Structural Relaxation Phenomena in Borosilicate Glass

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Evolution and Research Objectives

Borosilicate glass has been a subject of extensive research and development since its invention in the late 19th century. The evolution of this material has been driven by its unique properties, particularly its low thermal expansion coefficient and high chemical durability. These characteristics have made borosilicate glass an essential material in various industries, including laboratory glassware, cookware, and high-tech applications.

The structural relaxation phenomena in borosilicate glass have become a focal point of research due to their significant impact on the material's properties and performance. This phenomenon refers to the gradual changes in the glass structure over time, which can affect its mechanical, thermal, and optical properties. Understanding and controlling these relaxation processes are crucial for optimizing the glass's performance in different applications.

The primary research objectives in this field revolve around elucidating the mechanisms underlying structural relaxation in borosilicate glass. Scientists aim to develop predictive models that can accurately describe the relaxation behavior under various conditions. This includes investigating the influence of composition, thermal history, and environmental factors on the relaxation processes.

Another key research goal is to explore methods for manipulating and controlling structural relaxation to enhance specific properties of borosilicate glass. This may involve developing novel heat treatment protocols, investigating the effects of dopants or additives, or exploring surface modification techniques to tailor the relaxation behavior.

Researchers are also focusing on the long-term stability of borosilicate glass, particularly in demanding applications such as nuclear waste storage. Understanding how structural relaxation affects the glass's ability to retain its properties over extended periods is crucial for ensuring the safety and reliability of such critical applications.

Advanced characterization techniques play a vital role in these research objectives. The development and application of high-resolution spectroscopic methods, in-situ measurements, and advanced imaging techniques are essential for probing the structural changes at atomic and molecular levels during relaxation processes.

Computational modeling and simulation have emerged as powerful tools in this field. Researchers aim to develop and refine atomistic models that can accurately predict structural relaxation phenomena, enabling the design of new glass compositions with tailored properties and improved stability.

The structural relaxation phenomena in borosilicate glass have become a focal point of research due to their significant impact on the material's properties and performance. This phenomenon refers to the gradual changes in the glass structure over time, which can affect its mechanical, thermal, and optical properties. Understanding and controlling these relaxation processes are crucial for optimizing the glass's performance in different applications.

The primary research objectives in this field revolve around elucidating the mechanisms underlying structural relaxation in borosilicate glass. Scientists aim to develop predictive models that can accurately describe the relaxation behavior under various conditions. This includes investigating the influence of composition, thermal history, and environmental factors on the relaxation processes.

Another key research goal is to explore methods for manipulating and controlling structural relaxation to enhance specific properties of borosilicate glass. This may involve developing novel heat treatment protocols, investigating the effects of dopants or additives, or exploring surface modification techniques to tailor the relaxation behavior.

Researchers are also focusing on the long-term stability of borosilicate glass, particularly in demanding applications such as nuclear waste storage. Understanding how structural relaxation affects the glass's ability to retain its properties over extended periods is crucial for ensuring the safety and reliability of such critical applications.

Advanced characterization techniques play a vital role in these research objectives. The development and application of high-resolution spectroscopic methods, in-situ measurements, and advanced imaging techniques are essential for probing the structural changes at atomic and molecular levels during relaxation processes.

Computational modeling and simulation have emerged as powerful tools in this field. Researchers aim to develop and refine atomistic models that can accurately predict structural relaxation phenomena, enabling the design of new glass compositions with tailored properties and improved stability.

Market Analysis for Borosilicate Glass Applications

The market for borosilicate glass applications has been experiencing steady growth, driven by the material's unique properties and versatility across various industries. Borosilicate glass, known for its excellent thermal shock resistance, chemical durability, and optical clarity, has found widespread use in laboratory equipment, pharmaceutical packaging, cookware, and high-performance optical systems.

In the laboratory and scientific research sector, borosilicate glass remains the material of choice for beakers, test tubes, and other precision glassware. The global laboratory glassware market, largely dominated by borosilicate products, is projected to expand significantly in the coming years, fueled by increased research and development activities in pharmaceuticals, biotechnology, and academic institutions.

The pharmaceutical industry represents another major market for borosilicate glass, particularly in packaging applications. With the growing demand for injectable drugs and biologics, borosilicate glass vials and syringes are in high demand due to their chemical inertness and ability to maintain drug stability. The pharmaceutical glass packaging market, predominantly composed of borosilicate glass products, is expected to show robust growth, driven by the expansion of the healthcare sector in emerging economies and the increasing prevalence of chronic diseases worldwide.

In the consumer goods sector, borosilicate glass has gained popularity in kitchenware and home appliances. Its thermal shock resistance makes it ideal for bakeware, stovetop cookware, and microwave-safe containers. The global kitchenware market has seen a shift towards premium, durable products, benefiting borosilicate glass manufacturers.

The optical and lighting industries also rely heavily on borosilicate glass for its exceptional optical properties and thermal stability. High-end telescopes, camera lenses, and specialized lighting fixtures often incorporate borosilicate glass components. With the growing demand for advanced optical systems in astronomy, surveillance, and industrial applications, this segment of the market is poised for continued expansion.

Emerging applications in solar energy, particularly in concentrated solar power (CSP) systems, represent a promising growth area for borosilicate glass. Its ability to withstand high temperatures and maintain optical clarity makes it an excellent material for solar receivers and reflectors in CSP plants.

While the overall market outlook for borosilicate glass applications is positive, challenges such as competition from alternative materials like plastics and ceramics in certain applications, and the energy-intensive production process, need to be considered. However, ongoing research into improving the structural properties and manufacturing efficiency of borosilicate glass is likely to address some of these challenges and open up new market opportunities.

In the laboratory and scientific research sector, borosilicate glass remains the material of choice for beakers, test tubes, and other precision glassware. The global laboratory glassware market, largely dominated by borosilicate products, is projected to expand significantly in the coming years, fueled by increased research and development activities in pharmaceuticals, biotechnology, and academic institutions.

The pharmaceutical industry represents another major market for borosilicate glass, particularly in packaging applications. With the growing demand for injectable drugs and biologics, borosilicate glass vials and syringes are in high demand due to their chemical inertness and ability to maintain drug stability. The pharmaceutical glass packaging market, predominantly composed of borosilicate glass products, is expected to show robust growth, driven by the expansion of the healthcare sector in emerging economies and the increasing prevalence of chronic diseases worldwide.

In the consumer goods sector, borosilicate glass has gained popularity in kitchenware and home appliances. Its thermal shock resistance makes it ideal for bakeware, stovetop cookware, and microwave-safe containers. The global kitchenware market has seen a shift towards premium, durable products, benefiting borosilicate glass manufacturers.

The optical and lighting industries also rely heavily on borosilicate glass for its exceptional optical properties and thermal stability. High-end telescopes, camera lenses, and specialized lighting fixtures often incorporate borosilicate glass components. With the growing demand for advanced optical systems in astronomy, surveillance, and industrial applications, this segment of the market is poised for continued expansion.

Emerging applications in solar energy, particularly in concentrated solar power (CSP) systems, represent a promising growth area for borosilicate glass. Its ability to withstand high temperatures and maintain optical clarity makes it an excellent material for solar receivers and reflectors in CSP plants.

While the overall market outlook for borosilicate glass applications is positive, challenges such as competition from alternative materials like plastics and ceramics in certain applications, and the energy-intensive production process, need to be considered. However, ongoing research into improving the structural properties and manufacturing efficiency of borosilicate glass is likely to address some of these challenges and open up new market opportunities.

Current Challenges in Structural Relaxation of Borosilicate Glass

Structural relaxation in borosilicate glass presents several significant challenges that hinder both scientific understanding and industrial applications. One of the primary difficulties lies in the complex nature of the relaxation process itself, which involves multiple timescales and mechanisms operating simultaneously. This complexity makes it challenging to develop accurate models and predictions for glass behavior under various conditions.

The non-equilibrium nature of glass further complicates the study of structural relaxation. Unlike crystalline materials, glasses lack long-range order, and their structure continues to evolve over time, even at temperatures well below the glass transition. This ongoing relaxation process affects various properties of the glass, including density, refractive index, and mechanical strength, making it difficult to maintain consistent performance in applications.

Another significant challenge is the sensitivity of structural relaxation to composition and thermal history. Borosilicate glasses can have a wide range of compositions, and even small variations can lead to substantial differences in relaxation behavior. Additionally, the thermal history of the glass during production and subsequent heat treatments can profoundly influence its relaxation characteristics. This sensitivity makes it challenging to standardize production processes and achieve reproducible properties across different batches or manufacturing facilities.

The measurement and characterization of structural relaxation also pose technical difficulties. Many of the changes occurring during relaxation are subtle and occur over extended periods, requiring highly sensitive and stable measurement techniques. Furthermore, the need for long-term experiments to capture slow relaxation processes can be impractical in many research and industrial settings.

From an industrial perspective, controlling and predicting structural relaxation is crucial for maintaining the dimensional stability and optical properties of borosilicate glass products. However, the complex interplay between composition, processing conditions, and relaxation behavior makes it challenging to optimize manufacturing processes for specific applications. This is particularly problematic in high-precision applications such as telescope mirrors, where even minute changes in glass properties can have significant impacts on performance.

The development of accurate theoretical models and simulation techniques for structural relaxation in borosilicate glasses remains an ongoing challenge. While significant progress has been made in recent years, current models still struggle to capture the full complexity of the relaxation process, especially over long time scales and under varying environmental conditions. This limitation hampers efforts to predict and control glass behavior in real-world applications.

The non-equilibrium nature of glass further complicates the study of structural relaxation. Unlike crystalline materials, glasses lack long-range order, and their structure continues to evolve over time, even at temperatures well below the glass transition. This ongoing relaxation process affects various properties of the glass, including density, refractive index, and mechanical strength, making it difficult to maintain consistent performance in applications.

Another significant challenge is the sensitivity of structural relaxation to composition and thermal history. Borosilicate glasses can have a wide range of compositions, and even small variations can lead to substantial differences in relaxation behavior. Additionally, the thermal history of the glass during production and subsequent heat treatments can profoundly influence its relaxation characteristics. This sensitivity makes it challenging to standardize production processes and achieve reproducible properties across different batches or manufacturing facilities.

The measurement and characterization of structural relaxation also pose technical difficulties. Many of the changes occurring during relaxation are subtle and occur over extended periods, requiring highly sensitive and stable measurement techniques. Furthermore, the need for long-term experiments to capture slow relaxation processes can be impractical in many research and industrial settings.

From an industrial perspective, controlling and predicting structural relaxation is crucial for maintaining the dimensional stability and optical properties of borosilicate glass products. However, the complex interplay between composition, processing conditions, and relaxation behavior makes it challenging to optimize manufacturing processes for specific applications. This is particularly problematic in high-precision applications such as telescope mirrors, where even minute changes in glass properties can have significant impacts on performance.

The development of accurate theoretical models and simulation techniques for structural relaxation in borosilicate glasses remains an ongoing challenge. While significant progress has been made in recent years, current models still struggle to capture the full complexity of the relaxation process, especially over long time scales and under varying environmental conditions. This limitation hampers efforts to predict and control glass behavior in real-world applications.

Existing Methods for Studying Structural Relaxation

01 Thermal treatment for structural relaxation

Borosilicate glass undergoes structural relaxation through thermal treatment processes. This involves carefully controlled heating and cooling cycles to reduce internal stresses and improve the glass's mechanical properties. The process can enhance the glass's thermal shock resistance and overall durability.- Thermal treatment for structural relaxation: Borosilicate glass undergoes structural relaxation through thermal treatment processes. This involves carefully controlled heating and cooling cycles to reduce internal stresses and improve the glass's mechanical properties. The process can enhance the glass's thermal shock resistance and overall durability.

- Composition optimization for improved relaxation: The chemical composition of borosilicate glass can be optimized to facilitate better structural relaxation. Adjusting the ratios of boron oxide, silica, and other components can influence the glass's relaxation behavior, allowing for tailored properties such as improved thermal stability and reduced residual stress.

- Annealing techniques for stress reduction: Specific annealing techniques are employed to promote structural relaxation in borosilicate glass. These methods involve holding the glass at temperatures near its annealing point for extended periods, allowing for the gradual release of internal stresses and the achievement of a more stable molecular structure.

- Surface treatment to enhance relaxation: Surface treatments can be applied to borosilicate glass to enhance its structural relaxation properties. These treatments may include chemical etching, ion exchange processes, or the application of specialized coatings that can influence the glass's surface tension and facilitate more uniform relaxation throughout the material.

- Characterization methods for relaxation analysis: Advanced characterization techniques are used to analyze and quantify the structural relaxation of borosilicate glass. These may include differential scanning calorimetry, dilatometry, and spectroscopic methods that provide insights into the glass's molecular structure and relaxation behavior, enabling more precise control over the relaxation process.

02 Composition optimization for improved relaxation

The chemical composition of borosilicate glass can be optimized to facilitate better structural relaxation. Adjusting the ratios of boron oxide, silica, and other components can influence the glass's relaxation behavior, allowing for tailored properties such as improved thermal stability and reduced residual stress.Expand Specific Solutions03 Annealing techniques for stress reduction

Specific annealing techniques are employed to reduce internal stresses in borosilicate glass. These methods involve holding the glass at temperatures near its strain point for extended periods, allowing for the relaxation of molecular structures and the elimination of stress concentrations.Expand Specific Solutions04 Surface treatment effects on relaxation

Surface treatments can influence the structural relaxation of borosilicate glass. Techniques such as ion exchange, chemical etching, or surface coatings can modify the glass surface, affecting its relaxation behavior and potentially enhancing its mechanical and chemical properties.Expand Specific Solutions05 Characterization methods for relaxation analysis

Various characterization methods are used to analyze the structural relaxation of borosilicate glass. These include differential scanning calorimetry, dilatometry, and spectroscopic techniques. These methods help in understanding the relaxation kinetics and the effectiveness of different relaxation processes.Expand Specific Solutions

Key Players in Borosilicate Glass Manufacturing

The structural relaxation phenomena in borosilicate glass is a mature field with significant market potential, driven by applications in pharmaceuticals, electronics, and specialty materials. The industry is in a growth phase, with a global market size estimated in the billions. Leading players like SCHOTT AG, Corning, Inc., and AGC, Inc. have established strong technological capabilities and market presence. These companies are investing heavily in R&D to improve glass properties and manufacturing processes. Emerging players from China, such as Hunan Kibing and Zhangzhou Kibing, are also making strides in this sector, particularly in pharmaceutical glass production. The competitive landscape is characterized by a mix of established multinational corporations and newer entrants, with innovation and quality being key differentiators.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions with optimized structural relaxation properties. Their research focuses on tailoring the glass network structure to control relaxation phenomena. They utilize high-precision annealing processes to minimize residual stresses and improve dimensional stability[1]. SCHOTT's borosilicate glasses exhibit reduced structural relaxation rates, allowing for enhanced thermal and mechanical performance in demanding applications. The company employs sophisticated characterization techniques, including dynamic mechanical analysis and dilatometry, to quantify relaxation behavior across different temperature ranges[3].

Strengths: Extensive expertise in glass science, advanced manufacturing capabilities, and a wide range of specialized borosilicate glass products. Weaknesses: High production costs and potential limitations in scaling up novel glass compositions for mass production.

Corning, Inc.

Technical Solution: Corning has pioneered innovative approaches to control structural relaxation in borosilicate glasses. Their research involves modifying glass compositions with specific additives to manipulate the relaxation kinetics. Corning utilizes advanced computational modeling to predict and optimize relaxation behavior in complex glass systems[2]. They have developed proprietary heat treatment protocols to induce controlled structural changes, resulting in borosilicate glasses with enhanced stability and reduced relaxation-induced property drift over time. Corning's technology also incorporates nano-scale phase separation to create unique microstructures that influence relaxation phenomena[4].

Strengths: Strong R&D capabilities, extensive patent portfolio, and a history of successful commercialization of advanced glass technologies. Weaknesses: Potential challenges in adapting relaxation control techniques to diverse glass compositions and applications.

Innovative Approaches to Structural Relaxation Analysis

Borosilicate glass

PatentInactiveEP0767763A2

Innovation

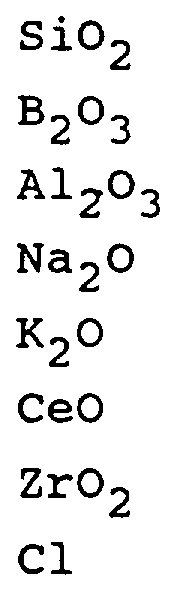

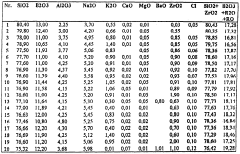

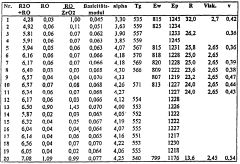

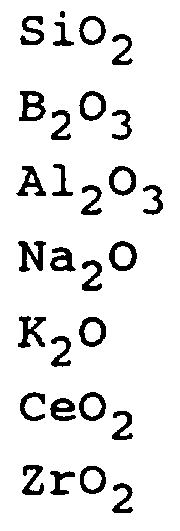

- A borosilicate glass composition with specific thermal, electrical, and chemical properties, including SiO2, ZrO2, Na2O, K2O, CaO, MgO, BaO, and Al2O3, optimized for stable electrical conductivity and viscosity, allowing full-electrical melting in cold-top furnaces with reduced gas release and no toxic heavy metal oxides, ensuring stable melting and high chemical resistance.

Borosilicate glass

PatentWO1996033954A2

Innovation

- A borosilicate glass composition with specific thermal expansion, viscosity, and electrical conductivity properties, optimized to include ZrO2, Na2O, K2O, CaO, MgO, and BaO, allowing for stable cold-top melting without toxic heavy metal oxides or fluorides, and controlling gas content to prevent reboiling.

Environmental Impact of Borosilicate Glass Production

The production of borosilicate glass, while offering numerous benefits in terms of durability and chemical resistance, carries significant environmental implications. The manufacturing process involves high-temperature melting of raw materials, including silica, boron oxide, and various metal oxides, which requires substantial energy input. This energy-intensive production contributes to greenhouse gas emissions, particularly when fossil fuels are used as the primary energy source.

The extraction of raw materials for borosilicate glass production also has environmental consequences. Mining operations for silica and boron compounds can lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the processing of these raw materials often involves chemical treatments that may generate hazardous waste streams requiring careful disposal or treatment.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling, cleaning, and various other stages, potentially straining local water resources in areas where water scarcity is an issue. Proper water management and recycling systems are crucial to mitigate this impact.

Air emissions from borosilicate glass production facilities can include particulate matter, nitrogen oxides, sulfur dioxide, and volatile organic compounds. These emissions, if not adequately controlled, can contribute to local air quality issues and potentially affect human health in surrounding communities. Advanced filtration and scrubbing technologies are essential to minimize these airborne pollutants.

The durability of borosilicate glass, while advantageous for many applications, presents challenges in terms of end-of-life management. Unlike some other glass types, borosilicate glass is not easily recyclable through conventional glass recycling streams due to its different melting point and chemical composition. This can lead to increased waste if proper recycling or repurposing methods are not implemented.

On the positive side, the long lifespan and chemical stability of borosilicate glass products can offset some of the environmental impacts associated with their production. By reducing the need for frequent replacements, borosilicate glass can contribute to overall resource conservation and waste reduction in certain applications, such as laboratory equipment or high-quality cookware.

Efforts to improve the environmental footprint of borosilicate glass production are ongoing. These include the development of more energy-efficient melting technologies, increased use of recycled materials in the production process, and the implementation of closed-loop systems for water and waste management. Additionally, research into alternative raw materials and production methods that could reduce the environmental impact while maintaining the desirable properties of borosilicate glass is an active area of investigation in the industry.

The extraction of raw materials for borosilicate glass production also has environmental consequences. Mining operations for silica and boron compounds can lead to habitat disruption, soil erosion, and water pollution if not managed properly. Additionally, the processing of these raw materials often involves chemical treatments that may generate hazardous waste streams requiring careful disposal or treatment.

Water usage in borosilicate glass production is another environmental concern. The manufacturing process requires water for cooling, cleaning, and various other stages, potentially straining local water resources in areas where water scarcity is an issue. Proper water management and recycling systems are crucial to mitigate this impact.

Air emissions from borosilicate glass production facilities can include particulate matter, nitrogen oxides, sulfur dioxide, and volatile organic compounds. These emissions, if not adequately controlled, can contribute to local air quality issues and potentially affect human health in surrounding communities. Advanced filtration and scrubbing technologies are essential to minimize these airborne pollutants.

The durability of borosilicate glass, while advantageous for many applications, presents challenges in terms of end-of-life management. Unlike some other glass types, borosilicate glass is not easily recyclable through conventional glass recycling streams due to its different melting point and chemical composition. This can lead to increased waste if proper recycling or repurposing methods are not implemented.

On the positive side, the long lifespan and chemical stability of borosilicate glass products can offset some of the environmental impacts associated with their production. By reducing the need for frequent replacements, borosilicate glass can contribute to overall resource conservation and waste reduction in certain applications, such as laboratory equipment or high-quality cookware.

Efforts to improve the environmental footprint of borosilicate glass production are ongoing. These include the development of more energy-efficient melting technologies, increased use of recycled materials in the production process, and the implementation of closed-loop systems for water and waste management. Additionally, research into alternative raw materials and production methods that could reduce the environmental impact while maintaining the desirable properties of borosilicate glass is an active area of investigation in the industry.

Standardization and Quality Control in Glass Manufacturing

Standardization and quality control play crucial roles in the glass manufacturing industry, particularly in the production of borosilicate glass. These processes ensure consistency, reliability, and safety in the final products, which are essential for various applications ranging from laboratory equipment to consumer goods.

In the context of structural relaxation phenomena in borosilicate glass, standardization efforts focus on establishing uniform methods for measuring and characterizing relaxation processes. This includes developing standardized testing procedures for thermal expansion, stress relaxation, and viscosity measurements. These standards enable manufacturers to compare results across different production batches and facilities, ensuring consistent quality and performance.

Quality control measures in borosilicate glass manufacturing involve rigorous monitoring of raw material composition, melting conditions, and forming processes. Advanced spectroscopic techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), are employed to verify the precise chemical composition of the glass. This is particularly important for controlling the boron and silica content, which directly influence the glass's thermal and mechanical properties.

Temperature control during the melting and annealing processes is another critical aspect of quality control. Precise temperature management is essential for achieving the desired structural relaxation characteristics in borosilicate glass. Manufacturers utilize sophisticated temperature monitoring systems and computer-controlled furnaces to maintain optimal thermal conditions throughout the production cycle.

Non-destructive testing methods, such as ultrasonic inspection and polarized light analysis, are implemented to detect internal stresses, inclusions, and other defects that may affect the glass's structural integrity. These techniques allow for real-time quality assessment and help identify potential issues before the final product reaches the market.

Statistical process control (SPC) techniques are widely adopted in the industry to monitor and control variability in the manufacturing process. By analyzing key performance indicators and process parameters, manufacturers can identify trends, detect anomalies, and implement corrective actions promptly. This data-driven approach helps maintain consistent quality and reduces the likelihood of defects related to structural relaxation phenomena.

Certification programs and industry standards, such as those developed by organizations like ASTM International and ISO, provide a framework for quality assurance in borosilicate glass manufacturing. These standards cover various aspects, including chemical composition, physical properties, and testing methodologies. Adherence to these standards ensures that borosilicate glass products meet specific performance criteria and safety requirements across different applications and industries.

In the context of structural relaxation phenomena in borosilicate glass, standardization efforts focus on establishing uniform methods for measuring and characterizing relaxation processes. This includes developing standardized testing procedures for thermal expansion, stress relaxation, and viscosity measurements. These standards enable manufacturers to compare results across different production batches and facilities, ensuring consistent quality and performance.

Quality control measures in borosilicate glass manufacturing involve rigorous monitoring of raw material composition, melting conditions, and forming processes. Advanced spectroscopic techniques, such as X-ray fluorescence (XRF) and inductively coupled plasma mass spectrometry (ICP-MS), are employed to verify the precise chemical composition of the glass. This is particularly important for controlling the boron and silica content, which directly influence the glass's thermal and mechanical properties.

Temperature control during the melting and annealing processes is another critical aspect of quality control. Precise temperature management is essential for achieving the desired structural relaxation characteristics in borosilicate glass. Manufacturers utilize sophisticated temperature monitoring systems and computer-controlled furnaces to maintain optimal thermal conditions throughout the production cycle.

Non-destructive testing methods, such as ultrasonic inspection and polarized light analysis, are implemented to detect internal stresses, inclusions, and other defects that may affect the glass's structural integrity. These techniques allow for real-time quality assessment and help identify potential issues before the final product reaches the market.

Statistical process control (SPC) techniques are widely adopted in the industry to monitor and control variability in the manufacturing process. By analyzing key performance indicators and process parameters, manufacturers can identify trends, detect anomalies, and implement corrective actions promptly. This data-driven approach helps maintain consistent quality and reduces the likelihood of defects related to structural relaxation phenomena.

Certification programs and industry standards, such as those developed by organizations like ASTM International and ISO, provide a framework for quality assurance in borosilicate glass manufacturing. These standards cover various aspects, including chemical composition, physical properties, and testing methodologies. Adherence to these standards ensures that borosilicate glass products meet specific performance criteria and safety requirements across different applications and industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!