What role do compatibilizers play in Nylon 6–polyolefin blends

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Compatibilizer Technology Background and Objectives

Compatibilizers have emerged as critical components in polymer blending technology, particularly for Nylon 6-polyolefin systems, which represent one of the most commercially significant engineering plastic-commodity polymer combinations. The historical development of compatibilizer technology dates back to the 1970s when researchers began exploring methods to overcome the inherent immiscibility between polar polyamides and non-polar polyolefins. Early approaches relied primarily on reactive extrusion techniques, but significant advancements occurred in the 1990s with the introduction of maleic anhydride grafted polyolefins.

The evolution of compatibilizer technology has followed a clear trajectory from simple physical blending to sophisticated reactive compatibilization strategies. This progression has been driven by increasing demands for materials with enhanced mechanical properties, improved processability, and reduced production costs across automotive, packaging, and consumer goods industries. The fundamental challenge being addressed is the poor interfacial adhesion between Nylon 6 and polyolefins, which results in phase separation and consequently inferior mechanical properties in the final blends.

Current technological trends indicate a shift toward more specialized compatibilizer designs, including functionalized block copolymers, core-shell nanoparticles, and in-situ reactive compatibilization approaches. These advanced compatibilizers aim to create controlled morphologies at the interface between Nylon 6 and polyolefin phases, thereby enhancing stress transfer and overall blend performance. The growing emphasis on sustainability has also spurred research into bio-based compatibilizers and recyclability-enhancing additives.

The primary technical objectives in this field include developing compatibilizers that can effectively reduce interfacial tension, promote finer dispersion of the minor phase, stabilize the morphology during processing, and create strong interfacial bonds between the blend components. Additionally, there is significant interest in compatibilizers that can function at lower loading levels while maintaining or improving blend properties, thus optimizing cost-performance ratios.

Recent advances in analytical techniques, particularly in electron microscopy and spectroscopic methods, have enabled more precise characterization of the interfacial phenomena in compatibilized blends. This improved understanding has facilitated more rational design approaches for compatibilizer molecules, moving beyond empirical formulation toward predictive models based on molecular architecture and reactivity principles.

The ultimate goal of compatibilizer technology development for Nylon 6-polyolefin blends is to create materials with synergistic property combinations that exceed those of the individual components, while maintaining processability comparable to conventional thermoplastics. This includes achieving enhanced impact strength without sacrificing tensile properties, improved barrier characteristics, and controlled crystallization behavior, all of which are critical for expanding the application range of these versatile material systems.

The evolution of compatibilizer technology has followed a clear trajectory from simple physical blending to sophisticated reactive compatibilization strategies. This progression has been driven by increasing demands for materials with enhanced mechanical properties, improved processability, and reduced production costs across automotive, packaging, and consumer goods industries. The fundamental challenge being addressed is the poor interfacial adhesion between Nylon 6 and polyolefins, which results in phase separation and consequently inferior mechanical properties in the final blends.

Current technological trends indicate a shift toward more specialized compatibilizer designs, including functionalized block copolymers, core-shell nanoparticles, and in-situ reactive compatibilization approaches. These advanced compatibilizers aim to create controlled morphologies at the interface between Nylon 6 and polyolefin phases, thereby enhancing stress transfer and overall blend performance. The growing emphasis on sustainability has also spurred research into bio-based compatibilizers and recyclability-enhancing additives.

The primary technical objectives in this field include developing compatibilizers that can effectively reduce interfacial tension, promote finer dispersion of the minor phase, stabilize the morphology during processing, and create strong interfacial bonds between the blend components. Additionally, there is significant interest in compatibilizers that can function at lower loading levels while maintaining or improving blend properties, thus optimizing cost-performance ratios.

Recent advances in analytical techniques, particularly in electron microscopy and spectroscopic methods, have enabled more precise characterization of the interfacial phenomena in compatibilized blends. This improved understanding has facilitated more rational design approaches for compatibilizer molecules, moving beyond empirical formulation toward predictive models based on molecular architecture and reactivity principles.

The ultimate goal of compatibilizer technology development for Nylon 6-polyolefin blends is to create materials with synergistic property combinations that exceed those of the individual components, while maintaining processability comparable to conventional thermoplastics. This includes achieving enhanced impact strength without sacrificing tensile properties, improved barrier characteristics, and controlled crystallization behavior, all of which are critical for expanding the application range of these versatile material systems.

Market Analysis for Nylon 6-Polyolefin Blends

The global market for Nylon 6-polyolefin blends has been experiencing steady growth, driven primarily by increasing demand in automotive, packaging, and consumer goods industries. These blends combine the excellent mechanical properties and heat resistance of Nylon 6 with the flexibility, chemical resistance, and cost-effectiveness of polyolefins, creating materials with enhanced performance characteristics.

Market research indicates that the automotive sector represents the largest application segment for these blends, accounting for approximately 40% of total consumption. The push for lightweight materials to improve fuel efficiency and reduce emissions has significantly boosted demand in this sector. Manufacturers are increasingly replacing metal components with high-performance polymer blends, particularly in under-the-hood applications where temperature resistance is critical.

The packaging industry follows as the second-largest consumer of Nylon 6-polyolefin blends, particularly in barrier film applications where oxygen and moisture resistance are essential. The food packaging segment has shown particularly strong growth rates due to increasing consumer preference for extended shelf-life products and convenient packaging solutions.

Regional analysis reveals that Asia-Pacific dominates the market, led by China and India's rapidly expanding manufacturing sectors. North America and Europe maintain significant market shares, with demand primarily driven by technological advancements in automotive and industrial applications. The Middle East market is showing promising growth potential due to increasing investments in plastic processing capabilities.

Market forecasts suggest a compound annual growth rate of 5-7% for Nylon 6-polyolefin blends over the next five years. This growth trajectory is supported by emerging applications in 3D printing materials, medical devices, and sustainable packaging solutions. The increasing focus on circular economy principles is also influencing market dynamics, with growing interest in recyclable and bio-based blend formulations.

Pricing trends indicate moderate volatility, largely influenced by fluctuations in raw material costs, particularly crude oil derivatives. The market has seen a gradual shift toward value-added specialty blends that command premium pricing due to their enhanced performance characteristics and application-specific formulations.

Customer demand patterns show increasing preference for customized solutions that address specific performance requirements rather than generic blend formulations. This trend has led to greater collaboration between material suppliers and end-users in developing tailored compatibilization strategies for specific applications.

Market research indicates that the automotive sector represents the largest application segment for these blends, accounting for approximately 40% of total consumption. The push for lightweight materials to improve fuel efficiency and reduce emissions has significantly boosted demand in this sector. Manufacturers are increasingly replacing metal components with high-performance polymer blends, particularly in under-the-hood applications where temperature resistance is critical.

The packaging industry follows as the second-largest consumer of Nylon 6-polyolefin blends, particularly in barrier film applications where oxygen and moisture resistance are essential. The food packaging segment has shown particularly strong growth rates due to increasing consumer preference for extended shelf-life products and convenient packaging solutions.

Regional analysis reveals that Asia-Pacific dominates the market, led by China and India's rapidly expanding manufacturing sectors. North America and Europe maintain significant market shares, with demand primarily driven by technological advancements in automotive and industrial applications. The Middle East market is showing promising growth potential due to increasing investments in plastic processing capabilities.

Market forecasts suggest a compound annual growth rate of 5-7% for Nylon 6-polyolefin blends over the next five years. This growth trajectory is supported by emerging applications in 3D printing materials, medical devices, and sustainable packaging solutions. The increasing focus on circular economy principles is also influencing market dynamics, with growing interest in recyclable and bio-based blend formulations.

Pricing trends indicate moderate volatility, largely influenced by fluctuations in raw material costs, particularly crude oil derivatives. The market has seen a gradual shift toward value-added specialty blends that command premium pricing due to their enhanced performance characteristics and application-specific formulations.

Customer demand patterns show increasing preference for customized solutions that address specific performance requirements rather than generic blend formulations. This trend has led to greater collaboration between material suppliers and end-users in developing tailored compatibilization strategies for specific applications.

Technical Challenges in Polymer Blend Compatibility

The compatibility between Nylon 6 and polyolefins represents one of the most significant challenges in polymer blend technology. These materials possess fundamentally different chemical structures, polarities, and crystallization behaviors, resulting in inherently poor interfacial adhesion and phase separation when blended. The highly polar amide groups in Nylon 6 contrast sharply with the non-polar nature of polyolefins such as polyethylene (PE) and polypropylene (PP), creating substantial thermodynamic incompatibility.

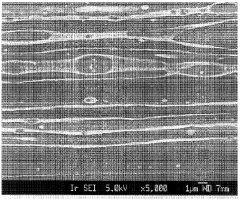

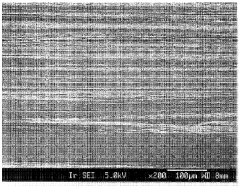

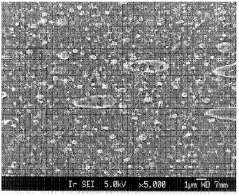

This incompatibility manifests in several technical problems. First, the high interfacial tension between the phases leads to coarse morphology with large dispersed domains, significantly compromising mechanical properties. Electron microscopy studies reveal distinct phase boundaries with minimal molecular entanglement across interfaces, resulting in stress concentration points during mechanical loading.

Second, the crystallization kinetics of these polymers differ substantially, with Nylon 6 typically crystallizing at higher temperatures than polyolefins. This sequential crystallization process creates internal stresses and further weakens the interface. Differential scanning calorimetry analyses consistently show separate crystallization and melting events, confirming the lack of co-crystallization that might otherwise enhance compatibility.

Third, the processing window presents significant challenges. Nylon 6 requires higher processing temperatures (typically 230-280°C) than polyolefins (170-230°C), creating a narrow viable processing range. Additionally, Nylon 6's hygroscopic nature necessitates thorough drying before processing to prevent hydrolytic degradation, adding complexity to manufacturing protocols.

The rheological mismatch between these polymers further complicates processing, as their different melt viscosities at processing temperatures lead to irregular dispersion and unstable morphology. Rheological measurements show that this mismatch becomes more pronounced at higher shear rates typical of industrial processing conditions.

Thermal stability differences also present challenges, with Nylon 6 being more susceptible to thermo-oxidative degradation during processing than polyolefins. This can lead to molecular weight reduction, discoloration, and deterioration of mechanical properties, particularly in recycled blends or during multiple processing cycles.

Finally, environmental factors pose long-term stability issues. Nylon 6 absorbs moisture from the environment, leading to dimensional instability and hydrolysis over time, while polyolefins remain relatively unaffected. This differential aging behavior creates progressive property deterioration in blends, particularly challenging for applications requiring long service life or exposure to humid environments.

This incompatibility manifests in several technical problems. First, the high interfacial tension between the phases leads to coarse morphology with large dispersed domains, significantly compromising mechanical properties. Electron microscopy studies reveal distinct phase boundaries with minimal molecular entanglement across interfaces, resulting in stress concentration points during mechanical loading.

Second, the crystallization kinetics of these polymers differ substantially, with Nylon 6 typically crystallizing at higher temperatures than polyolefins. This sequential crystallization process creates internal stresses and further weakens the interface. Differential scanning calorimetry analyses consistently show separate crystallization and melting events, confirming the lack of co-crystallization that might otherwise enhance compatibility.

Third, the processing window presents significant challenges. Nylon 6 requires higher processing temperatures (typically 230-280°C) than polyolefins (170-230°C), creating a narrow viable processing range. Additionally, Nylon 6's hygroscopic nature necessitates thorough drying before processing to prevent hydrolytic degradation, adding complexity to manufacturing protocols.

The rheological mismatch between these polymers further complicates processing, as their different melt viscosities at processing temperatures lead to irregular dispersion and unstable morphology. Rheological measurements show that this mismatch becomes more pronounced at higher shear rates typical of industrial processing conditions.

Thermal stability differences also present challenges, with Nylon 6 being more susceptible to thermo-oxidative degradation during processing than polyolefins. This can lead to molecular weight reduction, discoloration, and deterioration of mechanical properties, particularly in recycled blends or during multiple processing cycles.

Finally, environmental factors pose long-term stability issues. Nylon 6 absorbs moisture from the environment, leading to dimensional instability and hydrolysis over time, while polyolefins remain relatively unaffected. This differential aging behavior creates progressive property deterioration in blends, particularly challenging for applications requiring long service life or exposure to humid environments.

Current Compatibilizer Solutions for Nylon 6-Polyolefin

01 Maleic anhydride grafted polyolefins as compatibilizers

Maleic anhydride grafted polyolefins, particularly maleic anhydride grafted polypropylene (PP-g-MAH) and polyethylene (PE-g-MAH), are effective compatibilizers for Nylon 6-polyolefin blends. These functionalized polymers create chemical bonds with the amine end groups of Nylon 6 while the polyolefin segments interact with the polyolefin phase, resulting in improved interfacial adhesion and compatibility between the immiscible components. This leads to enhanced mechanical properties, better dispersion, and reduced phase separation in the final blend.- Maleic anhydride grafted polyolefins as compatibilizers: Maleic anhydride grafted polyolefins are widely used as compatibilizers in Nylon 6-polyolefin blends. The maleic anhydride groups react with the amine end groups of Nylon 6, forming chemical bonds at the interface between the two polymers. This improves the interfacial adhesion and enhances the mechanical properties of the blend. Common examples include maleic anhydride grafted polypropylene (PP-g-MAH) and maleic anhydride grafted polyethylene (PE-g-MAH), which effectively reduce the interfacial tension and improve the dispersion of the polyolefin phase in the nylon matrix.

- Functionalized copolymers as compatibilizing agents: Functionalized copolymers serve as effective compatibilizing agents for Nylon 6-polyolefin blends. These include ethylene-based copolymers containing functional groups such as acrylic acid, methacrylic acid, or glycidyl methacrylate that can interact with the polar groups of Nylon 6. The functional groups in these copolymers form hydrogen bonds or other interactions with the amide groups of Nylon 6, while the ethylene segments are compatible with the polyolefin phase. This dual compatibility helps bridge the interface between the immiscible polymers, resulting in improved blend morphology and enhanced mechanical properties.

- Reactive extrusion processing for improved compatibility: Reactive extrusion processing techniques can significantly enhance the compatibility of Nylon 6-polyolefin blends. During the extrusion process, reactive compatibilizers can be added that undergo chemical reactions with both polymer phases at elevated temperatures. This in-situ compatibilization creates copolymers at the interface between Nylon 6 and polyolefins. Process parameters such as screw configuration, residence time, and processing temperature play crucial roles in determining the extent of the compatibilization reaction and the final properties of the blend. This approach often results in finer dispersion of the minor phase and improved interfacial adhesion.

- Nanoparticles and fillers as compatibilization aids: Nanoparticles and fillers can serve as compatibilization aids in Nylon 6-polyolefin blends. Materials such as nanoclay, silica, carbon nanotubes, and graphene can localize at the interface between the two polymers, reducing interfacial tension and preventing coalescence of the dispersed phase. These particles can also be surface-modified to enhance their interaction with both polymer phases. The incorporation of such nanofillers not only improves the compatibility but also enhances mechanical properties, thermal stability, and barrier properties of the resulting blends.

- Block and graft copolymers as pre-made compatibilizers: Block and graft copolymers specifically designed with segments compatible with both Nylon 6 and polyolefins serve as effective pre-made compatibilizers. These copolymers contain polyamide-compatible segments (such as polyamide blocks or polar functional groups) and polyolefin-compatible segments (such as polyethylene or polypropylene blocks). When added to the blend, these copolymers preferentially locate at the interface, reducing interfacial tension and improving phase adhesion. Unlike reactive compatibilizers, these pre-made compatibilizers do not require chemical reactions during processing, making them suitable for processes with limited residence time or lower processing temperatures.

02 Reactive compatibilizers with functional groups

Reactive compatibilizers containing specific functional groups that can interact with both Nylon 6 and polyolefins are effective in improving blend compatibility. These include polymers with anhydride, carboxylic acid, epoxy, or isocyanate functionalities that can react with the amine or carboxyl end groups of Nylon 6. The reactive compatibilization approach creates copolymers at the interface during processing, leading to reduced interfacial tension, finer dispersion of the minor phase, and improved mechanical properties of the blends.Expand Specific Solutions03 Block and graft copolymers as compatibilizers

Block and graft copolymers containing segments that are chemically similar or compatible with both Nylon 6 and polyolefins serve as effective compatibilizers. These copolymers position themselves at the interface between the two immiscible phases, reducing interfacial tension and promoting finer dispersion. Examples include polyamide-polyolefin block copolymers, ethylene-vinyl acetate copolymers, and styrenic block copolymers. These compatibilizers improve the morphology stability and enhance the mechanical properties of the blends.Expand Specific Solutions04 Nanoparticle-based compatibilization systems

Nanoparticles such as clay, silica, and carbon nanotubes can act as compatibilizers in Nylon 6-polyolefin blends. These nanoparticles tend to localize at the interface between the two immiscible polymers, reducing interfacial tension and stabilizing the blend morphology. Additionally, surface-modified nanoparticles with functional groups that can interact with both phases further enhance compatibility. This approach not only improves the compatibility but also introduces additional benefits such as enhanced mechanical, thermal, and barrier properties.Expand Specific Solutions05 Processing techniques and additives for improved compatibility

Various processing techniques and additives can enhance the compatibility of Nylon 6-polyolefin blends. Reactive extrusion, where compatibilization reactions occur during processing, is particularly effective. The use of specific processing aids, antioxidants, and stabilizers can prevent degradation during high-temperature processing. Additionally, controlling processing parameters such as temperature, shear rate, and residence time significantly affects the morphology and properties of the blends. These techniques, when optimized, lead to improved dispersion and interfacial adhesion.Expand Specific Solutions

Key Industry Players in Polymer Blend Market

Compatibilizers play a crucial role in Nylon 6-polyolefin blends, currently at a growth stage with expanding market applications across automotive, packaging, and consumer goods sectors. The global market for these compatibilized blends is experiencing steady growth, driven by demand for lightweight, high-performance materials. Technologically, companies like Dow Global Technologies, SABIC, LG Chem, and Arkema have achieved significant advancements in compatibilizer development, with Lubrizol, Teknor Apex, and Kingfa demonstrating commercial maturity through specialized product lines. Research institutions including Hebei University of Technology and University of Southern Mississippi continue to innovate in this field, focusing on improving interfacial adhesion, mechanical properties, and processing characteristics of these immiscible polymer systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary maleic anhydride-grafted polyolefin compatibilizers specifically designed for Nylon 6-polyolefin blends. Their technology involves reactive extrusion processes where maleated polyolefins (primarily PP-g-MA and PE-g-MA) create covalent bonds between the amine end groups of Nylon 6 and the anhydride functionalities. Sinopec's approach achieves interfacial tension reduction between the immiscible phases, resulting in finer dispersion of the polyolefin phase within the nylon matrix. Their compatibilizers typically incorporate 0.5-2.0 wt% maleic anhydride content, optimized for maximum reactivity without compromising the base polymer properties. Recent advancements include the development of dual-functionality compatibilizers that simultaneously improve impact strength and heat resistance of the resulting blends.

Strengths: Excellent control of morphology with finer domain size distribution; improved mechanical properties including impact strength and elongation at break; enhanced processing stability during extrusion. Weaknesses: Relatively high processing temperatures required for optimal reactivity; potential for hydrolysis of maleic anhydride groups during processing; limited effectiveness in highly filled systems.

Lubrizol Advanced Materials, Inc.

Technical Solution: Lubrizol Advanced Materials has pioneered advanced compatibilizer systems for Nylon 6-polyolefin blends through their Estane® technology platform. Their approach utilizes functionalized styrenic block copolymers (SBCs) modified with reactive groups that can interact with both the polar nylon and non-polar polyolefin phases. The company's proprietary technology involves the incorporation of glycidyl methacrylate (GMA) functionalities that react with the terminal amine and carboxylic acid groups of Nylon 6, while the hydrocarbon segments are compatible with polyolefins. Lubrizol's compatibilizers are typically added at 3-8 wt% concentrations and have demonstrated the ability to reduce the domain size of dispersed phases from 5-10 μm to sub-micron levels. Their latest generation products feature multi-functional reactive sites that enable simultaneous improvements in impact strength, chemical resistance, and dimensional stability of the resulting blends.

Strengths: Superior interfacial adhesion leading to excellent mechanical property retention after aging; effective at relatively low addition levels; good processability with minimal increase in melt viscosity. Weaknesses: Higher cost compared to simpler maleated compatibilizers; potential for crosslinking reactions if processing conditions are not carefully controlled; limited effectiveness in high-temperature applications above 180°C.

Critical Patents in Compatibilizer Technology

Nanocomposite composition having super barrier property and article using the same

PatentInactiveNZ550192A

Innovation

- A nanocomposite composition comprising 1 to 97 wt % polyolefin resin, 1 to 95 wt % intercalated clay, and a compatibilizer such as epoxy-modified polystyrene copolymer, ethylene-ethylene anhydride-acrylic acid copolymer, or maleic anhydride modified polyethylene, combined with ethylene-vinyl alcohol copolymer and polyamide, to enhance mechanical strength and barrier properties through exfoliated intercalated clay dispersion.

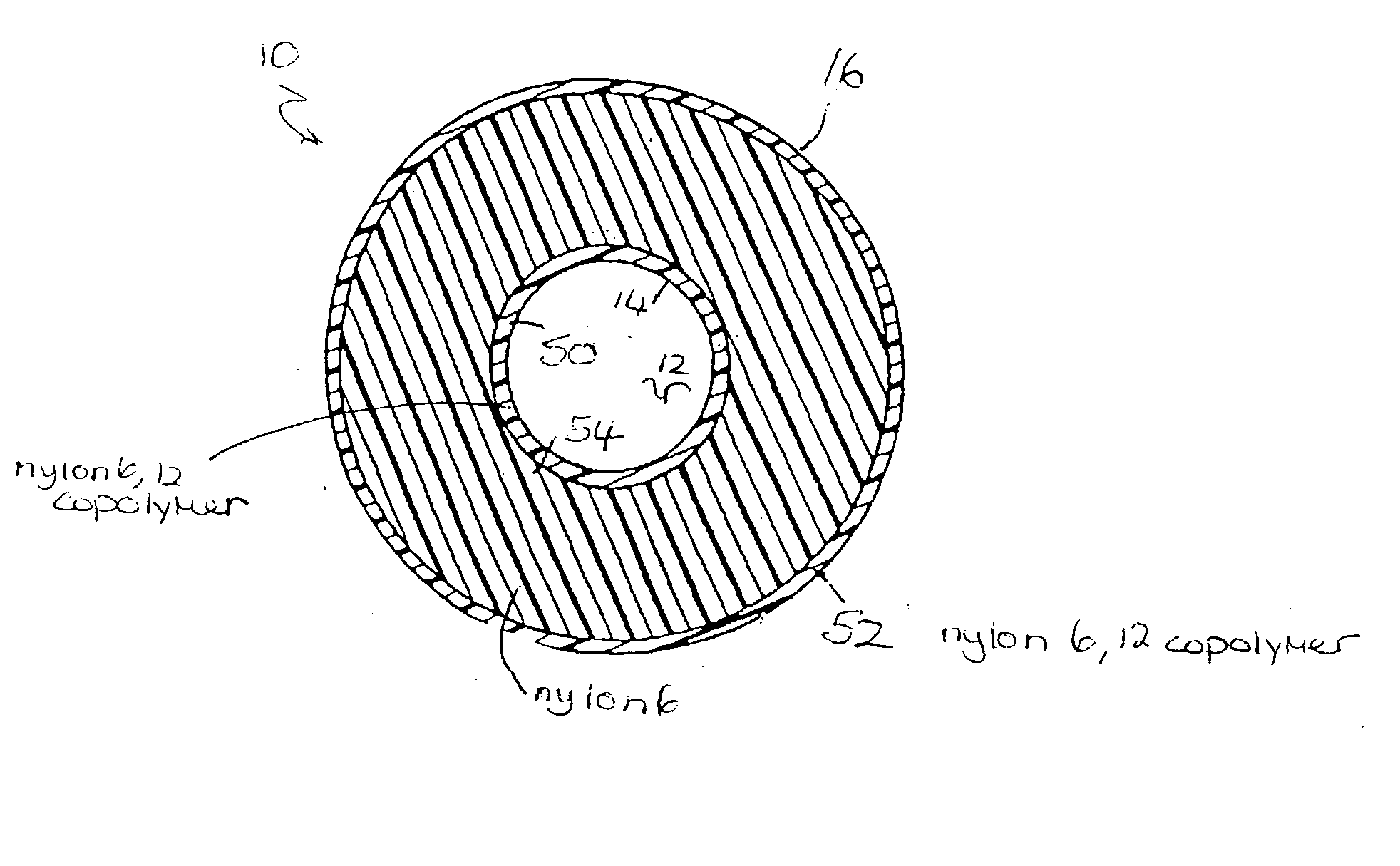

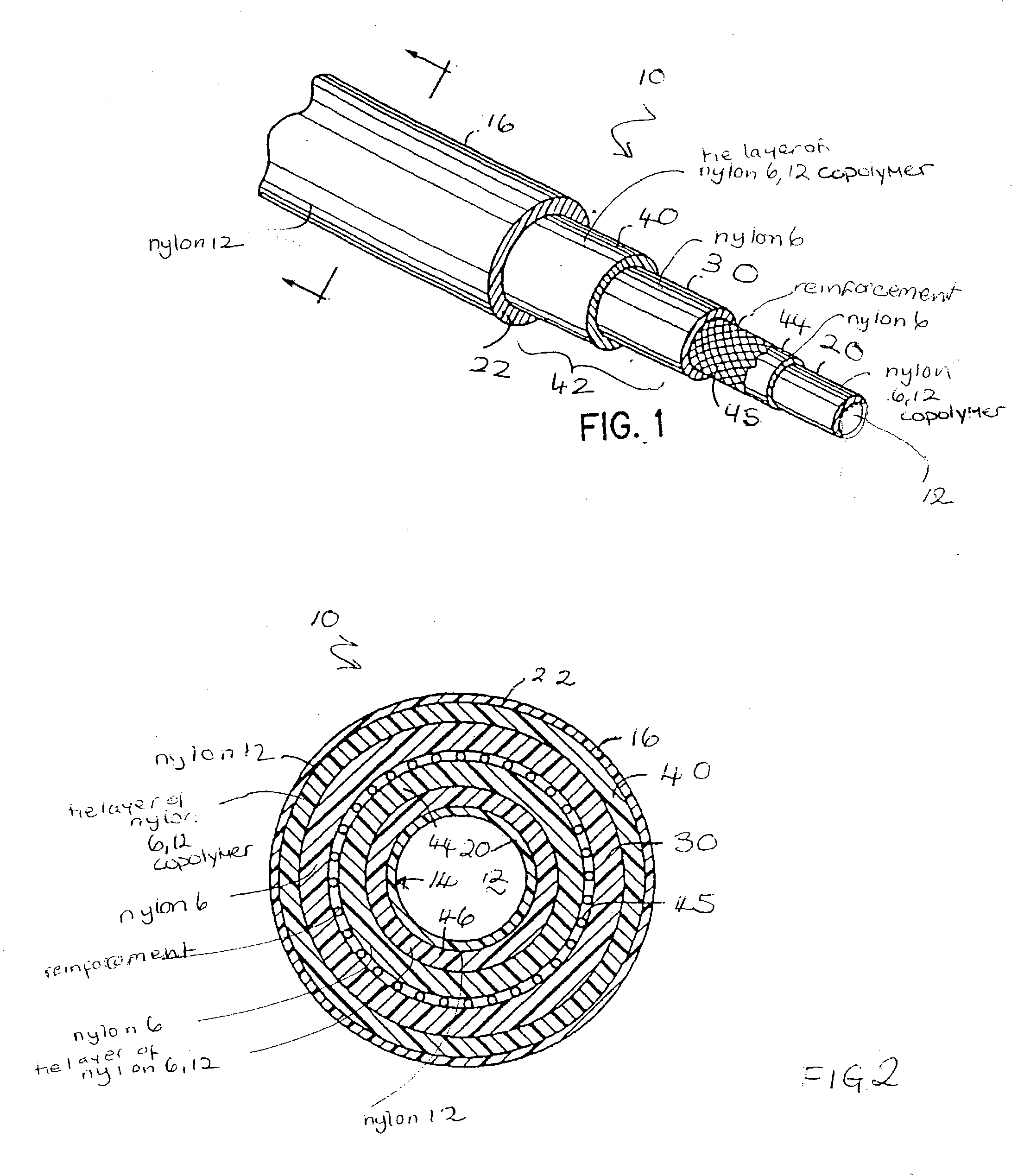

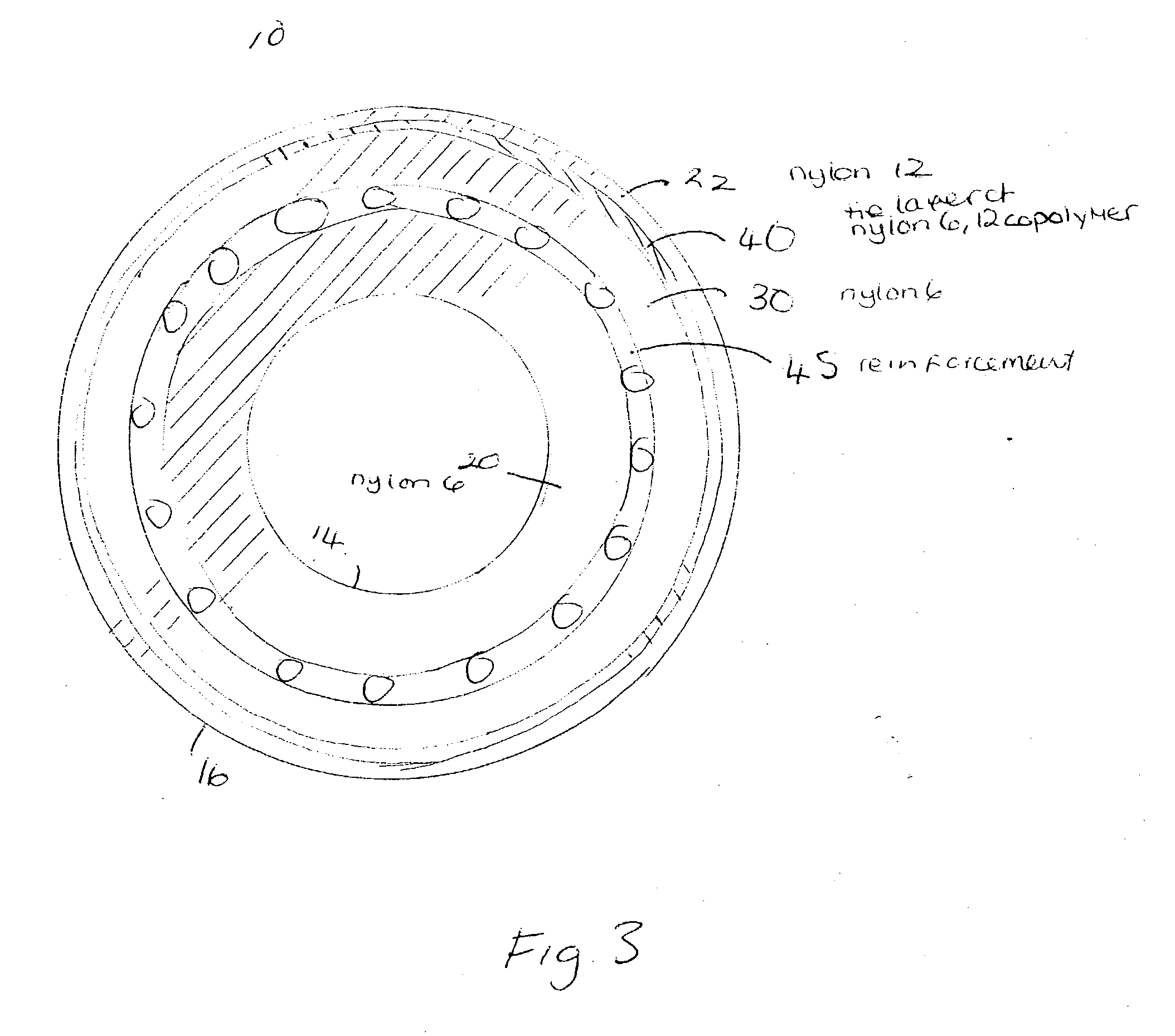

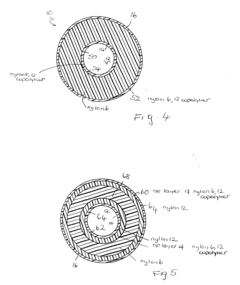

Hose comprising modified nylon 6,12 material

PatentInactiveUS20040096615A1

Innovation

- A modified nylon 6,12 copolymer is developed, incorporating caprolactam and undecanolactam or dodecanolactam monomer units with a compatibilizer like maleic anhydride modified polyethylene, allowing for coextrusion with nylon 6 and 12 layers without adhesives, enhancing zinc chloride resistance and mechanical properties.

Environmental Impact of Compatibilized Blends

The environmental implications of compatibilized Nylon 6-polyolefin blends represent a critical consideration in their industrial application and lifecycle assessment. These compatibilized systems offer significant environmental advantages compared to their non-compatibilized counterparts, primarily through enhanced material durability and recyclability. By improving the interfacial adhesion between Nylon 6 and polyolefins, compatibilizers create more stable blends that resist degradation, thereby extending product lifespans and reducing waste generation.

The improved mechanical properties of compatibilized blends contribute to resource efficiency by enabling the production of thinner-walled components with equivalent performance characteristics. This material optimization translates directly to reduced raw material consumption and lower energy requirements during manufacturing processes. Furthermore, the enhanced compatibility between these otherwise immiscible polymers facilitates the incorporation of recycled materials into new products without significant performance penalties.

Lifecycle analyses indicate that compatibilized Nylon 6-polyolefin blends can reduce the carbon footprint of composite materials by 15-30% compared to virgin polymer production, primarily through enabling effective recycling streams. The presence of compatibilizers allows for multiple recycling cycles without catastrophic property deterioration, creating a more circular materials economy and reducing dependence on virgin polymer synthesis.

However, environmental concerns persist regarding the compatibilizers themselves. Many commercial compatibilizing agents contain reactive functional groups that may present toxicity concerns or generate harmful byproducts during processing or end-of-life scenarios. Maleic anhydride-grafted compatibilizers, while effective, can release volatile organic compounds during high-temperature processing, contributing to air quality issues in manufacturing environments.

Recent research has focused on developing bio-based compatibilizers derived from renewable resources as environmentally preferable alternatives to petroleum-based options. These bio-compatibilizers, often based on modified plant oils or cellulosic derivatives, show promising performance while reducing reliance on fossil resources and potentially offering improved biodegradability profiles.

The end-of-life management of compatibilized blends presents both opportunities and challenges. While improved blend homogeneity facilitates mechanical recycling, the chemical complexity introduced by compatibilizers can complicate chemical recycling processes and biodegradation pathways. Advanced sorting technologies and dedicated recycling streams may be necessary to fully capitalize on the theoretical recyclability advantages of these materials.

The improved mechanical properties of compatibilized blends contribute to resource efficiency by enabling the production of thinner-walled components with equivalent performance characteristics. This material optimization translates directly to reduced raw material consumption and lower energy requirements during manufacturing processes. Furthermore, the enhanced compatibility between these otherwise immiscible polymers facilitates the incorporation of recycled materials into new products without significant performance penalties.

Lifecycle analyses indicate that compatibilized Nylon 6-polyolefin blends can reduce the carbon footprint of composite materials by 15-30% compared to virgin polymer production, primarily through enabling effective recycling streams. The presence of compatibilizers allows for multiple recycling cycles without catastrophic property deterioration, creating a more circular materials economy and reducing dependence on virgin polymer synthesis.

However, environmental concerns persist regarding the compatibilizers themselves. Many commercial compatibilizing agents contain reactive functional groups that may present toxicity concerns or generate harmful byproducts during processing or end-of-life scenarios. Maleic anhydride-grafted compatibilizers, while effective, can release volatile organic compounds during high-temperature processing, contributing to air quality issues in manufacturing environments.

Recent research has focused on developing bio-based compatibilizers derived from renewable resources as environmentally preferable alternatives to petroleum-based options. These bio-compatibilizers, often based on modified plant oils or cellulosic derivatives, show promising performance while reducing reliance on fossil resources and potentially offering improved biodegradability profiles.

The end-of-life management of compatibilized blends presents both opportunities and challenges. While improved blend homogeneity facilitates mechanical recycling, the chemical complexity introduced by compatibilizers can complicate chemical recycling processes and biodegradation pathways. Advanced sorting technologies and dedicated recycling streams may be necessary to fully capitalize on the theoretical recyclability advantages of these materials.

Processing Methods for Enhanced Blend Performance

The optimization of processing methods is crucial for achieving enhanced performance in Nylon 6-polyolefin blends with compatibilizers. Extrusion parameters significantly influence the efficacy of compatibilization, with screw design and configuration playing pivotal roles. Twin-screw extruders with high shear elements have demonstrated superior results compared to single-screw systems, as they provide better distributive and dispersive mixing necessary for effective compatibilizer distribution.

Temperature profiles during processing must be carefully controlled to balance the melting requirements of both Nylon 6 and polyolefins while preventing thermal degradation of the compatibilizer. Research indicates that processing temperatures slightly above the melting point of the higher-melting component (typically Nylon 6) yield optimal morphology development. Additionally, residence time in the extruder affects the reaction extent between compatibilizer functional groups and blend components, with moderate residence times generally producing superior results.

Injection molding parameters for compatibilized blends require specific adjustments compared to neat polymers. Higher injection pressures are often necessary to ensure proper mold filling due to the complex rheological behavior of these systems. Mold temperature control is equally important, as it influences crystallization behavior and interfacial adhesion development in the final part.

Reactive extrusion represents an advanced processing approach where compatibilization occurs in-situ during the blending process. This method utilizes functional group reactions between blend components and reactive compatibilizers under processing conditions, creating interfacial copolymers directly during manufacturing. Studies have shown that reactive extrusion can reduce processing steps while enhancing blend properties compared to pre-made compatibilizers.

Solid-state processing techniques, including solid-state shear pulverization and cryogenic milling, have emerged as alternative methods for preparing compatibilized Nylon 6-polyolefin blends. These techniques apply mechanical energy to polymers below their melting temperatures, creating intimate mixing while minimizing thermal degradation. Research demonstrates that such methods can enhance compatibilizer efficiency by creating more extensive interfacial areas.

Post-processing treatments, such as annealing, significantly impact the final properties of compatibilized blends. Controlled thermal treatments allow for reorganization at the interface, improving adhesion and stabilizing the morphology. Optimal annealing conditions depend on the specific compatibilizer chemistry and blend composition, with temperatures between the glass transition and melting points typically yielding the best results.

Temperature profiles during processing must be carefully controlled to balance the melting requirements of both Nylon 6 and polyolefins while preventing thermal degradation of the compatibilizer. Research indicates that processing temperatures slightly above the melting point of the higher-melting component (typically Nylon 6) yield optimal morphology development. Additionally, residence time in the extruder affects the reaction extent between compatibilizer functional groups and blend components, with moderate residence times generally producing superior results.

Injection molding parameters for compatibilized blends require specific adjustments compared to neat polymers. Higher injection pressures are often necessary to ensure proper mold filling due to the complex rheological behavior of these systems. Mold temperature control is equally important, as it influences crystallization behavior and interfacial adhesion development in the final part.

Reactive extrusion represents an advanced processing approach where compatibilization occurs in-situ during the blending process. This method utilizes functional group reactions between blend components and reactive compatibilizers under processing conditions, creating interfacial copolymers directly during manufacturing. Studies have shown that reactive extrusion can reduce processing steps while enhancing blend properties compared to pre-made compatibilizers.

Solid-state processing techniques, including solid-state shear pulverization and cryogenic milling, have emerged as alternative methods for preparing compatibilized Nylon 6-polyolefin blends. These techniques apply mechanical energy to polymers below their melting temperatures, creating intimate mixing while minimizing thermal degradation. Research demonstrates that such methods can enhance compatibilizer efficiency by creating more extensive interfacial areas.

Post-processing treatments, such as annealing, significantly impact the final properties of compatibilized blends. Controlled thermal treatments allow for reorganization at the interface, improving adhesion and stabilizing the morphology. Optimal annealing conditions depend on the specific compatibilizer chemistry and blend composition, with temperatures between the glass transition and melting points typically yielding the best results.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!