Cost-effective fabrication techniques for PEC water splitting devices.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEC Water Splitting Technology Background and Objectives

Photoelectrochemical (PEC) water splitting represents a promising approach for sustainable hydrogen production, leveraging solar energy to directly convert water into hydrogen and oxygen. This technology has evolved significantly since its inception in the 1970s with the groundbreaking work of Fujishima and Honda, who demonstrated the photocatalytic properties of titanium dioxide electrodes. Over the past five decades, research has progressed from fundamental understanding of semiconductor-electrolyte interfaces to the development of complex multi-junction devices with enhanced efficiency.

The technological evolution of PEC water splitting has been characterized by continuous improvements in photoelectrode materials, device architectures, and fabrication techniques. Early systems achieved less than 1% solar-to-hydrogen (STH) efficiency, while current state-of-the-art devices can reach over 15% under laboratory conditions. This progress has been driven by advances in nanomaterials, surface engineering, and the integration of multiple absorber materials to capture broader portions of the solar spectrum.

Despite these advancements, the widespread implementation of PEC water splitting technology remains constrained by economic factors. Current fabrication methods often rely on expensive materials and complex processing techniques, resulting in prohibitively high production costs for commercial viability. The primary technical objective in this field is therefore to develop cost-effective fabrication techniques that maintain high performance while significantly reducing manufacturing expenses.

Key technological goals include the development of scalable deposition methods for photoactive materials, reduction of noble metal catalyst loading, implementation of earth-abundant materials as alternatives to rare elements, and simplification of device architecture without compromising efficiency or stability. Additionally, there is a critical need to extend device operational lifetime from the current typical range of hundreds of hours to the thousands of hours required for commercial deployment.

The trajectory of PEC technology is increasingly focused on integrated systems that combine the advantages of photovoltaics and electrolysis while minimizing the complexities and costs associated with traditional PEC devices. Research is trending toward modular designs that facilitate mass production and reduce capital expenditure, with particular emphasis on roll-to-roll processing, solution-based deposition techniques, and additive manufacturing approaches.

The ultimate objective is to achieve an economically viable PEC water splitting technology capable of producing hydrogen at costs competitive with conventional methods (below $2/kg H₂), while maintaining STH efficiencies above 10% and operational lifetimes exceeding 5 years. This would position PEC water splitting as a key contributor to the emerging hydrogen economy and support global decarbonization efforts.

The technological evolution of PEC water splitting has been characterized by continuous improvements in photoelectrode materials, device architectures, and fabrication techniques. Early systems achieved less than 1% solar-to-hydrogen (STH) efficiency, while current state-of-the-art devices can reach over 15% under laboratory conditions. This progress has been driven by advances in nanomaterials, surface engineering, and the integration of multiple absorber materials to capture broader portions of the solar spectrum.

Despite these advancements, the widespread implementation of PEC water splitting technology remains constrained by economic factors. Current fabrication methods often rely on expensive materials and complex processing techniques, resulting in prohibitively high production costs for commercial viability. The primary technical objective in this field is therefore to develop cost-effective fabrication techniques that maintain high performance while significantly reducing manufacturing expenses.

Key technological goals include the development of scalable deposition methods for photoactive materials, reduction of noble metal catalyst loading, implementation of earth-abundant materials as alternatives to rare elements, and simplification of device architecture without compromising efficiency or stability. Additionally, there is a critical need to extend device operational lifetime from the current typical range of hundreds of hours to the thousands of hours required for commercial deployment.

The trajectory of PEC technology is increasingly focused on integrated systems that combine the advantages of photovoltaics and electrolysis while minimizing the complexities and costs associated with traditional PEC devices. Research is trending toward modular designs that facilitate mass production and reduce capital expenditure, with particular emphasis on roll-to-roll processing, solution-based deposition techniques, and additive manufacturing approaches.

The ultimate objective is to achieve an economically viable PEC water splitting technology capable of producing hydrogen at costs competitive with conventional methods (below $2/kg H₂), while maintaining STH efficiencies above 10% and operational lifetimes exceeding 5 years. This would position PEC water splitting as a key contributor to the emerging hydrogen economy and support global decarbonization efforts.

Market Analysis for Cost-effective PEC Hydrogen Production

The global market for photoelectrochemical (PEC) hydrogen production is experiencing significant growth, driven by increasing demand for clean energy solutions and the global push towards decarbonization. The hydrogen market itself is projected to reach $220 billion by 2030, with green hydrogen production methods like PEC technology capturing an increasingly important segment of this expanding market.

Cost-effective PEC water splitting devices represent a particularly promising avenue within the renewable hydrogen sector. Current market analysis indicates that PEC technology offers several competitive advantages over alternative hydrogen production methods, including lower energy input requirements compared to traditional electrolysis and greater scalability potential than biological hydrogen production methods.

Market segmentation reveals diverse application opportunities for cost-effective PEC hydrogen production. The industrial sector represents the largest potential market, with chemical manufacturing, refining, and metallurgical processes requiring substantial hydrogen inputs. Transportation applications constitute another rapidly growing segment, particularly for fuel cell electric vehicles (FCEVs) in heavy-duty transport, shipping, and potentially aviation.

Regional market analysis shows varying adoption patterns and growth potential. Asia-Pacific currently leads in investment and deployment of hydrogen technologies, with China, Japan, and South Korea implementing ambitious hydrogen strategies. Europe follows closely with strong policy support through initiatives like the European Hydrogen Strategy, while North America shows increasing commercial interest driven by both private investment and government incentives.

Price sensitivity analysis indicates that cost-effective fabrication techniques for PEC devices could potentially reduce hydrogen production costs from current levels of $5-8/kg to below $3/kg by 2030, making green hydrogen competitive with fossil-fuel derived hydrogen. This price threshold represents a critical market inflection point that would significantly accelerate adoption across multiple sectors.

Market barriers include competition from established hydrogen production technologies, infrastructure limitations for hydrogen storage and transport, and regulatory uncertainties. However, these challenges are increasingly offset by favorable policy environments, including carbon pricing mechanisms, renewable energy mandates, and direct subsidies for green hydrogen production in many major economies.

The investment landscape shows growing interest from both venture capital and corporate strategic investors, with annual investment in hydrogen technologies exceeding $300 million in recent years. This capital influx is accelerating commercialization timelines for cost-effective PEC technologies and supporting scale-up of manufacturing capabilities.

Cost-effective PEC water splitting devices represent a particularly promising avenue within the renewable hydrogen sector. Current market analysis indicates that PEC technology offers several competitive advantages over alternative hydrogen production methods, including lower energy input requirements compared to traditional electrolysis and greater scalability potential than biological hydrogen production methods.

Market segmentation reveals diverse application opportunities for cost-effective PEC hydrogen production. The industrial sector represents the largest potential market, with chemical manufacturing, refining, and metallurgical processes requiring substantial hydrogen inputs. Transportation applications constitute another rapidly growing segment, particularly for fuel cell electric vehicles (FCEVs) in heavy-duty transport, shipping, and potentially aviation.

Regional market analysis shows varying adoption patterns and growth potential. Asia-Pacific currently leads in investment and deployment of hydrogen technologies, with China, Japan, and South Korea implementing ambitious hydrogen strategies. Europe follows closely with strong policy support through initiatives like the European Hydrogen Strategy, while North America shows increasing commercial interest driven by both private investment and government incentives.

Price sensitivity analysis indicates that cost-effective fabrication techniques for PEC devices could potentially reduce hydrogen production costs from current levels of $5-8/kg to below $3/kg by 2030, making green hydrogen competitive with fossil-fuel derived hydrogen. This price threshold represents a critical market inflection point that would significantly accelerate adoption across multiple sectors.

Market barriers include competition from established hydrogen production technologies, infrastructure limitations for hydrogen storage and transport, and regulatory uncertainties. However, these challenges are increasingly offset by favorable policy environments, including carbon pricing mechanisms, renewable energy mandates, and direct subsidies for green hydrogen production in many major economies.

The investment landscape shows growing interest from both venture capital and corporate strategic investors, with annual investment in hydrogen technologies exceeding $300 million in recent years. This capital influx is accelerating commercialization timelines for cost-effective PEC technologies and supporting scale-up of manufacturing capabilities.

Current Fabrication Challenges and Technical Barriers

Despite significant advancements in photoelectrochemical (PEC) water splitting technology, several critical fabrication challenges continue to impede widespread commercial adoption. The primary barrier remains the high manufacturing costs associated with producing efficient and durable PEC devices. Current fabrication methods often require expensive materials such as platinum group metals as catalysts and high-purity semiconductors, substantially increasing the overall system costs and limiting economic viability when compared to conventional hydrogen production methods.

Material selection presents another significant challenge, as researchers must balance performance, durability, and cost considerations. Many high-performance photoelectrode materials contain rare or precious elements that are prohibitively expensive for large-scale applications. Additionally, the complex multi-layer architectures necessary for efficient PEC devices require precise deposition techniques that are difficult to scale up from laboratory to industrial production.

Scalability issues persist across the manufacturing process. Laboratory-scale fabrication techniques like atomic layer deposition (ALD) and physical vapor deposition (PVD) deliver excellent control over material properties but are inherently slow and expensive when applied to larger surface areas. The transition from small-scale prototypes to commercially viable production volumes represents a substantial technical barrier that has yet to be adequately addressed.

Reproducibility and quality control in manufacturing processes pose additional challenges. Current fabrication methods often suffer from batch-to-batch variations that affect device performance and lifetime. The intricate interfaces between different functional layers in PEC devices are particularly susceptible to defects during scaling, leading to performance degradation and reduced operational lifetimes.

Energy-intensive processing steps further undermine the sustainability credentials of PEC technology. Many fabrication techniques require high-temperature annealing or vacuum-based deposition methods that consume significant energy, contradicting the environmental benefits that green hydrogen production aims to deliver. These energy requirements add to both the economic and environmental costs of device production.

Integration challenges between the various components of PEC systems also present significant barriers. Achieving seamless connections between photoabsorbers, catalysts, and protective layers while maintaining optimal performance requires sophisticated engineering solutions that are difficult to implement in mass production environments.

Lastly, the lack of standardized fabrication protocols and quality assessment metrics hampers industry-wide progress. Without established manufacturing standards, companies and research institutions pursue divergent approaches, fragmenting efforts and slowing the overall advancement of cost-effective fabrication techniques for PEC water splitting devices.

Material selection presents another significant challenge, as researchers must balance performance, durability, and cost considerations. Many high-performance photoelectrode materials contain rare or precious elements that are prohibitively expensive for large-scale applications. Additionally, the complex multi-layer architectures necessary for efficient PEC devices require precise deposition techniques that are difficult to scale up from laboratory to industrial production.

Scalability issues persist across the manufacturing process. Laboratory-scale fabrication techniques like atomic layer deposition (ALD) and physical vapor deposition (PVD) deliver excellent control over material properties but are inherently slow and expensive when applied to larger surface areas. The transition from small-scale prototypes to commercially viable production volumes represents a substantial technical barrier that has yet to be adequately addressed.

Reproducibility and quality control in manufacturing processes pose additional challenges. Current fabrication methods often suffer from batch-to-batch variations that affect device performance and lifetime. The intricate interfaces between different functional layers in PEC devices are particularly susceptible to defects during scaling, leading to performance degradation and reduced operational lifetimes.

Energy-intensive processing steps further undermine the sustainability credentials of PEC technology. Many fabrication techniques require high-temperature annealing or vacuum-based deposition methods that consume significant energy, contradicting the environmental benefits that green hydrogen production aims to deliver. These energy requirements add to both the economic and environmental costs of device production.

Integration challenges between the various components of PEC systems also present significant barriers. Achieving seamless connections between photoabsorbers, catalysts, and protective layers while maintaining optimal performance requires sophisticated engineering solutions that are difficult to implement in mass production environments.

Lastly, the lack of standardized fabrication protocols and quality assessment metrics hampers industry-wide progress. Without established manufacturing standards, companies and research institutions pursue divergent approaches, fragmenting efforts and slowing the overall advancement of cost-effective fabrication techniques for PEC water splitting devices.

State-of-the-art Cost Reduction Manufacturing Methods

01 Materials optimization for cost-effective PEC devices

Cost-effective materials selection is crucial for photoelectrochemical water splitting devices. Research focuses on developing low-cost, earth-abundant materials that maintain high efficiency. This includes optimizing semiconductor materials, catalysts, and protective layers to reduce manufacturing costs while maintaining performance. Novel synthesis methods and material combinations are being explored to replace expensive noble metals and rare earth elements traditionally used in these systems.- Materials optimization for cost-effective PEC devices: Cost-effective materials selection is crucial for photoelectrochemical water splitting devices. Research focuses on developing low-cost, earth-abundant materials that maintain high efficiency. This includes optimizing semiconductor materials, catalysts, and protective coatings that can withstand the harsh conditions of water splitting while reducing manufacturing costs. Advanced fabrication techniques help minimize material usage while maximizing performance and durability.

- System design and integration for economic viability: The economic viability of PEC water splitting devices depends significantly on system design and integration. Innovations focus on modular designs that allow for scalability, simplified manufacturing processes, and reduced assembly costs. Integration with existing infrastructure and complementary renewable energy systems can improve overall cost-effectiveness. Optimized system architecture considers factors like light management, water flow dynamics, and hydrogen collection to maximize efficiency while minimizing material and operational costs.

- Manufacturing process improvements for cost reduction: Advancements in manufacturing processes significantly impact the cost-effectiveness of PEC water splitting devices. Innovations include roll-to-roll processing, solution-based deposition methods, and other scalable fabrication techniques that reduce production costs while maintaining device quality. Automation and standardization of manufacturing steps help minimize labor costs and improve consistency. Process optimization also focuses on reducing energy consumption during fabrication and minimizing waste materials.

- Economic analysis and cost modeling frameworks: Comprehensive economic analysis and cost modeling frameworks are essential for evaluating and improving the cost-effectiveness of PEC water splitting technologies. These frameworks consider capital costs, operational expenses, device lifetime, efficiency, and hydrogen production rates to calculate levelized costs. Techno-economic analyses help identify cost bottlenecks and guide research priorities. Modeling approaches also incorporate market factors, policy incentives, and competing technologies to assess commercial viability under different scenarios.

- Performance enhancement strategies for economic hydrogen production: Improving device performance is a key strategy for enhancing the economic viability of PEC water splitting. Research focuses on increasing solar-to-hydrogen conversion efficiency, extending device lifetime, and improving stability under operating conditions. Innovations include advanced light-harvesting architectures, efficient charge separation mechanisms, and robust catalyst systems. Enhanced performance allows devices to produce more hydrogen with the same material inputs, effectively lowering the cost per unit of hydrogen produced and improving overall cost-effectiveness.

02 System design and integration for improved efficiency

The overall design and integration of PEC water splitting systems significantly impacts cost-effectiveness. Innovations include modular designs that facilitate maintenance, integrated systems that combine multiple functions, and scalable architectures suitable for industrial applications. Advanced engineering approaches focus on optimizing light absorption, charge separation, and catalytic activity while minimizing material usage and complexity. These design improvements help reduce both capital and operational expenses.Expand Specific Solutions03 Manufacturing processes and scalability solutions

Developing cost-effective manufacturing processes is essential for commercial viability of PEC water splitting devices. Innovations include roll-to-roll processing, solution-based deposition methods, and other scalable fabrication techniques that reduce production costs. Research focuses on processes that minimize energy consumption during manufacturing, reduce waste generation, and enable mass production while maintaining device quality and performance characteristics.Expand Specific Solutions04 Economic analysis and lifecycle assessment

Comprehensive economic analysis and lifecycle assessment methodologies help evaluate the true cost-effectiveness of PEC water splitting technologies. These approaches consider capital costs, operational expenses, device lifetime, maintenance requirements, and environmental impacts. Research in this area focuses on developing standardized metrics for comparing different technologies, identifying cost drivers, and establishing economic benchmarks for commercial viability. These analyses guide research priorities and investment decisions.Expand Specific Solutions05 Integration with renewable energy systems

Integrating PEC water splitting devices with other renewable energy systems can significantly improve overall cost-effectiveness. Hybrid systems that combine solar photovoltaics, wind energy, or waste heat recovery with PEC technology can enhance efficiency and reduce intermittency issues. These integrated approaches optimize energy utilization, improve hydrogen production rates, and create more economically viable clean energy solutions by leveraging complementary technologies and existing infrastructure.Expand Specific Solutions

Leading Companies and Research Institutions in PEC Fabrication

The photoelectrochemical (PEC) water splitting device market is currently in its early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to expand substantially as hydrogen gains importance in clean energy transitions, though current estimates remain modest at under $100 million. Technologically, PEC water splitting is still evolving toward maturity, with key players pursuing different fabrication approaches. Companies like Toyota, SABIC, and Umicore are leveraging their materials expertise to develop cost-effective manufacturing techniques, while academic institutions including University of Michigan and South China University of Technology focus on fundamental innovations. Emerging players such as AquaHydrex and EDAC Labs are developing specialized fabrication methods, while semiconductor manufacturers like TSMC and Samsung Electro-Mechanics contribute precision manufacturing capabilities essential for scaling production.

Umicore SA

Technical Solution: Umicore has developed sophisticated materials and fabrication techniques for PEC water splitting devices focusing on cost reduction through advanced catalyst design. Their approach centers on the development of non-precious metal catalysts based on mixed metal oxides and sulfides that can be synthesized through solution-based methods at relatively low temperatures. Umicore employs a proprietary electrodeposition technique that enables precise control over catalyst morphology and composition, optimizing catalytic activity while minimizing material usage. Their PEC device fabrication incorporates specialized surface modification treatments that enhance the stability of semiconductor-electrolyte interfaces, addressing a key challenge in long-term device operation. Umicore has also pioneered scalable manufacturing processes for photoelectrode assemblies using continuous flow reactors, significantly reducing production time and energy requirements compared to batch processing methods. Their integrated approach includes recovery and recycling of critical materials from end-of-life devices, creating a circular economy model that further reduces overall system costs.

Strengths: Extensive expertise in catalyst development and materials science; established manufacturing capabilities that can be adapted to PEC device production; strong focus on sustainable materials and circular economy principles. Weaknesses: Less experience in system integration compared to dedicated renewable energy companies; technology still primarily at pilot scale rather than full commercial deployment; requires partnerships for complete PEC system development.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered several cost-effective fabrication approaches for PEC water splitting devices through their advanced energy materials research programs. Their technique centers on solution-processable semiconductor materials that can be deposited via spray coating, spin coating, and other scalable methods that eliminate the need for expensive vacuum deposition equipment. The university's researchers have developed specialized nanostructured photoelectrodes with hierarchical architectures that maximize surface area while maintaining efficient charge transport pathways, achieved through template-assisted growth methods compatible with large-scale manufacturing. Their innovation includes a unique atomic layer deposition process for applying ultrathin protective layers on semiconductor surfaces, dramatically improving stability in aqueous environments while using minimal amounts of protective materials. The University of Michigan has also developed low-temperature annealing protocols that reduce the energy requirements for device fabrication while maintaining high photoelectrochemical performance. Their integrated approach incorporates earth-abundant materials throughout the device architecture, from the semiconductor absorbers to the catalysts and transparent conductive layers.

Strengths: Cutting-edge materials science research capabilities; innovative approaches to nanostructured photoelectrode design; strong focus on fundamental understanding of PEC processes enabling rational design improvements. Weaknesses: Technologies primarily at laboratory scale requiring further development for commercial implementation; focus on academic research rather than manufacturing optimization; requires industrial partnerships for commercialization.

Key Patents and Innovations in Low-cost PEC Fabrication

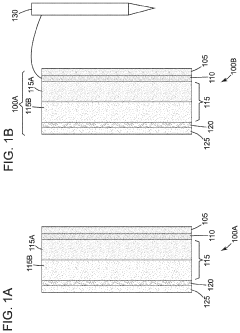

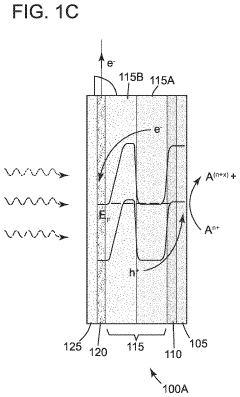

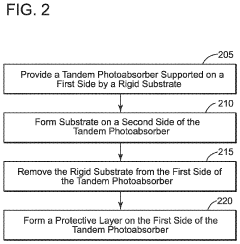

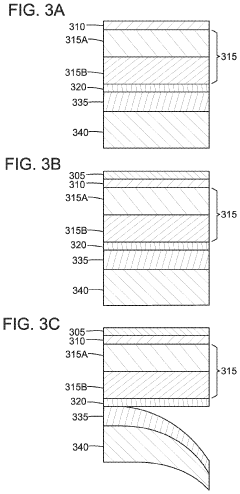

Photoelectrochemical device, monolithic water splitting device and methods of production

PatentInactiveUS20210025062A1

Innovation

- A photoelectrochemical device with a metallic substrate and a tandem photoabsorber using III-V materials, where the substrate is separated from the tandem photoabsorber using an epitaxial lift-off technique, allowing for a protective layer to be formed, reducing costs and preventing corrosion, and enabling unassisted water splitting without an external energy source.

Photoelectrochemical water splitting method

PatentActiveUS11851775B2

Innovation

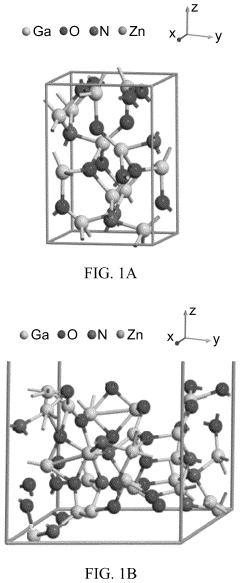

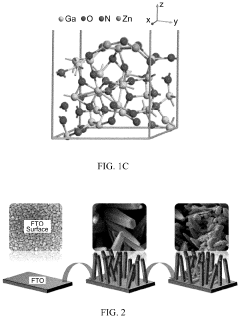

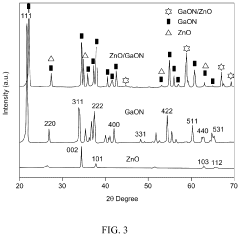

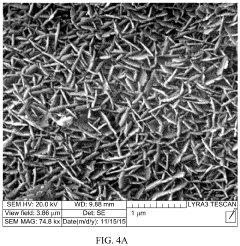

- A GaON/ZnO photoelectrode is developed with gallium oxynitride nanoparticles interspersed in zinc oxide nanoparticles, deposited on a metal oxide conducting substrate, optimizing the nanoarchitectured photocatalytic material for improved light absorption and charge separation, and used in a photoelectrochemical cell for efficient water splitting.

Scalability and Industrial Implementation Considerations

Scaling up PEC water splitting devices from laboratory prototypes to industrial-scale production presents significant challenges that must be addressed for commercial viability. Current fabrication methods often rely on expensive materials and complex processes that are feasible for small-scale research but prohibitive for mass production. The transition to industrial implementation requires developing manufacturing techniques that maintain performance while drastically reducing costs.

Material selection represents a critical factor in scalability considerations. While precious metal catalysts like platinum and iridium offer excellent performance, their scarcity and high cost make them impractical for large-scale deployment. Research into earth-abundant alternatives such as nickel-based catalysts, iron oxides, and carbon-based materials shows promising directions for cost-effective scaling, though these materials often require optimization to match performance benchmarks.

Manufacturing process adaptation constitutes another key challenge. Laboratory techniques like atomic layer deposition and physical vapor deposition deliver precise control but at prohibitively high costs for industrial scale. Roll-to-roll processing, electrodeposition, and solution-based methods offer more economically viable alternatives that can maintain acceptable performance metrics while enabling high-volume production. These methods require careful optimization to ensure uniform coating thickness and consistent material properties across large surface areas.

Durability and lifetime considerations become increasingly important at industrial scale. Accelerated aging tests under realistic operating conditions must be developed to predict long-term performance. Protective coatings and encapsulation strategies that can be applied through cost-effective processes will be essential for extending device lifetimes in real-world environments, where temperature fluctuations, pH variations, and contaminants can rapidly degrade unprotected materials.

Integration with existing infrastructure presents both challenges and opportunities. PEC systems must be designed to interface with current water treatment facilities, hydrogen storage systems, or electrical grids. Modular designs that can be incrementally deployed and scaled offer advantages for initial market entry and gradual capacity expansion. Standardization of components and connection interfaces will facilitate maintenance and reduce operational costs.

Economic viability ultimately depends on achieving competitive levelized cost metrics. Current estimates suggest PEC hydrogen production costs between $10-15/kg, significantly higher than the $2-3/kg target needed to compete with conventional hydrogen production methods. Pathway analysis indicates that combining manufacturing scale economies, material innovations, and process optimizations could potentially reduce costs by 70-80% over the next decade, bringing PEC technology within reach of commercial viability for specific applications.

Material selection represents a critical factor in scalability considerations. While precious metal catalysts like platinum and iridium offer excellent performance, their scarcity and high cost make them impractical for large-scale deployment. Research into earth-abundant alternatives such as nickel-based catalysts, iron oxides, and carbon-based materials shows promising directions for cost-effective scaling, though these materials often require optimization to match performance benchmarks.

Manufacturing process adaptation constitutes another key challenge. Laboratory techniques like atomic layer deposition and physical vapor deposition deliver precise control but at prohibitively high costs for industrial scale. Roll-to-roll processing, electrodeposition, and solution-based methods offer more economically viable alternatives that can maintain acceptable performance metrics while enabling high-volume production. These methods require careful optimization to ensure uniform coating thickness and consistent material properties across large surface areas.

Durability and lifetime considerations become increasingly important at industrial scale. Accelerated aging tests under realistic operating conditions must be developed to predict long-term performance. Protective coatings and encapsulation strategies that can be applied through cost-effective processes will be essential for extending device lifetimes in real-world environments, where temperature fluctuations, pH variations, and contaminants can rapidly degrade unprotected materials.

Integration with existing infrastructure presents both challenges and opportunities. PEC systems must be designed to interface with current water treatment facilities, hydrogen storage systems, or electrical grids. Modular designs that can be incrementally deployed and scaled offer advantages for initial market entry and gradual capacity expansion. Standardization of components and connection interfaces will facilitate maintenance and reduce operational costs.

Economic viability ultimately depends on achieving competitive levelized cost metrics. Current estimates suggest PEC hydrogen production costs between $10-15/kg, significantly higher than the $2-3/kg target needed to compete with conventional hydrogen production methods. Pathway analysis indicates that combining manufacturing scale economies, material innovations, and process optimizations could potentially reduce costs by 70-80% over the next decade, bringing PEC technology within reach of commercial viability for specific applications.

Environmental Impact and Sustainability Assessment

The environmental impact of photoelectrochemical (PEC) water splitting devices extends far beyond their operational efficiency. When evaluating cost-effective fabrication techniques, sustainability considerations must be integrated throughout the entire lifecycle. Current manufacturing processes for PEC devices often involve energy-intensive methods and potentially hazardous materials, including rare earth elements and toxic chemicals that pose significant environmental risks.

Material selection represents a critical environmental factor in PEC device fabrication. Traditional semiconductor materials like cadmium telluride and gallium arsenide contain toxic elements that require careful handling during manufacturing and proper disposal at end-of-life. More sustainable alternatives such as iron oxide, tungsten oxide, and carbon-based materials are gaining attention for their reduced environmental footprint, though their performance characteristics often require optimization.

Energy consumption during fabrication processes significantly impacts the sustainability profile of PEC technologies. High-temperature synthesis methods and vacuum deposition techniques commonly used in semiconductor manufacturing consume substantial energy, potentially offsetting the environmental benefits of hydrogen production. Emerging low-temperature solution-based processes and ambient-pressure deposition methods offer promising alternatives that reduce energy requirements by 40-60% compared to conventional techniques.

Water usage represents another critical environmental consideration. Traditional semiconductor fabrication can require thousands of liters of ultrapure water per square meter of device area. Developing water-efficient cleaning processes and closed-loop water recycling systems can substantially reduce this impact, with recent innovations demonstrating potential water usage reductions of up to 75%.

Waste management challenges arise throughout the PEC device lifecycle. Chemical etching processes generate acidic waste streams requiring neutralization and treatment, while thin-film deposition creates material waste through overspray and target inefficiencies. Implementing recovery systems for valuable materials and developing solvent-free processing methods can significantly reduce waste generation and associated environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental payback period for PEC water splitting devices ranges from 1-5 years depending on fabrication methods, with energy-intensive techniques extending this timeframe considerably. Adopting circular economy principles through modular design approaches and recyclable components can further enhance sustainability by enabling material recovery and extending device lifespans beyond the typical 5-10 year operational window.

Material selection represents a critical environmental factor in PEC device fabrication. Traditional semiconductor materials like cadmium telluride and gallium arsenide contain toxic elements that require careful handling during manufacturing and proper disposal at end-of-life. More sustainable alternatives such as iron oxide, tungsten oxide, and carbon-based materials are gaining attention for their reduced environmental footprint, though their performance characteristics often require optimization.

Energy consumption during fabrication processes significantly impacts the sustainability profile of PEC technologies. High-temperature synthesis methods and vacuum deposition techniques commonly used in semiconductor manufacturing consume substantial energy, potentially offsetting the environmental benefits of hydrogen production. Emerging low-temperature solution-based processes and ambient-pressure deposition methods offer promising alternatives that reduce energy requirements by 40-60% compared to conventional techniques.

Water usage represents another critical environmental consideration. Traditional semiconductor fabrication can require thousands of liters of ultrapure water per square meter of device area. Developing water-efficient cleaning processes and closed-loop water recycling systems can substantially reduce this impact, with recent innovations demonstrating potential water usage reductions of up to 75%.

Waste management challenges arise throughout the PEC device lifecycle. Chemical etching processes generate acidic waste streams requiring neutralization and treatment, while thin-film deposition creates material waste through overspray and target inefficiencies. Implementing recovery systems for valuable materials and developing solvent-free processing methods can significantly reduce waste generation and associated environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental payback period for PEC water splitting devices ranges from 1-5 years depending on fabrication methods, with energy-intensive techniques extending this timeframe considerably. Adopting circular economy principles through modular design approaches and recyclable components can further enhance sustainability by enabling material recovery and extending device lifespans beyond the typical 5-10 year operational window.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!