Optical Properties Optimization in Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Optical Evolution and Objectives

Borosilicate glass has been a cornerstone material in optical applications for over a century, with its development tracing back to the late 19th century. The evolution of this versatile material has been driven by the ever-increasing demands for improved optical performance across various industries, from scientific instruments to consumer electronics.

The journey of borosilicate glass in optics began with its invention by Otto Schott in 1893. Initially prized for its low thermal expansion coefficient, it quickly found applications in laboratory glassware and telescope mirrors. As the 20th century progressed, the optical properties of borosilicate glass became a focus of intense research and development.

In the 1930s and 1940s, significant advancements were made in understanding the relationship between glass composition and optical properties. This period saw the development of new formulations that expanded the range of refractive indices and dispersion characteristics achievable with borosilicate glass. These improvements were crucial for the creation of more sophisticated optical systems, particularly in the field of microscopy and spectroscopy.

The space race of the 1960s and 1970s further accelerated the development of borosilicate glass for optical applications. The need for lightweight, durable, and optically superior materials for space-based telescopes and satellites drove innovations in glass manufacturing and processing techniques. This era saw the introduction of advanced annealing processes and surface treatments that significantly enhanced the optical quality of borosilicate glass.

As we entered the digital age, the demands on optical materials shifted towards miniaturization and integration with electronic components. This led to the development of borosilicate glass formulations optimized for use in fiber optics, laser systems, and display technologies. The ability to precisely control the optical properties of borosilicate glass at the molecular level became a key focus of research.

Today, the objectives for optical properties optimization in borosilicate glass are multifaceted. There is a growing emphasis on enhancing transmission across a broader spectrum, from ultraviolet to infrared wavelengths. Researchers are also working on improving the glass's resistance to radiation-induced darkening, a critical factor for applications in space and nuclear industries.

Another key objective is the development of borosilicate glasses with ultra-low expansion coefficients while maintaining excellent optical properties. This is particularly important for large mirror substrates used in next-generation astronomical telescopes and high-power laser systems.

Furthermore, there is a push towards creating borosilicate glasses with higher refractive indices and lower dispersion, which would enable the design of more compact and efficient optical systems. This objective aligns with the broader trend of miniaturization in technology and the need for more sophisticated optical components in emerging fields such as augmented reality and autonomous vehicles.

The journey of borosilicate glass in optics began with its invention by Otto Schott in 1893. Initially prized for its low thermal expansion coefficient, it quickly found applications in laboratory glassware and telescope mirrors. As the 20th century progressed, the optical properties of borosilicate glass became a focus of intense research and development.

In the 1930s and 1940s, significant advancements were made in understanding the relationship between glass composition and optical properties. This period saw the development of new formulations that expanded the range of refractive indices and dispersion characteristics achievable with borosilicate glass. These improvements were crucial for the creation of more sophisticated optical systems, particularly in the field of microscopy and spectroscopy.

The space race of the 1960s and 1970s further accelerated the development of borosilicate glass for optical applications. The need for lightweight, durable, and optically superior materials for space-based telescopes and satellites drove innovations in glass manufacturing and processing techniques. This era saw the introduction of advanced annealing processes and surface treatments that significantly enhanced the optical quality of borosilicate glass.

As we entered the digital age, the demands on optical materials shifted towards miniaturization and integration with electronic components. This led to the development of borosilicate glass formulations optimized for use in fiber optics, laser systems, and display technologies. The ability to precisely control the optical properties of borosilicate glass at the molecular level became a key focus of research.

Today, the objectives for optical properties optimization in borosilicate glass are multifaceted. There is a growing emphasis on enhancing transmission across a broader spectrum, from ultraviolet to infrared wavelengths. Researchers are also working on improving the glass's resistance to radiation-induced darkening, a critical factor for applications in space and nuclear industries.

Another key objective is the development of borosilicate glasses with ultra-low expansion coefficients while maintaining excellent optical properties. This is particularly important for large mirror substrates used in next-generation astronomical telescopes and high-power laser systems.

Furthermore, there is a push towards creating borosilicate glasses with higher refractive indices and lower dispersion, which would enable the design of more compact and efficient optical systems. This objective aligns with the broader trend of miniaturization in technology and the need for more sophisticated optical components in emerging fields such as augmented reality and autonomous vehicles.

Market Analysis for High-Performance Optical Glass

The global market for high-performance optical glass, particularly borosilicate glass with optimized optical properties, has been experiencing significant growth driven by advancements in various industries. The demand for precision optics in sectors such as aerospace, defense, medical imaging, and telecommunications has been a key factor in market expansion. Borosilicate glass, known for its excellent thermal and chemical resistance, has become increasingly popular in high-performance optical applications due to its superior optical properties and durability.

In recent years, the market has witnessed a surge in demand for optical components with enhanced performance characteristics, including improved transmission, reduced dispersion, and increased refractive index. This trend has been particularly pronounced in the photonics industry, where the need for high-quality optical materials continues to grow. The development of advanced manufacturing techniques and the increasing focus on research and development have further contributed to the market's growth potential.

The aerospace and defense sectors have emerged as significant consumers of high-performance optical glass, driven by the need for advanced imaging systems, laser-based technologies, and precision guidance systems. Similarly, the medical imaging industry has shown a growing appetite for specialized optical glass components in devices such as endoscopes, microscopes, and diagnostic equipment. These applications require optical materials with exceptional clarity, stability, and resistance to environmental factors.

Geographically, North America and Europe have traditionally dominated the high-performance optical glass market, owing to their strong presence in aerospace, defense, and medical technology industries. However, the Asia-Pacific region has been rapidly gaining market share, fueled by the growth of the electronics and telecommunications sectors in countries like China, Japan, and South Korea. The increasing investment in research and development activities in these regions is expected to further boost market growth in the coming years.

The market for high-performance optical glass is characterized by intense competition among key players, with a focus on product innovation and technological advancements. Companies are investing heavily in developing new formulations and manufacturing processes to meet the evolving demands of various industries. The trend towards miniaturization and increased functionality in optical systems has also been driving the need for more sophisticated optical glass solutions.

In recent years, the market has witnessed a surge in demand for optical components with enhanced performance characteristics, including improved transmission, reduced dispersion, and increased refractive index. This trend has been particularly pronounced in the photonics industry, where the need for high-quality optical materials continues to grow. The development of advanced manufacturing techniques and the increasing focus on research and development have further contributed to the market's growth potential.

The aerospace and defense sectors have emerged as significant consumers of high-performance optical glass, driven by the need for advanced imaging systems, laser-based technologies, and precision guidance systems. Similarly, the medical imaging industry has shown a growing appetite for specialized optical glass components in devices such as endoscopes, microscopes, and diagnostic equipment. These applications require optical materials with exceptional clarity, stability, and resistance to environmental factors.

Geographically, North America and Europe have traditionally dominated the high-performance optical glass market, owing to their strong presence in aerospace, defense, and medical technology industries. However, the Asia-Pacific region has been rapidly gaining market share, fueled by the growth of the electronics and telecommunications sectors in countries like China, Japan, and South Korea. The increasing investment in research and development activities in these regions is expected to further boost market growth in the coming years.

The market for high-performance optical glass is characterized by intense competition among key players, with a focus on product innovation and technological advancements. Companies are investing heavily in developing new formulations and manufacturing processes to meet the evolving demands of various industries. The trend towards miniaturization and increased functionality in optical systems has also been driving the need for more sophisticated optical glass solutions.

Current Challenges in Borosilicate Optical Properties

Borosilicate glass, renowned for its exceptional thermal and chemical properties, faces several challenges in optimizing its optical characteristics. One of the primary hurdles is achieving consistent and uniform refractive index across large-scale production. The refractive index of borosilicate glass is highly sensitive to compositional variations, which can occur during the melting and forming processes. Even minor fluctuations in the ratio of boron oxide to silica can lead to significant optical inhomogeneities, affecting the glass's performance in precision optical applications.

Another significant challenge lies in minimizing stress-induced birefringence. The thermal expansion mismatch between the boron-rich and silica-rich phases in borosilicate glass can create residual stresses during cooling. These stresses manifest as birefringence, which can distort light transmission and compromise the glass's optical quality. Controlling and reducing this effect requires precise annealing procedures and potentially novel compositional adjustments.

The reduction of light scattering within borosilicate glass presents an ongoing challenge. Microscopic inhomogeneities, such as phase separations or crystalline inclusions, can cause unwanted light scattering, diminishing the glass's transparency and optical clarity. Addressing this issue involves refining melting techniques and exploring advanced purification methods to ensure a more homogeneous glass structure.

Chromatic dispersion control is another area of concern in borosilicate glass optimization. While borosilicate glass generally exhibits lower dispersion compared to soda-lime glass, fine-tuning its dispersion characteristics for specific optical applications remains challenging. This is particularly crucial in applications requiring achromatic performance or precise color rendering.

The development of borosilicate glasses with enhanced UV and IR transmission capabilities is an ongoing challenge. Current formulations often have limitations in these spectral regions, restricting their use in certain scientific and industrial applications. Expanding the transmission window while maintaining the glass's other desirable properties requires innovative compositional strategies and processing techniques.

Lastly, improving the surface quality and polishability of borosilicate glass poses a significant challenge. The glass's chemical durability, while beneficial in many aspects, can make it more difficult to achieve the ultra-smooth surfaces required for high-end optical components. Developing advanced polishing techniques and potentially modifying surface chemistry without compromising bulk properties are areas of active research and development.

Another significant challenge lies in minimizing stress-induced birefringence. The thermal expansion mismatch between the boron-rich and silica-rich phases in borosilicate glass can create residual stresses during cooling. These stresses manifest as birefringence, which can distort light transmission and compromise the glass's optical quality. Controlling and reducing this effect requires precise annealing procedures and potentially novel compositional adjustments.

The reduction of light scattering within borosilicate glass presents an ongoing challenge. Microscopic inhomogeneities, such as phase separations or crystalline inclusions, can cause unwanted light scattering, diminishing the glass's transparency and optical clarity. Addressing this issue involves refining melting techniques and exploring advanced purification methods to ensure a more homogeneous glass structure.

Chromatic dispersion control is another area of concern in borosilicate glass optimization. While borosilicate glass generally exhibits lower dispersion compared to soda-lime glass, fine-tuning its dispersion characteristics for specific optical applications remains challenging. This is particularly crucial in applications requiring achromatic performance or precise color rendering.

The development of borosilicate glasses with enhanced UV and IR transmission capabilities is an ongoing challenge. Current formulations often have limitations in these spectral regions, restricting their use in certain scientific and industrial applications. Expanding the transmission window while maintaining the glass's other desirable properties requires innovative compositional strategies and processing techniques.

Lastly, improving the surface quality and polishability of borosilicate glass poses a significant challenge. The glass's chemical durability, while beneficial in many aspects, can make it more difficult to achieve the ultra-smooth surfaces required for high-end optical components. Developing advanced polishing techniques and potentially modifying surface chemistry without compromising bulk properties are areas of active research and development.

Existing Techniques for Optical Property Improvement

01 Refractive index and dispersion properties

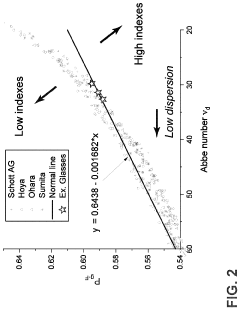

Borosilicate glass exhibits unique refractive index and dispersion characteristics, making it suitable for various optical applications. These properties can be tailored by adjusting the glass composition, particularly the ratio of boron oxide to silica. The low dispersion and high transparency of borosilicate glass make it ideal for precision optical components.- Refractive index and dispersion properties: Borosilicate glass exhibits unique refractive index and dispersion characteristics, making it suitable for various optical applications. These properties can be tailored by adjusting the glass composition, particularly the ratio of boron oxide to silica. The low dispersion and high refractive index of borosilicate glass contribute to its use in precision optical components.

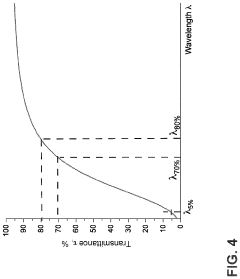

- Transmission and absorption characteristics: Borosilicate glass offers excellent light transmission across a wide spectral range, including visible and near-infrared wavelengths. It has low absorption coefficients, making it ideal for applications requiring high optical clarity. The glass can be doped with various elements to modify its transmission properties for specific wavelengths or to create optical filters.

- Thermal stability and low coefficient of thermal expansion: The thermal properties of borosilicate glass contribute to its optical stability. Its low coefficient of thermal expansion minimizes distortion and stress-induced birefringence when subjected to temperature changes. This characteristic makes it suitable for high-precision optical components in varying environmental conditions.

- Surface quality and polishability: Borosilicate glass can be manufactured and processed to achieve excellent surface quality, which is crucial for optical applications. Its composition allows for high-quality polishing, resulting in smooth surfaces with minimal defects. This property is essential for reducing light scattering and maintaining optical performance in lenses, mirrors, and other optical elements.

- Customization for specific optical applications: The versatility of borosilicate glass allows for customization of its optical properties through various manufacturing techniques and compositional adjustments. This includes creating gradient-index optics, incorporating dopants for specific spectral characteristics, and developing specialized coatings to enhance or modify optical performance for particular applications in fields such as astronomy, laser technology, and imaging systems.

02 Transmission and absorption characteristics

Borosilicate glass offers excellent light transmission across a wide spectral range, including visible and near-infrared regions. It has low absorption coefficients, allowing for high transmittance of light. The glass can be doped with specific elements to modify its transmission properties for specialized applications, such as filters or radiation shielding.Expand Specific Solutions03 Thermal stability and low coefficient of thermal expansion

The thermal stability of borosilicate glass contributes to its optical performance. Its low coefficient of thermal expansion ensures minimal distortion of optical properties under temperature changes. This characteristic makes it suitable for applications requiring high precision and stability, such as telescope mirrors and laser optics.Expand Specific Solutions04 Surface quality and polishability

Borosilicate glass can be manufactured and processed to achieve excellent surface quality, which is crucial for optical applications. Its composition allows for high polishability, resulting in smooth surfaces with minimal defects. This property is essential for reducing light scattering and maintaining optical performance in precision instruments.Expand Specific Solutions05 Customization for specific optical applications

The versatility of borosilicate glass allows for customization of its optical properties through various manufacturing techniques and compositional adjustments. This includes creating gradient-index optics, incorporating dopants for specific spectral characteristics, or developing specialized coatings to enhance performance in areas such as anti-reflection or UV protection.Expand Specific Solutions

Key Manufacturers in Optical Borosilicate Industry

The optical properties optimization in borosilicate glass market is in a mature growth stage, with a global market size estimated to exceed $5 billion. The technology has reached a high level of maturity, with established players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. leading innovation. These companies have extensive R&D capabilities and product portfolios, focusing on enhancing optical performance for various applications. Emerging players such as Hunan Kibing Pharmaceutical Material Technology Co., Ltd. and Ruyuan Yao Autonomous County East Sunshine Medical Glass Technology Co., Ltd. are also making strides in specialized segments, particularly in pharmaceutical glass. The competitive landscape is characterized by ongoing research into advanced formulations and manufacturing processes to improve optical clarity, durability, and specialized properties for high-tech applications.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions with optimized optical properties. Their BOROFLOAT® glass offers high transmission in the visible and near-infrared spectrum, with a refractive index of 1.47 and an Abbe number of 65.4[1]. They have implemented ion exchange processes to enhance surface strength and chemical durability. SCHOTT's innovative melting techniques ensure homogeneity and low bubble content, crucial for optical applications. They have also developed special coatings to further enhance transmission and reduce reflection, achieving over 99% transmission in specific wavelength ranges[2].

Strengths: Extensive experience in specialty glass, global presence, and strong R&D capabilities. Weaknesses: High production costs and potential limitations in scaling up new technologies rapidly.

Corning, Inc.

Technical Solution: Corning has pioneered several innovations in borosilicate glass optical properties. Their Gorilla® Glass technology, originally developed for electronic displays, has been adapted for optical applications with enhanced scratch resistance and durability. Corning's proprietary fusion draw process allows for the production of exceptionally thin, flat, and optically pure borosilicate glass sheets[3]. They have also developed specialized doping techniques to modify the refractive index and dispersion characteristics of borosilicate glass, enabling customization for specific optical applications such as high-performance lenses and filters[4].

Strengths: Strong patent portfolio, vertically integrated manufacturing, and diverse application expertise. Weaknesses: High R&D costs and potential overreliance on consumer electronics market.

Innovative Approaches in Borosilicate Optics

Low boric acid borosilicate glass and its use

PatentInactiveEP0699636A1

Innovation

- Developing new borosilicate glass compositions with specific ratios of SiO2, B2O3, Al2O3, Li2O, Na2O, K2O, MgO, CaO, BaO, ZnO, ZrO2, and other oxides, ensuring high alkali resistance (LBK 1), low thermal expansion (4.0-5.3 x 10^-6 K^-1), and high UV transmission, while maintaining mechanical and thermal strength through chemical and thermal toughening.

Silicoborate and borosilicate glasses having high refractive index and low density

PatentActiveUS11999651B2

Innovation

- The development of silicoborate and borosilicate glasses with specific compositions, including SiO2, B2O3, and additional oxides like ZrO2, La2O3, and Nb2O5, within defined proportions to achieve a refractive index parameter (Pn) of 1.7 to 1.95 and a density parameter (Pd) less than 4.5, while maintaining high transmittance and glass-forming ability, by optimizing the ratios and concentrations of these components to prevent crystallization and phase separation.

Environmental Impact of Optical Glass Production

The production of optical glass, particularly borosilicate glass for advanced optical applications, has significant environmental implications. The manufacturing process involves high-temperature melting of raw materials, which consumes substantial energy and releases greenhouse gases. Borosilicate glass production typically requires temperatures exceeding 1500°C, resulting in considerable CO2 emissions from both fuel combustion and chemical reactions during melting.

Raw material extraction for borosilicate glass, including silica, boron compounds, and various metal oxides, can lead to habitat disruption and soil erosion. Mining activities may also contaminate local water sources and impact biodiversity. Additionally, the use of rare earth elements in some specialized optical glasses raises concerns about resource depletion and the environmental impact of their extraction.

Water consumption is another critical environmental factor in optical glass production. Large volumes of water are used for cooling, cleaning, and processing, potentially straining local water resources. Wastewater from these processes may contain dissolved metals and other contaminants, requiring careful treatment before discharge to prevent water pollution.

The optimization of optical properties in borosilicate glass often involves the use of various additives and dopants. While these enhance the glass's performance, they can introduce additional environmental challenges. Some additives may be toxic or pose disposal issues at the end of the product's life cycle. This necessitates careful consideration of material selection and waste management strategies.

Efforts to mitigate the environmental impact of optical glass production are ongoing. These include improving energy efficiency through advanced furnace designs and heat recovery systems, developing lower-temperature melting processes, and exploring alternative raw materials with reduced environmental footprints. Recycling of optical glass is also gaining attention, although the high purity requirements for many applications present challenges.

The industry is increasingly adopting life cycle assessment (LCA) approaches to quantify and reduce the overall environmental impact of optical glass products. This holistic view considers impacts from raw material extraction through manufacturing, use, and eventual disposal or recycling. Such assessments are driving innovations in cleaner production technologies and more sustainable product designs.

Raw material extraction for borosilicate glass, including silica, boron compounds, and various metal oxides, can lead to habitat disruption and soil erosion. Mining activities may also contaminate local water sources and impact biodiversity. Additionally, the use of rare earth elements in some specialized optical glasses raises concerns about resource depletion and the environmental impact of their extraction.

Water consumption is another critical environmental factor in optical glass production. Large volumes of water are used for cooling, cleaning, and processing, potentially straining local water resources. Wastewater from these processes may contain dissolved metals and other contaminants, requiring careful treatment before discharge to prevent water pollution.

The optimization of optical properties in borosilicate glass often involves the use of various additives and dopants. While these enhance the glass's performance, they can introduce additional environmental challenges. Some additives may be toxic or pose disposal issues at the end of the product's life cycle. This necessitates careful consideration of material selection and waste management strategies.

Efforts to mitigate the environmental impact of optical glass production are ongoing. These include improving energy efficiency through advanced furnace designs and heat recovery systems, developing lower-temperature melting processes, and exploring alternative raw materials with reduced environmental footprints. Recycling of optical glass is also gaining attention, although the high purity requirements for many applications present challenges.

The industry is increasingly adopting life cycle assessment (LCA) approaches to quantify and reduce the overall environmental impact of optical glass products. This holistic view considers impacts from raw material extraction through manufacturing, use, and eventual disposal or recycling. Such assessments are driving innovations in cleaner production technologies and more sustainable product designs.

Applications Driving Borosilicate Optical Advancements

The optimization of optical properties in borosilicate glass is driven by a wide range of applications across various industries. In the field of optics and photonics, borosilicate glass plays a crucial role in the development of high-performance optical components and systems. The demand for improved optical properties is particularly evident in the production of precision lenses, prisms, and optical fibers.

One of the primary applications driving advancements in borosilicate optical properties is the semiconductor industry. As chip manufacturers continue to push the boundaries of miniaturization and performance, there is an increasing need for high-quality optical materials in photolithography systems. Borosilicate glass with enhanced optical properties is essential for producing the precise lenses and mirrors used in these systems, enabling the fabrication of smaller and more complex semiconductor devices.

In the field of astronomy and space exploration, borosilicate glass with optimized optical properties is critical for the construction of large telescope mirrors and other optical instruments. The ability to produce large, lightweight mirrors with excellent thermal stability and low coefficient of thermal expansion is crucial for advancing our understanding of the universe. Additionally, borosilicate glass is used in the development of optical windows and viewports for spacecraft and satellites, where its durability and optical clarity are essential.

The medical and life sciences sectors are also driving advancements in borosilicate optical properties. High-quality microscope objectives, endoscopes, and other imaging devices rely on borosilicate glass components with superior optical characteristics. As medical imaging technologies continue to evolve, there is a growing demand for glass materials that can provide improved resolution, contrast, and light transmission across a wide range of wavelengths.

In the telecommunications industry, the ongoing expansion of fiber-optic networks is fueling the need for borosilicate glass with enhanced optical properties. Optical fibers made from borosilicate glass are essential for long-distance data transmission, and improvements in their optical properties can lead to increased bandwidth and reduced signal loss. This is particularly important as the demand for high-speed internet and 5G networks continues to grow globally.

The automotive industry is another sector driving advancements in borosilicate optical properties. With the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles, there is a growing need for high-performance optical sensors and cameras. Borosilicate glass with optimized optical properties is used in the production of these components, enabling improved visibility and accuracy in various driving conditions.

One of the primary applications driving advancements in borosilicate optical properties is the semiconductor industry. As chip manufacturers continue to push the boundaries of miniaturization and performance, there is an increasing need for high-quality optical materials in photolithography systems. Borosilicate glass with enhanced optical properties is essential for producing the precise lenses and mirrors used in these systems, enabling the fabrication of smaller and more complex semiconductor devices.

In the field of astronomy and space exploration, borosilicate glass with optimized optical properties is critical for the construction of large telescope mirrors and other optical instruments. The ability to produce large, lightweight mirrors with excellent thermal stability and low coefficient of thermal expansion is crucial for advancing our understanding of the universe. Additionally, borosilicate glass is used in the development of optical windows and viewports for spacecraft and satellites, where its durability and optical clarity are essential.

The medical and life sciences sectors are also driving advancements in borosilicate optical properties. High-quality microscope objectives, endoscopes, and other imaging devices rely on borosilicate glass components with superior optical characteristics. As medical imaging technologies continue to evolve, there is a growing demand for glass materials that can provide improved resolution, contrast, and light transmission across a wide range of wavelengths.

In the telecommunications industry, the ongoing expansion of fiber-optic networks is fueling the need for borosilicate glass with enhanced optical properties. Optical fibers made from borosilicate glass are essential for long-distance data transmission, and improvements in their optical properties can lead to increased bandwidth and reduced signal loss. This is particularly important as the demand for high-speed internet and 5G networks continues to grow globally.

The automotive industry is another sector driving advancements in borosilicate optical properties. With the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles, there is a growing need for high-performance optical sensors and cameras. Borosilicate glass with optimized optical properties is used in the production of these components, enabling improved visibility and accuracy in various driving conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!