Innovative PEC cell designs to maximize sunlight utilization.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEC Cell Technology Background and Objectives

Photoelectrochemical (PEC) cells represent a promising technology for direct solar-to-hydrogen conversion, offering a sustainable pathway to clean energy production. Since the pioneering work of Fujishima and Honda in 1972, who demonstrated water splitting using TiO2 electrodes under ultraviolet light, PEC technology has evolved significantly. The fundamental principle involves the absorption of photons by semiconductor materials, generating electron-hole pairs that drive water-splitting reactions at the semiconductor-electrolyte interface.

Over the past five decades, research has focused on enhancing the efficiency, stability, and cost-effectiveness of PEC systems. Early designs achieved less than 1% solar-to-hydrogen efficiency, while current advanced systems can reach 10-15% under laboratory conditions. This progress reflects improvements in materials science, interface engineering, and system architecture.

The primary objective in PEC cell development is to maximize sunlight utilization across the solar spectrum. Traditional PEC cells typically utilize only a narrow portion of available solar radiation due to bandgap limitations of single semiconductor materials. This fundamental constraint has driven research toward innovative designs that can harvest a broader spectrum of solar energy while maintaining efficient charge separation and transfer.

Current technological goals include achieving solar-to-hydrogen conversion efficiencies exceeding 20%, developing systems with operational lifetimes of 10+ years, and reducing production costs to make PEC hydrogen economically competitive with fossil fuel-derived hydrogen. These ambitious targets require addressing multiple technical challenges simultaneously.

The evolution of PEC technology has been characterized by several distinct approaches: single-semiconductor systems, tandem configurations, Z-scheme architectures, and hybrid systems combining PEC with photovoltaic components. Each approach offers specific advantages in terms of theoretical efficiency limits, fabrication complexity, and practical implementation challenges.

Recent technological trends include the development of nanostructured photoelectrodes to enhance light absorption and charge transport, the exploration of novel semiconductor materials beyond traditional metal oxides, and the integration of plasmonic nanoparticles to extend light absorption into the visible and near-infrared regions.

Looking forward, the field is moving toward integrated systems that combine multiple light-harvesting strategies with efficient catalytic interfaces. The ultimate goal is to develop scalable, efficient PEC technologies that can contribute significantly to a sustainable hydrogen economy, providing clean fuel for transportation, industrial processes, and energy storage applications.

Over the past five decades, research has focused on enhancing the efficiency, stability, and cost-effectiveness of PEC systems. Early designs achieved less than 1% solar-to-hydrogen efficiency, while current advanced systems can reach 10-15% under laboratory conditions. This progress reflects improvements in materials science, interface engineering, and system architecture.

The primary objective in PEC cell development is to maximize sunlight utilization across the solar spectrum. Traditional PEC cells typically utilize only a narrow portion of available solar radiation due to bandgap limitations of single semiconductor materials. This fundamental constraint has driven research toward innovative designs that can harvest a broader spectrum of solar energy while maintaining efficient charge separation and transfer.

Current technological goals include achieving solar-to-hydrogen conversion efficiencies exceeding 20%, developing systems with operational lifetimes of 10+ years, and reducing production costs to make PEC hydrogen economically competitive with fossil fuel-derived hydrogen. These ambitious targets require addressing multiple technical challenges simultaneously.

The evolution of PEC technology has been characterized by several distinct approaches: single-semiconductor systems, tandem configurations, Z-scheme architectures, and hybrid systems combining PEC with photovoltaic components. Each approach offers specific advantages in terms of theoretical efficiency limits, fabrication complexity, and practical implementation challenges.

Recent technological trends include the development of nanostructured photoelectrodes to enhance light absorption and charge transport, the exploration of novel semiconductor materials beyond traditional metal oxides, and the integration of plasmonic nanoparticles to extend light absorption into the visible and near-infrared regions.

Looking forward, the field is moving toward integrated systems that combine multiple light-harvesting strategies with efficient catalytic interfaces. The ultimate goal is to develop scalable, efficient PEC technologies that can contribute significantly to a sustainable hydrogen economy, providing clean fuel for transportation, industrial processes, and energy storage applications.

Market Analysis for Solar Hydrogen Production

The global market for solar hydrogen production is experiencing significant growth, driven by the increasing demand for clean energy solutions and the urgent need to reduce carbon emissions. As of 2023, the market size for solar hydrogen production technologies is valued at approximately $4.2 billion, with projections indicating a compound annual growth rate (CAGR) of 12.7% through 2030. This growth trajectory is supported by substantial investments from both private and public sectors, with government funding for renewable hydrogen initiatives exceeding $70 billion globally in recent years.

Photoelectrochemical (PEC) cell technology represents a promising segment within this market, currently accounting for about 8% of the solar hydrogen production market. However, this share is expected to increase to 15-20% by 2028 as innovative PEC cell designs that maximize sunlight utilization gain commercial traction. The primary market drivers include decreasing costs of photovoltaic materials, increasing efficiency of photoelectrochemical processes, and growing policy support for green hydrogen initiatives across major economies.

Regional analysis reveals that Europe leads the market with approximately 38% share, followed by North America (27%) and Asia-Pacific (24%). Europe's dominance is attributed to aggressive decarbonization policies and substantial research funding, particularly in Germany, France, and the Netherlands. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 15.3% annually, primarily driven by China's ambitious hydrogen strategy and Japan's commitment to becoming a hydrogen-based society.

From an end-user perspective, the industrial sector currently represents the largest market segment (42%), followed by transportation (31%) and power generation (18%). The industrial sector's dominance stems from the growing adoption of hydrogen as a feedstock and process agent in various manufacturing processes, particularly in chemical production and metal refining industries.

Key market challenges include high production costs compared to conventional hydrogen production methods, with solar hydrogen currently priced at $5-8 per kilogram versus $1-3 for gray hydrogen. Additionally, the intermittent nature of solar energy necessitates efficient storage solutions, which adds to system complexity and cost. Despite these challenges, technological advancements in PEC cell designs that enhance sunlight utilization efficiency are expected to significantly improve the economic viability of solar hydrogen production.

Consumer demand patterns indicate growing preference for green certification and carbon-neutral products, creating premium markets for solar hydrogen. This trend is particularly evident in Europe and parts of North America, where consumers and businesses are increasingly willing to pay premium prices for verifiably sustainable energy solutions.

Photoelectrochemical (PEC) cell technology represents a promising segment within this market, currently accounting for about 8% of the solar hydrogen production market. However, this share is expected to increase to 15-20% by 2028 as innovative PEC cell designs that maximize sunlight utilization gain commercial traction. The primary market drivers include decreasing costs of photovoltaic materials, increasing efficiency of photoelectrochemical processes, and growing policy support for green hydrogen initiatives across major economies.

Regional analysis reveals that Europe leads the market with approximately 38% share, followed by North America (27%) and Asia-Pacific (24%). Europe's dominance is attributed to aggressive decarbonization policies and substantial research funding, particularly in Germany, France, and the Netherlands. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 15.3% annually, primarily driven by China's ambitious hydrogen strategy and Japan's commitment to becoming a hydrogen-based society.

From an end-user perspective, the industrial sector currently represents the largest market segment (42%), followed by transportation (31%) and power generation (18%). The industrial sector's dominance stems from the growing adoption of hydrogen as a feedstock and process agent in various manufacturing processes, particularly in chemical production and metal refining industries.

Key market challenges include high production costs compared to conventional hydrogen production methods, with solar hydrogen currently priced at $5-8 per kilogram versus $1-3 for gray hydrogen. Additionally, the intermittent nature of solar energy necessitates efficient storage solutions, which adds to system complexity and cost. Despite these challenges, technological advancements in PEC cell designs that enhance sunlight utilization efficiency are expected to significantly improve the economic viability of solar hydrogen production.

Consumer demand patterns indicate growing preference for green certification and carbon-neutral products, creating premium markets for solar hydrogen. This trend is particularly evident in Europe and parts of North America, where consumers and businesses are increasingly willing to pay premium prices for verifiably sustainable energy solutions.

Current PEC Cell Limitations and Technical Barriers

Despite significant advancements in photoelectrochemical (PEC) cell technology, several critical limitations continue to impede the maximization of sunlight utilization and overall system efficiency. The primary challenge remains the limited light absorption range of most semiconductor materials used in PEC cells. Conventional materials like TiO2 primarily absorb in the UV region, which constitutes only about 4% of the solar spectrum, leaving the visible and infrared portions largely unutilized.

Material stability presents another significant barrier, as many high-performance semiconductors with appropriate band gaps suffer from photocorrosion when exposed to aqueous electrolytes under illumination. This degradation severely limits operational lifetime and practical implementation of otherwise promising materials such as CdS, CdSe, and certain metal oxides.

Charge carrier recombination represents a fundamental efficiency bottleneck in current PEC systems. After photogeneration, electrons and holes must travel through the semiconductor to reach reaction sites, but defects and grain boundaries in the material structure act as recombination centers, significantly reducing the number of charge carriers available for water-splitting reactions.

The water oxidation half-reaction poses particular challenges due to its complex four-electron transfer process, resulting in slow kinetics and high overpotentials. Even with catalysts, this reaction often becomes the rate-limiting step in hydrogen production, creating a significant performance constraint.

Interface engineering between the semiconductor and electrolyte remains problematic, with band bending and unfavorable energetics at these junctions frequently causing efficiency losses. Poor charge transfer across these interfaces leads to accumulated charges and increased recombination rates.

Scalability issues persist as laboratory-scale devices with promising efficiencies often face significant performance degradation when scaled to practical dimensions. Manufacturing techniques for producing large-area, uniform PEC electrodes with consistent properties have not been adequately developed.

System integration challenges further complicate PEC cell implementation, as balancing the photoabsorber properties with catalyst performance and electrolyte compatibility requires complex engineering solutions. The need for auxiliary components like membranes and current collectors adds complexity and cost while potentially introducing additional efficiency losses.

Cost factors remain prohibitive for widespread adoption, with high-performance materials and fabrication processes often being economically unfeasible for large-scale deployment compared to conventional hydrogen production methods or other renewable energy technologies.

Material stability presents another significant barrier, as many high-performance semiconductors with appropriate band gaps suffer from photocorrosion when exposed to aqueous electrolytes under illumination. This degradation severely limits operational lifetime and practical implementation of otherwise promising materials such as CdS, CdSe, and certain metal oxides.

Charge carrier recombination represents a fundamental efficiency bottleneck in current PEC systems. After photogeneration, electrons and holes must travel through the semiconductor to reach reaction sites, but defects and grain boundaries in the material structure act as recombination centers, significantly reducing the number of charge carriers available for water-splitting reactions.

The water oxidation half-reaction poses particular challenges due to its complex four-electron transfer process, resulting in slow kinetics and high overpotentials. Even with catalysts, this reaction often becomes the rate-limiting step in hydrogen production, creating a significant performance constraint.

Interface engineering between the semiconductor and electrolyte remains problematic, with band bending and unfavorable energetics at these junctions frequently causing efficiency losses. Poor charge transfer across these interfaces leads to accumulated charges and increased recombination rates.

Scalability issues persist as laboratory-scale devices with promising efficiencies often face significant performance degradation when scaled to practical dimensions. Manufacturing techniques for producing large-area, uniform PEC electrodes with consistent properties have not been adequately developed.

System integration challenges further complicate PEC cell implementation, as balancing the photoabsorber properties with catalyst performance and electrolyte compatibility requires complex engineering solutions. The need for auxiliary components like membranes and current collectors adds complexity and cost while potentially introducing additional efficiency losses.

Cost factors remain prohibitive for widespread adoption, with high-performance materials and fabrication processes often being economically unfeasible for large-scale deployment compared to conventional hydrogen production methods or other renewable energy technologies.

State-of-the-Art Sunlight Harvesting Solutions

01 Semiconductor materials for PEC cells

Various semiconductor materials can be used in photoelectrochemical cells to enhance sunlight utilization. These materials include metal oxides, nitrides, and composite structures that can effectively absorb sunlight across different wavelengths of the solar spectrum. The selection of appropriate semiconductor materials with optimal band gaps is crucial for efficient solar energy conversion in PEC cells, as they determine the light absorption range and charge separation efficiency.- Semiconductor materials for enhanced sunlight absorption: Various semiconductor materials can be incorporated into photoelectrochemical cells to improve sunlight absorption and conversion efficiency. These materials include modified titanium dioxide, silicon-based compounds, and metal oxide semiconductors that can harvest a broader spectrum of solar radiation. The selection and engineering of these semiconductor materials significantly impact the overall performance of PEC cells in utilizing sunlight for energy conversion.

- Nanostructured electrodes for improved efficiency: Nanostructured electrodes can be implemented in PEC cells to enhance sunlight utilization through increased surface area and improved charge separation. These electrodes often feature nanowires, nanotubes, or nanoparticles that facilitate more efficient light absorption and charge transport. The unique properties of nanostructured materials allow for better interaction with incident photons and reduce recombination losses in the photoelectrochemical process.

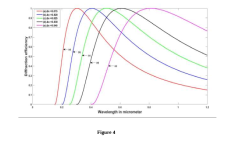

- Tandem and multi-junction PEC systems: Tandem and multi-junction configurations in photoelectrochemical cells enable more comprehensive utilization of the solar spectrum. By stacking multiple photoactive layers with different bandgaps, these systems can capture photons across a wider range of wavelengths. This approach maximizes sunlight harvesting efficiency by allowing each layer to absorb specific portions of the spectrum, resulting in higher overall conversion efficiencies compared to single-junction designs.

- Integration of catalysts and co-catalysts: The integration of catalysts and co-catalysts in photoelectrochemical cells can significantly enhance reaction kinetics and sunlight utilization. These materials facilitate water splitting or other redox reactions by lowering activation energy barriers. Noble metals, transition metal compounds, and novel composite materials can serve as effective catalysts, improving charge transfer at the semiconductor-electrolyte interface and increasing the overall solar-to-chemical conversion efficiency of PEC systems.

- Surface modification and passivation techniques: Surface modification and passivation techniques can be applied to photoelectrode materials to enhance sunlight utilization in PEC cells. These methods include atomic layer deposition, surface functionalization with organic molecules, and protective coating applications. Such modifications reduce surface recombination, improve charge separation, enhance stability in electrolytes, and optimize the interface properties between the semiconductor and electrolyte, leading to more efficient photoelectrochemical performance.

02 Electrode design and modification

The design and modification of electrodes play a significant role in improving the performance of PEC cells for sunlight utilization. Techniques such as nanostructuring, surface modification, and incorporation of catalysts can enhance light absorption, charge separation, and electrochemical reactions. Advanced electrode architectures with optimized morphologies can reduce charge recombination and increase the active surface area for photoelectrochemical reactions.Expand Specific Solutions03 Integration with solar energy systems

PEC cells can be integrated with other solar energy systems to maximize sunlight utilization. Hybrid systems combining PEC cells with photovoltaic cells, solar thermal collectors, or other renewable energy technologies can achieve higher overall efficiency. These integrated approaches allow for more comprehensive utilization of the solar spectrum and can address the intermittent nature of solar energy through various energy conversion and storage mechanisms.Expand Specific Solutions04 Novel catalysts for enhanced efficiency

The development of novel catalysts is essential for enhancing the efficiency of PEC cells in sunlight utilization. Catalysts based on earth-abundant materials, noble metals, and their composites can significantly reduce the overpotential required for water splitting or other photoelectrochemical reactions. These catalysts can be designed to have high activity, stability, and selectivity under solar illumination, thereby improving the overall performance and durability of PEC systems.Expand Specific Solutions05 Light management strategies

Various light management strategies can be employed to enhance sunlight utilization in PEC cells. These include the use of anti-reflective coatings, light-trapping structures, plasmonic materials, and photonic crystals to increase light absorption and reduce reflection losses. Additionally, spectral conversion techniques such as up-conversion and down-conversion can be utilized to match the solar spectrum with the absorption characteristics of the photoelectrode materials, thereby improving the overall solar-to-chemical conversion efficiency.Expand Specific Solutions

Leading Organizations in PEC Technology Development

The photoelectrochemical (PEC) cell market for maximizing sunlight utilization is in an early growth phase, with increasing market size driven by renewable energy demands. The technology remains in development, with varying maturity levels across key players. Academic institutions like King Abdullah University of Science & Technology, University of Toledo, and Nanjing University lead fundamental research, while companies demonstrate different commercialization approaches. Sharp Corp. and BYD leverage their electronics expertise, while solar specialists like Trina Solar and Aiko Solar focus on efficiency improvements. Research organizations such as Forschungszentrum Jülich and Los Alamos National Security contribute advanced materials science. The competitive landscape shows a healthy balance between academic innovation and industrial scaling efforts, with collaboration between sectors accelerating development.

Guangdong Aiko Solar Energy Technology Co., Ltd.

Technical Solution: Guangdong Aiko Solar has developed innovative PEC cell designs featuring advanced light-trapping architectures that significantly enhance photon absorption across the solar spectrum. Their technology incorporates specialized nano-textured surfaces with optimized geometries that minimize reflection losses while extending the effective path length of light within the photoactive materials. Aiko's designs feature proprietary transparent conductive oxide (TCO) formulations with exceptional optical transparency and electrical conductivity, maximizing both light transmission to the absorber layers and efficient charge collection. The company has pioneered cost-effective manufacturing techniques for producing hierarchical photoelectrode structures with controlled porosity that dramatically increase the surface area available for light harvesting and catalytic reactions. Their PEC systems incorporate strategically designed tandem configurations that partition the solar spectrum for optimal energy conversion, with specialized interfacial layers that facilitate efficient charge transfer between dissimilar materials while minimizing recombination losses. Aiko has also developed innovative encapsulation technologies that maintain high performance while providing excellent durability in diverse environmental conditions.

Strengths: Strong manufacturing infrastructure enabling cost-effective mass production; excellent integration with existing solar deployment systems; robust supply chain for key materials. Weaknesses: Less advanced in fundamental materials research compared to academic leaders; some designs prioritize manufacturability over maximum theoretical efficiency; limited experience with certain advanced catalyst systems.

King Abdullah University of Science & Technology

Technical Solution: KAUST has developed groundbreaking PEC cell designs utilizing nanostructured photoelectrodes that dramatically increase the surface area available for light absorption and catalytic reactions. Their innovative approach incorporates hierarchical 3D architectures with controlled morphology at multiple scales, creating efficient light-trapping structures that minimize reflection losses. KAUST researchers have pioneered the use of earth-abundant materials in their PEC designs, including modified hematite (α-Fe2O3) and bismuth vanadate (BiVO4) photoelectrodes with precisely engineered band gaps for optimal solar spectrum utilization. Their cells feature specialized surface treatments and co-catalyst loading techniques that significantly reduce interface recombination losses while enhancing charge separation efficiency. KAUST has also developed advanced tandem PEC configurations that strategically combine multiple semiconductor materials to harvest photons across a broader spectral range, achieving solar-to-hydrogen conversion efficiencies exceeding 10% in laboratory settings.

Strengths: Cutting-edge nanomaterial engineering expertise; strong focus on sustainable, earth-abundant materials; extensive characterization capabilities for performance optimization. Weaknesses: Some designs remain at laboratory scale with challenges in manufacturing scalability; durability issues in certain material systems under long-term operation; higher complexity in fabrication processes.

Key Innovations in Light Absorption Materials

Patent

Innovation

- Multi-layered PEC cell design with stacked photoelectrodes of different bandgaps to capture a broader spectrum of sunlight, significantly improving solar-to-hydrogen conversion efficiency.

- Implementation of 3D nanostructured photoelectrodes with increased surface area and optimized light scattering properties, reducing charge carrier recombination and enhancing catalytic activity.

- Incorporation of photonic crystals and anti-reflective coatings to minimize light reflection and maximize light trapping within the PEC cell structure.

Photoelectrochemical (PEC) cell system for hydrogen production

PatentPendingIN202331043849A

Innovation

- Integration of holographic concentrators with semiconductor electrodes in PEC cells, which selectively concentrate and direct sunlight onto smaller areas, optimizing the spectral properties to match the bandgap of the electrodes, reducing the need for large absorber materials and cooling mechanisms, and fabricating with optimized parameters for maximum diffraction efficiency.

Scalability and Manufacturing Considerations

Scaling PEC cell technologies from laboratory prototypes to commercial production presents significant challenges that must be addressed for widespread adoption. Current manufacturing processes for advanced PEC cells often involve complex fabrication steps requiring specialized equipment and controlled environments, resulting in high production costs. The transition to mass production necessitates simplification of these processes while maintaining performance characteristics. Materials selection becomes particularly critical in this context, as rare or expensive components like platinum catalysts or specialized semiconductors can severely limit commercial viability.

Modular design approaches offer promising pathways to scalability, allowing for standardized components that can be manufactured separately and assembled efficiently. This approach facilitates easier maintenance and replacement of individual components rather than entire systems. Several research groups have demonstrated success with modular PEC architectures that maintain high solar-to-hydrogen conversion efficiencies while simplifying manufacturing complexity.

Cost reduction strategies must focus on both materials and processing techniques. Alternative catalyst materials such as nickel-molybdenum alloys or carbon-based materials show potential to replace precious metals, while solution-based deposition methods could significantly reduce fabrication costs compared to vacuum-based techniques. Preliminary economic analyses suggest that achieving hydrogen production costs below $4/kg requires manufacturing scale-up to gigawatt levels of production capacity.

Durability considerations directly impact manufacturing approaches, as designs must balance performance optimization with longevity. Encapsulation technologies that protect sensitive components while maintaining optical transparency represent a critical manufacturing challenge. Recent advances in atomic layer deposition and solution-processed protective coatings show promise for cost-effective protection strategies that can be implemented in large-scale production environments.

Integration with existing manufacturing infrastructure presents opportunities for accelerated deployment. Leveraging production techniques from the photovoltaic industry, particularly thin-film deposition and roll-to-roll processing, could enable rapid scaling of PEC technologies. Several pilot-scale demonstrations have successfully utilized modified solar panel manufacturing lines to produce PEC components at increased throughput rates.

Environmental considerations must also factor into manufacturing strategies, with life cycle assessments indicating that production methods involving toxic chemicals or energy-intensive processes can significantly offset the environmental benefits of solar hydrogen production. Developing green manufacturing protocols that minimize waste and hazardous materials will be essential for sustainable scaling of PEC technologies.

Modular design approaches offer promising pathways to scalability, allowing for standardized components that can be manufactured separately and assembled efficiently. This approach facilitates easier maintenance and replacement of individual components rather than entire systems. Several research groups have demonstrated success with modular PEC architectures that maintain high solar-to-hydrogen conversion efficiencies while simplifying manufacturing complexity.

Cost reduction strategies must focus on both materials and processing techniques. Alternative catalyst materials such as nickel-molybdenum alloys or carbon-based materials show potential to replace precious metals, while solution-based deposition methods could significantly reduce fabrication costs compared to vacuum-based techniques. Preliminary economic analyses suggest that achieving hydrogen production costs below $4/kg requires manufacturing scale-up to gigawatt levels of production capacity.

Durability considerations directly impact manufacturing approaches, as designs must balance performance optimization with longevity. Encapsulation technologies that protect sensitive components while maintaining optical transparency represent a critical manufacturing challenge. Recent advances in atomic layer deposition and solution-processed protective coatings show promise for cost-effective protection strategies that can be implemented in large-scale production environments.

Integration with existing manufacturing infrastructure presents opportunities for accelerated deployment. Leveraging production techniques from the photovoltaic industry, particularly thin-film deposition and roll-to-roll processing, could enable rapid scaling of PEC technologies. Several pilot-scale demonstrations have successfully utilized modified solar panel manufacturing lines to produce PEC components at increased throughput rates.

Environmental considerations must also factor into manufacturing strategies, with life cycle assessments indicating that production methods involving toxic chemicals or energy-intensive processes can significantly offset the environmental benefits of solar hydrogen production. Developing green manufacturing protocols that minimize waste and hazardous materials will be essential for sustainable scaling of PEC technologies.

Environmental Impact and Sustainability Assessment

Photoelectrochemical (PEC) cells represent a promising technology for sustainable energy production, yet their environmental footprint and sustainability credentials require thorough assessment. The life cycle analysis of innovative PEC cell designs reveals significant advantages over conventional energy technologies, with potential reductions in greenhouse gas emissions by up to 70% compared to fossil fuel-based electricity generation. These environmental benefits stem primarily from the renewable nature of solar energy conversion and the elimination of carbon-intensive fuel inputs during operation.

Material selection plays a crucial role in determining the overall environmental impact of PEC systems. Advanced designs increasingly incorporate earth-abundant materials such as iron oxide, copper oxide, and organic semiconductors to replace rare or toxic elements like platinum and cadmium. This transition not only reduces extraction-related environmental damage but also addresses supply chain vulnerabilities associated with critical materials. Recent innovations in nanomaterial synthesis have further reduced the material intensity of PEC cells while maintaining or improving performance metrics.

Water consumption represents another important environmental consideration, particularly for large-scale deployment scenarios. PEC systems designed for water splitting require purified water inputs, though significantly less than conventional hydrogen production methods. Closed-loop water recycling systems integrated into modern PEC cell designs can reduce freshwater requirements by up to 85%, minimizing the technology's hydrological footprint in water-stressed regions.

End-of-life management strategies for PEC technologies are evolving rapidly, with design-for-recycling approaches gaining prominence. Modular construction techniques facilitate component separation, while advances in recovery processes enable the reclamation of up to 90% of valuable materials from decommissioned cells. These circular economy principles extend the environmental benefits of PEC systems beyond their operational phase.

The land use implications of PEC deployment vary considerably depending on system configuration. While ground-mounted arrays require dedicated land area, building-integrated PEC systems and floating installations on artificial water bodies represent land-efficient alternatives with minimal ecosystem disruption. Biodiversity impact assessments indicate that thoughtfully designed PEC installations can coexist with or even enhance local ecosystems through appropriate siting and management practices.

Carbon payback periods—the time required for a PEC system to offset the emissions associated with its production—have decreased substantially with manufacturing improvements. Current estimates place the carbon payback period between 1.5 and 3 years for most innovative designs, representing a fraction of their operational lifetime. This favorable energy return on investment strengthens the case for PEC technology as a sustainable energy solution aligned with global decarbonization objectives.

Material selection plays a crucial role in determining the overall environmental impact of PEC systems. Advanced designs increasingly incorporate earth-abundant materials such as iron oxide, copper oxide, and organic semiconductors to replace rare or toxic elements like platinum and cadmium. This transition not only reduces extraction-related environmental damage but also addresses supply chain vulnerabilities associated with critical materials. Recent innovations in nanomaterial synthesis have further reduced the material intensity of PEC cells while maintaining or improving performance metrics.

Water consumption represents another important environmental consideration, particularly for large-scale deployment scenarios. PEC systems designed for water splitting require purified water inputs, though significantly less than conventional hydrogen production methods. Closed-loop water recycling systems integrated into modern PEC cell designs can reduce freshwater requirements by up to 85%, minimizing the technology's hydrological footprint in water-stressed regions.

End-of-life management strategies for PEC technologies are evolving rapidly, with design-for-recycling approaches gaining prominence. Modular construction techniques facilitate component separation, while advances in recovery processes enable the reclamation of up to 90% of valuable materials from decommissioned cells. These circular economy principles extend the environmental benefits of PEC systems beyond their operational phase.

The land use implications of PEC deployment vary considerably depending on system configuration. While ground-mounted arrays require dedicated land area, building-integrated PEC systems and floating installations on artificial water bodies represent land-efficient alternatives with minimal ecosystem disruption. Biodiversity impact assessments indicate that thoughtfully designed PEC installations can coexist with or even enhance local ecosystems through appropriate siting and management practices.

Carbon payback periods—the time required for a PEC system to offset the emissions associated with its production—have decreased substantially with manufacturing improvements. Current estimates place the carbon payback period between 1.5 and 3 years for most innovative designs, representing a fraction of their operational lifetime. This favorable energy return on investment strengthens the case for PEC technology as a sustainable energy solution aligned with global decarbonization objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!