Characterization Techniques for Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Characterization Background

Borosilicate glass, a versatile material known for its exceptional thermal and chemical resistance, has been a cornerstone in various industries for over a century. Developed in the late 19th century by German glassmaker Otto Schott, this specialized glass composition has revolutionized scientific research, industrial processes, and consumer products. The unique properties of borosilicate glass stem from its composition, which typically includes silica, boron oxide, and small amounts of alkali and alumina.

The characterization of borosilicate glass has evolved significantly since its inception, driven by the need to understand and optimize its properties for diverse applications. Initially, characterization techniques were limited to basic physical and optical measurements. However, as technology advanced, more sophisticated methods emerged, allowing for in-depth analysis of the glass structure, composition, and behavior under various conditions.

Early characterization efforts focused on thermal expansion coefficients, chemical durability, and optical properties. These parameters were crucial for the glass's primary applications in laboratory glassware and heat-resistant cookware. As the material found its way into more specialized fields, such as optics, electronics, and nuclear waste storage, the demand for more precise and comprehensive characterization techniques grew.

The mid-20th century saw the introduction of advanced spectroscopic and microscopic techniques, which provided unprecedented insights into the atomic and molecular structure of borosilicate glass. X-ray diffraction (XRD) and nuclear magnetic resonance (NMR) spectroscopy became invaluable tools for understanding the glass network structure and the role of different components in determining its properties.

In recent decades, the characterization of borosilicate glass has become increasingly multidisciplinary, incorporating techniques from materials science, physics, and chemistry. Surface analysis methods, such as X-ray photoelectron spectroscopy (XPS) and secondary ion mass spectrometry (SIMS), have enabled researchers to study the glass-environment interface, crucial for applications in biomedical and environmental fields.

The advent of computational modeling and simulation has further enhanced our ability to characterize and predict the behavior of borosilicate glass under various conditions. These theoretical approaches, combined with experimental techniques, have led to a more comprehensive understanding of the material's structure-property relationships.

Today, the characterization of borosilicate glass continues to evolve, driven by emerging applications in areas such as photonics, energy storage, and advanced manufacturing. The integration of real-time, in-situ characterization methods and high-throughput screening techniques is paving the way for rapid material development and optimization, ensuring that borosilicate glass remains at the forefront of materials science and technology.

The characterization of borosilicate glass has evolved significantly since its inception, driven by the need to understand and optimize its properties for diverse applications. Initially, characterization techniques were limited to basic physical and optical measurements. However, as technology advanced, more sophisticated methods emerged, allowing for in-depth analysis of the glass structure, composition, and behavior under various conditions.

Early characterization efforts focused on thermal expansion coefficients, chemical durability, and optical properties. These parameters were crucial for the glass's primary applications in laboratory glassware and heat-resistant cookware. As the material found its way into more specialized fields, such as optics, electronics, and nuclear waste storage, the demand for more precise and comprehensive characterization techniques grew.

The mid-20th century saw the introduction of advanced spectroscopic and microscopic techniques, which provided unprecedented insights into the atomic and molecular structure of borosilicate glass. X-ray diffraction (XRD) and nuclear magnetic resonance (NMR) spectroscopy became invaluable tools for understanding the glass network structure and the role of different components in determining its properties.

In recent decades, the characterization of borosilicate glass has become increasingly multidisciplinary, incorporating techniques from materials science, physics, and chemistry. Surface analysis methods, such as X-ray photoelectron spectroscopy (XPS) and secondary ion mass spectrometry (SIMS), have enabled researchers to study the glass-environment interface, crucial for applications in biomedical and environmental fields.

The advent of computational modeling and simulation has further enhanced our ability to characterize and predict the behavior of borosilicate glass under various conditions. These theoretical approaches, combined with experimental techniques, have led to a more comprehensive understanding of the material's structure-property relationships.

Today, the characterization of borosilicate glass continues to evolve, driven by emerging applications in areas such as photonics, energy storage, and advanced manufacturing. The integration of real-time, in-situ characterization methods and high-throughput screening techniques is paving the way for rapid material development and optimization, ensuring that borosilicate glass remains at the forefront of materials science and technology.

Market Analysis for Borosilicate Glass Applications

The market for borosilicate glass applications has been experiencing steady growth, driven by the material's unique properties and versatility across various industries. Borosilicate glass, known for its excellent thermal shock resistance, chemical durability, and optical clarity, has found widespread use in laboratory glassware, pharmaceutical packaging, cookware, and high-performance optical systems.

In the laboratory and scientific research sector, borosilicate glass remains the material of choice for beakers, test tubes, and other precision glassware. The global laboratory glassware market, largely dominated by borosilicate products, has been expanding due to increased research and development activities in pharmaceuticals, biotechnology, and academic institutions. This sector is expected to maintain robust growth as scientific research continues to advance.

The pharmaceutical industry represents another significant market for borosilicate glass applications. Its use in vials, ampoules, and syringes is crucial due to its chemical inertness and ability to withstand sterilization processes. The growing demand for injectable drugs and vaccines has been a key driver for borosilicate glass in this sector. Additionally, the trend towards biologics and personalized medicine is likely to further boost demand for high-quality pharmaceutical packaging.

In the consumer goods sector, borosilicate glass has gained popularity in cookware and bakeware products. Its ability to withstand rapid temperature changes and its non-porous nature make it ideal for kitchen applications. The growing consumer preference for eco-friendly and durable kitchenware has contributed to the increased adoption of borosilicate glass in this segment.

The optical industry is another area where borosilicate glass finds significant application. Its use in telescope mirrors, camera lenses, and other precision optical components has been growing due to advancements in astronomy, photography, and industrial imaging. The increasing demand for high-quality optical systems in both consumer electronics and scientific instruments is expected to drive further growth in this segment.

Emerging applications in solar energy, where borosilicate glass is used in solar thermal collectors and concentrated solar power systems, represent a promising growth area. As renewable energy technologies continue to evolve, the demand for high-performance materials like borosilicate glass is likely to increase.

In the laboratory and scientific research sector, borosilicate glass remains the material of choice for beakers, test tubes, and other precision glassware. The global laboratory glassware market, largely dominated by borosilicate products, has been expanding due to increased research and development activities in pharmaceuticals, biotechnology, and academic institutions. This sector is expected to maintain robust growth as scientific research continues to advance.

The pharmaceutical industry represents another significant market for borosilicate glass applications. Its use in vials, ampoules, and syringes is crucial due to its chemical inertness and ability to withstand sterilization processes. The growing demand for injectable drugs and vaccines has been a key driver for borosilicate glass in this sector. Additionally, the trend towards biologics and personalized medicine is likely to further boost demand for high-quality pharmaceutical packaging.

In the consumer goods sector, borosilicate glass has gained popularity in cookware and bakeware products. Its ability to withstand rapid temperature changes and its non-porous nature make it ideal for kitchen applications. The growing consumer preference for eco-friendly and durable kitchenware has contributed to the increased adoption of borosilicate glass in this segment.

The optical industry is another area where borosilicate glass finds significant application. Its use in telescope mirrors, camera lenses, and other precision optical components has been growing due to advancements in astronomy, photography, and industrial imaging. The increasing demand for high-quality optical systems in both consumer electronics and scientific instruments is expected to drive further growth in this segment.

Emerging applications in solar energy, where borosilicate glass is used in solar thermal collectors and concentrated solar power systems, represent a promising growth area. As renewable energy technologies continue to evolve, the demand for high-performance materials like borosilicate glass is likely to increase.

Current Challenges in Borosilicate Glass Characterization

Despite significant advancements in borosilicate glass characterization techniques, several challenges persist in accurately analyzing and understanding the properties of this versatile material. One of the primary difficulties lies in the complex composition of borosilicate glass, which typically contains multiple elements and can vary significantly depending on the specific formulation and manufacturing process.

The heterogeneous nature of borosilicate glass poses a significant challenge for characterization techniques. The presence of both amorphous and crystalline phases within the glass structure makes it difficult to obtain comprehensive and accurate data using a single analytical method. This complexity often necessitates the use of multiple complementary techniques to gain a complete understanding of the material's properties.

Another major challenge is the accurate determination of the glass transition temperature (Tg) and other thermal properties. Borosilicate glasses exhibit a broad range of transition temperatures, and the precise measurement of Tg can be affected by factors such as thermal history, cooling rate, and sample preparation. This variability can lead to inconsistencies in reported values and difficulties in comparing results across different studies.

The characterization of surface properties and defects in borosilicate glass presents additional challenges. Surface analysis techniques must contend with issues such as surface contamination, adsorbed layers, and the potential for surface modification during sample preparation or analysis. These factors can significantly impact the accuracy and reliability of surface characterization results.

Furthermore, the analysis of chemical durability and corrosion resistance of borosilicate glass remains a complex task. Long-term stability studies are often required to accurately assess the glass's performance under various environmental conditions. However, accelerated testing methods may not always provide results that correlate well with real-world performance, leading to uncertainties in predicting long-term behavior.

The characterization of mechanical properties, particularly at the micro and nanoscale, presents unique challenges for borosilicate glass. Techniques such as nanoindentation and atomic force microscopy require careful sample preparation and data interpretation to account for the material's brittle nature and potential surface effects.

Lastly, the development of non-destructive characterization techniques for borosilicate glass components remains an ongoing challenge. While methods such as X-ray computed tomography have shown promise, limitations in resolution and contrast sensitivity continue to hinder their widespread application for detailed analysis of glass microstructure and defects.

The heterogeneous nature of borosilicate glass poses a significant challenge for characterization techniques. The presence of both amorphous and crystalline phases within the glass structure makes it difficult to obtain comprehensive and accurate data using a single analytical method. This complexity often necessitates the use of multiple complementary techniques to gain a complete understanding of the material's properties.

Another major challenge is the accurate determination of the glass transition temperature (Tg) and other thermal properties. Borosilicate glasses exhibit a broad range of transition temperatures, and the precise measurement of Tg can be affected by factors such as thermal history, cooling rate, and sample preparation. This variability can lead to inconsistencies in reported values and difficulties in comparing results across different studies.

The characterization of surface properties and defects in borosilicate glass presents additional challenges. Surface analysis techniques must contend with issues such as surface contamination, adsorbed layers, and the potential for surface modification during sample preparation or analysis. These factors can significantly impact the accuracy and reliability of surface characterization results.

Furthermore, the analysis of chemical durability and corrosion resistance of borosilicate glass remains a complex task. Long-term stability studies are often required to accurately assess the glass's performance under various environmental conditions. However, accelerated testing methods may not always provide results that correlate well with real-world performance, leading to uncertainties in predicting long-term behavior.

The characterization of mechanical properties, particularly at the micro and nanoscale, presents unique challenges for borosilicate glass. Techniques such as nanoindentation and atomic force microscopy require careful sample preparation and data interpretation to account for the material's brittle nature and potential surface effects.

Lastly, the development of non-destructive characterization techniques for borosilicate glass components remains an ongoing challenge. While methods such as X-ray computed tomography have shown promise, limitations in resolution and contrast sensitivity continue to hinder their widespread application for detailed analysis of glass microstructure and defects.

Existing Characterization Methods for Borosilicate Glass

01 Composition and properties of borosilicate glass

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.- Composition and properties of borosilicate glass: Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. It is known for its low thermal expansion coefficient, high chemical resistance, and excellent thermal shock resistance. These properties make it suitable for various applications in laboratory equipment, cookware, and industrial uses.

- Manufacturing processes for borosilicate glass: Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.

- Applications of borosilicate glass in laboratory and industrial settings: Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and pipettes, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, process vessels, and heat exchangers. The material's durability and transparency make it ideal for these demanding environments.

- Borosilicate glass in consumer products: Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and home appliances. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The material's clarity and eco-friendly nature also make it popular for reusable water bottles and food storage solutions.

- Innovations and modifications in borosilicate glass: Ongoing research and development in borosilicate glass focus on enhancing its properties and expanding its applications. This includes developing new compositions with improved characteristics, such as increased strength or specific optical properties. Innovations also involve surface treatments, coatings, and the integration of borosilicate glass with other materials for specialized applications.

02 Manufacturing processes for borosilicate glass

Various manufacturing processes are employed to produce borosilicate glass, including melting, forming, and annealing. Advanced techniques such as float glass production and precision molding are used to create different forms of borosilicate glass products. The manufacturing process often involves careful control of temperature and composition to achieve desired properties.Expand Specific Solutions03 Applications of borosilicate glass in laboratory and industrial settings

Borosilicate glass is widely used in laboratory glassware, such as beakers, test tubes, and flasks, due to its chemical resistance and thermal stability. It is also employed in industrial applications, including sight glasses, process vessels, and piping systems. The material's durability and transparency make it ideal for these demanding environments.Expand Specific Solutions04 Borosilicate glass in consumer products

Borosilicate glass is increasingly used in consumer products, particularly in kitchenware and home appliances. Its heat resistance and durability make it suitable for bakeware, storage containers, and coffee makers. The material's clarity and eco-friendly nature also make it popular for reusable water bottles and food storage solutions.Expand Specific Solutions05 Innovations and modifications in borosilicate glass

Ongoing research and development in borosilicate glass focus on enhancing its properties and expanding its applications. This includes developing new compositions with improved characteristics, such as increased strength or specific optical properties. Innovations also involve surface treatments, coatings, and the incorporation of additional materials to create specialized borosilicate glass products for emerging technologies and industries.Expand Specific Solutions

Key Players in Glass Analysis Industry

The characterization techniques for borosilicate glass market is in a mature stage, with established players and well-developed technologies. The global market size is estimated to be in the billions of dollars, driven by demand from pharmaceutical, laboratory, and industrial sectors. Leading companies like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. have advanced R&D capabilities and extensive product portfolios. The technology is well-established, with ongoing innovations focused on improving glass properties and manufacturing processes. Emerging players from China, such as Hunan Kibing Pharmaceutical Material Technology Co., Ltd., are also entering the market, potentially disrupting the competitive landscape.

SCHOTT AG

Technical Solution: SCHOTT AG employs advanced characterization techniques for borosilicate glass, including X-ray diffraction (XRD) for structural analysis, scanning electron microscopy (SEM) for surface morphology, and differential thermal analysis (DTA) for thermal properties[1]. They utilize Raman spectroscopy to study the glass network structure and identify specific chemical bonds[2]. SCHOTT has developed a proprietary high-precision dilatometry method to measure the coefficient of thermal expansion (CTE) with accuracy up to 10^-8 K^-1[3]. For chemical durability testing, they use accelerated weathering chambers and ion chromatography to analyze leached elements[4]. SCHOTT also employs atomic force microscopy (AFM) for nanoscale surface characterization and mechanical property measurements[5].

Strengths: Comprehensive suite of characterization techniques, proprietary high-precision methods, and extensive experience in borosilicate glass analysis. Weaknesses: Potential high costs associated with advanced equipment and specialized expertise required.

Corning, Inc.

Technical Solution: Corning's characterization techniques for borosilicate glass include advanced spectroscopic methods such as X-ray photoelectron spectroscopy (XPS) for surface composition analysis and secondary ion mass spectrometry (SIMS) for depth profiling[1]. They employ nanoindentation techniques to measure mechanical properties at the microscale, allowing for precise determination of hardness and elastic modulus[2]. Corning utilizes synchrotron-based X-ray techniques for in-situ studies of glass formation and structure under extreme conditions[3]. For optical characterization, they use spectrophotometry and ellipsometry to measure refractive index and transmission across a wide spectral range[4]. Corning has also developed proprietary non-destructive testing methods using ultrasonic techniques to detect micro-defects in large glass sheets[5].

Strengths: Access to cutting-edge characterization tools, expertise in non-destructive testing, and capabilities for in-situ studies under extreme conditions. Weaknesses: Some techniques may be limited to research settings and not easily scalable for high-volume production.

Advanced Techniques in Borosilicate Glass Analysis

Borosilicate glass compositions and uses thereof

PatentWO2004050575A1

Innovation

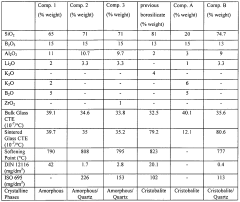

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a suitable coefficient of thermal expansion and mechanical strength.

Borosilicate glass compositions and uses thereof

PatentInactiveEP1567459A1

Innovation

- A borosilicate glass composition with silicon dioxide, boric oxide, aluminum oxide, and at least one alkali oxide, which resists devitrification without the addition of inhibitor oxides, maintaining a coefficient of thermal expansion between 30 x 10^-7/°C and 55 x 10^-7/°C, thereby preventing mechanical strength loss and crack formation.

Environmental Impact of Borosilicate Glass Production

The production of borosilicate glass, while offering numerous benefits in terms of durability and chemical resistance, carries significant environmental implications. The manufacturing process involves high-temperature melting of raw materials, including silica, boron oxide, and other additives, which requires substantial energy consumption. This energy-intensive production contributes to greenhouse gas emissions, particularly when fossil fuels are used as the primary energy source.

The extraction of raw materials for borosilicate glass production also has environmental consequences. Mining operations for silica and boron compounds can lead to habitat disruption, soil erosion, and potential water pollution if not managed properly. Additionally, the transportation of these raw materials to production facilities further increases the carbon footprint of the industry.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling and cleaning, which can strain local water resources, especially in water-scarce regions. Proper water management and recycling systems are crucial to mitigate this impact.

The production process also generates air emissions, including particulate matter, nitrogen oxides, and sulfur dioxide. These pollutants can contribute to air quality issues and potential health risks for workers and nearby communities if not adequately controlled through emission reduction technologies.

Waste management is a critical aspect of the environmental impact of borosilicate glass production. While glass itself is recyclable, the specialized composition of borosilicate glass can complicate recycling efforts. Proper disposal or recycling of production waste, including broken glass and furnace residues, is essential to minimize landfill impact and resource depletion.

On a positive note, the durability and chemical resistance of borosilicate glass contribute to its long lifespan and potential for reuse, which can offset some of the environmental costs associated with its production. Furthermore, advancements in manufacturing technologies and the adoption of cleaner energy sources are gradually reducing the environmental footprint of borosilicate glass production.

To address these environmental challenges, the industry is increasingly focusing on sustainable practices. This includes improving energy efficiency in furnaces, implementing closed-loop water systems, and exploring alternative raw material sources. Some manufacturers are also investing in renewable energy sources to power their facilities, further reducing the carbon intensity of production.

The extraction of raw materials for borosilicate glass production also has environmental consequences. Mining operations for silica and boron compounds can lead to habitat disruption, soil erosion, and potential water pollution if not managed properly. Additionally, the transportation of these raw materials to production facilities further increases the carbon footprint of the industry.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling and cleaning, which can strain local water resources, especially in water-scarce regions. Proper water management and recycling systems are crucial to mitigate this impact.

The production process also generates air emissions, including particulate matter, nitrogen oxides, and sulfur dioxide. These pollutants can contribute to air quality issues and potential health risks for workers and nearby communities if not adequately controlled through emission reduction technologies.

Waste management is a critical aspect of the environmental impact of borosilicate glass production. While glass itself is recyclable, the specialized composition of borosilicate glass can complicate recycling efforts. Proper disposal or recycling of production waste, including broken glass and furnace residues, is essential to minimize landfill impact and resource depletion.

On a positive note, the durability and chemical resistance of borosilicate glass contribute to its long lifespan and potential for reuse, which can offset some of the environmental costs associated with its production. Furthermore, advancements in manufacturing technologies and the adoption of cleaner energy sources are gradually reducing the environmental footprint of borosilicate glass production.

To address these environmental challenges, the industry is increasingly focusing on sustainable practices. This includes improving energy efficiency in furnaces, implementing closed-loop water systems, and exploring alternative raw material sources. Some manufacturers are also investing in renewable energy sources to power their facilities, further reducing the carbon intensity of production.

Standardization of Borosilicate Glass Testing Protocols

The standardization of borosilicate glass testing protocols is crucial for ensuring consistent and reliable characterization across different laboratories and applications. Currently, there is a lack of universally accepted standards for testing borosilicate glass properties, leading to potential discrepancies in results and difficulties in comparing data from different sources.

To address this issue, several key areas require standardization. Firstly, sample preparation methods need to be unified, including specifications for sample size, surface finish, and any pre-treatment procedures. This ensures that all tests are performed on comparable specimens, reducing variability due to sample-related factors.

Secondly, testing conditions must be standardized. This includes parameters such as temperature, humidity, and loading rates for mechanical tests. For thermal and chemical resistance tests, exposure times, temperature cycles, and chemical concentrations should be clearly defined. Standardized environmental conditions are essential for obtaining reproducible results across different testing facilities.

Thirdly, measurement techniques and equipment calibration procedures need to be harmonized. This involves specifying the types of instruments to be used for various tests, such as spectrophotometers for optical measurements or dilatometers for thermal expansion tests. Calibration protocols should be established to ensure accuracy and comparability of results between different laboratories.

Furthermore, data analysis and reporting methods require standardization. This includes defining how raw data should be processed, which statistical methods to apply, and how to present results. Standardized reporting formats would facilitate easier comparison of results from different studies and improve overall data quality in the field.

Efforts to develop these standards are ongoing, with organizations such as ASTM International and ISO working on comprehensive testing protocols for borosilicate glass. These standards aim to cover a wide range of properties, including mechanical strength, thermal shock resistance, chemical durability, and optical characteristics.

Implementing standardized testing protocols will have several benefits for the borosilicate glass industry. It will enhance quality control processes, allowing manufacturers to more accurately assess and compare their products. Researchers will benefit from improved reproducibility of experiments and easier validation of results. Additionally, standardization will facilitate more effective communication between suppliers and customers, as well as support regulatory compliance in industries where borosilicate glass is used, such as pharmaceuticals and laboratory equipment.

To address this issue, several key areas require standardization. Firstly, sample preparation methods need to be unified, including specifications for sample size, surface finish, and any pre-treatment procedures. This ensures that all tests are performed on comparable specimens, reducing variability due to sample-related factors.

Secondly, testing conditions must be standardized. This includes parameters such as temperature, humidity, and loading rates for mechanical tests. For thermal and chemical resistance tests, exposure times, temperature cycles, and chemical concentrations should be clearly defined. Standardized environmental conditions are essential for obtaining reproducible results across different testing facilities.

Thirdly, measurement techniques and equipment calibration procedures need to be harmonized. This involves specifying the types of instruments to be used for various tests, such as spectrophotometers for optical measurements or dilatometers for thermal expansion tests. Calibration protocols should be established to ensure accuracy and comparability of results between different laboratories.

Furthermore, data analysis and reporting methods require standardization. This includes defining how raw data should be processed, which statistical methods to apply, and how to present results. Standardized reporting formats would facilitate easier comparison of results from different studies and improve overall data quality in the field.

Efforts to develop these standards are ongoing, with organizations such as ASTM International and ISO working on comprehensive testing protocols for borosilicate glass. These standards aim to cover a wide range of properties, including mechanical strength, thermal shock resistance, chemical durability, and optical characteristics.

Implementing standardized testing protocols will have several benefits for the borosilicate glass industry. It will enhance quality control processes, allowing manufacturers to more accurately assess and compare their products. Researchers will benefit from improved reproducibility of experiments and easier validation of results. Additionally, standardization will facilitate more effective communication between suppliers and customers, as well as support regulatory compliance in industries where borosilicate glass is used, such as pharmaceuticals and laboratory equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!