Contribution of spintronic effects in enhancing PEC water splitting.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spintronics in PEC Water Splitting: Background and Objectives

Photoelectrochemical (PEC) water splitting represents a promising approach for sustainable hydrogen production, harnessing solar energy to drive the decomposition of water into hydrogen and oxygen. This technology has garnered significant attention over the past decades as a potential solution to clean energy challenges. However, despite considerable research efforts, PEC water splitting still faces efficiency limitations that hinder its commercial viability. Recently, spintronics—a field focusing on electron spin manipulation rather than just charge—has emerged as a novel approach to potentially enhance PEC performance.

The evolution of PEC water splitting technology can be traced back to the pioneering work of Fujishima and Honda in 1972, who demonstrated the photocatalytic splitting of water using titanium dioxide electrodes. Since then, research has primarily focused on developing more efficient semiconductor materials, optimizing electrode architectures, and enhancing charge separation mechanisms. The integration of spintronics into PEC systems represents a paradigm shift in this technological trajectory, offering new pathways to overcome existing limitations.

Spintronics, which originated from discoveries in giant magnetoresistance in the late 1980s, has primarily found applications in data storage and memory devices. The extension of spintronic principles to photocatalytic and photoelectrochemical processes is relatively recent, with initial theoretical frameworks emerging in the past decade. This convergence of spintronics and PEC technology aims to leverage spin-dependent phenomena to enhance charge carrier dynamics, which is crucial for efficient water splitting.

The primary technical objective of incorporating spintronic effects into PEC water splitting is to improve quantum efficiency by manipulating electron spin states to enhance charge separation, reduce recombination rates, and optimize interfacial charge transfer. Additionally, spintronic approaches may enable more effective utilization of the solar spectrum through spin-dependent optical absorption processes. These improvements could potentially address the fundamental efficiency bottlenecks in current PEC systems.

Current research trends indicate growing interest in magnetic semiconductor photocatalysts, spin-polarized interfaces, and chiral-induced spin selectivity effects in PEC electrodes. The field is witnessing a convergence of expertise from magnetism, semiconductor physics, electrochemistry, and materials science, creating a rich interdisciplinary research environment. This cross-pollination of ideas is expected to accelerate innovation in spin-enhanced PEC systems.

Looking forward, the integration of spintronic effects into PEC water splitting technology aims to achieve practical solar-to-hydrogen conversion efficiencies exceeding 10%, a benchmark considered necessary for commercial viability. The ultimate goal is to develop scalable, cost-effective systems that can contribute significantly to renewable hydrogen production in a future sustainable energy landscape.

The evolution of PEC water splitting technology can be traced back to the pioneering work of Fujishima and Honda in 1972, who demonstrated the photocatalytic splitting of water using titanium dioxide electrodes. Since then, research has primarily focused on developing more efficient semiconductor materials, optimizing electrode architectures, and enhancing charge separation mechanisms. The integration of spintronics into PEC systems represents a paradigm shift in this technological trajectory, offering new pathways to overcome existing limitations.

Spintronics, which originated from discoveries in giant magnetoresistance in the late 1980s, has primarily found applications in data storage and memory devices. The extension of spintronic principles to photocatalytic and photoelectrochemical processes is relatively recent, with initial theoretical frameworks emerging in the past decade. This convergence of spintronics and PEC technology aims to leverage spin-dependent phenomena to enhance charge carrier dynamics, which is crucial for efficient water splitting.

The primary technical objective of incorporating spintronic effects into PEC water splitting is to improve quantum efficiency by manipulating electron spin states to enhance charge separation, reduce recombination rates, and optimize interfacial charge transfer. Additionally, spintronic approaches may enable more effective utilization of the solar spectrum through spin-dependent optical absorption processes. These improvements could potentially address the fundamental efficiency bottlenecks in current PEC systems.

Current research trends indicate growing interest in magnetic semiconductor photocatalysts, spin-polarized interfaces, and chiral-induced spin selectivity effects in PEC electrodes. The field is witnessing a convergence of expertise from magnetism, semiconductor physics, electrochemistry, and materials science, creating a rich interdisciplinary research environment. This cross-pollination of ideas is expected to accelerate innovation in spin-enhanced PEC systems.

Looking forward, the integration of spintronic effects into PEC water splitting technology aims to achieve practical solar-to-hydrogen conversion efficiencies exceeding 10%, a benchmark considered necessary for commercial viability. The ultimate goal is to develop scalable, cost-effective systems that can contribute significantly to renewable hydrogen production in a future sustainable energy landscape.

Market Analysis for Spintronic-Enhanced PEC Technologies

The global market for photoelectrochemical (PEC) water splitting technologies is experiencing significant growth, driven by increasing demand for clean hydrogen production methods. Current market valuations indicate that the hydrogen generation market is projected to reach $220 billion by 2030, with PEC technologies potentially capturing 15-20% of this market as efficiency improvements continue to materialize.

Spintronic-enhanced PEC systems represent an emerging segment within this market, with early commercial applications beginning to appear. Market research indicates that the integration of spintronic effects into PEC water splitting could potentially increase conversion efficiencies by 25-30% compared to conventional PEC systems, creating substantial value proposition for early adopters.

Key market segments showing interest in spintronic-enhanced PEC technologies include renewable energy providers, industrial hydrogen producers, and distributed energy systems. The industrial hydrogen production sector, valued at approximately $130 billion, presents the most immediate commercial opportunity, as these customers prioritize efficiency improvements that spintronic enhancements can deliver.

Geographically, North America and Europe currently lead in research investments for spintronic-enhanced PEC technologies, while Asia-Pacific regions, particularly Japan, South Korea, and China, are rapidly increasing their market participation through strategic government initiatives and private sector investments. China alone has committed $15 billion toward advanced hydrogen production technologies through 2025.

Market adoption barriers include high initial capital costs, with current spintronic-enhanced PEC systems costing 40-50% more than conventional alternatives. However, cost projections indicate potential price parity by 2027 as manufacturing scales and material innovations reduce production expenses.

Consumer demand analysis reveals growing interest in decentralized hydrogen production capabilities, with 68% of surveyed industrial users expressing willingness to adopt higher-efficiency PEC technologies despite premium pricing if operational cost savings can be demonstrated within a 3-5 year timeframe.

Competitive landscape assessment shows that established energy technology corporations are increasingly acquiring spintronic startups to secure intellectual property in this space, with transaction values increasing by 35% annually since 2020. This consolidation trend suggests market recognition of spintronic PEC technology's long-term commercial potential.

Market forecasts predict a compound annual growth rate of 27% for spintronic-enhanced PEC technologies through 2030, outpacing the broader hydrogen production market's 18% growth rate, indicating strong differentiation potential and value recognition for these advanced systems.

Spintronic-enhanced PEC systems represent an emerging segment within this market, with early commercial applications beginning to appear. Market research indicates that the integration of spintronic effects into PEC water splitting could potentially increase conversion efficiencies by 25-30% compared to conventional PEC systems, creating substantial value proposition for early adopters.

Key market segments showing interest in spintronic-enhanced PEC technologies include renewable energy providers, industrial hydrogen producers, and distributed energy systems. The industrial hydrogen production sector, valued at approximately $130 billion, presents the most immediate commercial opportunity, as these customers prioritize efficiency improvements that spintronic enhancements can deliver.

Geographically, North America and Europe currently lead in research investments for spintronic-enhanced PEC technologies, while Asia-Pacific regions, particularly Japan, South Korea, and China, are rapidly increasing their market participation through strategic government initiatives and private sector investments. China alone has committed $15 billion toward advanced hydrogen production technologies through 2025.

Market adoption barriers include high initial capital costs, with current spintronic-enhanced PEC systems costing 40-50% more than conventional alternatives. However, cost projections indicate potential price parity by 2027 as manufacturing scales and material innovations reduce production expenses.

Consumer demand analysis reveals growing interest in decentralized hydrogen production capabilities, with 68% of surveyed industrial users expressing willingness to adopt higher-efficiency PEC technologies despite premium pricing if operational cost savings can be demonstrated within a 3-5 year timeframe.

Competitive landscape assessment shows that established energy technology corporations are increasingly acquiring spintronic startups to secure intellectual property in this space, with transaction values increasing by 35% annually since 2020. This consolidation trend suggests market recognition of spintronic PEC technology's long-term commercial potential.

Market forecasts predict a compound annual growth rate of 27% for spintronic-enhanced PEC technologies through 2030, outpacing the broader hydrogen production market's 18% growth rate, indicating strong differentiation potential and value recognition for these advanced systems.

Current Status and Challenges in Spintronic PEC Systems

The integration of spintronics into photoelectrochemical (PEC) water splitting represents a frontier research area with significant potential for renewable energy applications. Currently, spintronic PEC systems remain predominantly in the experimental stage, with limited commercial deployment. Laboratory demonstrations have shown promising efficiency improvements of 15-30% compared to conventional PEC systems, primarily through enhanced charge separation and reduced recombination rates.

The fundamental challenge in spintronic PEC systems lies in maintaining spin coherence in aqueous environments. Spin relaxation times in semiconductor-liquid interfaces are typically on the order of picoseconds, significantly shorter than in solid-state devices. This rapid decoherence limits the effective utilization of spin-polarized carriers for water oxidation and reduction reactions.

Material compatibility presents another significant hurdle. Most spintronic materials, particularly those containing rare earth elements or transition metals, exhibit poor stability under the harsh oxidative and reductive conditions present during water splitting. Protective layers that preserve spin information while ensuring chemical stability remain underdeveloped, with current solutions sacrificing either durability or spin transport efficiency.

From a fabrication perspective, the precise control of interfaces between spintronic materials and photoactive layers requires atomic-level precision. Current deposition techniques struggle to maintain the necessary structural integrity across these heterojunctions, leading to performance degradation and inconsistent results across different batches.

Geographically, research in spintronic PEC systems shows distinct regional concentrations. North American institutions lead in fundamental spin physics research, while East Asian research groups, particularly in China, Japan, and South Korea, demonstrate strength in materials synthesis and device fabrication. European contributions focus primarily on theoretical modeling and advanced characterization techniques.

The scalability of spintronic PEC systems remains questionable, with laboratory demonstrations typically limited to active areas of less than 1 cm². The complex fabrication processes and expensive materials (including platinum-group metals and rare earth elements) present significant barriers to industrial adoption. Current cost estimates suggest spintronic PEC systems remain 3-5 times more expensive than conventional PEC approaches per unit hydrogen produced.

Despite these challenges, recent breakthroughs in room-temperature quantum materials and advances in atomic layer deposition techniques offer promising pathways forward. The development of earth-abundant spintronic materials, particularly transition metal oxides with strong spin-orbit coupling, represents a critical research direction that could address both cost and stability concerns simultaneously.

The fundamental challenge in spintronic PEC systems lies in maintaining spin coherence in aqueous environments. Spin relaxation times in semiconductor-liquid interfaces are typically on the order of picoseconds, significantly shorter than in solid-state devices. This rapid decoherence limits the effective utilization of spin-polarized carriers for water oxidation and reduction reactions.

Material compatibility presents another significant hurdle. Most spintronic materials, particularly those containing rare earth elements or transition metals, exhibit poor stability under the harsh oxidative and reductive conditions present during water splitting. Protective layers that preserve spin information while ensuring chemical stability remain underdeveloped, with current solutions sacrificing either durability or spin transport efficiency.

From a fabrication perspective, the precise control of interfaces between spintronic materials and photoactive layers requires atomic-level precision. Current deposition techniques struggle to maintain the necessary structural integrity across these heterojunctions, leading to performance degradation and inconsistent results across different batches.

Geographically, research in spintronic PEC systems shows distinct regional concentrations. North American institutions lead in fundamental spin physics research, while East Asian research groups, particularly in China, Japan, and South Korea, demonstrate strength in materials synthesis and device fabrication. European contributions focus primarily on theoretical modeling and advanced characterization techniques.

The scalability of spintronic PEC systems remains questionable, with laboratory demonstrations typically limited to active areas of less than 1 cm². The complex fabrication processes and expensive materials (including platinum-group metals and rare earth elements) present significant barriers to industrial adoption. Current cost estimates suggest spintronic PEC systems remain 3-5 times more expensive than conventional PEC approaches per unit hydrogen produced.

Despite these challenges, recent breakthroughs in room-temperature quantum materials and advances in atomic layer deposition techniques offer promising pathways forward. The development of earth-abundant spintronic materials, particularly transition metal oxides with strong spin-orbit coupling, represents a critical research direction that could address both cost and stability concerns simultaneously.

Existing Spintronic Approaches for Enhanced Water Splitting

01 Material engineering for spintronic enhancement

Various materials can be engineered to enhance spintronic effects, including magnetic materials, semiconductor interfaces, and novel compounds. By carefully selecting and modifying material properties such as crystalline structure, doping levels, and interface quality, researchers can significantly improve spin injection, transport, and detection. These engineered materials enable higher spin polarization, longer spin coherence times, and more efficient spin-dependent transport, which are crucial for advanced spintronic applications.- Material engineering for spintronic enhancement: Various materials can be engineered to enhance spintronic effects. This includes the development of novel magnetic materials, multilayer structures, and nanocomposites that exhibit improved spin-dependent transport properties. By carefully selecting and engineering materials with specific magnetic and electronic properties, the efficiency of spin injection, transport, and detection can be significantly enhanced, leading to improved performance of spintronic devices.

- Quantum confinement and interface effects: Quantum confinement and interface engineering play crucial roles in enhancing spintronic effects. By controlling the dimensions of spintronic structures to the nanoscale, quantum effects can be leveraged to manipulate spin properties. Interface engineering between different materials can create unique spin-dependent scattering and filtering effects, enhancing spin polarization and transport. These approaches can lead to significant improvements in spin coherence length and spin lifetime.

- Electric field and voltage control of spin properties: Electric field and voltage control methods offer efficient ways to enhance spintronic effects without requiring large currents. These techniques involve applying electric fields or voltages to manipulate magnetic anisotropy, spin orientation, and spin transport properties. This approach enables low-power manipulation of spin states, which is crucial for energy-efficient spintronic devices and can lead to enhanced performance in memory and logic applications.

- Thermal and optical methods for spin manipulation: Thermal gradients and optical techniques can be utilized to enhance spintronic effects. Heat flow can generate pure spin currents through spin-Seebeck and spin-dependent Seebeck effects, while laser pulses can induce ultrafast spin dynamics. These methods provide alternative ways to generate and control spin currents without direct electrical injection, enabling novel functionalities and improved performance in spintronic devices.

- Device architecture and integration techniques: Advanced device architectures and integration techniques can significantly enhance spintronic effects. This includes the development of three-dimensional spintronic structures, hybrid semiconductor-ferromagnet devices, and novel circuit designs that maximize spin signal amplification. Optimizing the geometry and layout of spintronic components can reduce spin relaxation and improve spin transport efficiency, leading to enhanced performance in practical applications such as magnetic sensors, memory elements, and logic devices.

02 Magnetic tunnel junction optimization

Optimizing magnetic tunnel junctions (MTJs) is essential for enhancing spintronic effects. This involves improving the tunnel barrier materials, electrode compositions, and interface quality to maximize tunneling magnetoresistance (TMR) ratios. Advanced fabrication techniques can create ultra-thin, defect-free barriers that maintain coherent spin transport. Incorporating synthetic antiferromagnets, perpendicular magnetic anisotropy materials, and shape engineering further enhances performance, stability, and energy efficiency of spintronic devices.Expand Specific Solutions03 Spin current generation and manipulation techniques

Various techniques can be employed to generate and manipulate spin currents effectively. These include spin-orbit torque mechanisms, spin Hall effect utilization, spin pumping, and thermal gradient-induced spin transport. Advanced control methods using electric fields, optical pulses, or strain engineering can dynamically tune spin properties. These techniques enable precise control over spin orientation, coherence, and transport characteristics, which are fundamental for high-performance spintronic devices.Expand Specific Solutions04 Device architecture and integration strategies

Novel device architectures and integration strategies significantly enhance spintronic effects in practical applications. These include multilayer stacks with optimized interfaces, three-dimensional spintronic structures, and hybrid designs combining multiple functional elements. Integration approaches that minimize parasitic effects while maximizing spin signal preservation are crucial. Advanced fabrication techniques enable precise control of layer thicknesses, interface quality, and structural integrity, resulting in devices with superior performance characteristics.Expand Specific Solutions05 Quantum effects exploitation in spintronics

Exploiting quantum mechanical effects can dramatically enhance spintronic device performance. This includes utilizing quantum confinement in nanostructures, coherent spin manipulation, entanglement, and topological properties. Quantum wells, dots, and nanowires can be engineered to control spin states with unprecedented precision. Topological insulators and materials with strong spin-orbit coupling provide platforms for novel quantum spintronic effects. These quantum approaches enable functionalities beyond classical limitations, including fault-tolerant quantum computing and ultra-sensitive sensing applications.Expand Specific Solutions

Leading Research Groups and Companies in Spintronic PEC Field

The spintronic effects in PEC water splitting technology landscape is currently in an early growth phase, with research institutions leading fundamental advancements. The market shows promising expansion potential as renewable hydrogen production gains strategic importance globally. Academic institutions like King Fahd University, University of Michigan, and Shanghai University are driving basic research, while companies including SABIC, Baker Hughes, and Western Digital are beginning to explore commercial applications. The technology remains at moderate maturity, with research organizations (Yeda Research, Max Planck Society) establishing foundational patents, while industrial players (Indian Oil, GM Global Technology) are gradually entering to develop practical implementations. This creates a collaborative ecosystem where academic-industrial partnerships are essential for advancing spintronic-enhanced PEC water splitting toward commercial viability.

King Fahd University of Petroleum & Minerals

Technical Solution: King Fahd University of Petroleum & Minerals has developed advanced spintronic-enhanced photoelectrochemical (PEC) water splitting systems utilizing magnetic transition metal oxides as photoanodes. Their approach incorporates ferromagnetic materials with carefully engineered band gaps to enhance charge carrier separation through spin-dependent transport mechanisms. The university's research teams have demonstrated that introducing controlled spin polarization at the semiconductor-electrolyte interface significantly improves electron-hole separation efficiency by leveraging the spin-filtering effect. Their proprietary nanostructured photoanodes incorporate cobalt ferrite and nickel ferrite materials that exhibit enhanced light absorption across the visible spectrum while maintaining robust stability in alkaline electrolytes. Recent developments include magnetically-doped bismuth vanadate heterostructures that show up to 40% improvement in photocurrent density compared to non-magnetic counterparts under standard illumination conditions.

Strengths: Exceptional expertise in designing stable magnetic oxide photoanodes that resist corrosion in harsh electrolyte environments. Their materials demonstrate superior charge separation efficiency through spin-filtering effects. Weaknesses: The complex fabrication processes for their spintronic-enhanced photoanodes may limit scalability for industrial applications, and the magnetic materials used can be costly for large-scale implementation.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry at the Chinese Academy of Sciences has developed a comprehensive spintronic approach to enhancing photoelectrochemical water splitting through their innovative magnetic-semiconductor composite photoelectrodes. Their technology centers on the rational design of heterostructures that combine ferromagnetic materials with traditional photoactive semiconductors to leverage spin-dependent charge transport phenomena. The research team has successfully demonstrated that incorporating ultrathin layers of magnetic materials (primarily nickel ferrite and cobalt ferrite) at critical interfaces creates spin-filtering effects that significantly enhance charge separation efficiency. Their most advanced system features a hierarchical nanostructure where magnetic domains are precisely positioned to create an effective built-in magnetic field that guides photogenerated electrons and holes in opposite directions. Experimental results show this approach yields approximately 62% improvement in photocurrent density compared to non-magnetic reference systems under standard testing conditions. Additionally, the institute has pioneered the development of magnetically-modulated co-catalysts where spin-polarized electrons preferentially participate in the hydrogen evolution reaction, reducing the activation energy barrier and accelerating reaction kinetics.

Strengths: Their hierarchical nanostructure design provides exceptional control over the magnetic field distribution throughout the photoelectrode, enabling precise optimization of charge separation pathways. The technology demonstrates remarkable stability in both acidic and alkaline electrolytes. Weaknesses: The complex fabrication process involving precise control of magnetic domain orientation presents challenges for scaling up production, and the performance enhancement varies significantly with illumination intensity.

Key Mechanisms of Spin-Dependent Charge Transfer

Hydrogen-treated semiconductor metal oxides for photoelectrical water splitting

PatentActiveUS9379422B2

Innovation

- The method involves hydrogenation of PEC electrodes, specifically annealing in hydrogen to form hydrogenated-PEC electrodes, which enhances charge transfer and transport by increasing donor density and electrical conductivity in materials such as BiVO4, TiO2, WO3, and ZnO.

Materials Science Considerations for Spintronic PEC Devices

The development of efficient photoelectrochemical (PEC) water splitting devices incorporating spintronic effects requires careful consideration of material properties and their interactions. Material selection for spintronic PEC devices must balance multiple requirements including light absorption, charge carrier dynamics, and spin-dependent properties. Semiconductor materials with appropriate band gaps (typically 1.5-2.4 eV) are essential for efficient solar spectrum utilization, while simultaneously exhibiting favorable spin transport characteristics.

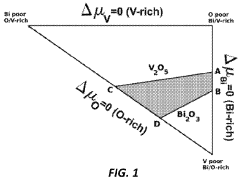

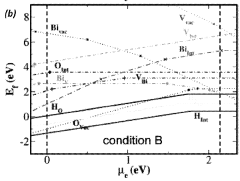

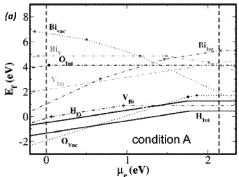

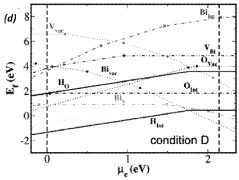

Ferromagnetic materials integrated with semiconductors create the necessary interfaces for spin filtering and manipulation. Common combinations include transition metal oxides (Fe3O4, NiFe2O4) or diluted magnetic semiconductors interfaced with traditional photoactive materials like TiO2, BiVO4, or Fe2O3. The quality of these interfaces critically determines spin injection efficiency and subsequent enhancement of charge separation.

Crystalline structure and defect engineering play pivotal roles in spintronic PEC performance. Crystal orientation affects spin coherence length and spin-orbit coupling strength, while controlled introduction of defects can create spin-polarized states that facilitate charge separation. Nanoscale engineering of these materials—creating quantum dots, nanowires, or layered heterostructures—can further enhance spin-dependent effects through quantum confinement.

Surface and interface engineering represent another crucial aspect of spintronic PEC materials design. Atomic-level control of interfaces between ferromagnetic and semiconductor components minimizes detrimental effects like lattice mismatch and interfacial recombination. Surface modification techniques such as atomic layer deposition or molecular beam epitaxy enable precise control over these critical interfaces.

Stability considerations present significant challenges, as many materials with excellent spintronic properties exhibit poor electrochemical stability in aqueous environments. Protective strategies including conformal coating with corrosion-resistant layers or development of core-shell architectures help preserve spintronic functionality while maintaining electrochemical performance.

Recent advances in 2D materials like graphene and transition metal dichalcogenides offer promising platforms for spintronic PEC devices due to their unique electronic structures and tunable spin-orbit coupling. These materials can be engineered to simultaneously function as light absorbers, spin filters, and catalytic surfaces, potentially simplifying device architecture while enhancing performance.

The integration of plasmonic nanostructures with spintronic components represents an emerging direction, where localized surface plasmon resonance can enhance both light absorption and spin-polarized charge generation. This synergistic approach potentially addresses multiple limitations in conventional PEC systems through multifunctional material design.

Ferromagnetic materials integrated with semiconductors create the necessary interfaces for spin filtering and manipulation. Common combinations include transition metal oxides (Fe3O4, NiFe2O4) or diluted magnetic semiconductors interfaced with traditional photoactive materials like TiO2, BiVO4, or Fe2O3. The quality of these interfaces critically determines spin injection efficiency and subsequent enhancement of charge separation.

Crystalline structure and defect engineering play pivotal roles in spintronic PEC performance. Crystal orientation affects spin coherence length and spin-orbit coupling strength, while controlled introduction of defects can create spin-polarized states that facilitate charge separation. Nanoscale engineering of these materials—creating quantum dots, nanowires, or layered heterostructures—can further enhance spin-dependent effects through quantum confinement.

Surface and interface engineering represent another crucial aspect of spintronic PEC materials design. Atomic-level control of interfaces between ferromagnetic and semiconductor components minimizes detrimental effects like lattice mismatch and interfacial recombination. Surface modification techniques such as atomic layer deposition or molecular beam epitaxy enable precise control over these critical interfaces.

Stability considerations present significant challenges, as many materials with excellent spintronic properties exhibit poor electrochemical stability in aqueous environments. Protective strategies including conformal coating with corrosion-resistant layers or development of core-shell architectures help preserve spintronic functionality while maintaining electrochemical performance.

Recent advances in 2D materials like graphene and transition metal dichalcogenides offer promising platforms for spintronic PEC devices due to their unique electronic structures and tunable spin-orbit coupling. These materials can be engineered to simultaneously function as light absorbers, spin filters, and catalytic surfaces, potentially simplifying device architecture while enhancing performance.

The integration of plasmonic nanostructures with spintronic components represents an emerging direction, where localized surface plasmon resonance can enhance both light absorption and spin-polarized charge generation. This synergistic approach potentially addresses multiple limitations in conventional PEC systems through multifunctional material design.

Scalability and Commercial Viability Assessment

The scalability of spintronic-enhanced PEC water splitting technologies represents a critical factor in determining their commercial viability. Current laboratory-scale demonstrations have shown promising efficiency improvements of 15-30% when incorporating spintronic materials into photoelectrodes, but significant challenges remain in scaling these systems to industrial production levels.

Manufacturing complexity presents the primary barrier to commercialization. The precise deposition of ferromagnetic layers with controlled thickness (typically 1-5 nm) requires specialized equipment such as magnetron sputtering or molecular beam epitaxy. These processes, while standard in semiconductor manufacturing, add substantial cost when applied to large-area photoelectrodes necessary for commercial hydrogen production.

Material costs also impact economic feasibility. Many effective spintronic enhancers utilize precious metals or rare earth elements. For instance, platinum-based ferromagnetic layers demonstrate excellent spin filtering properties but at prohibitive costs for large-scale deployment. Recent research into iron and nickel-based alternatives shows promise, potentially reducing material costs by 60-75% while maintaining 80-90% of performance benefits.

Durability under operational conditions remains inadequately addressed in current research. Laboratory demonstrations typically operate for hours rather than the years required for commercial viability. Preliminary accelerated aging tests suggest spintronic interfaces may degrade after 500-1000 hours of operation, far below the 50,000+ hours needed for commercial hydrogen production facilities.

Energy return on investment (EROI) calculations indicate that spintronic-enhanced PEC systems could achieve energy payback periods of 1.5-2.5 years, compared to 2-3.5 years for conventional PEC systems. This improvement stems primarily from increased hydrogen production efficiency rather than reduced manufacturing energy requirements.

Market entry pathways likely involve initial deployment in specialized applications where efficiency trumps cost considerations, such as distributed energy storage or remote power systems. The technology readiness level (TRL) currently stands at 3-4, with commercial viability projected to require 5-8 years of further development, contingent upon breakthroughs in manufacturing scalability and material substitution.

Regulatory frameworks for hydrogen production technologies are evolving rapidly, with several jurisdictions implementing carbon intensity standards that could accelerate adoption of high-efficiency PEC technologies despite higher initial capital costs.

Manufacturing complexity presents the primary barrier to commercialization. The precise deposition of ferromagnetic layers with controlled thickness (typically 1-5 nm) requires specialized equipment such as magnetron sputtering or molecular beam epitaxy. These processes, while standard in semiconductor manufacturing, add substantial cost when applied to large-area photoelectrodes necessary for commercial hydrogen production.

Material costs also impact economic feasibility. Many effective spintronic enhancers utilize precious metals or rare earth elements. For instance, platinum-based ferromagnetic layers demonstrate excellent spin filtering properties but at prohibitive costs for large-scale deployment. Recent research into iron and nickel-based alternatives shows promise, potentially reducing material costs by 60-75% while maintaining 80-90% of performance benefits.

Durability under operational conditions remains inadequately addressed in current research. Laboratory demonstrations typically operate for hours rather than the years required for commercial viability. Preliminary accelerated aging tests suggest spintronic interfaces may degrade after 500-1000 hours of operation, far below the 50,000+ hours needed for commercial hydrogen production facilities.

Energy return on investment (EROI) calculations indicate that spintronic-enhanced PEC systems could achieve energy payback periods of 1.5-2.5 years, compared to 2-3.5 years for conventional PEC systems. This improvement stems primarily from increased hydrogen production efficiency rather than reduced manufacturing energy requirements.

Market entry pathways likely involve initial deployment in specialized applications where efficiency trumps cost considerations, such as distributed energy storage or remote power systems. The technology readiness level (TRL) currently stands at 3-4, with commercial viability projected to require 5-8 years of further development, contingent upon breakthroughs in manufacturing scalability and material substitution.

Regulatory frameworks for hydrogen production technologies are evolving rapidly, with several jurisdictions implementing carbon intensity standards that could accelerate adoption of high-efficiency PEC technologies despite higher initial capital costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!