Hybrid Organic-Inorganic Borosilicate Glass Devices

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Glass Evolution

The evolution of hybrid organic-inorganic borosilicate glass devices represents a significant advancement in materials science, combining the best properties of both organic and inorganic components. This technological progression has been driven by the need for materials with enhanced performance characteristics in various applications, including optics, electronics, and energy storage.

In the early stages of development, researchers focused on incorporating organic molecules into traditional borosilicate glass matrices. This approach aimed to modify the physical and chemical properties of the glass while maintaining its inherent thermal and mechanical stability. The initial experiments involved simple organic compounds, such as dyes or small molecules, dispersed within the glass structure.

As the field progressed, more complex organic-inorganic hybrid systems were developed. Scientists began exploring the use of organosilanes and other silicon-based precursors to create covalent bonds between the organic and inorganic components. This led to the development of sol-gel processes, which allowed for better control over the material's composition and structure at the molecular level.

The next significant milestone in hybrid glass evolution was the incorporation of functional organic polymers. This advancement enabled the creation of materials with tunable optical, electrical, and mechanical properties. Researchers developed methods to synthesize hybrid glasses with controlled porosity, allowing for the integration of larger organic molecules and even biomolecules within the glass network.

Recent years have seen a shift towards more sophisticated hybrid architectures. Scientists have explored the use of block copolymers and self-assembly techniques to create nanostructured hybrid glasses with precise control over domain sizes and morphologies. This has opened up new possibilities for creating materials with hierarchical structures and multifunctional properties.

The latest frontier in hybrid glass evolution involves the integration of responsive and adaptive organic components. This includes the development of hybrid glasses that can change their properties in response to external stimuli such as light, temperature, or electric fields. Such smart materials have potential applications in areas like sensing, display technologies, and energy-efficient windows.

Throughout this evolution, researchers have continuously improved fabrication techniques, moving from bulk synthesis methods to more advanced approaches such as layer-by-layer deposition, 3D printing, and nanoimprinting. These advancements have enabled the creation of hybrid glass devices with complex geometries and precise control over material composition at multiple length scales.

In the early stages of development, researchers focused on incorporating organic molecules into traditional borosilicate glass matrices. This approach aimed to modify the physical and chemical properties of the glass while maintaining its inherent thermal and mechanical stability. The initial experiments involved simple organic compounds, such as dyes or small molecules, dispersed within the glass structure.

As the field progressed, more complex organic-inorganic hybrid systems were developed. Scientists began exploring the use of organosilanes and other silicon-based precursors to create covalent bonds between the organic and inorganic components. This led to the development of sol-gel processes, which allowed for better control over the material's composition and structure at the molecular level.

The next significant milestone in hybrid glass evolution was the incorporation of functional organic polymers. This advancement enabled the creation of materials with tunable optical, electrical, and mechanical properties. Researchers developed methods to synthesize hybrid glasses with controlled porosity, allowing for the integration of larger organic molecules and even biomolecules within the glass network.

Recent years have seen a shift towards more sophisticated hybrid architectures. Scientists have explored the use of block copolymers and self-assembly techniques to create nanostructured hybrid glasses with precise control over domain sizes and morphologies. This has opened up new possibilities for creating materials with hierarchical structures and multifunctional properties.

The latest frontier in hybrid glass evolution involves the integration of responsive and adaptive organic components. This includes the development of hybrid glasses that can change their properties in response to external stimuli such as light, temperature, or electric fields. Such smart materials have potential applications in areas like sensing, display technologies, and energy-efficient windows.

Throughout this evolution, researchers have continuously improved fabrication techniques, moving from bulk synthesis methods to more advanced approaches such as layer-by-layer deposition, 3D printing, and nanoimprinting. These advancements have enabled the creation of hybrid glass devices with complex geometries and precise control over material composition at multiple length scales.

Market Applications

Hybrid organic-inorganic borosilicate glass devices represent a promising frontier in materials science, offering a unique combination of properties that make them suitable for a wide range of market applications. These innovative materials blend the thermal and chemical stability of inorganic borosilicate glass with the flexibility and functionality of organic compounds, opening up new possibilities across various industries.

In the field of optoelectronics, hybrid organic-inorganic borosilicate glass devices are finding significant applications. Their tunable optical properties make them ideal for use in advanced display technologies, including next-generation smart windows and high-performance optical filters. The ability to incorporate organic chromophores into the glass matrix allows for the development of novel light-emitting devices with improved efficiency and color purity, potentially revolutionizing the display industry.

The energy sector is another area where these hybrid materials show great promise. Their unique properties make them excellent candidates for solar cell applications, particularly in the development of dye-sensitized solar cells (DSSCs) and perovskite solar cells. The incorporation of organic components into the borosilicate glass structure can enhance light absorption and charge transport, leading to improved solar cell efficiency and durability.

In the biomedical field, hybrid organic-inorganic borosilicate glass devices are being explored for drug delivery systems and biosensors. The biocompatibility of borosilicate glass, combined with the functionality of organic molecules, allows for the creation of smart drug delivery platforms that can respond to specific biological stimuli. Additionally, these materials can be engineered to detect and monitor various biomarkers, offering potential advancements in medical diagnostics and personalized medicine.

The aerospace and automotive industries are also showing interest in these hybrid materials. Their low thermal expansion coefficient, coupled with enhanced mechanical properties derived from the organic components, makes them suitable for high-performance coatings and structural materials in extreme environments. This could lead to the development of more durable and lightweight components for aircraft and vehicles, contributing to improved fuel efficiency and performance.

In the field of environmental technology, hybrid organic-inorganic borosilicate glass devices are being investigated for applications in water purification and air filtration. The ability to functionalize these materials with specific organic groups allows for the creation of highly selective membranes and adsorbents capable of removing contaminants from water and air with greater efficiency than traditional materials.

As research in this field progresses, it is likely that new applications will continue to emerge, further expanding the market potential of hybrid organic-inorganic borosilicate glass devices. The versatility and tunability of these materials make them a promising platform for addressing various technological challenges across multiple industries, driving innovation and creating new market opportunities.

In the field of optoelectronics, hybrid organic-inorganic borosilicate glass devices are finding significant applications. Their tunable optical properties make them ideal for use in advanced display technologies, including next-generation smart windows and high-performance optical filters. The ability to incorporate organic chromophores into the glass matrix allows for the development of novel light-emitting devices with improved efficiency and color purity, potentially revolutionizing the display industry.

The energy sector is another area where these hybrid materials show great promise. Their unique properties make them excellent candidates for solar cell applications, particularly in the development of dye-sensitized solar cells (DSSCs) and perovskite solar cells. The incorporation of organic components into the borosilicate glass structure can enhance light absorption and charge transport, leading to improved solar cell efficiency and durability.

In the biomedical field, hybrid organic-inorganic borosilicate glass devices are being explored for drug delivery systems and biosensors. The biocompatibility of borosilicate glass, combined with the functionality of organic molecules, allows for the creation of smart drug delivery platforms that can respond to specific biological stimuli. Additionally, these materials can be engineered to detect and monitor various biomarkers, offering potential advancements in medical diagnostics and personalized medicine.

The aerospace and automotive industries are also showing interest in these hybrid materials. Their low thermal expansion coefficient, coupled with enhanced mechanical properties derived from the organic components, makes them suitable for high-performance coatings and structural materials in extreme environments. This could lead to the development of more durable and lightweight components for aircraft and vehicles, contributing to improved fuel efficiency and performance.

In the field of environmental technology, hybrid organic-inorganic borosilicate glass devices are being investigated for applications in water purification and air filtration. The ability to functionalize these materials with specific organic groups allows for the creation of highly selective membranes and adsorbents capable of removing contaminants from water and air with greater efficiency than traditional materials.

As research in this field progresses, it is likely that new applications will continue to emerge, further expanding the market potential of hybrid organic-inorganic borosilicate glass devices. The versatility and tunability of these materials make them a promising platform for addressing various technological challenges across multiple industries, driving innovation and creating new market opportunities.

Technical Challenges

The development of hybrid organic-inorganic borosilicate glass devices faces several significant technical challenges that researchers and engineers must overcome to realize their full potential. One of the primary obstacles is achieving seamless integration between the organic and inorganic components while maintaining the desirable properties of both materials. This integration process often involves complex chemical reactions and precise control of synthesis conditions, which can be difficult to optimize and scale up for industrial production.

Another major challenge lies in the stability and durability of these hybrid materials. The organic components are typically more susceptible to degradation from environmental factors such as heat, light, and moisture compared to their inorganic counterparts. Ensuring long-term stability and performance of the hybrid devices under various operating conditions remains a critical area of research. This is particularly important for applications in harsh environments or those requiring extended operational lifetimes.

The control of interface properties between the organic and inorganic phases presents yet another technical hurdle. The nature of this interface significantly influences the overall performance of the hybrid devices, affecting properties such as charge transfer, optical transparency, and mechanical strength. Developing methods to precisely engineer and characterize these interfaces at the nanoscale is crucial for optimizing device performance.

Reproducibility and uniformity in the fabrication of hybrid organic-inorganic borosilicate glass devices pose additional challenges. The complex nature of these materials often leads to variations in composition and structure, which can result in inconsistent device performance. Establishing robust and repeatable manufacturing processes that can produce uniform devices at scale is essential for commercial viability.

Furthermore, the characterization of these hybrid materials presents unique difficulties. Traditional analytical techniques may not be sufficient to fully understand the complex interactions between the organic and inorganic components. Developing new characterization methods or adapting existing ones to accurately assess the structure, composition, and properties of these hybrid materials is an ongoing challenge in the field.

Lastly, the optimization of specific properties for targeted applications remains a significant technical challenge. Different applications may require conflicting material properties, necessitating careful balancing and trade-offs in the design of hybrid organic-inorganic borosilicate glass devices. This often involves extensive experimentation and modeling to achieve the desired combination of optical, electrical, mechanical, and thermal properties for each specific application.

Another major challenge lies in the stability and durability of these hybrid materials. The organic components are typically more susceptible to degradation from environmental factors such as heat, light, and moisture compared to their inorganic counterparts. Ensuring long-term stability and performance of the hybrid devices under various operating conditions remains a critical area of research. This is particularly important for applications in harsh environments or those requiring extended operational lifetimes.

The control of interface properties between the organic and inorganic phases presents yet another technical hurdle. The nature of this interface significantly influences the overall performance of the hybrid devices, affecting properties such as charge transfer, optical transparency, and mechanical strength. Developing methods to precisely engineer and characterize these interfaces at the nanoscale is crucial for optimizing device performance.

Reproducibility and uniformity in the fabrication of hybrid organic-inorganic borosilicate glass devices pose additional challenges. The complex nature of these materials often leads to variations in composition and structure, which can result in inconsistent device performance. Establishing robust and repeatable manufacturing processes that can produce uniform devices at scale is essential for commercial viability.

Furthermore, the characterization of these hybrid materials presents unique difficulties. Traditional analytical techniques may not be sufficient to fully understand the complex interactions between the organic and inorganic components. Developing new characterization methods or adapting existing ones to accurately assess the structure, composition, and properties of these hybrid materials is an ongoing challenge in the field.

Lastly, the optimization of specific properties for targeted applications remains a significant technical challenge. Different applications may require conflicting material properties, necessitating careful balancing and trade-offs in the design of hybrid organic-inorganic borosilicate glass devices. This often involves extensive experimentation and modeling to achieve the desired combination of optical, electrical, mechanical, and thermal properties for each specific application.

Current Fabrication

01 Synthesis of hybrid organic-inorganic borosilicate glass

Methods for synthesizing hybrid organic-inorganic borosilicate glass materials, combining the properties of organic compounds with inorganic borosilicate glass. This approach allows for the creation of materials with unique optical, mechanical, and chemical properties, suitable for various applications in optics and electronics.- Synthesis of hybrid organic-inorganic borosilicate glass: Methods for synthesizing hybrid organic-inorganic borosilicate glass materials, combining the properties of organic compounds with inorganic borosilicate glass. These processes often involve sol-gel techniques or other specialized synthesis methods to create materials with unique optical, mechanical, or chemical properties.

- Applications in optoelectronic devices: Utilization of hybrid organic-inorganic borosilicate glass in various optoelectronic devices, such as displays, sensors, and photovoltaic cells. The unique properties of these materials allow for improved performance in light emission, detection, or energy conversion applications.

- Fabrication of thin films and coatings: Techniques for creating thin films and coatings using hybrid organic-inorganic borosilicate glass materials. These methods can involve deposition techniques, spin-coating, or other processes to create functional layers for various applications, including protective coatings or optical films.

- Integration with semiconductor technologies: Incorporation of hybrid organic-inorganic borosilicate glass materials into semiconductor devices and processes. This integration can lead to improved performance in areas such as insulation, passivation, or as functional components in advanced electronic devices.

- Modification of material properties: Methods for modifying the properties of hybrid organic-inorganic borosilicate glass materials through doping, surface treatments, or structural modifications. These techniques can enhance specific characteristics such as conductivity, optical properties, or chemical resistance for targeted applications.

02 Fabrication of optical devices using hybrid borosilicate glass

Techniques for fabricating optical devices such as waveguides, lenses, and filters using hybrid organic-inorganic borosilicate glass. These devices benefit from the combined properties of organic and inorganic components, offering improved performance in areas like light transmission, refractive index control, and durability.Expand Specific Solutions03 Electronic components based on hybrid borosilicate glass

Development of electronic components and devices utilizing hybrid organic-inorganic borosilicate glass as a substrate or active material. This includes applications in displays, sensors, and other electronic systems where the unique properties of the hybrid material can enhance performance or enable new functionalities.Expand Specific Solutions04 Surface modification of hybrid borosilicate glass

Methods for modifying the surface properties of hybrid organic-inorganic borosilicate glass materials. This includes techniques for improving adhesion, altering wettability, or functionalizing the surface for specific applications, such as biomedical devices or advanced coatings.Expand Specific Solutions05 Hybrid borosilicate glass for energy applications

Use of hybrid organic-inorganic borosilicate glass materials in energy-related applications, such as solar cells, fuel cells, or energy storage devices. The unique properties of these hybrid materials can enhance efficiency, durability, or functionality in various energy conversion and storage systems.Expand Specific Solutions

Industry Leaders

The research on hybrid organic-inorganic borosilicate glass devices is in an emerging phase, with growing market potential due to increasing applications in optoelectronics and advanced materials. The global market for these devices is expanding, driven by demand in sectors like telecommunications and healthcare. Technologically, the field is rapidly evolving, with companies like SCHOTT AG, Corning, Inc., and Central Glass Co., Ltd. leading innovation. These firms are developing advanced manufacturing processes and novel compositions to enhance device performance. Academic institutions such as Duke University and the University of Strasbourg are also contributing significantly to fundamental research, pushing the boundaries of material science in this domain.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced hybrid organic-inorganic borosilicate glass devices utilizing their CERAN® technology. Their approach involves incorporating organic compounds into the inorganic borosilicate glass matrix, resulting in materials with enhanced properties[1]. The company employs a sol-gel process to create these hybrid materials, allowing for precise control over the organic-inorganic interface[2]. SCHOTT's hybrid glass devices exhibit improved mechanical strength, thermal stability, and optical properties compared to traditional borosilicate glass[3]. The company has successfully applied this technology in various fields, including optoelectronics, biomedical devices, and smart windows[4].

Strengths: Extensive experience in glass manufacturing, established CERAN® technology, precise control over material properties. Weaknesses: Potential challenges in scaling up production, higher costs compared to traditional glass materials.

The Regents of the University of California

Technical Solution: The University of California has conducted extensive research on hybrid organic-inorganic borosilicate glass devices, focusing on novel synthesis methods and applications. Their approach involves using molecular precursors to create hybrid materials with tailored properties at the molecular level[9]. The university's research teams have developed sol-gel techniques that allow for the incorporation of a wide range of organic molecules into the borosilicate glass network[10]. This has resulted in hybrid materials with tunable optical, electrical, and mechanical properties[11]. The university has also explored the use of these hybrid materials in advanced sensing devices, energy storage systems, and biomedical applications[12].

Strengths: Cutting-edge research capabilities, diverse range of potential applications, strong focus on fundamental material science. Weaknesses: Potential challenges in translating research to commercial products, limited large-scale manufacturing experience.

Key Innovations

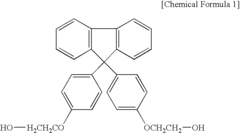

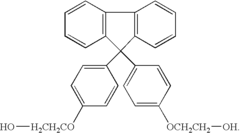

Organic-Inorganic Hybrid Vitreous Material

PatentInactiveUS20090131598A1

Innovation

- A composite material comprising 40-70 wt% polycondensate of organoalkoxysilane and 30-60 wt% organic polymer, specifically polyester, with a controlled synthesis process involving hydrolysis, partial polycondensation, and high-temperature steps, to achieve a balance of low water absorption, transparency, and sufficient strength.

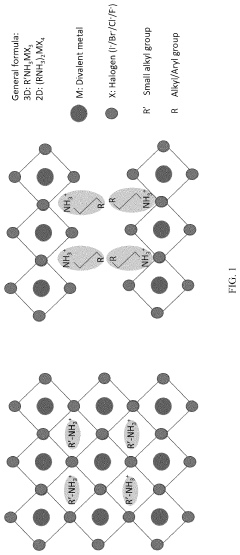

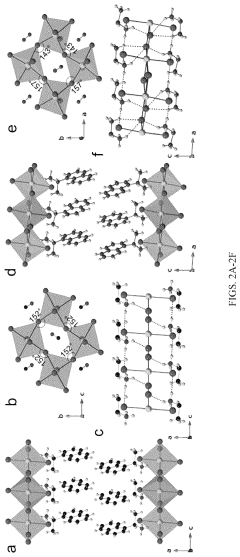

Organic-inorganic metal halide glass

PatentActiveUS11825728B2

Innovation

- Development of an organic-inorganic hybrid material comprising a metal halide anionic framework and organic cations, which is reversibly switchable between glass and crystalline states, allowing for control over temperature relationships and properties like optical absorption and electrical conductivity.

Environmental Impact

The environmental impact of hybrid organic-inorganic borosilicate glass devices is a crucial consideration in their development and implementation. These innovative materials offer potential advantages in terms of sustainability and reduced environmental footprint compared to traditional glass or plastic alternatives.

One of the primary environmental benefits of hybrid organic-inorganic borosilicate glass devices is their potential for improved durability and longevity. The incorporation of organic components into the inorganic borosilicate glass matrix can enhance the material's resistance to mechanical stress, thermal shock, and chemical degradation. This increased durability translates to longer product lifespans, reducing the frequency of replacement and, consequently, the overall environmental impact associated with manufacturing and disposal.

The production process of hybrid organic-inorganic borosilicate glass devices may also offer environmental advantages. Traditional glass manufacturing often requires high temperatures and energy-intensive processes. In contrast, the synthesis of hybrid materials can sometimes be achieved at lower temperatures, potentially reducing energy consumption and associated greenhouse gas emissions. Additionally, the organic components used in these hybrid materials may be derived from renewable sources, further contributing to their sustainability profile.

End-of-life considerations for hybrid organic-inorganic borosilicate glass devices present both challenges and opportunities. The complex nature of these materials may complicate recycling efforts, as separating the organic and inorganic components can be challenging. However, research into advanced recycling technologies and circular economy approaches may provide solutions for efficient material recovery and reuse.

The potential for reduced material usage in hybrid organic-inorganic borosilicate glass devices is another environmental benefit. The unique properties of these materials may allow for thinner, lighter designs without compromising performance. This reduction in material consumption can lead to decreased resource extraction and lower transportation-related emissions throughout the product lifecycle.

Water and chemical usage in the manufacturing process of hybrid organic-inorganic borosilicate glass devices is an area that requires careful consideration. While the integration of organic components may introduce new chemical processes, there is potential for optimization to minimize water consumption and reduce the use of harmful chemicals compared to traditional glass manufacturing.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications of hybrid organic-inorganic borosilicate glass devices. These assessments should consider raw material extraction, manufacturing processes, use phase performance, and end-of-life management to provide a holistic view of the environmental impact and identify areas for further improvement.

One of the primary environmental benefits of hybrid organic-inorganic borosilicate glass devices is their potential for improved durability and longevity. The incorporation of organic components into the inorganic borosilicate glass matrix can enhance the material's resistance to mechanical stress, thermal shock, and chemical degradation. This increased durability translates to longer product lifespans, reducing the frequency of replacement and, consequently, the overall environmental impact associated with manufacturing and disposal.

The production process of hybrid organic-inorganic borosilicate glass devices may also offer environmental advantages. Traditional glass manufacturing often requires high temperatures and energy-intensive processes. In contrast, the synthesis of hybrid materials can sometimes be achieved at lower temperatures, potentially reducing energy consumption and associated greenhouse gas emissions. Additionally, the organic components used in these hybrid materials may be derived from renewable sources, further contributing to their sustainability profile.

End-of-life considerations for hybrid organic-inorganic borosilicate glass devices present both challenges and opportunities. The complex nature of these materials may complicate recycling efforts, as separating the organic and inorganic components can be challenging. However, research into advanced recycling technologies and circular economy approaches may provide solutions for efficient material recovery and reuse.

The potential for reduced material usage in hybrid organic-inorganic borosilicate glass devices is another environmental benefit. The unique properties of these materials may allow for thinner, lighter designs without compromising performance. This reduction in material consumption can lead to decreased resource extraction and lower transportation-related emissions throughout the product lifecycle.

Water and chemical usage in the manufacturing process of hybrid organic-inorganic borosilicate glass devices is an area that requires careful consideration. While the integration of organic components may introduce new chemical processes, there is potential for optimization to minimize water consumption and reduce the use of harmful chemicals compared to traditional glass manufacturing.

As research in this field progresses, it is essential to conduct comprehensive life cycle assessments to fully understand the environmental implications of hybrid organic-inorganic borosilicate glass devices. These assessments should consider raw material extraction, manufacturing processes, use phase performance, and end-of-life management to provide a holistic view of the environmental impact and identify areas for further improvement.

Regulatory Framework

The regulatory framework surrounding hybrid organic-inorganic borosilicate glass devices is complex and multifaceted, reflecting the diverse applications and potential risks associated with these innovative materials. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) have developed standards that indirectly apply to these devices, particularly in areas of materials safety and performance.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating hybrid organic-inorganic borosilicate glass devices, especially when used in medical applications. These devices may fall under the purview of the Center for Devices and Radiological Health (CDRH), requiring premarket approval or 510(k) clearance depending on their intended use and risk classification. The Environmental Protection Agency (EPA) also has oversight, particularly concerning the environmental impact and potential toxicity of the organic components used in these hybrid materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and use of hybrid organic-inorganic materials. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive may apply to electronic applications of these devices, limiting the use of certain hazardous substances.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare (MHLW) oversees medical applications, while the Ministry of Economy, Trade and Industry (METI) regulates industrial uses. South Korea's Ministry of Food and Drug Safety (MFDS) has similar responsibilities for medical devices incorporating these materials.

Emerging economies, such as China and India, are rapidly developing their regulatory landscapes. China's National Medical Products Administration (NMPA) has been updating its regulations to address novel materials and devices, including those based on hybrid organic-inorganic borosilicate glass.

As research in this field progresses, regulatory bodies worldwide are likely to adapt their frameworks to address the unique properties and potential risks of hybrid organic-inorganic borosilicate glass devices. This may include the development of specific guidelines for toxicity testing, biocompatibility assessments, and long-term stability evaluations. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and facilitate the successful commercialization of their innovations.

In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating hybrid organic-inorganic borosilicate glass devices, especially when used in medical applications. These devices may fall under the purview of the Center for Devices and Radiological Health (CDRH), requiring premarket approval or 510(k) clearance depending on their intended use and risk classification. The Environmental Protection Agency (EPA) also has oversight, particularly concerning the environmental impact and potential toxicity of the organic components used in these hybrid materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the production and use of hybrid organic-inorganic materials. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive may apply to electronic applications of these devices, limiting the use of certain hazardous substances.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks. Japan's Ministry of Health, Labour and Welfare (MHLW) oversees medical applications, while the Ministry of Economy, Trade and Industry (METI) regulates industrial uses. South Korea's Ministry of Food and Drug Safety (MFDS) has similar responsibilities for medical devices incorporating these materials.

Emerging economies, such as China and India, are rapidly developing their regulatory landscapes. China's National Medical Products Administration (NMPA) has been updating its regulations to address novel materials and devices, including those based on hybrid organic-inorganic borosilicate glass.

As research in this field progresses, regulatory bodies worldwide are likely to adapt their frameworks to address the unique properties and potential risks of hybrid organic-inorganic borosilicate glass devices. This may include the development of specific guidelines for toxicity testing, biocompatibility assessments, and long-term stability evaluations. Manufacturers and researchers must stay informed about these evolving regulations to ensure compliance and facilitate the successful commercialization of their innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!