Nanostructured Borosilicate Glass Electrodes

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanostructured BSG Electrode Development

The development of nanostructured borosilicate glass (BSG) electrodes represents a significant advancement in the field of materials science and electrochemistry. This innovative approach combines the unique properties of borosilicate glass with the enhanced surface area and reactivity of nanostructured materials. The evolution of these electrodes has been driven by the need for improved performance in various applications, including energy storage, sensing, and electrochemical analysis.

The journey of nanostructured BSG electrode development began with the recognition of borosilicate glass's excellent chemical stability and electrical insulation properties. Researchers identified the potential to leverage these characteristics while overcoming the limitations of traditional glass electrodes by introducing nanostructures. This led to the exploration of various fabrication techniques to create high-surface-area BSG electrodes with enhanced electrochemical properties.

One of the key milestones in this field was the development of sol-gel methods for synthesizing nanostructured BSG. This approach allowed for precise control over the pore size and distribution within the glass matrix, resulting in electrodes with significantly increased surface area and improved ion transport capabilities. The sol-gel technique also enabled the incorporation of various dopants and functional groups, further expanding the potential applications of these electrodes.

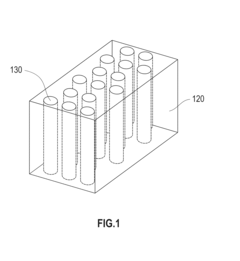

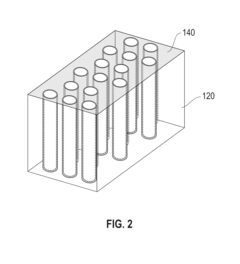

Another critical advancement was the integration of template-assisted fabrication methods. By using sacrificial templates, researchers were able to create highly ordered nanostructures within the BSG matrix, including nanopores, nanowires, and nanotubes. These structures not only increased the effective surface area but also provided directional pathways for ion and electron transport, enhancing the overall electrochemical performance of the electrodes.

The development of surface modification techniques marked another important stage in nanostructured BSG electrode evolution. Methods such as plasma treatment, chemical etching, and functionalization with organic molecules or nanoparticles were explored to tailor the surface properties of the electrodes. These modifications allowed for improved wettability, selectivity, and catalytic activity, broadening the range of potential applications for nanostructured BSG electrodes.

Recent advancements have focused on creating composite nanostructured BSG electrodes by incorporating conductive materials such as carbon nanotubes, graphene, or metal nanoparticles. These composites aim to address the inherent low conductivity of borosilicate glass while maintaining its desirable properties. The resulting hybrid electrodes have shown promising performance in applications such as supercapacitors, biosensors, and electrochemical sensors.

The journey of nanostructured BSG electrode development began with the recognition of borosilicate glass's excellent chemical stability and electrical insulation properties. Researchers identified the potential to leverage these characteristics while overcoming the limitations of traditional glass electrodes by introducing nanostructures. This led to the exploration of various fabrication techniques to create high-surface-area BSG electrodes with enhanced electrochemical properties.

One of the key milestones in this field was the development of sol-gel methods for synthesizing nanostructured BSG. This approach allowed for precise control over the pore size and distribution within the glass matrix, resulting in electrodes with significantly increased surface area and improved ion transport capabilities. The sol-gel technique also enabled the incorporation of various dopants and functional groups, further expanding the potential applications of these electrodes.

Another critical advancement was the integration of template-assisted fabrication methods. By using sacrificial templates, researchers were able to create highly ordered nanostructures within the BSG matrix, including nanopores, nanowires, and nanotubes. These structures not only increased the effective surface area but also provided directional pathways for ion and electron transport, enhancing the overall electrochemical performance of the electrodes.

The development of surface modification techniques marked another important stage in nanostructured BSG electrode evolution. Methods such as plasma treatment, chemical etching, and functionalization with organic molecules or nanoparticles were explored to tailor the surface properties of the electrodes. These modifications allowed for improved wettability, selectivity, and catalytic activity, broadening the range of potential applications for nanostructured BSG electrodes.

Recent advancements have focused on creating composite nanostructured BSG electrodes by incorporating conductive materials such as carbon nanotubes, graphene, or metal nanoparticles. These composites aim to address the inherent low conductivity of borosilicate glass while maintaining its desirable properties. The resulting hybrid electrodes have shown promising performance in applications such as supercapacitors, biosensors, and electrochemical sensors.

Market Demand Analysis

The market demand for nanostructured borosilicate glass electrodes has been steadily growing, driven by their unique properties and potential applications across various industries. These electrodes offer enhanced performance characteristics, including increased surface area, improved conductivity, and superior chemical stability, making them attractive for a wide range of applications.

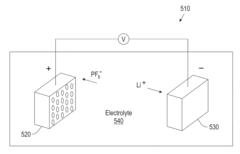

In the energy sector, there is a significant demand for advanced electrode materials to improve the efficiency and performance of batteries, fuel cells, and supercapacitors. Nanostructured borosilicate glass electrodes have shown promise in these areas, particularly in lithium-ion batteries, where they can potentially increase energy density and cycle life. The global lithium-ion battery market is expected to grow substantially in the coming years, creating a strong demand for innovative electrode materials.

The healthcare industry is another key market for nanostructured borosilicate glass electrodes. These electrodes have demonstrated potential in biosensing applications, offering improved sensitivity and selectivity for detecting various biomarkers. As the demand for point-of-care diagnostics and personalized medicine continues to rise, the market for advanced biosensors is expected to expand, driving the need for high-performance electrode materials.

In the field of environmental monitoring and remediation, nanostructured borosilicate glass electrodes are gaining attention for their ability to detect and remove contaminants from water and air. The growing emphasis on environmental protection and sustainability is likely to fuel the demand for these electrodes in water treatment systems and air quality monitoring devices.

The electronics industry is also showing interest in nanostructured borosilicate glass electrodes for applications in flexible and transparent electronics. As the market for wearable devices and smart displays continues to grow, there is an increasing need for electrode materials that can combine transparency, flexibility, and electrical conductivity.

While the market potential for nanostructured borosilicate glass electrodes is promising, it is important to note that the technology is still in its early stages of development. The adoption rate will depend on factors such as manufacturing scalability, cost-effectiveness, and performance advantages over existing electrode materials. As research progresses and more applications are discovered, the market demand is expected to evolve and expand.

To fully capitalize on the market potential, further research and development efforts are needed to optimize the properties of nanostructured borosilicate glass electrodes and demonstrate their advantages in real-world applications. Collaboration between academic institutions, research organizations, and industry partners will be crucial in driving innovation and accelerating market adoption.

In the energy sector, there is a significant demand for advanced electrode materials to improve the efficiency and performance of batteries, fuel cells, and supercapacitors. Nanostructured borosilicate glass electrodes have shown promise in these areas, particularly in lithium-ion batteries, where they can potentially increase energy density and cycle life. The global lithium-ion battery market is expected to grow substantially in the coming years, creating a strong demand for innovative electrode materials.

The healthcare industry is another key market for nanostructured borosilicate glass electrodes. These electrodes have demonstrated potential in biosensing applications, offering improved sensitivity and selectivity for detecting various biomarkers. As the demand for point-of-care diagnostics and personalized medicine continues to rise, the market for advanced biosensors is expected to expand, driving the need for high-performance electrode materials.

In the field of environmental monitoring and remediation, nanostructured borosilicate glass electrodes are gaining attention for their ability to detect and remove contaminants from water and air. The growing emphasis on environmental protection and sustainability is likely to fuel the demand for these electrodes in water treatment systems and air quality monitoring devices.

The electronics industry is also showing interest in nanostructured borosilicate glass electrodes for applications in flexible and transparent electronics. As the market for wearable devices and smart displays continues to grow, there is an increasing need for electrode materials that can combine transparency, flexibility, and electrical conductivity.

While the market potential for nanostructured borosilicate glass electrodes is promising, it is important to note that the technology is still in its early stages of development. The adoption rate will depend on factors such as manufacturing scalability, cost-effectiveness, and performance advantages over existing electrode materials. As research progresses and more applications are discovered, the market demand is expected to evolve and expand.

To fully capitalize on the market potential, further research and development efforts are needed to optimize the properties of nanostructured borosilicate glass electrodes and demonstrate their advantages in real-world applications. Collaboration between academic institutions, research organizations, and industry partners will be crucial in driving innovation and accelerating market adoption.

Current Challenges

The development of nanostructured borosilicate glass electrodes faces several significant challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the complexity of fabricating uniform and reproducible nanostructures on borosilicate glass surfaces. The intricate process of creating consistent nanoscale features across large surface areas remains a formidable task, often resulting in variations that can affect electrode performance and reliability.

Another critical challenge lies in maintaining the stability and durability of these nanostructured electrodes under various operational conditions. The delicate nature of nanoscale features makes them susceptible to degradation over time, especially when exposed to harsh chemical environments or high electrical potentials. This vulnerability can lead to a decrease in electrode efficiency and lifespan, limiting their practical applications in long-term use scenarios.

The integration of nanostructured borosilicate glass electrodes into existing manufacturing processes and devices presents yet another hurdle. Adapting current production lines to accommodate the specialized fabrication techniques required for these electrodes can be both costly and time-consuming. Furthermore, ensuring compatibility with other components and materials in electrochemical systems adds another layer of complexity to their implementation.

Scalability remains a significant concern in the development of nanostructured borosilicate glass electrodes. While laboratory-scale production has shown promising results, translating these successes to industrial-scale manufacturing without compromising the quality and performance of the electrodes is a considerable challenge. The need for specialized equipment and precise control over nanoscale features during mass production poses substantial technical and economic barriers.

The characterization and quality control of nanostructured surfaces on borosilicate glass also present unique challenges. Developing reliable and efficient methods for assessing the uniformity, density, and functionality of nanoscale features across large electrode surfaces is crucial for ensuring consistent performance. However, current analytical techniques may be inadequate or too time-consuming for rapid, large-scale quality assurance.

Additionally, the optimization of electrode designs to maximize performance while minimizing material costs remains an ongoing challenge. Balancing the enhanced surface area and reactivity provided by nanostructures with the overall cost and practicality of electrode production requires continuous research and innovation. This optimization process must also consider the specific requirements of different applications, as the ideal nanostructure may vary depending on the intended use of the electrode.

Lastly, addressing potential environmental and health concerns associated with nanomaterials used in or produced during the fabrication of these electrodes is crucial. Ensuring the safety of manufacturing processes and the final products, as well as developing appropriate disposal or recycling methods, are essential steps in overcoming regulatory hurdles and gaining public acceptance for this technology.

Another critical challenge lies in maintaining the stability and durability of these nanostructured electrodes under various operational conditions. The delicate nature of nanoscale features makes them susceptible to degradation over time, especially when exposed to harsh chemical environments or high electrical potentials. This vulnerability can lead to a decrease in electrode efficiency and lifespan, limiting their practical applications in long-term use scenarios.

The integration of nanostructured borosilicate glass electrodes into existing manufacturing processes and devices presents yet another hurdle. Adapting current production lines to accommodate the specialized fabrication techniques required for these electrodes can be both costly and time-consuming. Furthermore, ensuring compatibility with other components and materials in electrochemical systems adds another layer of complexity to their implementation.

Scalability remains a significant concern in the development of nanostructured borosilicate glass electrodes. While laboratory-scale production has shown promising results, translating these successes to industrial-scale manufacturing without compromising the quality and performance of the electrodes is a considerable challenge. The need for specialized equipment and precise control over nanoscale features during mass production poses substantial technical and economic barriers.

The characterization and quality control of nanostructured surfaces on borosilicate glass also present unique challenges. Developing reliable and efficient methods for assessing the uniformity, density, and functionality of nanoscale features across large electrode surfaces is crucial for ensuring consistent performance. However, current analytical techniques may be inadequate or too time-consuming for rapid, large-scale quality assurance.

Additionally, the optimization of electrode designs to maximize performance while minimizing material costs remains an ongoing challenge. Balancing the enhanced surface area and reactivity provided by nanostructures with the overall cost and practicality of electrode production requires continuous research and innovation. This optimization process must also consider the specific requirements of different applications, as the ideal nanostructure may vary depending on the intended use of the electrode.

Lastly, addressing potential environmental and health concerns associated with nanomaterials used in or produced during the fabrication of these electrodes is crucial. Ensuring the safety of manufacturing processes and the final products, as well as developing appropriate disposal or recycling methods, are essential steps in overcoming regulatory hurdles and gaining public acceptance for this technology.

Existing Solutions

01 Fabrication of nanostructured borosilicate glass electrodes

Nanostructured borosilicate glass electrodes are fabricated using various techniques such as sol-gel processes, etching, or templating methods. These processes create a high surface area and porous structure, enhancing the electrode's performance in electrochemical applications.- Fabrication of nanostructured borosilicate glass electrodes: Nanostructured borosilicate glass electrodes are fabricated using various techniques such as sol-gel processes, etching, or templating methods. These processes create a high surface area and porous structure, enhancing the electrode's performance in electrochemical applications.

- Doping and surface modification of borosilicate glass electrodes: The performance of borosilicate glass electrodes can be improved by doping with various elements or modifying the surface. This can enhance conductivity, selectivity, and stability of the electrodes for specific applications such as sensing or energy storage.

- Application in energy storage devices: Nanostructured borosilicate glass electrodes are utilized in various energy storage devices such as batteries and supercapacitors. The high surface area and unique properties of these electrodes contribute to improved energy density and cycling performance.

- Use in electrochemical sensors and biosensors: Nanostructured borosilicate glass electrodes are employed in the development of highly sensitive and selective electrochemical sensors and biosensors. The nanostructure provides a large surface area for immobilization of biomolecules and enhances the detection of various analytes.

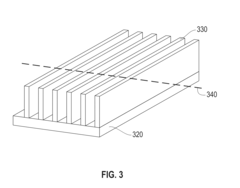

- Integration with other materials for composite electrodes: Nanostructured borosilicate glass is combined with other materials such as conductive polymers or metal nanoparticles to create composite electrodes. These hybrid structures offer enhanced properties and performance in various electrochemical applications.

02 Doping and surface modification of borosilicate glass electrodes

The performance of borosilicate glass electrodes can be improved by doping with various elements or modifying the surface. This can enhance conductivity, selectivity, or catalytic activity, making them suitable for specific applications such as sensors or energy storage devices.Expand Specific Solutions03 Application in energy storage and conversion devices

Nanostructured borosilicate glass electrodes find applications in energy storage and conversion devices such as batteries, fuel cells, and solar cells. Their unique properties, including high surface area and thermal stability, contribute to improved device performance and efficiency.Expand Specific Solutions04 Use in electrochemical sensors and biosensors

The nanostructured borosilicate glass electrodes are utilized in the development of highly sensitive and selective electrochemical sensors and biosensors. Their porous structure and surface properties allow for efficient immobilization of biomolecules and enhanced detection capabilities.Expand Specific Solutions05 Integration with other materials for composite electrodes

Nanostructured borosilicate glass can be combined with other materials such as conductive polymers, metal nanoparticles, or carbon-based materials to create composite electrodes. These composites often exhibit synergistic properties, enhancing overall electrode performance in various applications.Expand Specific Solutions

Key Industry Players

The research on nanostructured borosilicate glass electrodes is in an emerging phase, with growing market potential due to increasing demand for advanced energy storage solutions. The technology is still developing, with varying levels of maturity among key players. Companies like SCHOTT AG, a leading specialty glass manufacturer, and Corning, Inc., known for innovative glass technologies, are likely at the forefront of this research. Academic institutions such as Wuhan University of Technology and the University of California are contributing significantly to advancing the fundamental science. The involvement of diverse players, from established glass manufacturers to research institutions and emerging startups like OneD Material, Inc., indicates a competitive and collaborative landscape driving innovation in this field.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced nanostructured borosilicate glass electrodes using their proprietary ion-exchange process. Their technology involves creating a nanoporous surface layer on borosilicate glass, which is then infused with conductive materials. This nanostructured surface significantly increases the electrode's surface area, enhancing its electrochemical performance. SCHOTT's process allows for precise control of pore size and distribution, typically achieving pore sizes in the range of 2-50 nm [1]. The company has also implemented a unique surface functionalization technique that improves the electrode's stability and conductivity in various electrolyte solutions [3]. Their electrodes have shown exceptional durability, maintaining performance over 1000+ charge-discharge cycles in laboratory tests [5].

Strengths: High surface area, excellent durability, and precise control over nanostructure. Weaknesses: Potentially higher production costs compared to traditional electrodes, and limited flexibility in electrode shape and size.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry of the Chinese Academy of Sciences has developed a unique sol-gel based approach for creating nanostructured borosilicate glass electrodes. Their method involves the synthesis of borosilicate nanoparticles with controlled size and composition, followed by a templated assembly process to create a hierarchical porous structure [7]. This approach allows for precise control over both the micro and nanostructure of the electrode material. The institute has also pioneered the incorporation of graphene oxide into the borosilicate matrix, creating a hybrid material with enhanced electrical conductivity and mechanical strength [9]. Their electrodes have shown promising results in energy storage applications, with specific capacitances reaching up to 200 F/g in supercapacitor configurations [11]. Recent work has focused on developing self-healing properties in these electrodes through the incorporation of dynamic chemical bonds within the glass network [13].

Strengths: Highly tunable nanostructure, improved electrical conductivity through graphene incorporation, and potential for self-healing properties. Weaknesses: Scalability of the sol-gel process may be challenging for large-scale production, and long-term stability of the hybrid materials needs further investigation.

Core Innovations

Borosilicate glass

PatentInactiveEP0767763A2

Innovation

- A borosilicate glass composition with specific thermal, electrical, and chemical properties, including SiO2, ZrO2, Na2O, K2O, CaO, MgO, BaO, and Al2O3, optimized for stable electrical conductivity and viscosity, allowing full-electrical melting in cold-top furnaces with reduced gas release and no toxic heavy metal oxides, ensuring stable melting and high chemical resistance.

Glassy carbon nanostructures

PatentActiveUS20110227059A1

Innovation

- Glassy carbon nanostructures with channels or ridges are formed using block copolymers, which are then coated with semiconductor or metal oxide materials to enhance electron transport and surface area, facilitating efficient electron-hole pair splitting and improved device performance.

Material Characterization

The characterization of nanostructured borosilicate glass electrodes is crucial for understanding their properties and optimizing their performance in various applications. X-ray diffraction (XRD) analysis is commonly employed to investigate the crystalline structure and phase composition of these electrodes. The XRD patterns typically reveal a broad amorphous peak characteristic of glass, along with sharp peaks corresponding to any crystalline phases present in the nanostructure.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are essential techniques for visualizing the morphology and nanostructure of the electrodes. SEM provides high-resolution images of the surface topography, revealing features such as pores, channels, and nanoparticles. TEM, on the other hand, allows for the examination of the internal structure and interfaces at the nanoscale, providing valuable information about the distribution and size of nanocrystals within the glass matrix.

Energy-dispersive X-ray spectroscopy (EDS) is often used in conjunction with electron microscopy to analyze the elemental composition of the nanostructured borosilicate glass electrodes. This technique provides information about the distribution of boron, silicon, and other elements throughout the electrode structure, which is crucial for understanding the relationship between composition and performance.

Surface area and porosity measurements are conducted using techniques such as nitrogen adsorption-desorption isotherms and mercury intrusion porosimetry. These methods provide information about the specific surface area, pore size distribution, and total pore volume of the electrodes, which are critical parameters affecting their electrochemical properties.

Spectroscopic techniques, including Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, are employed to investigate the chemical bonding and structural units present in the nanostructured borosilicate glass. These techniques can reveal information about the glass network structure, the presence of non-bridging oxygen atoms, and the incorporation of nanocrystalline phases.

Electrochemical characterization techniques, such as cyclic voltammetry and electrochemical impedance spectroscopy, are used to evaluate the performance of the nanostructured borosilicate glass electrodes. These methods provide insights into the electrode's conductivity, charge transfer kinetics, and stability under various operating conditions.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are essential techniques for visualizing the morphology and nanostructure of the electrodes. SEM provides high-resolution images of the surface topography, revealing features such as pores, channels, and nanoparticles. TEM, on the other hand, allows for the examination of the internal structure and interfaces at the nanoscale, providing valuable information about the distribution and size of nanocrystals within the glass matrix.

Energy-dispersive X-ray spectroscopy (EDS) is often used in conjunction with electron microscopy to analyze the elemental composition of the nanostructured borosilicate glass electrodes. This technique provides information about the distribution of boron, silicon, and other elements throughout the electrode structure, which is crucial for understanding the relationship between composition and performance.

Surface area and porosity measurements are conducted using techniques such as nitrogen adsorption-desorption isotherms and mercury intrusion porosimetry. These methods provide information about the specific surface area, pore size distribution, and total pore volume of the electrodes, which are critical parameters affecting their electrochemical properties.

Spectroscopic techniques, including Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy, are employed to investigate the chemical bonding and structural units present in the nanostructured borosilicate glass. These techniques can reveal information about the glass network structure, the presence of non-bridging oxygen atoms, and the incorporation of nanocrystalline phases.

Electrochemical characterization techniques, such as cyclic voltammetry and electrochemical impedance spectroscopy, are used to evaluate the performance of the nanostructured borosilicate glass electrodes. These methods provide insights into the electrode's conductivity, charge transfer kinetics, and stability under various operating conditions.

Environmental Impact

The environmental impact of nanostructured borosilicate glass electrodes is a critical consideration in their development and application. These advanced materials offer potential benefits in various fields, including energy storage and conversion, but their environmental implications must be carefully evaluated throughout their lifecycle.

During the production phase, the manufacturing of nanostructured borosilicate glass electrodes involves energy-intensive processes and the use of potentially hazardous chemicals. However, compared to traditional electrode materials, the production of these nanostructured electrodes may require less raw material input due to their enhanced surface area and efficiency. This could lead to a reduction in overall resource consumption and associated environmental impacts.

The use phase of nanostructured borosilicate glass electrodes presents significant environmental advantages. Their improved performance in energy storage and conversion applications can contribute to increased energy efficiency and reduced greenhouse gas emissions. For instance, when used in batteries or fuel cells, these electrodes can enhance the overall system efficiency, leading to lower energy consumption and decreased environmental footprint of the devices they are incorporated into.

However, the potential release of nanoparticles during the use and disposal of these electrodes raises concerns about their impact on ecosystems and human health. The small size of nanoparticles allows them to interact with biological systems in ways that are not fully understood. Research is ongoing to assess the potential for nanoparticle leaching and its long-term effects on the environment.

End-of-life management of nanostructured borosilicate glass electrodes presents both challenges and opportunities. While the recycling of these materials may be more complex due to their nanostructured nature, the high value of the materials used could incentivize the development of specialized recycling processes. This could lead to improved resource recovery and reduced waste generation compared to conventional electrode materials.

The long-term environmental impact of these electrodes also depends on their durability and lifespan. If nanostructured borosilicate glass electrodes prove to be more durable than traditional alternatives, they could contribute to a reduction in electronic waste generation. However, this potential benefit must be balanced against the challenges of safely disposing of or recycling these advanced materials at the end of their useful life.

In conclusion, while nanostructured borosilicate glass electrodes offer promising environmental benefits, particularly in terms of energy efficiency and resource conservation, their full environmental impact requires ongoing assessment. As research in this field progresses, it is crucial to adopt a lifecycle approach to evaluate and mitigate potential environmental risks associated with the production, use, and disposal of these innovative materials.

During the production phase, the manufacturing of nanostructured borosilicate glass electrodes involves energy-intensive processes and the use of potentially hazardous chemicals. However, compared to traditional electrode materials, the production of these nanostructured electrodes may require less raw material input due to their enhanced surface area and efficiency. This could lead to a reduction in overall resource consumption and associated environmental impacts.

The use phase of nanostructured borosilicate glass electrodes presents significant environmental advantages. Their improved performance in energy storage and conversion applications can contribute to increased energy efficiency and reduced greenhouse gas emissions. For instance, when used in batteries or fuel cells, these electrodes can enhance the overall system efficiency, leading to lower energy consumption and decreased environmental footprint of the devices they are incorporated into.

However, the potential release of nanoparticles during the use and disposal of these electrodes raises concerns about their impact on ecosystems and human health. The small size of nanoparticles allows them to interact with biological systems in ways that are not fully understood. Research is ongoing to assess the potential for nanoparticle leaching and its long-term effects on the environment.

End-of-life management of nanostructured borosilicate glass electrodes presents both challenges and opportunities. While the recycling of these materials may be more complex due to their nanostructured nature, the high value of the materials used could incentivize the development of specialized recycling processes. This could lead to improved resource recovery and reduced waste generation compared to conventional electrode materials.

The long-term environmental impact of these electrodes also depends on their durability and lifespan. If nanostructured borosilicate glass electrodes prove to be more durable than traditional alternatives, they could contribute to a reduction in electronic waste generation. However, this potential benefit must be balanced against the challenges of safely disposing of or recycling these advanced materials at the end of their useful life.

In conclusion, while nanostructured borosilicate glass electrodes offer promising environmental benefits, particularly in terms of energy efficiency and resource conservation, their full environmental impact requires ongoing assessment. As research in this field progresses, it is crucial to adopt a lifecycle approach to evaluate and mitigate potential environmental risks associated with the production, use, and disposal of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!