore structure manipulation. The competitive landscape is characterized by a mix of large multinational corporations and specialized glass manufacturers, with research institutions like Wuhan University of Technology contributing to technological advancements.

SCHOTT AG

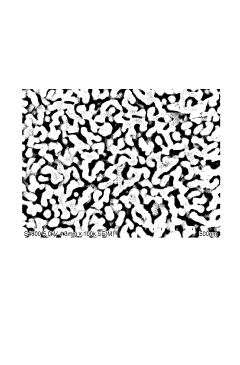

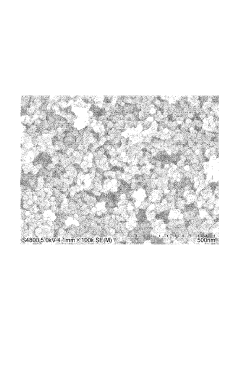

Technical Solution: SCHOTT AG has developed advanced techniques for controlling the pore structure of borosilicate glass to enhance its properties. They utilize a proprietary melting and forming process that allows precise manipulation of the glass microstructure[1]. This process involves carefully controlling the cooling rate and adding specific dopants to create a network of nanoscale pores within the glass matrix. The company has also implemented advanced characterization methods, such as high-resolution electron microscopy and small-angle neutron scattering, to analyze and optimize the pore structure[3]. SCHOTT's research has shown that tailoring the pore size distribution and connectivity can significantly improve the glass's mechanical strength, chemical durability, and thermal shock resistance[5].

Strengths: Precise control over pore structure, enhanced mechanical and chemical properties. Weaknesses: Potentially higher production costs, limited to specialized applications.

Corning, Inc.

Technical Solution: Corning has developed a novel approach to manipulating the pore structure of borosilicate glass through a process called "phase separation and leaching." This technique involves creating a glass composition that naturally separates into two distinct phases during cooling. One phase is then selectively etched away, leaving behind a controlled porous structure[2]. Corning has refined this process to create borosilicate glasses with tailored pore sizes ranging from nanometers to micrometers. Their research has demonstrated that these porous glasses exhibit enhanced properties such as increased surface area, improved catalytic activity, and superior ion exchange capabilities[4]. Corning has also explored the use of templating agents and sol-gel techniques to further control pore geometry and distribution[6].

Strengths: Versatile pore size control, enhanced functional properties. Weaknesses: Complex manufacturing process, potential for reduced mechanical strength.

Innovative Approaches to Pore Structure Modification

Borosilicate glass, porous glass, and method for producing the same

PatentInactiveJP2012193067A

Innovation

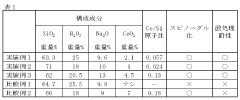

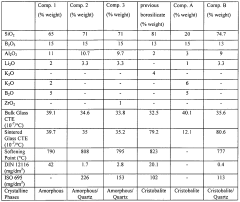

- Incorporating cerium oxide into borosilicate glass compositions with 60% to 72% silicon oxide, 18% to 30% boron oxide, and 9.5% to 15% sodium oxide, promoting phase separation and enabling the production of high-strength porous glass through controlled etching of the non-silica-rich phase.

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Environmental Impact of Borosilicate Glass Production

The production of borosilicate glass has significant environmental implications that warrant careful consideration. The manufacturing process involves high-temperature melting of raw materials, which consumes substantial energy and contributes to greenhouse gas emissions. The primary energy sources for glass furnaces are typically natural gas or electricity, with the choice impacting the overall carbon footprint of production.

Emissions from borosilicate glass production include particulate matter, nitrogen oxides, sulfur oxides, and volatile organic compounds. These pollutants can contribute to air quality issues and potential health concerns in surrounding communities. Advanced emission control technologies, such as electrostatic precipitators and scrubbers, are often employed to mitigate these impacts, but their effectiveness varies.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling, cleaning, and as a component in some formulations. Proper water management and recycling systems are essential to minimize consumption and reduce wastewater discharge.

Raw material extraction for borosilicate glass components, including silica, boron compounds, and other minerals, can lead to habitat disruption and landscape alterations at mining sites. Sustainable sourcing practices and efficient use of materials are crucial to minimizing these impacts.

The durability and chemical resistance of borosilicate glass offer environmental benefits in its applications. Its long lifespan and recyclability contribute to waste reduction in various industries, particularly in laboratory and pharmaceutical settings where it is widely used.

End-of-life considerations for borosilicate glass products are generally favorable from an environmental perspective. The material is 100% recyclable without loss of quality, which can significantly reduce the need for virgin raw materials and associated environmental impacts. However, the recycling process itself requires energy and may produce emissions, necessitating a balanced approach to waste management.

Innovations in borosilicate glass production, such as improved furnace designs and alternative raw materials, are ongoing efforts to enhance energy efficiency and reduce environmental impacts. These advancements aim to create a more sustainable production process while maintaining the high-quality properties that make borosilicate glass valuable in numerous applications.

Emissions from borosilicate glass production include particulate matter, nitrogen oxides, sulfur oxides, and volatile organic compounds. These pollutants can contribute to air quality issues and potential health concerns in surrounding communities. Advanced emission control technologies, such as electrostatic precipitators and scrubbers, are often employed to mitigate these impacts, but their effectiveness varies.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling, cleaning, and as a component in some formulations. Proper water management and recycling systems are essential to minimize consumption and reduce wastewater discharge.

Raw material extraction for borosilicate glass components, including silica, boron compounds, and other minerals, can lead to habitat disruption and landscape alterations at mining sites. Sustainable sourcing practices and efficient use of materials are crucial to minimizing these impacts.

The durability and chemical resistance of borosilicate glass offer environmental benefits in its applications. Its long lifespan and recyclability contribute to waste reduction in various industries, particularly in laboratory and pharmaceutical settings where it is widely used.

End-of-life considerations for borosilicate glass products are generally favorable from an environmental perspective. The material is 100% recyclable without loss of quality, which can significantly reduce the need for virgin raw materials and associated environmental impacts. However, the recycling process itself requires energy and may produce emissions, necessitating a balanced approach to waste management.

Innovations in borosilicate glass production, such as improved furnace designs and alternative raw materials, are ongoing efforts to enhance energy efficiency and reduce environmental impacts. These advancements aim to create a more sustainable production process while maintaining the high-quality properties that make borosilicate glass valuable in numerous applications.

Applications of Pore-Optimized Borosilicate Glass

Borosilicate glass with optimized pore structures offers a wide range of applications across various industries. In the field of catalysis, porous borosilicate glass serves as an excellent support material for catalysts due to its high surface area and controllable pore size distribution. This enables enhanced catalytic activity and selectivity in chemical reactions, particularly in petrochemical processes and environmental remediation.

In the biomedical sector, pore-optimized borosilicate glass finds applications in drug delivery systems and tissue engineering scaffolds. The tailored pore structure allows for controlled release of therapeutic agents and promotes cell growth and tissue regeneration. Additionally, these materials show promise in bone tissue engineering, where the interconnected pore network facilitates bone ingrowth and vascularization.

The electronics industry benefits from porous borosilicate glass in the development of advanced sensors and electronic components. The high surface area and tunable pore structure enable the fabrication of sensitive gas sensors and humidity detectors. Moreover, these materials can be used as dielectric layers in microelectronic devices, offering improved insulation properties and reduced signal interference.

In the field of energy storage and conversion, pore-optimized borosilicate glass plays a crucial role in the development of next-generation batteries and fuel cells. The porous structure provides efficient ion transport pathways and enhances electrode-electrolyte interfaces, leading to improved energy storage capacity and faster charging rates in lithium-ion batteries. Similarly, in solid oxide fuel cells, the optimized pore structure of borosilicate glass-based components contributes to enhanced ionic conductivity and overall cell performance.

Environmental applications of pore-optimized borosilicate glass include water purification and gas separation technologies. The tailored pore structure allows for efficient filtration and adsorption of contaminants from water and air streams. Additionally, these materials show potential in carbon capture and storage applications, where the high surface area and controlled pore size distribution facilitate the adsorption and sequestration of greenhouse gases.

In the optical industry, porous borosilicate glass finds applications in the development of advanced optical coatings and photonic devices. The controlled pore structure enables the creation of antireflective coatings with enhanced light transmission properties. Furthermore, these materials can be used as templates for the fabrication of photonic crystals and optical waveguides, opening up new possibilities in optical communication and sensing technologies.

In the biomedical sector, pore-optimized borosilicate glass finds applications in drug delivery systems and tissue engineering scaffolds. The tailored pore structure allows for controlled release of therapeutic agents and promotes cell growth and tissue regeneration. Additionally, these materials show promise in bone tissue engineering, where the interconnected pore network facilitates bone ingrowth and vascularization.

The electronics industry benefits from porous borosilicate glass in the development of advanced sensors and electronic components. The high surface area and tunable pore structure enable the fabrication of sensitive gas sensors and humidity detectors. Moreover, these materials can be used as dielectric layers in microelectronic devices, offering improved insulation properties and reduced signal interference.

In the field of energy storage and conversion, pore-optimized borosilicate glass plays a crucial role in the development of next-generation batteries and fuel cells. The porous structure provides efficient ion transport pathways and enhances electrode-electrolyte interfaces, leading to improved energy storage capacity and faster charging rates in lithium-ion batteries. Similarly, in solid oxide fuel cells, the optimized pore structure of borosilicate glass-based components contributes to enhanced ionic conductivity and overall cell performance.

Environmental applications of pore-optimized borosilicate glass include water purification and gas separation technologies. The tailored pore structure allows for efficient filtration and adsorption of contaminants from water and air streams. Additionally, these materials show potential in carbon capture and storage applications, where the high surface area and controlled pore size distribution facilitate the adsorption and sequestration of greenhouse gases.

In the optical industry, porous borosilicate glass finds applications in the development of advanced optical coatings and photonic devices. The controlled pore structure enables the creation of antireflective coatings with enhanced light transmission properties. Furthermore, these materials can be used as templates for the fabrication of photonic crystals and optical waveguides, opening up new possibilities in optical communication and sensing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!