Nylon 6 modification through reactive extrusion and crosslinking

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Modification Background and Objectives

Nylon 6, a synthetic polymer first developed in the 1930s by Wallace Carothers at DuPont, has become one of the most widely used engineering thermoplastics due to its excellent mechanical properties, chemical resistance, and processability. Despite its commercial success, Nylon 6 exhibits certain limitations including moisture sensitivity, dimensional instability, and relatively low heat deflection temperature, which restrict its application in demanding environments.

The evolution of Nylon 6 modification techniques has progressed significantly over the past decades, from simple blending with other polymers to more sophisticated chemical modifications. Reactive extrusion emerged in the 1980s as a cost-effective, environmentally friendly, and industrially viable technique for polymer modification, allowing for continuous processing and eliminating the need for solvents.

Crosslinking, as a specific modification approach, has gained substantial attention since the 1990s for its ability to create three-dimensional networks within the polymer matrix, thereby enhancing thermal stability, mechanical strength, and chemical resistance. The combination of reactive extrusion with crosslinking represents a particularly promising direction for Nylon 6 modification, as it enables precise control over the modification process while maintaining industrial scalability.

Current technological trends in this field are moving toward more sustainable and efficient modification methods, including the use of bio-based crosslinking agents, catalyst optimization for lower energy consumption, and the development of multi-functional additives that can simultaneously address multiple property limitations of Nylon 6.

The primary objectives of research in Nylon 6 modification through reactive extrusion and crosslinking are multifaceted. First, to develop industrially viable processes that can be implemented without significant capital investment in existing manufacturing facilities. Second, to enhance the thermal stability of Nylon 6, increasing its heat deflection temperature by at least 20-30°C to expand its application range in automotive and electrical components.

Additionally, researchers aim to improve the hydrolytic stability of Nylon 6, reducing its moisture absorption by 40-50% compared to unmodified material, while maintaining or enhancing its mechanical properties, particularly impact strength and tensile modulus. Another critical objective is to achieve these improvements without significantly compromising the recyclability of the material, addressing growing sustainability concerns in the plastics industry.

The ultimate goal is to position modified Nylon 6 as a cost-effective alternative to higher-performance engineering plastics such as polyphenylene sulfide (PPS) or polyetherimide (PEI) in specific applications, thereby expanding market opportunities while maintaining the economic advantages that have made Nylon 6 successful in various industries.

The evolution of Nylon 6 modification techniques has progressed significantly over the past decades, from simple blending with other polymers to more sophisticated chemical modifications. Reactive extrusion emerged in the 1980s as a cost-effective, environmentally friendly, and industrially viable technique for polymer modification, allowing for continuous processing and eliminating the need for solvents.

Crosslinking, as a specific modification approach, has gained substantial attention since the 1990s for its ability to create three-dimensional networks within the polymer matrix, thereby enhancing thermal stability, mechanical strength, and chemical resistance. The combination of reactive extrusion with crosslinking represents a particularly promising direction for Nylon 6 modification, as it enables precise control over the modification process while maintaining industrial scalability.

Current technological trends in this field are moving toward more sustainable and efficient modification methods, including the use of bio-based crosslinking agents, catalyst optimization for lower energy consumption, and the development of multi-functional additives that can simultaneously address multiple property limitations of Nylon 6.

The primary objectives of research in Nylon 6 modification through reactive extrusion and crosslinking are multifaceted. First, to develop industrially viable processes that can be implemented without significant capital investment in existing manufacturing facilities. Second, to enhance the thermal stability of Nylon 6, increasing its heat deflection temperature by at least 20-30°C to expand its application range in automotive and electrical components.

Additionally, researchers aim to improve the hydrolytic stability of Nylon 6, reducing its moisture absorption by 40-50% compared to unmodified material, while maintaining or enhancing its mechanical properties, particularly impact strength and tensile modulus. Another critical objective is to achieve these improvements without significantly compromising the recyclability of the material, addressing growing sustainability concerns in the plastics industry.

The ultimate goal is to position modified Nylon 6 as a cost-effective alternative to higher-performance engineering plastics such as polyphenylene sulfide (PPS) or polyetherimide (PEI) in specific applications, thereby expanding market opportunities while maintaining the economic advantages that have made Nylon 6 successful in various industries.

Market Demand Analysis for Modified Nylon 6

The global market for modified Nylon 6 has been experiencing robust growth, driven primarily by increasing demand from automotive, electrical & electronics, and consumer goods industries. The market size for modified Nylon 6 was valued at approximately 7.2 billion USD in 2022 and is projected to reach 10.5 billion USD by 2028, representing a compound annual growth rate (CAGR) of 6.4%.

Reactive extrusion and crosslinking modifications of Nylon 6 are gaining significant traction due to their ability to enhance mechanical properties, thermal stability, and chemical resistance of the base polymer. The automotive sector remains the largest consumer of modified Nylon 6, accounting for nearly 35% of the total market share. This demand is fueled by the ongoing trend toward vehicle lightweighting to improve fuel efficiency and reduce emissions, where modified Nylon 6 serves as an excellent metal replacement option.

The electrical and electronics industry represents the fastest-growing segment for modified Nylon 6, with a CAGR of 7.8%. This growth is attributed to the material's excellent electrical insulation properties, flame retardancy, and dimensional stability under varying temperatures - critical requirements for components in modern electronic devices and electrical systems.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. The region's manufacturing prowess, coupled with increasing industrialization and urbanization, continues to drive demand. North America and Europe follow with market shares of 25% and 22% respectively, where demand is primarily driven by high-performance applications in automotive and aerospace sectors.

Consumer preferences are increasingly shifting toward sustainable and eco-friendly materials. This trend has created a growing niche for bio-based and recyclable modified Nylon 6 variants. Market research indicates that products marketed as environmentally sustainable command a premium of 15-20% and are growing at nearly twice the rate of conventional alternatives.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, causing a 12% decline in market value during 2020. However, the market demonstrated remarkable resilience, recovering fully by mid-2021 and subsequently exceeding pre-pandemic growth trajectories. This recovery was partly accelerated by increased demand from healthcare applications, where modified Nylon 6 found new uses in medical devices and personal protective equipment.

Industry forecasts suggest that technological advancements in reactive extrusion processes and novel crosslinking agents will continue to expand the application scope of modified Nylon 6, creating new market opportunities. The growing emphasis on circular economy principles is expected to further drive innovation in recyclable and biodegradable variants of modified Nylon 6 in the coming years.

Reactive extrusion and crosslinking modifications of Nylon 6 are gaining significant traction due to their ability to enhance mechanical properties, thermal stability, and chemical resistance of the base polymer. The automotive sector remains the largest consumer of modified Nylon 6, accounting for nearly 35% of the total market share. This demand is fueled by the ongoing trend toward vehicle lightweighting to improve fuel efficiency and reduce emissions, where modified Nylon 6 serves as an excellent metal replacement option.

The electrical and electronics industry represents the fastest-growing segment for modified Nylon 6, with a CAGR of 7.8%. This growth is attributed to the material's excellent electrical insulation properties, flame retardancy, and dimensional stability under varying temperatures - critical requirements for components in modern electronic devices and electrical systems.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, led by China, Japan, and South Korea. The region's manufacturing prowess, coupled with increasing industrialization and urbanization, continues to drive demand. North America and Europe follow with market shares of 25% and 22% respectively, where demand is primarily driven by high-performance applications in automotive and aerospace sectors.

Consumer preferences are increasingly shifting toward sustainable and eco-friendly materials. This trend has created a growing niche for bio-based and recyclable modified Nylon 6 variants. Market research indicates that products marketed as environmentally sustainable command a premium of 15-20% and are growing at nearly twice the rate of conventional alternatives.

The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, causing a 12% decline in market value during 2020. However, the market demonstrated remarkable resilience, recovering fully by mid-2021 and subsequently exceeding pre-pandemic growth trajectories. This recovery was partly accelerated by increased demand from healthcare applications, where modified Nylon 6 found new uses in medical devices and personal protective equipment.

Industry forecasts suggest that technological advancements in reactive extrusion processes and novel crosslinking agents will continue to expand the application scope of modified Nylon 6, creating new market opportunities. The growing emphasis on circular economy principles is expected to further drive innovation in recyclable and biodegradable variants of modified Nylon 6 in the coming years.

Technical Challenges in Reactive Extrusion Processes

Reactive extrusion of Nylon 6 presents several significant technical challenges that must be addressed to achieve successful modification and crosslinking. The primary challenge lies in controlling the reaction kinetics during the extrusion process. Unlike batch reactors, extruders provide limited residence time, typically ranging from 30 seconds to 5 minutes, which necessitates rapid reaction rates to achieve desired conversion levels within this constrained timeframe.

Temperature control represents another critical challenge, as Nylon 6 processing requires high temperatures (230-280°C) that can simultaneously promote desired reactions and unwanted side reactions. The narrow processing window between effective modification and polymer degradation demands precise thermal management throughout the extruder barrel sections. Even minor temperature fluctuations can significantly impact reaction pathways and product quality.

Mixing efficiency poses substantial difficulties due to the high viscosity of molten Nylon 6. Achieving homogeneous distribution of reactive agents throughout the polymer matrix requires specialized screw designs and mixing elements. Inadequate mixing leads to concentration gradients, resulting in inconsistent modification and property variations across the final product.

Moisture control emerges as a particularly challenging aspect specific to Nylon 6 processing. As a hygroscopic material, Nylon 6 must be thoroughly dried before processing to prevent hydrolytic degradation. However, certain modification reactions may actually require controlled amounts of moisture as a reaction medium, creating a complex balance between necessary and detrimental moisture levels.

Reactive agent selection and delivery mechanisms present additional challenges. Crosslinking agents must possess sufficient thermal stability to survive processing temperatures while maintaining reactivity toward specific functional groups. The timing of reactive agent introduction into the extruder becomes critical - premature reaction can cause screw blockage, while delayed introduction may result in insufficient reaction time.

Monitoring and characterizing reactions in real-time within the extruder environment remains technically difficult. Unlike laboratory settings, the high-pressure, high-temperature conditions inside an extruder limit the application of conventional analytical techniques. This creates significant obstacles for process optimization and quality control.

Scale-up challenges further complicate industrial implementation. Reaction parameters optimized at laboratory scale often perform differently in production-scale extruders due to differences in surface-to-volume ratios, heat transfer characteristics, and mixing dynamics. Developing reliable scale-up methodologies requires extensive experimentation and modeling.

Finally, achieving consistent product quality while maintaining production efficiency presents an ongoing challenge. The reactive extrusion process must be robust enough to accommodate minor variations in raw materials and processing conditions without compromising the modified Nylon 6 properties.

Temperature control represents another critical challenge, as Nylon 6 processing requires high temperatures (230-280°C) that can simultaneously promote desired reactions and unwanted side reactions. The narrow processing window between effective modification and polymer degradation demands precise thermal management throughout the extruder barrel sections. Even minor temperature fluctuations can significantly impact reaction pathways and product quality.

Mixing efficiency poses substantial difficulties due to the high viscosity of molten Nylon 6. Achieving homogeneous distribution of reactive agents throughout the polymer matrix requires specialized screw designs and mixing elements. Inadequate mixing leads to concentration gradients, resulting in inconsistent modification and property variations across the final product.

Moisture control emerges as a particularly challenging aspect specific to Nylon 6 processing. As a hygroscopic material, Nylon 6 must be thoroughly dried before processing to prevent hydrolytic degradation. However, certain modification reactions may actually require controlled amounts of moisture as a reaction medium, creating a complex balance between necessary and detrimental moisture levels.

Reactive agent selection and delivery mechanisms present additional challenges. Crosslinking agents must possess sufficient thermal stability to survive processing temperatures while maintaining reactivity toward specific functional groups. The timing of reactive agent introduction into the extruder becomes critical - premature reaction can cause screw blockage, while delayed introduction may result in insufficient reaction time.

Monitoring and characterizing reactions in real-time within the extruder environment remains technically difficult. Unlike laboratory settings, the high-pressure, high-temperature conditions inside an extruder limit the application of conventional analytical techniques. This creates significant obstacles for process optimization and quality control.

Scale-up challenges further complicate industrial implementation. Reaction parameters optimized at laboratory scale often perform differently in production-scale extruders due to differences in surface-to-volume ratios, heat transfer characteristics, and mixing dynamics. Developing reliable scale-up methodologies requires extensive experimentation and modeling.

Finally, achieving consistent product quality while maintaining production efficiency presents an ongoing challenge. The reactive extrusion process must be robust enough to accommodate minor variations in raw materials and processing conditions without compromising the modified Nylon 6 properties.

Current Reactive Extrusion and Crosslinking Methods

01 Chemical crosslinking methods for Nylon 6

Various chemical agents can be used to create crosslinks in Nylon 6 polymers, enhancing their mechanical properties and thermal stability. These methods typically involve the use of reactive compounds that can form covalent bonds between polymer chains. Common crosslinking agents include peroxides, isocyanates, epoxides, and multifunctional carboxylic acids. The crosslinking reaction often requires specific catalysts and controlled reaction conditions to achieve the desired degree of crosslinking without degrading the polymer.- Chemical crosslinking methods for Nylon 6: Various chemical agents can be used to create crosslinks in Nylon 6 polymers, enhancing their mechanical properties and thermal stability. Common crosslinking agents include isocyanates, epoxides, and peroxides that react with the amide groups or chain ends of Nylon 6. These reactions typically form covalent bonds between polymer chains, resulting in a three-dimensional network structure that improves the material's resistance to deformation and chemical solvents.

- Radiation-induced crosslinking of Nylon 6: Radiation techniques can be employed to modify Nylon 6 through crosslinking without chemical additives. High-energy radiation sources such as electron beams, gamma rays, or UV light generate free radicals in the polymer structure, which then recombine to form crosslinks between adjacent polymer chains. This method allows for controlled modification of material properties and can be performed on finished products. The degree of crosslinking can be adjusted by varying the radiation dose and exposure time.

- Nylon 6 modification with functional additives: Incorporating functional additives into Nylon 6 can enhance specific properties while facilitating crosslinking. These additives include nanoparticles, reactive monomers, and functional fillers that can be blended with the polymer matrix. The additives often contain reactive groups that participate in crosslinking reactions during processing or post-treatment. This approach allows for tailored modification of properties such as flame retardancy, conductivity, or antimicrobial activity while simultaneously improving the mechanical performance through crosslinking.

- Processing techniques for crosslinked Nylon 6: Specialized processing techniques are essential for effectively crosslinking Nylon 6 while maintaining processability. These include reactive extrusion, where crosslinking agents are introduced during the melt processing stage, and post-processing treatments such as annealing or curing steps. The processing parameters, including temperature profiles, residence time, and cooling rates, significantly influence the crosslinking density and distribution throughout the material. Advanced techniques like multi-stage processing allow for optimized material properties while overcoming the challenges associated with processing increasingly viscous crosslinked materials.

- Applications of modified and crosslinked Nylon 6: Crosslinked Nylon 6 materials find applications in demanding environments where standard polyamides would be insufficient. These applications include high-temperature automotive components, chemical-resistant industrial parts, and durable consumer goods. The enhanced properties achieved through crosslinking, such as improved creep resistance, reduced water absorption, and better dimensional stability, make these materials suitable for specialized applications. Modified Nylon 6 can also be formulated into composites, fibers, and films with unique property combinations not achievable with conventional polyamides.

02 Radiation-induced crosslinking of Nylon 6

Radiation techniques can be employed to modify Nylon 6 through crosslinking without the need for chemical additives. This process involves exposing the polymer to high-energy radiation such as gamma rays, electron beams, or UV light, which generates free radicals that subsequently form crosslinks between polymer chains. The degree of crosslinking can be controlled by adjusting the radiation dose and exposure time. This method is particularly valuable for applications requiring sterile materials, as the radiation process can simultaneously crosslink the polymer and sterilize the product.Expand Specific Solutions03 Nylon 6 modification with nanomaterials

Incorporating nanomaterials into Nylon 6 can significantly enhance its properties while facilitating crosslinking. Nanofillers such as clay, silica, carbon nanotubes, and graphene can be dispersed within the polymer matrix, creating interfacial interactions that effectively serve as physical crosslinks. These nanomaterials can also be functionalized to form chemical bonds with the polymer chains. The resulting nanocomposites exhibit improved mechanical strength, thermal stability, barrier properties, and flame resistance compared to unmodified Nylon 6.Expand Specific Solutions04 Blending and copolymerization approaches

Nylon 6 can be modified through blending with other polymers or through copolymerization with different monomers to introduce crosslinking sites. Reactive blending involves mixing Nylon 6 with polymers containing functional groups that can react with the amide groups in Nylon 6. Copolymerization introduces comonomers with multiple functional groups that can participate in crosslinking reactions. These approaches allow for tailoring the degree of crosslinking and the resulting properties of the modified material, such as improved impact resistance, reduced water absorption, and enhanced dimensional stability.Expand Specific Solutions05 Surface modification and crosslinking of Nylon 6 fibers

Surface treatments can be applied to Nylon 6 fibers to introduce crosslinks primarily at the surface while maintaining the bulk properties of the material. These treatments include plasma processing, UV irradiation, chemical grafting, and coating with crosslinkable resins. Surface crosslinking enhances the fiber's resistance to abrasion, chemicals, and weathering. It can also improve dyeability, adhesion properties, and reduce static charge accumulation. This approach is particularly valuable for textile applications where the surface properties significantly impact the performance of the final product.Expand Specific Solutions

Key Industry Players in Polymer Modification

The Nylon 6 modification market through reactive extrusion and crosslinking is currently in a growth phase, with increasing demand driven by automotive, electronics, and industrial applications requiring enhanced mechanical properties. The global market size for modified nylon materials is estimated at $2-3 billion annually, with projected CAGR of 5-7%. Technologically, the field shows varying maturity levels across players. Leading companies like Ascend Performance Materials and China Petroleum & Chemical Corp. demonstrate advanced capabilities in reactive modification techniques, while academic institutions including Hunan University and Donghua University contribute significant research innovations. Chinese enterprises such as Silver Age Engineering Plastics and PRET Composites are rapidly advancing their technological capabilities, narrowing the gap with international competitors through strategic R&D investments in crosslinking methodologies and functional additives.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive reactive extrusion technology for Nylon 6 modification that employs multi-functional epoxy compounds as crosslinking agents. Their process utilizes twin-screw extruders with specialized screw configurations to optimize mixing and reaction kinetics. The technology incorporates controlled addition of chain extenders and reactive compatibilizers during extrusion, allowing for precise control of crosslinking density. Sinopec's approach includes a proprietary stabilization system that prevents thermal degradation during processing while promoting uniform crosslink formation. Their method achieves significant improvements in heat resistance, with heat deflection temperature increases of up to 30°C, and enhanced chemical resistance against automotive fluids and hydrocarbons. The modified Nylon 6 exhibits improved dimensional stability with reduced water absorption (approximately 40% lower than standard Nylon 6) and superior mechanical properties under elevated temperatures.

Strengths: Excellent control over crosslinking density, superior thermal stability during processing, and significant improvements in heat and chemical resistance. The technology is scalable for industrial production with consistent quality. Weaknesses: Requires specialized equipment and precise process control, potentially increasing production costs. The crosslinking process may reduce recyclability of the material.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend Performance Materials has pioneered an innovative reactive extrusion technology for Nylon 6 modification called HiDura™, which utilizes a proprietary blend of multifunctional peroxides and co-agents to achieve controlled crosslinking. Their process employs a specialized reactive extrusion system with optimized screw design that creates distinct reaction zones for melting, additive incorporation, and controlled crosslinking. The technology incorporates real-time monitoring of torque and melt pressure to dynamically adjust processing parameters, ensuring consistent crosslink density. Ascend's method introduces nano-dispersed silica particles functionalized with reactive groups that participate in the crosslinking reaction, creating a hybrid organic-inorganic network structure. This approach results in Nylon 6 with exceptional dimensional stability (less than 0.2% dimensional change after 1000 hours at 150°C), improved chemical resistance to automotive fluids, and enhanced mechanical properties retention at elevated temperatures (maintaining over 70% of room temperature tensile strength at 150°C).

Strengths: Highly controlled crosslinking process with real-time monitoring capabilities, excellent high-temperature performance, and superior dimensional stability. The hybrid network structure provides a unique combination of properties. Weaknesses: The specialized additives and processing equipment increase production costs. The complex formulation may create challenges for quality control and consistency across production batches.

Critical Patents in Nylon 6 Crosslinking Technology

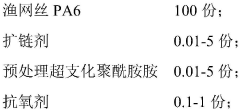

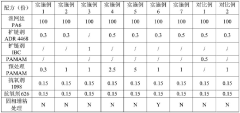

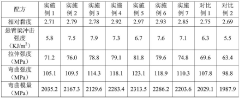

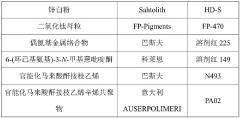

Isomeric micro-crosslinking regenerated nylon and preparation method thereof

PatentActiveCN115160771A

Innovation

- Active end-group dendritic polyamidoamines are used in conjunction with chain extenders. The hyperbranched polyamidoamines and high melting point polymers are evenly dispersed through pretreatment to avoid the chain extenders from forming gels in local areas, and through specific extrusion The process parameters control the reaction between the chain extender and the hyperbranched polyamidoamine in the melt plasticizing section and the mixing section to form a micro-crosslinked structure.

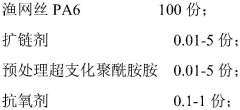

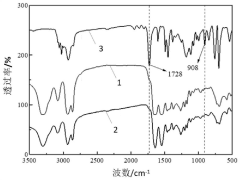

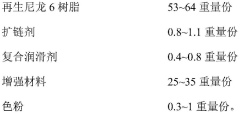

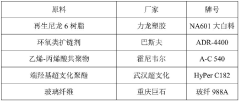

Anti-discoloration chain extension modified regenerated nylon 6 material as well as preparation method and application thereof

PatentActiveCN115160775A

Innovation

- By adding a chain extender and a specific portion of toner to the raw materials, combined with a composite lubricant and reinforcing materials, chemical chain extension is used to modify the regenerated nylon 6 resin to improve its mechanical properties and thermal stability, and through a specific composition According to the proportion and process conditions, a regenerated nylon 6 material with excellent color change resistance was prepared.

Environmental Impact and Sustainability Considerations

The environmental impact of Nylon 6 modification through reactive extrusion and crosslinking processes requires careful consideration as polymer manufacturing traditionally involves significant resource consumption and waste generation. The reactive extrusion process, while efficient for continuous production, consumes substantial energy due to high processing temperatures (typically 220-260°C) required for Nylon 6 modification. This energy demand contributes to the carbon footprint of the final product, particularly when fossil fuel-derived energy sources are utilized.

Chemical crosslinking agents employed in Nylon 6 modification present additional environmental concerns. Many traditional crosslinking agents contain formaldehyde, isocyanates, or other potentially hazardous compounds that may pose risks to ecosystems and human health if improperly managed. Residual unreacted crosslinking agents and byproducts can potentially leach into the environment during the product lifecycle, necessitating thorough assessment of their ecotoxicological profiles.

Water consumption represents another significant environmental aspect of modified Nylon 6 production. The polymer processing and subsequent washing steps to remove unreacted components can require substantial water resources. Additionally, wastewater from these processes may contain polymer residues, unreacted monomers, and processing additives that require appropriate treatment before discharge.

Recent sustainability advancements in Nylon 6 modification include the development of bio-based crosslinking agents derived from renewable resources such as citric acid, plant oils, and carbohydrates. These alternatives can reduce dependence on petroleum-derived chemicals while maintaining comparable performance characteristics. Furthermore, research into catalyst optimization has demonstrated potential for lowering reaction temperatures and processing energy requirements by 15-20%.

End-of-life considerations for crosslinked Nylon 6 present particular challenges for sustainability. The crosslinked structure, while beneficial for mechanical and thermal properties, inherently reduces recyclability through conventional mechanical recycling methods. Chemical recycling approaches, such as depolymerization through hydrolysis or aminolysis, offer promising alternatives but require additional energy input and specialized facilities.

Life cycle assessment (LCA) studies comparing traditional and modified Nylon 6 indicate that improvements in durability and performance from crosslinking can offset initial environmental impacts through extended product lifespans. For instance, crosslinked Nylon 6 components in automotive applications demonstrate 30-40% longer service lives, potentially reducing overall material consumption and associated environmental impacts over time.

Chemical crosslinking agents employed in Nylon 6 modification present additional environmental concerns. Many traditional crosslinking agents contain formaldehyde, isocyanates, or other potentially hazardous compounds that may pose risks to ecosystems and human health if improperly managed. Residual unreacted crosslinking agents and byproducts can potentially leach into the environment during the product lifecycle, necessitating thorough assessment of their ecotoxicological profiles.

Water consumption represents another significant environmental aspect of modified Nylon 6 production. The polymer processing and subsequent washing steps to remove unreacted components can require substantial water resources. Additionally, wastewater from these processes may contain polymer residues, unreacted monomers, and processing additives that require appropriate treatment before discharge.

Recent sustainability advancements in Nylon 6 modification include the development of bio-based crosslinking agents derived from renewable resources such as citric acid, plant oils, and carbohydrates. These alternatives can reduce dependence on petroleum-derived chemicals while maintaining comparable performance characteristics. Furthermore, research into catalyst optimization has demonstrated potential for lowering reaction temperatures and processing energy requirements by 15-20%.

End-of-life considerations for crosslinked Nylon 6 present particular challenges for sustainability. The crosslinked structure, while beneficial for mechanical and thermal properties, inherently reduces recyclability through conventional mechanical recycling methods. Chemical recycling approaches, such as depolymerization through hydrolysis or aminolysis, offer promising alternatives but require additional energy input and specialized facilities.

Life cycle assessment (LCA) studies comparing traditional and modified Nylon 6 indicate that improvements in durability and performance from crosslinking can offset initial environmental impacts through extended product lifespans. For instance, crosslinked Nylon 6 components in automotive applications demonstrate 30-40% longer service lives, potentially reducing overall material consumption and associated environmental impacts over time.

Scale-up Challenges and Industrial Implementation

The transition from laboratory-scale reactive extrusion processes for Nylon 6 modification to industrial implementation presents significant challenges that require careful consideration. When scaling up reactive extrusion and crosslinking processes, maintaining consistent product quality becomes increasingly difficult due to variations in residence time distribution, mixing efficiency, and heat transfer characteristics across larger equipment.

One primary challenge is achieving uniform temperature control throughout the extruder barrel. In laboratory settings, the small diameter of extruders allows for relatively homogeneous temperature profiles. However, industrial-scale extruders with larger diameters create temperature gradients that can lead to inconsistent reaction kinetics and product properties. This necessitates sophisticated temperature control systems and potentially modified screw designs to ensure proper heat distribution.

Mixing efficiency represents another critical scale-up challenge. The crosslinking reactions in Nylon 6 modification require intimate contact between polymer chains and crosslinking agents. As equipment size increases, achieving the same level of distributive and dispersive mixing becomes more difficult. Industrial implementations often require specialized mixing elements and optimized screw configurations to maintain reaction homogeneity throughout the larger processing volume.

Residence time control also becomes more complex at industrial scale. The reaction kinetics for crosslinking are highly time-dependent, and variations in residence time can significantly impact the degree of modification. Larger extruders typically exhibit broader residence time distributions, potentially resulting in inconsistent product properties. Manufacturers must carefully design screw geometries and operating parameters to narrow these distributions and ensure consistent reaction completion.

Material handling considerations intensify with scale-up as well. The reactive additives used for Nylon 6 modification often require precise dosing and may be sensitive to atmospheric exposure. Industrial implementation necessitates robust feeding systems capable of accurately metering reactive components while maintaining their chemical integrity. Additionally, the increased throughput demands efficient downstream processing equipment to handle the modified polymer without degradation.

Economic viability represents the final major hurdle in scale-up. The capital investment for industrial-scale reactive extrusion equipment is substantial, and operating costs increase with size. Manufacturers must carefully balance production efficiency against quality requirements to ensure the modified Nylon 6 products can be produced at competitive price points while maintaining the enhanced properties that justify the modification process.

One primary challenge is achieving uniform temperature control throughout the extruder barrel. In laboratory settings, the small diameter of extruders allows for relatively homogeneous temperature profiles. However, industrial-scale extruders with larger diameters create temperature gradients that can lead to inconsistent reaction kinetics and product properties. This necessitates sophisticated temperature control systems and potentially modified screw designs to ensure proper heat distribution.

Mixing efficiency represents another critical scale-up challenge. The crosslinking reactions in Nylon 6 modification require intimate contact between polymer chains and crosslinking agents. As equipment size increases, achieving the same level of distributive and dispersive mixing becomes more difficult. Industrial implementations often require specialized mixing elements and optimized screw configurations to maintain reaction homogeneity throughout the larger processing volume.

Residence time control also becomes more complex at industrial scale. The reaction kinetics for crosslinking are highly time-dependent, and variations in residence time can significantly impact the degree of modification. Larger extruders typically exhibit broader residence time distributions, potentially resulting in inconsistent product properties. Manufacturers must carefully design screw geometries and operating parameters to narrow these distributions and ensure consistent reaction completion.

Material handling considerations intensify with scale-up as well. The reactive additives used for Nylon 6 modification often require precise dosing and may be sensitive to atmospheric exposure. Industrial implementation necessitates robust feeding systems capable of accurately metering reactive components while maintaining their chemical integrity. Additionally, the increased throughput demands efficient downstream processing equipment to handle the modified polymer without degradation.

Economic viability represents the final major hurdle in scale-up. The capital investment for industrial-scale reactive extrusion equipment is substantial, and operating costs increase with size. Manufacturers must carefully balance production efficiency against quality requirements to ensure the modified Nylon 6 products can be produced at competitive price points while maintaining the enhanced properties that justify the modification process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!