Analysis of dynamic mechanical behavior of Nylon 6 under temperature variation

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Thermal-Mechanical Behavior Background and Objectives

Nylon 6, a semi-crystalline thermoplastic polyamide, has been extensively utilized across various industries since its development in the 1930s. The evolution of this versatile polymer has been marked by continuous improvements in synthesis methods, processing techniques, and understanding of its structure-property relationships. Initially developed as a synthetic alternative to silk, Nylon 6 has evolved into a critical engineering material with applications ranging from automotive components to consumer goods, medical devices, and industrial machinery parts.

The thermal-mechanical behavior of Nylon 6 represents a complex interplay between molecular structure, crystallinity, and environmental conditions. Historically, research has progressed from basic characterization of mechanical properties to sophisticated analyses of viscoelastic responses under varying thermal conditions. This progression reflects the growing industrial demand for materials that can maintain structural integrity across diverse operating environments.

Recent technological advancements have enabled more precise measurement and modeling of dynamic mechanical properties, revealing the nuanced relationships between temperature, frequency, and mechanical response in Nylon 6. The glass transition temperature (Tg) of approximately 50°C and melting point around 220°C define critical regions where dramatic changes in mechanical behavior occur, presenting both challenges and opportunities for engineering applications.

Current research trends indicate growing interest in understanding the time-dependent aspects of Nylon 6's mechanical response, particularly how temperature variations affect relaxation processes, creep behavior, and fatigue resistance. This interest is driven by increasingly demanding applications where components experience complex thermal cycling and mechanical loading patterns simultaneously.

The primary objective of this technical research is to comprehensively analyze the dynamic mechanical behavior of Nylon 6 under temperature variation, with particular emphasis on characterizing the viscoelastic response across industrially relevant temperature ranges. This includes mapping the storage modulus, loss modulus, and damping characteristics as functions of temperature and frequency.

Secondary objectives include identifying critical transition points where material behavior changes significantly, developing predictive models for mechanical response under combined thermal and mechanical loading, and establishing design guidelines for applications involving temperature fluctuations. These objectives align with industry needs for more reliable performance prediction in thermally variable environments.

The anticipated outcomes of this research will contribute to advancing material selection methodologies, optimizing processing parameters, and enhancing product design approaches for Nylon 6 components. By establishing clearer correlations between thermal history, molecular structure, and mechanical performance, this work aims to expand the practical application range of this versatile polymer in next-generation engineering solutions.

The thermal-mechanical behavior of Nylon 6 represents a complex interplay between molecular structure, crystallinity, and environmental conditions. Historically, research has progressed from basic characterization of mechanical properties to sophisticated analyses of viscoelastic responses under varying thermal conditions. This progression reflects the growing industrial demand for materials that can maintain structural integrity across diverse operating environments.

Recent technological advancements have enabled more precise measurement and modeling of dynamic mechanical properties, revealing the nuanced relationships between temperature, frequency, and mechanical response in Nylon 6. The glass transition temperature (Tg) of approximately 50°C and melting point around 220°C define critical regions where dramatic changes in mechanical behavior occur, presenting both challenges and opportunities for engineering applications.

Current research trends indicate growing interest in understanding the time-dependent aspects of Nylon 6's mechanical response, particularly how temperature variations affect relaxation processes, creep behavior, and fatigue resistance. This interest is driven by increasingly demanding applications where components experience complex thermal cycling and mechanical loading patterns simultaneously.

The primary objective of this technical research is to comprehensively analyze the dynamic mechanical behavior of Nylon 6 under temperature variation, with particular emphasis on characterizing the viscoelastic response across industrially relevant temperature ranges. This includes mapping the storage modulus, loss modulus, and damping characteristics as functions of temperature and frequency.

Secondary objectives include identifying critical transition points where material behavior changes significantly, developing predictive models for mechanical response under combined thermal and mechanical loading, and establishing design guidelines for applications involving temperature fluctuations. These objectives align with industry needs for more reliable performance prediction in thermally variable environments.

The anticipated outcomes of this research will contribute to advancing material selection methodologies, optimizing processing parameters, and enhancing product design approaches for Nylon 6 components. By establishing clearer correlations between thermal history, molecular structure, and mechanical performance, this work aims to expand the practical application range of this versatile polymer in next-generation engineering solutions.

Market Applications and Demand Analysis for Temperature-Resistant Polymers

The temperature-resistant polymer market has witnessed substantial growth in recent years, driven primarily by increasing demand from automotive, aerospace, electronics, and industrial sectors. Temperature-resistant polymers like Nylon 6 have become critical materials in applications requiring mechanical stability under varying thermal conditions. The global market for these specialized polymers was valued at approximately $9.3 billion in 2022 and is projected to reach $14.7 billion by 2028, representing a compound annual growth rate of 7.8%.

The automotive industry constitutes the largest application segment for temperature-resistant polymers, accounting for nearly 32% of the total market share. This demand stems from the ongoing transition toward lightweight materials to improve fuel efficiency and reduce emissions. Specifically, Nylon 6's dynamic mechanical behavior under temperature variation makes it ideal for under-hood components, fuel systems, and electrical connectors that must withstand extreme temperature fluctuations.

The aerospace sector represents another significant market, with temperature-resistant polymers increasingly replacing metal components in aircraft interiors, structural elements, and engine compartments. Market analysis indicates that this sector is growing at 9.2% annually, faster than the overall market, driven by the need for materials that maintain mechanical integrity across the wide temperature ranges experienced during flight operations.

Electronics manufacturing has emerged as the fastest-growing application segment, expanding at 10.5% annually. The miniaturization trend in consumer electronics and the development of 5G infrastructure require polymers that can maintain dimensional stability and mechanical properties despite heat generated during operation. Nylon 6 variants with enhanced temperature resistance are particularly valued in this sector.

Industrial applications, including chemical processing equipment, oil and gas infrastructure, and industrial machinery, constitute approximately 24% of the market. These applications demand materials that can withstand not only temperature variations but also chemical exposure and mechanical stress simultaneously.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China and India are experiencing the most rapid growth rates due to expanding manufacturing bases and increasing domestic consumption of high-performance materials.

Customer requirements are evolving toward materials with wider operating temperature ranges, improved aging resistance, and better mechanical property retention after thermal cycling. This trend is driving research into modified Nylon 6 formulations with enhanced temperature stability. Market surveys indicate that manufacturers are willing to pay premium prices for polymers that can demonstrate consistent mechanical behavior across broader temperature ranges, highlighting the commercial value of research focused on the dynamic mechanical analysis of Nylon 6 under temperature variation.

The automotive industry constitutes the largest application segment for temperature-resistant polymers, accounting for nearly 32% of the total market share. This demand stems from the ongoing transition toward lightweight materials to improve fuel efficiency and reduce emissions. Specifically, Nylon 6's dynamic mechanical behavior under temperature variation makes it ideal for under-hood components, fuel systems, and electrical connectors that must withstand extreme temperature fluctuations.

The aerospace sector represents another significant market, with temperature-resistant polymers increasingly replacing metal components in aircraft interiors, structural elements, and engine compartments. Market analysis indicates that this sector is growing at 9.2% annually, faster than the overall market, driven by the need for materials that maintain mechanical integrity across the wide temperature ranges experienced during flight operations.

Electronics manufacturing has emerged as the fastest-growing application segment, expanding at 10.5% annually. The miniaturization trend in consumer electronics and the development of 5G infrastructure require polymers that can maintain dimensional stability and mechanical properties despite heat generated during operation. Nylon 6 variants with enhanced temperature resistance are particularly valued in this sector.

Industrial applications, including chemical processing equipment, oil and gas infrastructure, and industrial machinery, constitute approximately 24% of the market. These applications demand materials that can withstand not only temperature variations but also chemical exposure and mechanical stress simultaneously.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, followed by North America (28%) and Europe (23%). China and India are experiencing the most rapid growth rates due to expanding manufacturing bases and increasing domestic consumption of high-performance materials.

Customer requirements are evolving toward materials with wider operating temperature ranges, improved aging resistance, and better mechanical property retention after thermal cycling. This trend is driving research into modified Nylon 6 formulations with enhanced temperature stability. Market surveys indicate that manufacturers are willing to pay premium prices for polymers that can demonstrate consistent mechanical behavior across broader temperature ranges, highlighting the commercial value of research focused on the dynamic mechanical analysis of Nylon 6 under temperature variation.

Current Challenges in Nylon 6 Dynamic Mechanical Performance

Despite significant advancements in polymer science, Nylon 6 continues to present several critical challenges when subjected to varying temperature conditions, particularly in applications requiring reliable dynamic mechanical performance. The viscoelastic nature of Nylon 6 makes its behavior highly temperature-dependent, creating substantial difficulties in predicting performance across operational temperature ranges.

One of the primary challenges is the pronounced glass transition temperature (Tg) effect, which typically occurs around 47-57°C for Nylon 6. This transition region creates a dramatic shift in mechanical properties, with stiffness decreasing by orders of magnitude as the material transitions from a glassy to a rubbery state. Engineers struggle to design components that must function reliably across this critical temperature threshold.

Moisture absorption presents another significant challenge, as Nylon 6 is notably hygroscopic. Water molecules act as plasticizers, effectively lowering the Tg and altering the dynamic mechanical response. This creates a complex interrelationship between temperature, humidity, and mechanical performance that is difficult to model accurately, especially in environments with fluctuating conditions.

The crystallinity of Nylon 6 further complicates its temperature-dependent behavior. The semi-crystalline structure exhibits different mechanical responses in crystalline versus amorphous regions, with temperature affecting these regions differently. Higher processing temperatures can increase crystallinity, but controlling this parameter precisely during manufacturing remains challenging, leading to batch-to-batch variations in dynamic mechanical properties.

Thermal aging and degradation mechanisms pose long-term reliability concerns. Extended exposure to elevated temperatures accelerates oxidative degradation, chain scission, and cross-linking reactions, progressively altering the dynamic mechanical response. Current accelerated aging models often fail to accurately predict these changes over the full service life of components.

Rate-dependent behavior adds another layer of complexity. The strain rate sensitivity of Nylon 6 varies significantly with temperature, creating challenges in applications with variable loading rates across different thermal environments. This becomes particularly problematic in impact scenarios or vibration damping applications where both temperature and loading rate fluctuate.

Finally, there remains a significant gap between laboratory characterization techniques and real-world performance prediction. Dynamic Mechanical Analysis (DMA) provides valuable insights into viscoelastic properties, but translating these results to complex loading scenarios in actual applications requires sophisticated constitutive models that are still being refined. Current models struggle to simultaneously account for temperature effects, strain rate dependency, and long-term viscoelastic phenomena.

One of the primary challenges is the pronounced glass transition temperature (Tg) effect, which typically occurs around 47-57°C for Nylon 6. This transition region creates a dramatic shift in mechanical properties, with stiffness decreasing by orders of magnitude as the material transitions from a glassy to a rubbery state. Engineers struggle to design components that must function reliably across this critical temperature threshold.

Moisture absorption presents another significant challenge, as Nylon 6 is notably hygroscopic. Water molecules act as plasticizers, effectively lowering the Tg and altering the dynamic mechanical response. This creates a complex interrelationship between temperature, humidity, and mechanical performance that is difficult to model accurately, especially in environments with fluctuating conditions.

The crystallinity of Nylon 6 further complicates its temperature-dependent behavior. The semi-crystalline structure exhibits different mechanical responses in crystalline versus amorphous regions, with temperature affecting these regions differently. Higher processing temperatures can increase crystallinity, but controlling this parameter precisely during manufacturing remains challenging, leading to batch-to-batch variations in dynamic mechanical properties.

Thermal aging and degradation mechanisms pose long-term reliability concerns. Extended exposure to elevated temperatures accelerates oxidative degradation, chain scission, and cross-linking reactions, progressively altering the dynamic mechanical response. Current accelerated aging models often fail to accurately predict these changes over the full service life of components.

Rate-dependent behavior adds another layer of complexity. The strain rate sensitivity of Nylon 6 varies significantly with temperature, creating challenges in applications with variable loading rates across different thermal environments. This becomes particularly problematic in impact scenarios or vibration damping applications where both temperature and loading rate fluctuate.

Finally, there remains a significant gap between laboratory characterization techniques and real-world performance prediction. Dynamic Mechanical Analysis (DMA) provides valuable insights into viscoelastic properties, but translating these results to complex loading scenarios in actual applications requires sophisticated constitutive models that are still being refined. Current models struggle to simultaneously account for temperature effects, strain rate dependency, and long-term viscoelastic phenomena.

Established Methodologies for Dynamic Mechanical Analysis (DMA)

01 Thermal and mechanical properties of Nylon 6 composites

Nylon 6 composites exhibit unique dynamic mechanical behavior when combined with various fillers and reinforcements. These composites show improved thermal stability, enhanced mechanical strength, and modified viscoelastic properties compared to pure Nylon 6. The incorporation of fillers affects the glass transition temperature, storage modulus, and damping characteristics, which are critical parameters in dynamic mechanical analysis. These modifications allow for tailored mechanical responses under different loading conditions and temperatures.- Temperature-dependent mechanical properties of Nylon 6: Nylon 6 exhibits distinct mechanical behavior at different temperatures, affecting its stiffness, strength, and viscoelastic properties. The glass transition temperature significantly influences its dynamic mechanical response, with notable changes in storage modulus and loss factor. Temperature variations can alter crystallinity levels, which directly impacts mechanical performance under dynamic loading conditions.

- Impact resistance and energy absorption characteristics: Nylon 6 demonstrates specific impact resistance properties under dynamic loading conditions. Its ability to absorb energy during impact events is related to its molecular structure and crystalline morphology. The material exhibits strain-rate dependent behavior, with different mechanical responses at varying loading rates, making it suitable for applications requiring energy dissipation and impact resistance.

- Reinforcement effects on dynamic mechanical behavior: The incorporation of reinforcing materials such as glass fibers, carbon fibers, or mineral fillers significantly alters the dynamic mechanical properties of Nylon 6. These reinforcements can enhance stiffness, damping characteristics, and fatigue resistance. The interface between the reinforcement and polymer matrix plays a crucial role in determining the overall dynamic mechanical response of the composite material.

- Viscoelastic behavior and creep resistance: Nylon 6 exhibits time-dependent viscoelastic behavior characterized by both elastic and viscous components. This results in phenomena such as creep, stress relaxation, and hysteresis under dynamic loading conditions. The material's molecular weight, crystallinity, and moisture content significantly influence its viscoelastic response, affecting applications where dimensional stability under sustained or cyclic loading is required.

- Environmental factors affecting dynamic mechanical properties: Environmental conditions such as humidity, moisture absorption, and chemical exposure can substantially alter the dynamic mechanical behavior of Nylon 6. Water absorption particularly affects its glass transition temperature and damping characteristics. Additionally, aging processes and UV exposure can lead to changes in molecular structure that impact long-term dynamic mechanical performance, requiring consideration in applications exposed to varying environmental conditions.

02 Temperature-dependent viscoelastic behavior of Nylon 6

Nylon 6 demonstrates significant temperature-dependent viscoelastic properties that affect its dynamic mechanical behavior. As temperature increases, particularly near the glass transition temperature, Nylon 6 experiences changes in storage modulus, loss modulus, and damping factor. These changes reflect the polymer's transition from glassy to rubbery state and influence its energy absorption capabilities. Understanding these temperature-dependent properties is crucial for applications involving cyclic loading or varying temperature conditions.Expand Specific Solutions03 Frequency response and dynamic fatigue resistance

The dynamic mechanical behavior of Nylon 6 varies significantly with loading frequency, showing frequency-dependent stiffness and damping characteristics. At higher frequencies, Nylon 6 typically exhibits increased storage modulus and reduced damping, while at lower frequencies, it shows more viscous behavior. This frequency dependence affects the material's fatigue resistance under cyclic loading conditions. The molecular structure and crystallinity of Nylon 6 play important roles in determining its long-term performance under dynamic mechanical stress.Expand Specific Solutions04 Moisture and environmental effects on dynamic properties

Moisture absorption significantly influences the dynamic mechanical properties of Nylon 6. As a hygroscopic material, Nylon 6 can absorb moisture from the environment, which acts as a plasticizer, lowering the glass transition temperature and reducing stiffness while increasing damping capacity. Environmental factors such as humidity, temperature cycling, and exposure to chemicals can alter the viscoelastic response of Nylon 6. These effects must be considered when designing components that will operate in varying environmental conditions.Expand Specific Solutions05 Testing methods and characterization techniques

Various testing methods and characterization techniques are employed to analyze the dynamic mechanical behavior of Nylon 6. Dynamic Mechanical Analysis (DMA) is commonly used to measure storage modulus, loss modulus, and tan delta as functions of temperature, frequency, and amplitude. Other techniques include creep testing, stress relaxation measurements, and fatigue testing. Advanced analytical methods such as time-temperature superposition can be applied to predict long-term behavior from short-term tests. These testing protocols are essential for understanding the complex viscoelastic nature of Nylon 6 under dynamic conditions.Expand Specific Solutions

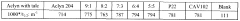

Leading Research Institutions and Manufacturers in Polymer Science

The dynamic mechanical behavior of Nylon 6 under temperature variation represents a mature research area within the broader polymer materials market, which is currently in a growth phase with increasing applications across automotive, electronics, and consumer goods sectors. The global market for high-performance polymers like Nylon 6 exceeds $30 billion annually, with steady growth projected. Technologically, companies like Kingfa Sci. & Tech., Ascend Performance Materials, and Shanghai Genius New Material have achieved significant advancements in temperature-dependent mechanical property optimization. Academic institutions including South China University of Technology and Huaqiao University collaborate with industrial players such as Stratasys and Donaldson Co. to develop enhanced thermal stability solutions, indicating a well-established ecosystem of innovation in this specialized field.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend Performance Materials has developed comprehensive methodologies for analyzing the dynamic mechanical behavior of Nylon 6 under varying temperature conditions. Their approach combines Dynamic Mechanical Analysis (DMA) with advanced thermal characterization techniques to map the viscoelastic properties across temperature ranges from -40°C to 200°C. Their proprietary testing protocols measure storage modulus, loss modulus, and tan delta values to characterize the glass transition temperature (Tg) and other thermal transitions specific to Nylon 6. Ascend has particularly focused on understanding how crystallinity levels affect mechanical performance under thermal cycling, developing predictive models that correlate processing conditions with final temperature-dependent properties. Their research has demonstrated that controlled cooling rates during processing can optimize crystalline structure to maintain mechanical integrity at elevated temperatures.

Strengths: Industry-leading expertise in polyamide chemistry with vertically integrated production capabilities allowing precise control over material formulation. Weaknesses: Their analysis methods may be optimized for their specific Nylon 6 formulations rather than providing universally applicable characterization approaches.

Huaqiao University

Technical Solution: Huaqiao University has conducted pioneering academic research on the dynamic mechanical behavior of Nylon 6 under temperature variation, with particular emphasis on multi-frequency analysis techniques. Their methodology employs advanced time-temperature superposition principles to develop master curves that predict mechanical behavior across broader temperature and frequency ranges than can be directly measured. Their research team has developed novel sample preparation techniques that control the initial crystallinity and orientation of Nylon 6 specimens, allowing systematic investigation of how these microstructural features influence temperature-dependent properties. Using a combination of DMA, DSC, and X-ray diffraction, they've mapped the relationship between crystal form transitions (α and γ phases) and mechanical property changes across temperature ranges from -40°C to 200°C. Their work has demonstrated that the α-to-γ crystal form transition, which occurs during thermal cycling, significantly impacts the dynamic mechanical response, with changes in storage modulus of up to 30% observed during this transition. Their research has also explored how various nucleating agents and processing aids can be used to control these transitions and optimize temperature-dependent mechanical properties.

Strengths: Fundamental scientific approach with deep understanding of structure-property relationships and crystal phase transitions in Nylon 6. Weaknesses: Academic focus may emphasize theoretical understanding over practical industrial applications and processing considerations.

Critical Research Findings on Nylon 6 Temperature-Dependent Properties

Nucleating agent for nylon system

PatentWO2013085970A1

Innovation

- A nucleating agent comprising ethylene-acrylic acid ionomers, talcum, and ethylene-acrylic acid copolymers, with specific molecular weight ranges and ratios, is used to enhance crystallization rate and heat distortion temperature in nylon resins, improving the nucleation process and resulting physical properties.

Material Processing Techniques Impact on Thermal-Mechanical Properties

The processing techniques employed in the manufacturing of Nylon 6 significantly influence its thermal-mechanical properties, particularly under varying temperature conditions. Conventional methods such as injection molding, extrusion, and compression molding each impart distinct molecular orientations and crystalline structures to the polymer matrix, directly affecting its dynamic mechanical behavior.

Injection molding, widely used for complex geometries, subjects Nylon 6 to rapid cooling from melt state, resulting in varying degrees of crystallinity throughout the part. This non-uniform crystalline structure creates anisotropic mechanical properties that respond differently to temperature fluctuations. Studies have shown that injection-molded Nylon 6 exhibits a more pronounced decrease in storage modulus with increasing temperature compared to other processing methods.

Extrusion processing, conversely, allows for more controlled cooling rates and typically produces more uniform crystallinity. The molecular chains in extruded Nylon 6 tend to align in the flow direction, creating directional mechanical properties that demonstrate greater thermal stability in the machine direction. This processing technique typically yields materials with higher temperature resistance before significant mechanical property degradation occurs.

Compression molding, characterized by lower shear rates and longer cooling times, produces Nylon 6 with higher overall crystallinity. This higher crystalline content translates to enhanced dimensional stability across broader temperature ranges, though often at the expense of impact resistance at lower temperatures. The glass transition temperature (Tg) of compression-molded Nylon 6 tends to shift slightly higher compared to other processing methods.

Post-processing treatments such as annealing significantly alter the thermal-mechanical profile of Nylon 6. Annealing allows for secondary crystallization, reducing internal stresses and enhancing dimensional stability under temperature variations. Research indicates that annealed Nylon 6 exhibits a less pronounced drop in storage modulus at temperatures approaching Tg, maintaining structural integrity over wider temperature ranges.

The incorporation of nucleating agents during processing represents another critical factor. These additives promote more uniform and finer crystalline structures, resulting in more consistent mechanical properties across temperature gradients. Nucleated Nylon 6 typically demonstrates reduced temperature sensitivity in its dynamic mechanical response, particularly in the range between room temperature and Tg.

Processing parameters such as mold temperature, cooling rate, and holding pressure further modulate the thermal-mechanical behavior. Higher mold temperatures generally produce higher crystallinity and better temperature resistance, while rapid cooling tends to create amorphous regions that exhibit more dramatic property changes with temperature variation. The optimization of these parameters enables tailoring of Nylon 6's performance for specific thermal-mechanical requirements.

Injection molding, widely used for complex geometries, subjects Nylon 6 to rapid cooling from melt state, resulting in varying degrees of crystallinity throughout the part. This non-uniform crystalline structure creates anisotropic mechanical properties that respond differently to temperature fluctuations. Studies have shown that injection-molded Nylon 6 exhibits a more pronounced decrease in storage modulus with increasing temperature compared to other processing methods.

Extrusion processing, conversely, allows for more controlled cooling rates and typically produces more uniform crystallinity. The molecular chains in extruded Nylon 6 tend to align in the flow direction, creating directional mechanical properties that demonstrate greater thermal stability in the machine direction. This processing technique typically yields materials with higher temperature resistance before significant mechanical property degradation occurs.

Compression molding, characterized by lower shear rates and longer cooling times, produces Nylon 6 with higher overall crystallinity. This higher crystalline content translates to enhanced dimensional stability across broader temperature ranges, though often at the expense of impact resistance at lower temperatures. The glass transition temperature (Tg) of compression-molded Nylon 6 tends to shift slightly higher compared to other processing methods.

Post-processing treatments such as annealing significantly alter the thermal-mechanical profile of Nylon 6. Annealing allows for secondary crystallization, reducing internal stresses and enhancing dimensional stability under temperature variations. Research indicates that annealed Nylon 6 exhibits a less pronounced drop in storage modulus at temperatures approaching Tg, maintaining structural integrity over wider temperature ranges.

The incorporation of nucleating agents during processing represents another critical factor. These additives promote more uniform and finer crystalline structures, resulting in more consistent mechanical properties across temperature gradients. Nucleated Nylon 6 typically demonstrates reduced temperature sensitivity in its dynamic mechanical response, particularly in the range between room temperature and Tg.

Processing parameters such as mold temperature, cooling rate, and holding pressure further modulate the thermal-mechanical behavior. Higher mold temperatures generally produce higher crystallinity and better temperature resistance, while rapid cooling tends to create amorphous regions that exhibit more dramatic property changes with temperature variation. The optimization of these parameters enables tailoring of Nylon 6's performance for specific thermal-mechanical requirements.

Sustainability Considerations in Nylon 6 Applications

The environmental impact of Nylon 6 has become increasingly significant as sustainability concerns rise across industries. When analyzing the dynamic mechanical behavior of Nylon 6 under temperature variation, it is essential to consider how these properties intersect with sustainability goals. Nylon 6's temperature-dependent performance directly influences product longevity, energy consumption during processing, and end-of-life management options.

Material efficiency represents a critical sustainability aspect of Nylon 6 applications. The polymer's mechanical resilience across varying temperatures enables the design of thinner, lighter components that maintain structural integrity, thereby reducing raw material consumption. However, this advantage must be balanced against the fossil fuel-derived nature of traditional Nylon 6 production, which contributes significantly to its carbon footprint.

Renewable alternatives are emerging in response to sustainability challenges. Bio-based Nylon 6 variants, derived partially or wholly from renewable resources, demonstrate comparable temperature-dependent mechanical properties while reducing reliance on petroleum feedstocks. These alternatives typically exhibit 15-30% lower carbon emissions during production, though often at premium costs and with potential land-use implications.

Recycling considerations are particularly relevant when examining Nylon 6's mechanical behavior across temperature ranges. The polymer's ability to maintain structural properties through multiple thermal processing cycles makes it theoretically suitable for mechanical recycling. However, practical challenges persist, as repeated thermal exposure during recycling processes can degrade performance properties, particularly impact resistance at low temperatures and dimensional stability at elevated temperatures.

Energy efficiency during processing represents another sustainability dimension. Understanding Nylon 6's dynamic mechanical response to temperature variations enables optimization of processing parameters, potentially reducing energy consumption during manufacturing. Advanced process control systems that leverage this knowledge can achieve energy savings of 10-20% compared to conventional approaches.

Lifecycle assessment studies indicate that the use phase often dominates Nylon 6's environmental impact profile, particularly in automotive and industrial applications. The material's temperature-dependent mechanical properties directly influence durability and functional longevity, with properly engineered components potentially extending service life by 30-50% compared to less optimized alternatives, significantly improving lifecycle sustainability metrics.

Emerging circular economy models for Nylon 6 are increasingly focusing on designing for disassembly and material recovery, informed by the polymer's mechanical behavior across its operational temperature range. These approaches aim to preserve the material's value through multiple use cycles, reducing overall environmental impact while maintaining economic viability.

Material efficiency represents a critical sustainability aspect of Nylon 6 applications. The polymer's mechanical resilience across varying temperatures enables the design of thinner, lighter components that maintain structural integrity, thereby reducing raw material consumption. However, this advantage must be balanced against the fossil fuel-derived nature of traditional Nylon 6 production, which contributes significantly to its carbon footprint.

Renewable alternatives are emerging in response to sustainability challenges. Bio-based Nylon 6 variants, derived partially or wholly from renewable resources, demonstrate comparable temperature-dependent mechanical properties while reducing reliance on petroleum feedstocks. These alternatives typically exhibit 15-30% lower carbon emissions during production, though often at premium costs and with potential land-use implications.

Recycling considerations are particularly relevant when examining Nylon 6's mechanical behavior across temperature ranges. The polymer's ability to maintain structural properties through multiple thermal processing cycles makes it theoretically suitable for mechanical recycling. However, practical challenges persist, as repeated thermal exposure during recycling processes can degrade performance properties, particularly impact resistance at low temperatures and dimensional stability at elevated temperatures.

Energy efficiency during processing represents another sustainability dimension. Understanding Nylon 6's dynamic mechanical response to temperature variations enables optimization of processing parameters, potentially reducing energy consumption during manufacturing. Advanced process control systems that leverage this knowledge can achieve energy savings of 10-20% compared to conventional approaches.

Lifecycle assessment studies indicate that the use phase often dominates Nylon 6's environmental impact profile, particularly in automotive and industrial applications. The material's temperature-dependent mechanical properties directly influence durability and functional longevity, with properly engineered components potentially extending service life by 30-50% compared to less optimized alternatives, significantly improving lifecycle sustainability metrics.

Emerging circular economy models for Nylon 6 are increasingly focusing on designing for disassembly and material recovery, informed by the polymer's mechanical behavior across its operational temperature range. These approaches aim to preserve the material's value through multiple use cycles, reducing overall environmental impact while maintaining economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!