Synergies between photovoltaic and PEC technologies for hydrogen production.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PV-PEC Hydrogen Production Background and Objectives

The evolution of hydrogen production technologies has witnessed significant advancements over the past decades, with increasing focus on sustainable methods that can replace traditional fossil fuel-based processes. Among these emerging approaches, the synergistic integration of photovoltaic (PV) and photoelectrochemical (PEC) technologies represents a promising frontier in clean hydrogen production. This technological convergence aims to harness solar energy efficiently for water splitting, offering a carbon-neutral pathway to hydrogen generation.

Historically, PV and PEC technologies have developed along separate trajectories. Conventional photovoltaic systems convert solar radiation directly into electricity, which can then power electrolyzers for hydrogen production in a two-step process. In contrast, PEC systems integrate light absorption and water splitting functions into a single device, potentially offering higher theoretical efficiencies through direct solar-to-hydrogen conversion.

The fundamental objective of PV-PEC synergistic systems is to overcome the limitations inherent in each individual technology while capitalizing on their respective strengths. PV technology brings mature manufacturing processes and relatively high solar-to-electricity conversion efficiencies, currently reaching over 25% for commercial silicon cells and exceeding 47% for multi-junction concentrator cells in laboratory settings. Meanwhile, PEC technology offers the advantage of direct water splitting without the need for external wiring or separate electrolyzer units.

Current technological goals include achieving solar-to-hydrogen (STH) conversion efficiencies exceeding 10% with system lifetimes of more than 10 years at costs competitive with fossil fuel-derived hydrogen. This represents a significant challenge, as standalone PEC systems typically demonstrate efficiencies below 5% with limited durability in real-world conditions.

The evolution trend points toward hybrid systems that leverage the high efficiency of PV cells to generate the necessary photovoltage, while utilizing specialized photoelectrodes for the water-splitting reaction. These tandem configurations aim to optimize the solar spectrum utilization through complementary absorption profiles between the PV and PEC components.

Recent research has focused on developing earth-abundant, stable materials for photoelectrodes, novel device architectures that minimize interface losses, and protective coatings that enhance durability in corrosive electrolytes. The ultimate technological objective is to create scalable, cost-effective systems that can be deployed globally as part of a sustainable hydrogen economy, contributing significantly to decarbonization efforts across industrial, transportation, and energy storage sectors.

Historically, PV and PEC technologies have developed along separate trajectories. Conventional photovoltaic systems convert solar radiation directly into electricity, which can then power electrolyzers for hydrogen production in a two-step process. In contrast, PEC systems integrate light absorption and water splitting functions into a single device, potentially offering higher theoretical efficiencies through direct solar-to-hydrogen conversion.

The fundamental objective of PV-PEC synergistic systems is to overcome the limitations inherent in each individual technology while capitalizing on their respective strengths. PV technology brings mature manufacturing processes and relatively high solar-to-electricity conversion efficiencies, currently reaching over 25% for commercial silicon cells and exceeding 47% for multi-junction concentrator cells in laboratory settings. Meanwhile, PEC technology offers the advantage of direct water splitting without the need for external wiring or separate electrolyzer units.

Current technological goals include achieving solar-to-hydrogen (STH) conversion efficiencies exceeding 10% with system lifetimes of more than 10 years at costs competitive with fossil fuel-derived hydrogen. This represents a significant challenge, as standalone PEC systems typically demonstrate efficiencies below 5% with limited durability in real-world conditions.

The evolution trend points toward hybrid systems that leverage the high efficiency of PV cells to generate the necessary photovoltage, while utilizing specialized photoelectrodes for the water-splitting reaction. These tandem configurations aim to optimize the solar spectrum utilization through complementary absorption profiles between the PV and PEC components.

Recent research has focused on developing earth-abundant, stable materials for photoelectrodes, novel device architectures that minimize interface losses, and protective coatings that enhance durability in corrosive electrolytes. The ultimate technological objective is to create scalable, cost-effective systems that can be deployed globally as part of a sustainable hydrogen economy, contributing significantly to decarbonization efforts across industrial, transportation, and energy storage sectors.

Market Analysis for Solar Hydrogen Production

The global market for hydrogen production technologies is experiencing significant growth, driven by the increasing focus on decarbonization and renewable energy integration. The solar hydrogen production sector, particularly through photovoltaic (PV) and photoelectrochemical (PEC) technologies, represents a promising segment within this expanding market.

Current market assessments value the global green hydrogen market at approximately $2.5 billion as of 2022, with projections indicating growth to reach $90 billion by 2030, representing a compound annual growth rate (CAGR) of over 54%. Within this broader market, solar hydrogen production technologies are gaining substantial traction due to their potential for zero-emission hydrogen generation.

The demand for solar hydrogen production systems is being fueled by several key market drivers. Industrial sectors, including chemical manufacturing, steel production, and ammonia synthesis, are increasingly seeking carbon-neutral feedstocks. Transportation represents another significant market, with hydrogen fuel cell vehicles gaining momentum in heavy-duty transport applications where battery electric solutions face limitations.

Regional market analysis reveals distinct patterns in adoption and investment. Europe leads in policy support and commercial deployment, with Germany, the Netherlands, and Denmark establishing ambitious hydrogen strategies. The Asia-Pacific region, particularly Japan, South Korea, and Australia, demonstrates strong market growth potential, leveraging abundant solar resources and industrial demand. North America shows increasing investment activity, though somewhat behind European deployment levels.

Market segmentation indicates that large-scale centralized production facilities currently dominate investment, but distributed generation systems are expected to gain market share as technology costs decrease. The integration of PV and PEC technologies creates a distinct market segment with unique value propositions around efficiency and system integration.

Competitive analysis reveals traditional energy companies and specialized renewable hydrogen firms as the primary market participants. Companies with expertise in both photovoltaic and electrochemical technologies possess strategic advantages in this convergent market space. Recent market entries from major semiconductor and materials science companies signal growing commercial interest.

Cost trends show steady improvement, with solar hydrogen production costs decreasing from approximately $10-15/kg in 2015 to $5-8/kg in 2022. Industry projections suggest potential for reaching $2-3/kg by 2030, approaching cost parity with conventional hydrogen production methods when carbon pricing mechanisms are considered.

Market barriers include high capital expenditure requirements, infrastructure limitations, and policy uncertainty. However, supportive government initiatives, corporate sustainability commitments, and technology advancements are progressively addressing these challenges.

Current market assessments value the global green hydrogen market at approximately $2.5 billion as of 2022, with projections indicating growth to reach $90 billion by 2030, representing a compound annual growth rate (CAGR) of over 54%. Within this broader market, solar hydrogen production technologies are gaining substantial traction due to their potential for zero-emission hydrogen generation.

The demand for solar hydrogen production systems is being fueled by several key market drivers. Industrial sectors, including chemical manufacturing, steel production, and ammonia synthesis, are increasingly seeking carbon-neutral feedstocks. Transportation represents another significant market, with hydrogen fuel cell vehicles gaining momentum in heavy-duty transport applications where battery electric solutions face limitations.

Regional market analysis reveals distinct patterns in adoption and investment. Europe leads in policy support and commercial deployment, with Germany, the Netherlands, and Denmark establishing ambitious hydrogen strategies. The Asia-Pacific region, particularly Japan, South Korea, and Australia, demonstrates strong market growth potential, leveraging abundant solar resources and industrial demand. North America shows increasing investment activity, though somewhat behind European deployment levels.

Market segmentation indicates that large-scale centralized production facilities currently dominate investment, but distributed generation systems are expected to gain market share as technology costs decrease. The integration of PV and PEC technologies creates a distinct market segment with unique value propositions around efficiency and system integration.

Competitive analysis reveals traditional energy companies and specialized renewable hydrogen firms as the primary market participants. Companies with expertise in both photovoltaic and electrochemical technologies possess strategic advantages in this convergent market space. Recent market entries from major semiconductor and materials science companies signal growing commercial interest.

Cost trends show steady improvement, with solar hydrogen production costs decreasing from approximately $10-15/kg in 2015 to $5-8/kg in 2022. Industry projections suggest potential for reaching $2-3/kg by 2030, approaching cost parity with conventional hydrogen production methods when carbon pricing mechanisms are considered.

Market barriers include high capital expenditure requirements, infrastructure limitations, and policy uncertainty. However, supportive government initiatives, corporate sustainability commitments, and technology advancements are progressively addressing these challenges.

Current Status and Challenges in PV-PEC Integration

The integration of photovoltaic (PV) and photoelectrochemical (PEC) technologies for hydrogen production represents a promising approach to sustainable energy generation. Currently, this integration exists in various stages of development globally, with significant advancements in laboratory settings but limited commercial deployment. Research institutions across North America, Europe, and Asia have demonstrated functional prototypes achieving solar-to-hydrogen efficiencies ranging from 10% to 18%, yet these remain primarily experimental.

The primary technical challenge facing PV-PEC integration is the optimization of the interface between photovoltaic cells and electrochemical components. Current systems often suffer from energy losses at this junction, reducing overall efficiency. Material compatibility issues arise when combining semiconductor materials with electrolytes, leading to degradation and shortened operational lifespans. Most laboratory demonstrations show significant performance decline after 500-1000 hours of operation, far below the 20,000+ hours required for commercial viability.

Scalability presents another significant hurdle. While laboratory-scale devices demonstrate promising performance, scaling these systems to industrial production levels introduces new challenges in maintaining uniform performance across larger surface areas. Manufacturing processes for integrated devices remain complex and costly, with current production methods unsuitable for mass manufacturing at competitive price points.

Stability under real-world operating conditions continues to be problematic. PEC components are particularly vulnerable to photocorrosion and deactivation in the presence of common water impurities. Most current systems require highly purified water inputs, limiting their practical application in diverse environments. Temperature fluctuations and intermittent solar irradiation further complicate system performance and durability.

From a geographical perspective, research leadership in this field is distributed unevenly. The United States, Germany, Japan, and China lead in patent filings and research publications, with specialized research clusters emerging around institutions like NREL (USA), Helmholtz-Zentrum Berlin (Germany), and the Dalian Institute of Chemical Physics (China). This concentration of expertise creates both opportunities for collaboration and challenges for technology transfer to regions with high solar potential but limited research infrastructure.

Economic barriers also impede widespread adoption. Current integrated PV-PEC systems have estimated hydrogen production costs of $5-8/kg, significantly higher than the $2/kg target needed to compete with conventional hydrogen production methods. The capital expenditure for these systems remains prohibitively high, with insufficient economies of scale to drive cost reductions through manufacturing optimization.

The primary technical challenge facing PV-PEC integration is the optimization of the interface between photovoltaic cells and electrochemical components. Current systems often suffer from energy losses at this junction, reducing overall efficiency. Material compatibility issues arise when combining semiconductor materials with electrolytes, leading to degradation and shortened operational lifespans. Most laboratory demonstrations show significant performance decline after 500-1000 hours of operation, far below the 20,000+ hours required for commercial viability.

Scalability presents another significant hurdle. While laboratory-scale devices demonstrate promising performance, scaling these systems to industrial production levels introduces new challenges in maintaining uniform performance across larger surface areas. Manufacturing processes for integrated devices remain complex and costly, with current production methods unsuitable for mass manufacturing at competitive price points.

Stability under real-world operating conditions continues to be problematic. PEC components are particularly vulnerable to photocorrosion and deactivation in the presence of common water impurities. Most current systems require highly purified water inputs, limiting their practical application in diverse environments. Temperature fluctuations and intermittent solar irradiation further complicate system performance and durability.

From a geographical perspective, research leadership in this field is distributed unevenly. The United States, Germany, Japan, and China lead in patent filings and research publications, with specialized research clusters emerging around institutions like NREL (USA), Helmholtz-Zentrum Berlin (Germany), and the Dalian Institute of Chemical Physics (China). This concentration of expertise creates both opportunities for collaboration and challenges for technology transfer to regions with high solar potential but limited research infrastructure.

Economic barriers also impede widespread adoption. Current integrated PV-PEC systems have estimated hydrogen production costs of $5-8/kg, significantly higher than the $2/kg target needed to compete with conventional hydrogen production methods. The capital expenditure for these systems remains prohibitively high, with insufficient economies of scale to drive cost reductions through manufacturing optimization.

Current PV-PEC Hybrid System Architectures

01 Integrated PV-PEC systems for enhanced energy conversion

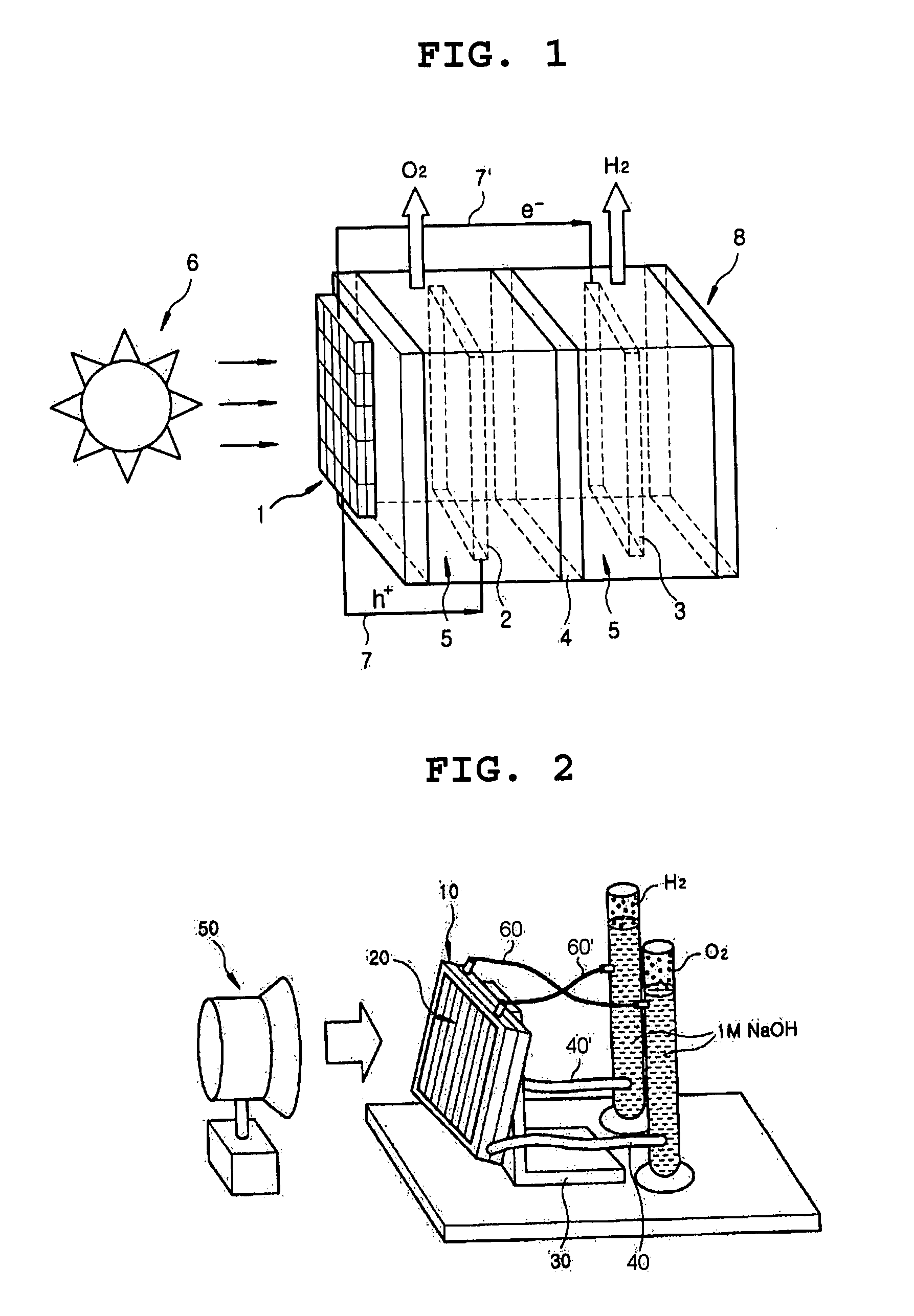

Integration of photovoltaic (PV) and photoelectrochemical (PEC) technologies creates synergistic systems that can achieve higher overall energy conversion efficiencies. These hybrid systems utilize PV cells to generate electricity while simultaneously powering PEC cells for hydrogen production or other electrochemical reactions. The complementary nature of these technologies allows for more efficient utilization of the solar spectrum, with PV capturing visible light while PEC components can be optimized for different wavelength ranges.- Integrated photovoltaic and photoelectrochemical systems: Systems that integrate photovoltaic (PV) and photoelectrochemical (PEC) technologies to enhance overall energy conversion efficiency. These hybrid systems utilize PV cells to generate electricity while simultaneously using PEC components for chemical reactions such as water splitting or CO2 reduction. The synergistic design allows for better utilization of the solar spectrum and improved energy harvesting capabilities.

- Tandem cell architectures combining PV and PEC technologies: Tandem cell configurations that stack photovoltaic and photoelectrochemical components to maximize solar energy utilization. These architectures allow different parts of the solar spectrum to be absorbed by different layers, with PV cells typically capturing higher energy photons while PEC cells utilize lower energy wavelengths. This complementary approach increases overall system efficiency beyond what either technology could achieve independently.

- Novel materials for enhanced PV-PEC synergy: Development of advanced materials that bridge the gap between photovoltaic and photoelectrochemical properties. These materials often feature tailored band gaps, improved charge carrier mobility, and enhanced stability in various electrolytes. Innovations include nanostructured semiconductors, perovskite-based materials, and composite structures that facilitate both efficient light absorption and catalytic activity at interfaces.

- Energy storage integration with PV-PEC systems: Systems that combine photovoltaic electricity generation with photoelectrochemical production of energy storage media such as hydrogen or other solar fuels. These integrated approaches address intermittency issues in renewable energy by converting excess electricity into storable chemical forms. The synergy allows for on-demand energy utilization and improves the overall reliability of solar energy systems.

- Control systems and optimization for PV-PEC hybrid technologies: Advanced control and monitoring systems designed specifically for managing the complex interplay between photovoltaic and photoelectrochemical components. These systems optimize energy flow, balance electrical and chemical production pathways, and adapt to changing environmental conditions. Smart controllers enable real-time adjustments to maximize efficiency and extend the operational lifetime of integrated PV-PEC technologies.

02 Novel materials and structures for dual PV-PEC functionality

Advanced materials and structural designs enable components to serve both photovoltaic and photoelectrochemical functions simultaneously. These include specialized semiconductors, nanostructured electrodes, and multi-junction architectures that can harvest light for direct electricity generation while also facilitating electrochemical reactions. Such materials often feature optimized band gaps, enhanced charge separation properties, and improved stability in both dry and aqueous environments.Expand Specific Solutions03 Water-splitting systems powered by integrated solar technologies

Combined photovoltaic and photoelectrochemical systems offer efficient approaches to solar water splitting for hydrogen production. These integrated systems use PV components to generate the necessary voltage to drive water electrolysis, while PEC components directly convert solar energy into chemical energy at the semiconductor-electrolyte interface. This synergistic approach overcomes efficiency limitations of standalone systems and provides pathways for sustainable hydrogen production as an energy carrier.Expand Specific Solutions04 Modular and scalable hybrid energy systems

Modular designs that combine photovoltaic and photoelectrochemical technologies enable scalable deployment across various applications. These systems feature interchangeable components that can be optimized for specific environmental conditions or energy needs. The modular approach allows for easier maintenance, component replacement, and system upgrades while maintaining the synergistic benefits of the integrated technologies. Such systems can be deployed in various settings from distributed residential applications to large-scale industrial facilities.Expand Specific Solutions05 Energy management and storage solutions for PV-PEC systems

Integrated control and energy management systems optimize the operation of combined photovoltaic and photoelectrochemical technologies. These solutions include advanced power electronics, smart grid integration, and complementary energy storage technologies that address the intermittent nature of solar energy. By intelligently managing energy flows between PV electricity generation, PEC chemical production, and storage systems, these integrated approaches maximize overall system efficiency and provide consistent energy output despite variable solar conditions.Expand Specific Solutions

Leading Companies and Research Institutions in PV-PEC Field

The photovoltaic (PV) and photoelectrochemical (PEC) hydrogen production market is in an early growth phase, with significant research momentum but limited commercial deployment. The global market is projected to expand substantially as hydrogen gains importance in clean energy transitions. Technologically, the field shows varying maturity levels, with leading institutions demonstrating different approaches. Research powerhouses like The Regents of the University of California, KAUST, and Xi'an Jiaotong University are advancing fundamental science, while organizations like Alliance for Sustainable Energy and Korea Institute of Energy Research focus on practical applications. Companies including SABIC and State Grid Corp. of China are exploring industrial-scale implementation. The synergy between PV and PEC technologies represents a promising pathway for efficient solar hydrogen production, with collaborative efforts across academia and industry accelerating development.

Alliance for Sustainable Energy LLC

Technical Solution: Alliance for Sustainable Energy LLC, which manages the National Renewable Energy Laboratory (NREL), has developed an integrated photovoltaic-photoelectrochemical (PV-PEC) system that combines high-efficiency III-V semiconductor PV cells with specialized photoelectrodes. Their approach utilizes a tandem configuration where the PV component captures high-energy photons while transmitting lower-energy photons to the PEC component, achieving solar-to-hydrogen efficiencies exceeding 16%. The system incorporates protective coatings and catalysts to enhance durability in corrosive electrolytes, with demonstrated stability over 1000+ hours of operation. NREL's design also features modular architecture allowing for independent optimization of PV and PEC components, with recent innovations focusing on earth-abundant materials to reduce dependency on rare elements while maintaining performance.

Strengths: Industry-leading solar-to-hydrogen conversion efficiencies; extensive durability testing protocols; strong integration with existing renewable infrastructure. Weaknesses: Higher manufacturing costs compared to conventional electrolyzers; requires specialized materials that may limit large-scale deployment; performance degradation in real-world conditions remains a challenge.

King Abdullah University of Science & Technology

Technical Solution: King Abdullah University of Science & Technology (KAUST) has pioneered a hybrid photovoltaic-photoelectrochemical (PV-PEC) system utilizing their proprietary bismuth vanadate (BiVO4) photoanodes coupled with perovskite solar cells. Their innovative approach features a wireless configuration where the PV component provides additional bias voltage to the PEC system, overcoming traditional thermodynamic limitations. KAUST researchers have developed specialized surface treatments and heterojunction architectures that significantly reduce interface recombination losses, achieving solar-to-hydrogen efficiencies of approximately 12% under standard testing conditions. Their system incorporates a unique water management design that minimizes mass transport limitations and enables operation in regions with high solar irradiance and limited water resources. Recent advancements include the integration of earth-abundant co-catalysts and the development of scalable manufacturing techniques for their photoelectrode materials.

Strengths: Exceptional performance in high-temperature desert environments; innovative materials science approach reducing dependency on precious metals; strong integration potential with desalination systems. Weaknesses: Technology still requires further scale-up validation; long-term stability under fluctuating conditions needs improvement; higher initial capital costs compared to conventional PV systems.

Key Innovations in Photoelectrochemical Catalysts

Photoelectrochemical(PEC) device Comprising CIGS Photovoltaic-Photoelectrode Tandem Configuration

PatentActiveKR1020210092503A

Innovation

- A PEC device comprising a CIGS photovoltaic cell and a cathode forms a tandem structure, utilizing solar energy to induce biocatalytic reactions without external bias, with a solution containing an oxidized cofactor, electron transfer mediator, and electron donor, and regenerating cofactors through light irradiation.

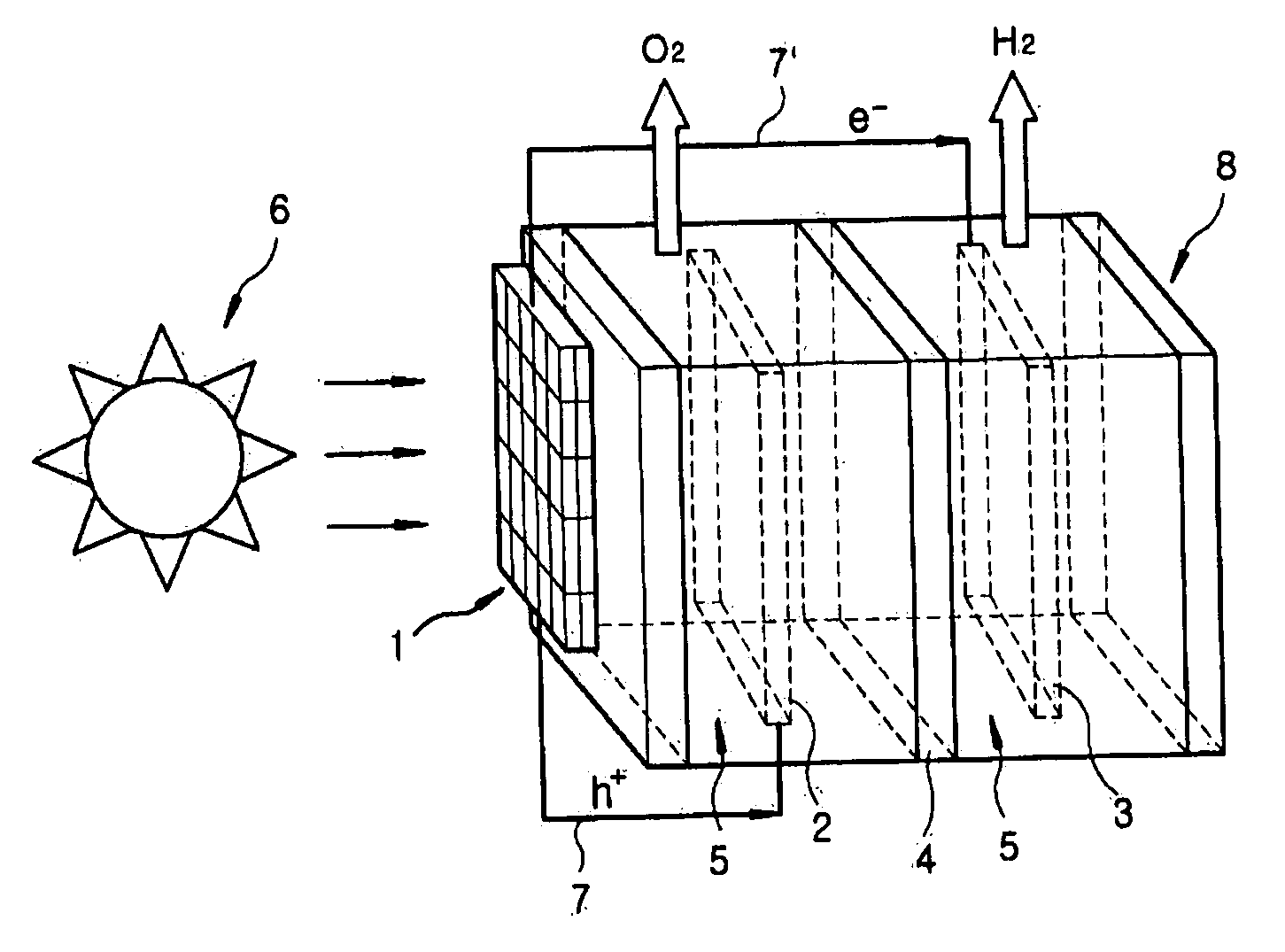

Photoelectrochemical system for hydrogen production from water

PatentInactiveUS20080131762A1

Innovation

- A photoelectrochemical system where the photoelectrode is positioned outside the electrolytic bath and electrically connected to catalytic oxidation and reduction electrodes, eliminating direct contact with the aqueous electrolyte solution, and utilizing an ion separation film between the electrodes to facilitate hydrogen production.

Techno-economic Assessment of Solar Hydrogen Production

The techno-economic assessment of solar hydrogen production reveals significant potential for cost reduction through integrated photovoltaic (PV) and photoelectrochemical (PEC) systems. Current levelized cost of hydrogen (LCOH) from conventional PV-electrolysis systems ranges between $4-6/kg, while integrated PEC systems show theoretical potential to reduce costs to $2-3/kg under optimized conditions. These economic projections depend heavily on solar conversion efficiency, system lifetime, and capital expenditure requirements.

Analysis of capital costs indicates that PV-electrolysis systems benefit from economies of scale in manufacturing but suffer from system complexity requiring separate components. Conversely, PEC technologies offer potential capital cost advantages through integrated designs but currently face higher manufacturing costs due to limited production scale and specialized materials requirements. The balance of system costs represents approximately 30-40% of total capital expenditure for both technologies.

Operational expenditures differ significantly between the approaches. PV-electrolysis systems incur higher maintenance costs due to the complexity of separate components, particularly electrolyzers requiring periodic stack replacement. PEC systems potentially offer lower operational costs through simplified designs but currently face durability challenges that increase replacement frequency and associated costs.

Sensitivity analysis demonstrates that solar-to-hydrogen efficiency improvements yield the most substantial economic benefits for both technologies. For PV-electrolysis, increasing module efficiency from 20% to 25% could reduce LCOH by approximately 15%, while extending electrolyzer lifetime from 5 to 10 years could reduce costs by 12%. For PEC systems, improving stability to achieve 5+ year lifetimes represents the critical economic threshold for commercial viability.

Regional variations significantly impact economic feasibility. Locations with high solar irradiance (>2000 kWh/m²/year) can achieve 30-40% lower LCOH compared to moderate-irradiance regions. Additionally, regions with existing hydrogen infrastructure or high natural gas prices offer more favorable economic conditions for solar hydrogen adoption.

Future cost trajectories suggest PV-electrolysis systems will reach economic competitiveness with fossil-based hydrogen ($1.5-2/kg) by 2030-2035 in optimal locations, driven primarily by continued PV cost reductions and electrolyzer scaling. PEC technologies require breakthrough advances in materials durability and manufacturing processes to achieve similar economics, with potential commercial viability projected for 2035-2040 if current technical challenges are overcome.

Analysis of capital costs indicates that PV-electrolysis systems benefit from economies of scale in manufacturing but suffer from system complexity requiring separate components. Conversely, PEC technologies offer potential capital cost advantages through integrated designs but currently face higher manufacturing costs due to limited production scale and specialized materials requirements. The balance of system costs represents approximately 30-40% of total capital expenditure for both technologies.

Operational expenditures differ significantly between the approaches. PV-electrolysis systems incur higher maintenance costs due to the complexity of separate components, particularly electrolyzers requiring periodic stack replacement. PEC systems potentially offer lower operational costs through simplified designs but currently face durability challenges that increase replacement frequency and associated costs.

Sensitivity analysis demonstrates that solar-to-hydrogen efficiency improvements yield the most substantial economic benefits for both technologies. For PV-electrolysis, increasing module efficiency from 20% to 25% could reduce LCOH by approximately 15%, while extending electrolyzer lifetime from 5 to 10 years could reduce costs by 12%. For PEC systems, improving stability to achieve 5+ year lifetimes represents the critical economic threshold for commercial viability.

Regional variations significantly impact economic feasibility. Locations with high solar irradiance (>2000 kWh/m²/year) can achieve 30-40% lower LCOH compared to moderate-irradiance regions. Additionally, regions with existing hydrogen infrastructure or high natural gas prices offer more favorable economic conditions for solar hydrogen adoption.

Future cost trajectories suggest PV-electrolysis systems will reach economic competitiveness with fossil-based hydrogen ($1.5-2/kg) by 2030-2035 in optimal locations, driven primarily by continued PV cost reductions and electrolyzer scaling. PEC technologies require breakthrough advances in materials durability and manufacturing processes to achieve similar economics, with potential commercial viability projected for 2035-2040 if current technical challenges are overcome.

Environmental Impact and Sustainability Considerations

The integration of photovoltaic (PV) and photoelectrochemical (PEC) technologies for hydrogen production represents a significant advancement in renewable energy systems, with substantial environmental and sustainability implications that warrant careful consideration.

The environmental benefits of these integrated systems are multifaceted. By harnessing solar energy for hydrogen production, these technologies offer a pathway to decarbonize energy systems and reduce greenhouse gas emissions. Compared to conventional hydrogen production methods like steam methane reforming, which emits approximately 9-12 kg CO2 per kg of hydrogen produced, solar-driven hydrogen production can potentially eliminate these emissions entirely when powered by renewable electricity.

Life cycle assessments (LCAs) of integrated PV-PEC systems indicate favorable environmental profiles, particularly regarding carbon footprint and energy payback time. Recent studies suggest that such systems can achieve energy payback periods of 1-3 years, depending on geographical location and system configuration, with lifetime carbon emissions significantly lower than fossil fuel alternatives.

Water consumption represents another critical environmental consideration. While hydrogen production through electrolysis requires substantial water inputs (approximately 9 kg of water per kg of hydrogen), the integration of water recovery systems can significantly reduce net consumption. Advanced PEC designs incorporating water vapor electrolysis may further reduce freshwater requirements, making these technologies viable even in water-stressed regions.

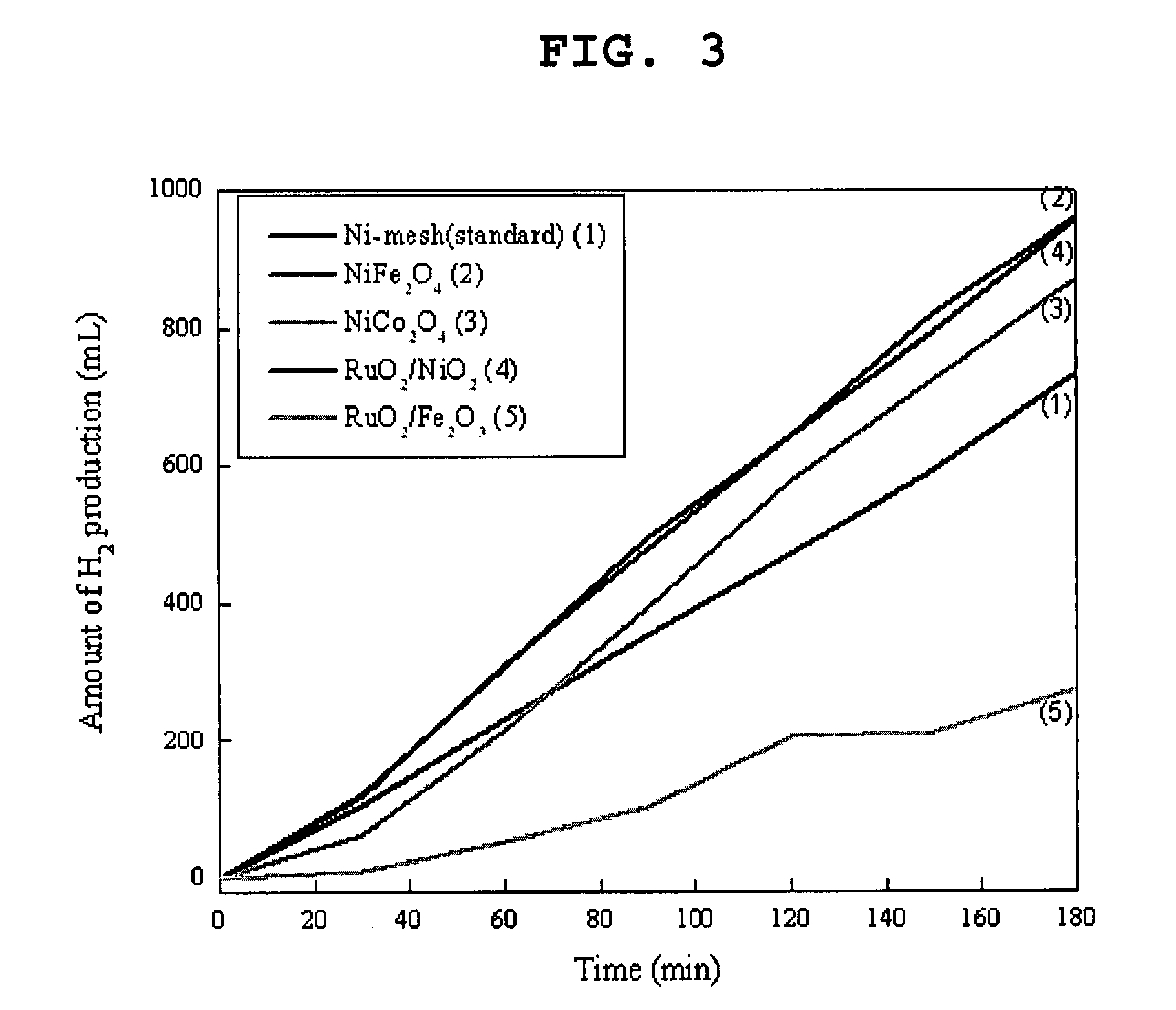

Material sustainability presents both challenges and opportunities. Current PEC technologies often utilize rare earth elements and precious metals as catalysts, raising concerns about resource depletion and supply chain vulnerabilities. However, research into earth-abundant alternatives such as nickel-iron catalysts and carbon-based materials shows promising results for reducing dependence on critical materials while maintaining system efficiency.

Land use impacts must also be considered, particularly for large-scale deployment. Integrated PV-PEC systems typically require less land area than separate installations, with dual-function designs potentially achieving 20-30% space efficiency improvements. Innovative approaches such as floating solar-hydrogen facilities and building-integrated systems offer pathways to minimize land competition with agriculture and natural ecosystems.

End-of-life management represents the final sustainability frontier for these technologies. Developing effective recycling protocols for PV panels, electrodes, and catalysts will be essential for closing material loops and minimizing waste. Emerging design-for-disassembly approaches and dedicated recycling infrastructure could potentially recover up to 95% of valuable materials from decommissioned systems, significantly enhancing their lifecycle sustainability.

The environmental benefits of these integrated systems are multifaceted. By harnessing solar energy for hydrogen production, these technologies offer a pathway to decarbonize energy systems and reduce greenhouse gas emissions. Compared to conventional hydrogen production methods like steam methane reforming, which emits approximately 9-12 kg CO2 per kg of hydrogen produced, solar-driven hydrogen production can potentially eliminate these emissions entirely when powered by renewable electricity.

Life cycle assessments (LCAs) of integrated PV-PEC systems indicate favorable environmental profiles, particularly regarding carbon footprint and energy payback time. Recent studies suggest that such systems can achieve energy payback periods of 1-3 years, depending on geographical location and system configuration, with lifetime carbon emissions significantly lower than fossil fuel alternatives.

Water consumption represents another critical environmental consideration. While hydrogen production through electrolysis requires substantial water inputs (approximately 9 kg of water per kg of hydrogen), the integration of water recovery systems can significantly reduce net consumption. Advanced PEC designs incorporating water vapor electrolysis may further reduce freshwater requirements, making these technologies viable even in water-stressed regions.

Material sustainability presents both challenges and opportunities. Current PEC technologies often utilize rare earth elements and precious metals as catalysts, raising concerns about resource depletion and supply chain vulnerabilities. However, research into earth-abundant alternatives such as nickel-iron catalysts and carbon-based materials shows promising results for reducing dependence on critical materials while maintaining system efficiency.

Land use impacts must also be considered, particularly for large-scale deployment. Integrated PV-PEC systems typically require less land area than separate installations, with dual-function designs potentially achieving 20-30% space efficiency improvements. Innovative approaches such as floating solar-hydrogen facilities and building-integrated systems offer pathways to minimize land competition with agriculture and natural ecosystems.

End-of-life management represents the final sustainability frontier for these technologies. Developing effective recycling protocols for PV panels, electrodes, and catalysts will be essential for closing material loops and minimizing waste. Emerging design-for-disassembly approaches and dedicated recycling infrastructure could potentially recover up to 95% of valuable materials from decommissioned systems, significantly enhancing their lifecycle sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!