Alternatives to conventional photoanode materials in PEC.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEC Photoanode Evolution and Research Objectives

Photoelectrochemical cells (PEC) have emerged as a promising technology for solar energy conversion, particularly for hydrogen production through water splitting. The evolution of photoanode materials represents a critical aspect of PEC development, with conventional materials facing significant limitations in efficiency, stability, and cost-effectiveness. This research aims to explore alternative photoanode materials that can overcome these constraints and advance PEC technology toward commercial viability.

The historical trajectory of photoanode development began with titanium dioxide (TiO2) in the 1970s, following Fujishima and Honda's groundbreaking work. While TiO2 offered excellent stability, its wide bandgap limited solar spectrum absorption to primarily UV light. Subsequent decades saw the exploration of various metal oxides including hematite (α-Fe2O3), tungsten trioxide (WO3), and bismuth vanadate (BiVO4), each offering specific advantages but also presenting unique challenges.

Current research trends indicate a shift toward complex material systems, including nanostructured composites, heterojunctions, and doped materials that can address multiple performance parameters simultaneously. The integration of plasmonic nanoparticles, quantum dots, and 2D materials represents another significant trend, leveraging quantum confinement effects and enhanced light-matter interactions to improve photoanode performance.

The primary objective of this technical research is to systematically evaluate alternative photoanode materials beyond conventional options, with specific focus on their fundamental properties, synthesis methods, and performance metrics. We aim to identify materials that demonstrate superior solar-to-hydrogen conversion efficiency while maintaining long-term stability under operational conditions. Additionally, we seek to understand structure-property relationships that govern photoelectrochemical performance.

Secondary objectives include assessing scalability and cost-effectiveness of promising alternative materials, as these factors will ultimately determine commercial viability. Environmental impact and sustainability considerations will also be evaluated, including material abundance, toxicity, and end-of-life recyclability. The research will further explore integration challenges with other PEC components to ensure system-level compatibility.

The expected outcomes of this research include a comprehensive mapping of alternative photoanode materials according to their performance parameters, identification of the most promising candidates for further development, and establishment of design principles for next-generation photoanodes. By addressing fundamental limitations of conventional materials, this research aims to accelerate the advancement of PEC technology toward practical applications in renewable energy systems.

The historical trajectory of photoanode development began with titanium dioxide (TiO2) in the 1970s, following Fujishima and Honda's groundbreaking work. While TiO2 offered excellent stability, its wide bandgap limited solar spectrum absorption to primarily UV light. Subsequent decades saw the exploration of various metal oxides including hematite (α-Fe2O3), tungsten trioxide (WO3), and bismuth vanadate (BiVO4), each offering specific advantages but also presenting unique challenges.

Current research trends indicate a shift toward complex material systems, including nanostructured composites, heterojunctions, and doped materials that can address multiple performance parameters simultaneously. The integration of plasmonic nanoparticles, quantum dots, and 2D materials represents another significant trend, leveraging quantum confinement effects and enhanced light-matter interactions to improve photoanode performance.

The primary objective of this technical research is to systematically evaluate alternative photoanode materials beyond conventional options, with specific focus on their fundamental properties, synthesis methods, and performance metrics. We aim to identify materials that demonstrate superior solar-to-hydrogen conversion efficiency while maintaining long-term stability under operational conditions. Additionally, we seek to understand structure-property relationships that govern photoelectrochemical performance.

Secondary objectives include assessing scalability and cost-effectiveness of promising alternative materials, as these factors will ultimately determine commercial viability. Environmental impact and sustainability considerations will also be evaluated, including material abundance, toxicity, and end-of-life recyclability. The research will further explore integration challenges with other PEC components to ensure system-level compatibility.

The expected outcomes of this research include a comprehensive mapping of alternative photoanode materials according to their performance parameters, identification of the most promising candidates for further development, and establishment of design principles for next-generation photoanodes. By addressing fundamental limitations of conventional materials, this research aims to accelerate the advancement of PEC technology toward practical applications in renewable energy systems.

Market Analysis for Advanced PEC Technologies

The global market for photoelectrochemical cells (PEC) is experiencing significant growth, driven by increasing demand for clean energy solutions and sustainable hydrogen production methods. The market for advanced PEC technologies is projected to reach $2.5 billion by 2028, with a compound annual growth rate of 15.7% from 2023 to 2028. This growth is primarily fueled by governmental initiatives promoting green hydrogen production and increasing investments in renewable energy infrastructure worldwide.

The demand for alternative photoanode materials is particularly strong in regions with ambitious decarbonization targets, including the European Union, Japan, South Korea, and increasingly China and the United States. These markets are characterized by substantial research funding and supportive regulatory frameworks that incentivize the adoption of hydrogen-based energy systems.

Industrial applications represent the largest market segment for advanced PEC technologies, accounting for approximately 45% of the total market share. This includes chemical manufacturing, refineries, and metallurgical processes where hydrogen is a critical input. The transportation sector follows closely, representing about 30% of the market, driven by the growing interest in hydrogen fuel cells for vehicles.

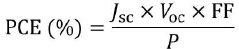

Market analysis indicates that end-users are increasingly prioritizing efficiency and durability over initial cost considerations. This trend favors the development of novel photoanode materials that can demonstrate superior stability and conversion efficiency compared to conventional titanium dioxide or hematite-based systems. Materials showing solar-to-hydrogen conversion efficiencies above 10% are positioned to capture premium market segments.

Regional market distribution shows Asia-Pacific leading with 38% market share, followed by North America (27%) and Europe (25%). However, Europe demonstrates the fastest growth rate at 17.3% annually, reflecting aggressive clean energy policies and substantial research investments in advanced materials for PEC applications.

The market for alternative photoanode materials is further segmented by material type, with metal oxides currently dominating (52%), followed by perovskites (18%), quantum dots (15%), and emerging nanomaterials (15%). Notably, perovskites and quantum dot-based photoanodes are showing the highest growth rates, indicating shifting market preferences toward these newer technologies.

Customer willingness to pay premium prices for high-performance PEC systems creates significant market opportunities for innovative photoanode materials that can demonstrate tangible improvements in efficiency, durability, or reduced dependence on rare elements. Market surveys indicate that industrial customers are willing to pay up to 40% more for systems that can demonstrate a 25% improvement in operational lifetime or efficiency.

The demand for alternative photoanode materials is particularly strong in regions with ambitious decarbonization targets, including the European Union, Japan, South Korea, and increasingly China and the United States. These markets are characterized by substantial research funding and supportive regulatory frameworks that incentivize the adoption of hydrogen-based energy systems.

Industrial applications represent the largest market segment for advanced PEC technologies, accounting for approximately 45% of the total market share. This includes chemical manufacturing, refineries, and metallurgical processes where hydrogen is a critical input. The transportation sector follows closely, representing about 30% of the market, driven by the growing interest in hydrogen fuel cells for vehicles.

Market analysis indicates that end-users are increasingly prioritizing efficiency and durability over initial cost considerations. This trend favors the development of novel photoanode materials that can demonstrate superior stability and conversion efficiency compared to conventional titanium dioxide or hematite-based systems. Materials showing solar-to-hydrogen conversion efficiencies above 10% are positioned to capture premium market segments.

Regional market distribution shows Asia-Pacific leading with 38% market share, followed by North America (27%) and Europe (25%). However, Europe demonstrates the fastest growth rate at 17.3% annually, reflecting aggressive clean energy policies and substantial research investments in advanced materials for PEC applications.

The market for alternative photoanode materials is further segmented by material type, with metal oxides currently dominating (52%), followed by perovskites (18%), quantum dots (15%), and emerging nanomaterials (15%). Notably, perovskites and quantum dot-based photoanodes are showing the highest growth rates, indicating shifting market preferences toward these newer technologies.

Customer willingness to pay premium prices for high-performance PEC systems creates significant market opportunities for innovative photoanode materials that can demonstrate tangible improvements in efficiency, durability, or reduced dependence on rare elements. Market surveys indicate that industrial customers are willing to pay up to 40% more for systems that can demonstrate a 25% improvement in operational lifetime or efficiency.

Current Limitations of Conventional Photoanode Materials

Despite significant advancements in photoelectrochemical cell technology, conventional photoanode materials continue to face substantial limitations that hinder their widespread commercial adoption. The most prevalent materials, including titanium dioxide (TiO₂), hematite (α-Fe₂O₃), and tungsten trioxide (WO₃), suffer from fundamental constraints that restrict their practical efficiency.

A primary limitation is the suboptimal band gap energy of many conventional photoanode materials. TiO₂, while stable and cost-effective, possesses a wide band gap (3.0-3.2 eV) that restricts light absorption to the ultraviolet region, which constitutes only about 4% of the solar spectrum. Conversely, materials with narrower band gaps often struggle with poor charge carrier mobility and rapid recombination rates.

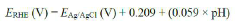

Charge carrier dynamics present another significant challenge. The short diffusion length of photogenerated holes in materials like hematite (2-4 nm) severely limits charge separation efficiency. This results in high recombination rates and consequently poor quantum efficiency, as most carriers recombine before reaching the semiconductor-electrolyte interface where water oxidation occurs.

Stability under operating conditions remains a critical concern for many promising photoanode materials. Silicon-based photoanodes, despite favorable electronic properties, suffer from photocorrosion in aqueous environments. Similarly, many metal sulfides and phosphides with appropriate band gaps demonstrate poor long-term stability in water oxidation conditions, limiting their practical application despite promising initial performance metrics.

Surface catalysis inefficiency further compounds these limitations. The oxygen evolution reaction (OER) at photoanode surfaces involves complex four-electron transfer processes with high kinetic barriers. Most semiconductor materials lack intrinsic catalytic activity for this reaction, necessitating the addition of co-catalysts that often introduce new interfaces and potential recombination sites.

Scalability and manufacturing constraints also impede commercial viability. High-performance materials like III-V semiconductors deliver superior efficiencies but at prohibitive costs that render large-scale deployment economically unfeasible. Meanwhile, earth-abundant alternatives frequently require complex nanostructuring or doping strategies to achieve competitive performance, complicating mass production.

The trade-off between transparency and conductivity in photoanode materials presents another significant challenge. Optimal light absorption requires sufficient material thickness, yet charge transport limitations demand thin films, creating an inherent design conflict that restricts overall device efficiency.

These multifaceted limitations collectively establish the imperative for exploring alternative photoanode materials that can simultaneously address issues of light absorption, charge transport, stability, and catalytic activity while maintaining economic viability for large-scale implementation.

A primary limitation is the suboptimal band gap energy of many conventional photoanode materials. TiO₂, while stable and cost-effective, possesses a wide band gap (3.0-3.2 eV) that restricts light absorption to the ultraviolet region, which constitutes only about 4% of the solar spectrum. Conversely, materials with narrower band gaps often struggle with poor charge carrier mobility and rapid recombination rates.

Charge carrier dynamics present another significant challenge. The short diffusion length of photogenerated holes in materials like hematite (2-4 nm) severely limits charge separation efficiency. This results in high recombination rates and consequently poor quantum efficiency, as most carriers recombine before reaching the semiconductor-electrolyte interface where water oxidation occurs.

Stability under operating conditions remains a critical concern for many promising photoanode materials. Silicon-based photoanodes, despite favorable electronic properties, suffer from photocorrosion in aqueous environments. Similarly, many metal sulfides and phosphides with appropriate band gaps demonstrate poor long-term stability in water oxidation conditions, limiting their practical application despite promising initial performance metrics.

Surface catalysis inefficiency further compounds these limitations. The oxygen evolution reaction (OER) at photoanode surfaces involves complex four-electron transfer processes with high kinetic barriers. Most semiconductor materials lack intrinsic catalytic activity for this reaction, necessitating the addition of co-catalysts that often introduce new interfaces and potential recombination sites.

Scalability and manufacturing constraints also impede commercial viability. High-performance materials like III-V semiconductors deliver superior efficiencies but at prohibitive costs that render large-scale deployment economically unfeasible. Meanwhile, earth-abundant alternatives frequently require complex nanostructuring or doping strategies to achieve competitive performance, complicating mass production.

The trade-off between transparency and conductivity in photoanode materials presents another significant challenge. Optimal light absorption requires sufficient material thickness, yet charge transport limitations demand thin films, creating an inherent design conflict that restricts overall device efficiency.

These multifaceted limitations collectively establish the imperative for exploring alternative photoanode materials that can simultaneously address issues of light absorption, charge transport, stability, and catalytic activity while maintaining economic viability for large-scale implementation.

Alternative Photoanode Material Solutions

01 Metal oxide-based photoanode materials

Metal oxides such as titanium dioxide (TiO2), zinc oxide (ZnO), and hematite (Fe2O3) are widely used as photoanode materials in photoelectrochemical cells due to their stability, abundance, and suitable band gap energies. These materials can be modified through doping, nanostructuring, or surface treatment to enhance their light absorption properties and charge separation efficiency, leading to improved photoelectrochemical performance.- Metal oxide-based photoanode materials: Metal oxides are widely used as photoanode materials in photoelectrochemical cells due to their stability, abundance, and tunable electronic properties. These materials, including titanium dioxide, zinc oxide, and iron oxide, can be modified through doping or surface treatments to enhance their light absorption and charge separation capabilities. The photoelectrochemical performance of metal oxide photoanodes depends on their crystallinity, morphology, and band gap, which affect their ability to harvest solar energy and generate photocurrent.

- Nanostructured photoanode architectures: Nanostructured photoanode architectures, such as nanowires, nanotubes, and hierarchical structures, offer advantages for photoelectrochemical applications by providing high surface area, efficient charge transport pathways, and enhanced light absorption. These structures can be engineered to optimize the interface between the photoanode and electrolyte, reducing charge recombination and improving overall photoelectrochemical performance. The dimensional control and morphological design of nanostructured photoanodes are crucial for maximizing their efficiency in solar energy conversion systems.

- Composite and heterojunction photoanode materials: Composite and heterojunction photoanode materials combine different semiconductors or incorporate carbon-based materials to create synergistic effects that enhance photoelectrochemical performance. These hybrid structures facilitate efficient charge separation, extend light absorption range, and improve charge transport properties. By engineering the interfaces between different materials, the band alignment can be optimized to reduce recombination losses and increase photocurrent generation. These composite systems often demonstrate superior stability and efficiency compared to single-component photoanodes.

- Surface modification and co-catalyst integration: Surface modification techniques and co-catalyst integration are effective strategies to enhance the photoelectrochemical performance of photoanode materials. By depositing co-catalysts such as noble metals or transition metal compounds on the photoanode surface, the charge transfer kinetics and reaction selectivity can be significantly improved. Surface treatments, including passivation layers and functional groups, can reduce surface recombination sites and enhance stability in electrolytes. These approaches address the limitations of bare photoanode materials and optimize their interaction with the electrolyte.

- Novel fabrication methods for high-performance photoanodes: Advanced fabrication methods play a crucial role in developing high-performance photoanode materials with controlled composition, structure, and properties. Techniques such as hydrothermal synthesis, electrodeposition, atomic layer deposition, and sol-gel processes enable precise control over material characteristics at multiple scales. These methods can be used to create photoanodes with optimized light absorption, charge separation, and catalytic properties. The development of scalable and cost-effective fabrication approaches is essential for the practical application of photoelectrochemical systems in renewable energy technologies.

02 Nanostructured photoanode architectures

Nanostructured photoanode architectures, including nanowires, nanotubes, and hierarchical structures, offer advantages such as increased surface area, shortened charge carrier transport distances, and enhanced light harvesting capabilities. These structures can significantly improve the photoelectrochemical performance by facilitating efficient charge separation and reducing recombination losses, ultimately leading to higher photocurrent densities and conversion efficiencies.Expand Specific Solutions03 Composite and heterojunction photoanode materials

Composite and heterojunction photoanode materials combine different semiconductors or incorporate carbon-based materials to create synergistic effects that enhance photoelectrochemical performance. These materials can achieve broader light absorption ranges, improved charge separation at interfaces, and reduced recombination rates. Examples include TiO2/CdS, ZnO/CuO heterojunctions, and graphene-semiconductor composites that demonstrate superior photocurrent generation compared to single-component photoanodes.Expand Specific Solutions04 Surface modification and co-catalyst integration

Surface modification techniques and co-catalyst integration are effective strategies to enhance the photoelectrochemical performance of photoanode materials. These approaches include depositing noble metal nanoparticles, transition metal compounds, or applying passivation layers to reduce surface recombination and enhance charge transfer kinetics. Co-catalysts such as platinum, ruthenium oxide, or cobalt phosphate can significantly lower the activation energy for water oxidation reactions, improving overall system efficiency.Expand Specific Solutions05 Novel materials and fabrication methods

Emerging novel materials and advanced fabrication methods are being developed to push the boundaries of photoelectrochemical performance. These include perovskite-based photoanodes, quantum dot-sensitized electrodes, and atomic layer deposition techniques for precise control of material composition and structure. These innovations aim to address the limitations of traditional photoanode materials by offering enhanced light absorption, improved charge carrier dynamics, and better stability under operating conditions.Expand Specific Solutions

Leading Institutions and Companies in PEC Research

The photoelectrochemical cell (PEC) market is currently in a growth phase, with increasing research focus on alternatives to conventional photoanode materials. The global market is projected to expand significantly as renewable energy demands rise, though commercial applications remain limited. Technical maturity varies across different alternative materials, with leading research institutions like The Regents of the University of California, Nanjing University, and KAIST making significant advancements. Companies including Sharp Corp., Signify Holding, and General Electric are investing in commercial applications, while research organizations such as Forschungszentrum Jülich and Korea Institute of Energy Research are developing next-generation materials with improved efficiency and stability. The field is characterized by collaborative efforts between academic institutions and industry players seeking to overcome current limitations in durability, cost, and conversion efficiency.

The Regents of the University of California

Technical Solution: The University of California has developed innovative photoanode materials based on metal oxide semiconductors with enhanced properties. Their approach focuses on nanostructured bismuth vanadate (BiVO4) photoanodes with controlled morphology and doping strategies to improve charge carrier separation and transport. They've implemented gradient doping techniques where the concentration of dopants like tungsten or molybdenum varies across the photoanode thickness, creating an internal electric field that facilitates electron transport[1]. Additionally, they've pioneered heterojunction structures combining BiVO4 with other semiconductors like WO3 or Fe2O3 to create cascade band alignments that enhance charge separation efficiency. Their photoanodes incorporate surface modification with oxygen evolution catalysts such as cobalt phosphate (CoPi) or nickel-iron layered double hydroxides to accelerate water oxidation kinetics[3].

Strengths: Superior charge separation efficiency through gradient doping and heterojunction architectures; excellent visible light absorption; improved stability through surface passivation techniques. Weaknesses: Complex fabrication processes requiring precise control of multiple parameters; potential scalability challenges for large-area applications; some materials contain relatively expensive elements.

Sharp Corp.

Technical Solution: Sharp Corporation has developed advanced photoanode materials focusing on silicon-based photoelectrodes with enhanced stability and efficiency. Their primary innovation involves crystalline silicon photoanodes protected by transparent conductive oxide layers and catalytic overlayers. They've pioneered a multi-layer protection strategy where ultrathin layers of titanium dioxide and nickel oxide are deposited on silicon surfaces using atomic layer deposition to prevent corrosion while maintaining electrical conductivity[9]. Their photoanodes incorporate buried junction architectures where the p-n junction is formed within the silicon substrate rather than at the semiconductor-liquid interface, significantly improving charge separation efficiency. Additionally, Sharp has developed novel surface texturing techniques that enhance light absorption through multiple reflection events. Their technology includes the integration of earth-abundant catalysts such as nickel-iron layered double hydroxides directly onto the protected silicon surface to accelerate water oxidation kinetics while maintaining optical transparency[10]. Recent innovations include the development of tandem photoelectrode configurations that combine silicon with wider bandgap semiconductors to harvest a broader portion of the solar spectrum.

Strengths: Excellent photovoltage generation due to high-quality semiconductor junctions; leverages established silicon manufacturing infrastructure; high theoretical efficiency potential. Weaknesses: Complex protection strategies required to prevent corrosion in aqueous electrolytes; relatively high manufacturing costs for high-efficiency configurations; challenges in achieving long-term stability under continuous operation.

Key Patents and Breakthroughs in Novel Photoanode Materials

Photoelectrode for PEC cell including nanoparticles of metal oxide hydroxide and capping layer of graphene and hybrid organic PEC cell having them

PatentActiveKR1020170051575A

Innovation

- The integration of nickel hydroxide oxide nanoparticles and reduced graphene oxide layers with a polymeric active layer, along with surface modifications using UV-ozone treatment, to improve interfacial properties and create a hydrophilic environment, coupled with a multi-junction structure incorporating tungsten oxide and silver nanowires for enhanced charge transport.

Photoelectrochemical(PEC) device Comprising CIGS Photovoltaic-Photoelectrode Tandem Configuration

PatentActiveKR1020210092503A

Innovation

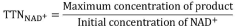

- A PEC device comprising a CIGS photovoltaic cell and a cathode forms a tandem structure, utilizing solar energy to induce biocatalytic reactions without external bias, with a solution containing an oxidized cofactor, electron transfer mediator, and electron donor, and regenerating cofactors through light irradiation.

Environmental Impact and Sustainability Considerations

The environmental impact of photoelectrochemical (PEC) cell materials represents a critical consideration in the development and deployment of sustainable energy technologies. Conventional photoanode materials such as titanium dioxide (TiO2) and hematite (α-Fe2O3) often involve energy-intensive manufacturing processes, potentially offsetting the environmental benefits of the resulting renewable energy systems. Alternative photoanode materials must therefore be evaluated not only for their performance but also for their complete environmental footprint across the entire lifecycle.

Material extraction processes for alternative photoanodes present varying degrees of environmental concern. While silicon-based alternatives may leverage established semiconductor industry supply chains, emerging materials like bismuth vanadate (BiVO4) and copper-based oxides require careful assessment of mining impacts, particularly in regions with less stringent environmental regulations. The extraction of rare elements used in some promising photoanode formulations can lead to habitat destruction, water pollution, and significant carbon emissions if not properly managed.

Manufacturing processes for alternative photoanode materials demonstrate considerable variation in energy requirements and chemical waste generation. Solution-based synthesis methods for organic photoanodes and carbon-based materials typically require lower processing temperatures compared to conventional metal oxides, potentially reducing the embodied energy of these components. Additionally, earth-abundant alternatives like carbon nitride (g-C3N4) can be synthesized from widely available precursors under relatively mild conditions, minimizing both resource depletion and manufacturing emissions.

End-of-life considerations reveal significant advantages for certain alternative photoanode materials. Metal oxide alternatives generally demonstrate good stability and recyclability potential, while organic and carbon-based materials may offer biodegradability options not available with conventional inorganic photoanodes. The presence of toxic elements in some alternative formulations, however, necessitates careful disposal protocols to prevent environmental contamination after decommissioning.

Water consumption represents another critical sustainability metric, particularly relevant for technologies intended to address water-energy nexus challenges. Alternative photoanode materials that enable efficient operation in saline or wastewater environments, rather than requiring purified water, offer substantial sustainability advantages by reducing freshwater demand. Materials demonstrating self-cleaning properties or resistance to biofouling can further reduce maintenance requirements and associated environmental impacts.

Carbon footprint analysis across the complete lifecycle reveals that despite higher initial manufacturing impacts, high-efficiency alternative photoanodes can deliver superior environmental performance through extended operational lifetimes and improved solar-to-hydrogen conversion efficiencies. Quantitative life cycle assessment studies indicate that materials enabling stable operation beyond 10,000 hours typically overcome their embodied carbon through clean energy generation, highlighting the importance of durability in sustainable photoanode design.

Material extraction processes for alternative photoanodes present varying degrees of environmental concern. While silicon-based alternatives may leverage established semiconductor industry supply chains, emerging materials like bismuth vanadate (BiVO4) and copper-based oxides require careful assessment of mining impacts, particularly in regions with less stringent environmental regulations. The extraction of rare elements used in some promising photoanode formulations can lead to habitat destruction, water pollution, and significant carbon emissions if not properly managed.

Manufacturing processes for alternative photoanode materials demonstrate considerable variation in energy requirements and chemical waste generation. Solution-based synthesis methods for organic photoanodes and carbon-based materials typically require lower processing temperatures compared to conventional metal oxides, potentially reducing the embodied energy of these components. Additionally, earth-abundant alternatives like carbon nitride (g-C3N4) can be synthesized from widely available precursors under relatively mild conditions, minimizing both resource depletion and manufacturing emissions.

End-of-life considerations reveal significant advantages for certain alternative photoanode materials. Metal oxide alternatives generally demonstrate good stability and recyclability potential, while organic and carbon-based materials may offer biodegradability options not available with conventional inorganic photoanodes. The presence of toxic elements in some alternative formulations, however, necessitates careful disposal protocols to prevent environmental contamination after decommissioning.

Water consumption represents another critical sustainability metric, particularly relevant for technologies intended to address water-energy nexus challenges. Alternative photoanode materials that enable efficient operation in saline or wastewater environments, rather than requiring purified water, offer substantial sustainability advantages by reducing freshwater demand. Materials demonstrating self-cleaning properties or resistance to biofouling can further reduce maintenance requirements and associated environmental impacts.

Carbon footprint analysis across the complete lifecycle reveals that despite higher initial manufacturing impacts, high-efficiency alternative photoanodes can deliver superior environmental performance through extended operational lifetimes and improved solar-to-hydrogen conversion efficiencies. Quantitative life cycle assessment studies indicate that materials enabling stable operation beyond 10,000 hours typically overcome their embodied carbon through clean energy generation, highlighting the importance of durability in sustainable photoanode design.

Scalability and Commercial Viability Assessment

The scalability of alternative photoanode materials for photoelectrochemical cells represents a critical factor in their potential for widespread adoption. Current manufacturing processes for novel materials such as metal oxides, nitrides, and sulfides often rely on laboratory-scale synthesis methods that present significant challenges when considered for industrial production. Techniques such as hydrothermal synthesis, sol-gel processing, and atomic layer deposition deliver excellent control over material properties but typically yield small quantities at high costs.

Economic viability remains a substantial hurdle for emerging photoanode technologies. Traditional silicon-based photovoltaics benefit from decades of manufacturing optimization and economies of scale, creating a formidable cost benchmark for alternative PEC materials to overcome. Analysis of production costs indicates that materials like hematite (α-Fe2O3) and bismuth vanadate (BiVO4) could potentially achieve cost parity with conventional systems, but only with significant advances in processing efficiency and yield rates.

Material availability presents another dimension of scalability concerns. While abundant elements like iron and titanium offer sustainable scaling potential, other promising candidates incorporate rare elements such as tantalum, indium, or platinum group metals. Supply chain vulnerabilities and geopolitical considerations may impact long-term viability of these materials, necessitating either material substitution strategies or advanced recycling technologies.

Durability and lifetime performance metrics significantly influence commercial feasibility. Alternative photoanode materials must demonstrate stability under operational conditions for thousands of hours to compete with established technologies. Current laboratory demonstrations often show promising initial performance but suffer from degradation mechanisms including photocorrosion, surface passivation, and structural changes that limit practical deployment.

Manufacturing infrastructure requirements vary considerably among candidate materials. Some alternatives can leverage existing semiconductor fabrication facilities, while others demand specialized equipment and processes. This disparity in manufacturing readiness levels (MRLs) creates uneven commercialization timelines across the spectrum of alternative photoanode materials.

Regulatory frameworks and environmental impact assessments further complicate commercialization pathways. Materials containing toxic elements face additional scrutiny and compliance costs, while those requiring energy-intensive processing methods must overcome lifecycle carbon footprint concerns to maintain alignment with sustainability objectives that drive interest in PEC technology.

Economic viability remains a substantial hurdle for emerging photoanode technologies. Traditional silicon-based photovoltaics benefit from decades of manufacturing optimization and economies of scale, creating a formidable cost benchmark for alternative PEC materials to overcome. Analysis of production costs indicates that materials like hematite (α-Fe2O3) and bismuth vanadate (BiVO4) could potentially achieve cost parity with conventional systems, but only with significant advances in processing efficiency and yield rates.

Material availability presents another dimension of scalability concerns. While abundant elements like iron and titanium offer sustainable scaling potential, other promising candidates incorporate rare elements such as tantalum, indium, or platinum group metals. Supply chain vulnerabilities and geopolitical considerations may impact long-term viability of these materials, necessitating either material substitution strategies or advanced recycling technologies.

Durability and lifetime performance metrics significantly influence commercial feasibility. Alternative photoanode materials must demonstrate stability under operational conditions for thousands of hours to compete with established technologies. Current laboratory demonstrations often show promising initial performance but suffer from degradation mechanisms including photocorrosion, surface passivation, and structural changes that limit practical deployment.

Manufacturing infrastructure requirements vary considerably among candidate materials. Some alternatives can leverage existing semiconductor fabrication facilities, while others demand specialized equipment and processes. This disparity in manufacturing readiness levels (MRLs) creates uneven commercialization timelines across the spectrum of alternative photoanode materials.

Regulatory frameworks and environmental impact assessments further complicate commercialization pathways. Materials containing toxic elements face additional scrutiny and compliance costs, while those requiring energy-intensive processing methods must overcome lifecycle carbon footprint concerns to maintain alignment with sustainability objectives that drive interest in PEC technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!