Comparative study of recycled and virgin Nylon 6 material properties

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Recycling Background and Objectives

Nylon 6, a synthetic polymer first developed in the 1930s by Wallace Carothers at DuPont, has evolved into one of the most versatile engineering plastics in modern manufacturing. The historical trajectory of Nylon 6 has seen significant advancements in production techniques, material properties, and applications across industries including automotive, textiles, electronics, and consumer goods. As global plastic consumption continues to rise, the environmental implications of Nylon 6 production and disposal have become increasingly concerning, prompting a shift toward sustainable alternatives and recycling methodologies.

The recycling of Nylon 6 represents a critical frontier in sustainable materials management. Traditional virgin Nylon 6 production is energy-intensive and petroleum-dependent, contributing substantially to carbon emissions and resource depletion. The technical evolution of Nylon 6 recycling has progressed from basic mechanical recycling methods to more sophisticated chemical depolymerization processes that can recover caprolactam monomers for repolymerization, effectively closing the material loop.

Current technological trends in Nylon 6 recycling include advancements in sorting technologies using near-infrared spectroscopy, improvements in washing and contaminant removal processes, and innovations in chemical recycling that yield higher purity recovered materials. The integration of artificial intelligence and machine learning algorithms has further enhanced the efficiency and effectiveness of recycling operations, allowing for more precise material identification and separation.

The primary objective of this comparative study is to establish a comprehensive understanding of the property differentials between recycled and virgin Nylon 6 materials. This includes mechanical properties such as tensile strength, impact resistance, and elongation at break; thermal properties including melting point, glass transition temperature, and heat deflection temperature; and chemical resistance characteristics. Additionally, the study aims to identify the key factors influencing these property variations, such as recycling method, contamination levels, and processing conditions.

Secondary objectives include evaluating the economic viability of recycled Nylon 6 as a substitute for virgin material in various applications, assessing the environmental benefits through life cycle assessment methodologies, and exploring potential modifications or additives that could enhance the performance of recycled Nylon 6 to match or exceed that of virgin material. The ultimate goal is to provide evidence-based recommendations for optimizing recycled Nylon 6 formulations for specific industrial applications.

This research is positioned within the broader context of circular economy principles and sustainable development goals, particularly those related to responsible consumption and production. By establishing the technical feasibility of substituting virgin Nylon 6 with recycled alternatives, this study contributes to the growing body of knowledge supporting the transition toward more sustainable material systems in manufacturing industries.

The recycling of Nylon 6 represents a critical frontier in sustainable materials management. Traditional virgin Nylon 6 production is energy-intensive and petroleum-dependent, contributing substantially to carbon emissions and resource depletion. The technical evolution of Nylon 6 recycling has progressed from basic mechanical recycling methods to more sophisticated chemical depolymerization processes that can recover caprolactam monomers for repolymerization, effectively closing the material loop.

Current technological trends in Nylon 6 recycling include advancements in sorting technologies using near-infrared spectroscopy, improvements in washing and contaminant removal processes, and innovations in chemical recycling that yield higher purity recovered materials. The integration of artificial intelligence and machine learning algorithms has further enhanced the efficiency and effectiveness of recycling operations, allowing for more precise material identification and separation.

The primary objective of this comparative study is to establish a comprehensive understanding of the property differentials between recycled and virgin Nylon 6 materials. This includes mechanical properties such as tensile strength, impact resistance, and elongation at break; thermal properties including melting point, glass transition temperature, and heat deflection temperature; and chemical resistance characteristics. Additionally, the study aims to identify the key factors influencing these property variations, such as recycling method, contamination levels, and processing conditions.

Secondary objectives include evaluating the economic viability of recycled Nylon 6 as a substitute for virgin material in various applications, assessing the environmental benefits through life cycle assessment methodologies, and exploring potential modifications or additives that could enhance the performance of recycled Nylon 6 to match or exceed that of virgin material. The ultimate goal is to provide evidence-based recommendations for optimizing recycled Nylon 6 formulations for specific industrial applications.

This research is positioned within the broader context of circular economy principles and sustainable development goals, particularly those related to responsible consumption and production. By establishing the technical feasibility of substituting virgin Nylon 6 with recycled alternatives, this study contributes to the growing body of knowledge supporting the transition toward more sustainable material systems in manufacturing industries.

Market Demand Analysis for Recycled Nylon 6

The global market for recycled Nylon 6 has witnessed significant growth in recent years, driven by increasing environmental awareness and sustainability initiatives across industries. The demand for recycled Nylon 6 is primarily fueled by the textile and automotive sectors, with growing applications in packaging, electronics, and consumer goods industries.

Market research indicates that the global recycled nylon market was valued at approximately $1.6 billion in 2022 and is projected to reach $3.4 billion by 2030, growing at a CAGR of 9.8% during the forecast period. Specifically, recycled Nylon 6 accounts for over 40% of this market share due to its widespread application and relatively established recycling infrastructure compared to other nylon variants.

Consumer preferences are increasingly shifting toward sustainable products, with 73% of global consumers willing to pay a premium for environmentally friendly alternatives. This trend is particularly pronounced in developed markets such as Europe and North America, where regulatory frameworks actively promote circular economy principles. The European Union's Circular Economy Action Plan and similar initiatives worldwide have created a favorable environment for recycled materials, including Nylon 6.

The automotive industry represents a substantial demand driver, with manufacturers increasingly incorporating recycled materials to meet sustainability targets and comply with regulations. Major automotive companies have announced commitments to increase the percentage of recycled materials in their vehicles, with some targeting 20-30% recycled content by 2025.

In the textile sector, fashion brands are responding to consumer demand for sustainable products by incorporating recycled nylon into their collections. The outdoor apparel segment has been particularly proactive, with several leading brands launching product lines made entirely from recycled materials, including Nylon 6 recovered from post-consumer waste such as fishing nets and carpet fibers.

Supply chain challenges remain a significant factor affecting market dynamics. The collection, sorting, and processing infrastructure for nylon waste requires further development to meet growing demand. Currently, the supply of high-quality recycled Nylon 6 lags behind demand, creating opportunities for technological innovation in recycling processes.

Price sensitivity continues to influence market adoption rates. While recycled Nylon 6 typically commands a 10-15% premium over virgin material, this gap is narrowing as recycling technologies improve and economies of scale are achieved. Industry analysts predict price parity could be reached in certain applications within the next 5-7 years, potentially accelerating market growth.

Regional analysis reveals that Europe leads in recycled Nylon 6 consumption, followed by North America and Asia-Pacific. However, the fastest growth is expected in emerging economies, particularly in Asia, where rapid industrialization and increasing environmental regulations are creating new market opportunities.

Market research indicates that the global recycled nylon market was valued at approximately $1.6 billion in 2022 and is projected to reach $3.4 billion by 2030, growing at a CAGR of 9.8% during the forecast period. Specifically, recycled Nylon 6 accounts for over 40% of this market share due to its widespread application and relatively established recycling infrastructure compared to other nylon variants.

Consumer preferences are increasingly shifting toward sustainable products, with 73% of global consumers willing to pay a premium for environmentally friendly alternatives. This trend is particularly pronounced in developed markets such as Europe and North America, where regulatory frameworks actively promote circular economy principles. The European Union's Circular Economy Action Plan and similar initiatives worldwide have created a favorable environment for recycled materials, including Nylon 6.

The automotive industry represents a substantial demand driver, with manufacturers increasingly incorporating recycled materials to meet sustainability targets and comply with regulations. Major automotive companies have announced commitments to increase the percentage of recycled materials in their vehicles, with some targeting 20-30% recycled content by 2025.

In the textile sector, fashion brands are responding to consumer demand for sustainable products by incorporating recycled nylon into their collections. The outdoor apparel segment has been particularly proactive, with several leading brands launching product lines made entirely from recycled materials, including Nylon 6 recovered from post-consumer waste such as fishing nets and carpet fibers.

Supply chain challenges remain a significant factor affecting market dynamics. The collection, sorting, and processing infrastructure for nylon waste requires further development to meet growing demand. Currently, the supply of high-quality recycled Nylon 6 lags behind demand, creating opportunities for technological innovation in recycling processes.

Price sensitivity continues to influence market adoption rates. While recycled Nylon 6 typically commands a 10-15% premium over virgin material, this gap is narrowing as recycling technologies improve and economies of scale are achieved. Industry analysts predict price parity could be reached in certain applications within the next 5-7 years, potentially accelerating market growth.

Regional analysis reveals that Europe leads in recycled Nylon 6 consumption, followed by North America and Asia-Pacific. However, the fastest growth is expected in emerging economies, particularly in Asia, where rapid industrialization and increasing environmental regulations are creating new market opportunities.

Technical Challenges in Nylon 6 Recycling

The recycling of Nylon 6 presents several significant technical challenges that impact the quality and performance of recycled materials compared to virgin counterparts. The primary obstacle lies in the degradation mechanisms that occur during the material's lifecycle and subsequent recycling processes. Thermal degradation during both initial processing and recycling leads to chain scission, reducing molecular weight and consequently diminishing mechanical properties. Oxidative degradation further compounds this issue, particularly when materials are exposed to UV radiation and environmental factors during their service life.

Contamination represents another major challenge in Nylon 6 recycling. Post-consumer waste often contains various additives, colorants, and foreign materials that are difficult to separate completely. These contaminants can significantly alter the crystallization behavior, melt flow characteristics, and overall performance of recycled Nylon 6. Even trace amounts of certain contaminants can catalyze degradation reactions or create stress concentration points that compromise structural integrity.

Moisture sensitivity presents a unique challenge specific to polyamides like Nylon 6. The material's hygroscopic nature means it readily absorbs moisture, which can trigger hydrolytic degradation during high-temperature processing. This necessitates stringent drying protocols that add complexity and cost to the recycling process. Failure to properly manage moisture content results in further molecular weight reduction and property deterioration.

The heterogeneity of recycled feedstock poses significant processing difficulties. Variations in the source, age, and prior processing history of collected Nylon 6 waste create inconsistencies in melt behavior, rheological properties, and crystallization kinetics. This variability makes it challenging to establish stable processing parameters and achieve consistent quality in recycled products.

Advanced analytical techniques are required to accurately characterize recycled Nylon 6 and predict its performance. Methods such as gel permeation chromatography for molecular weight distribution, differential scanning calorimetry for thermal properties, and spectroscopic techniques for chemical composition analysis are essential but add complexity to quality control processes.

Economically viable solutions for these technical challenges remain elusive. Current recycling technologies often struggle to produce recycled Nylon 6 that matches virgin material properties without significant cost increases. The development of more efficient separation technologies, stabilization additives specifically designed for recycled polyamides, and advanced processing techniques that can accommodate feedstock variability represent critical areas for innovation in this field.

Contamination represents another major challenge in Nylon 6 recycling. Post-consumer waste often contains various additives, colorants, and foreign materials that are difficult to separate completely. These contaminants can significantly alter the crystallization behavior, melt flow characteristics, and overall performance of recycled Nylon 6. Even trace amounts of certain contaminants can catalyze degradation reactions or create stress concentration points that compromise structural integrity.

Moisture sensitivity presents a unique challenge specific to polyamides like Nylon 6. The material's hygroscopic nature means it readily absorbs moisture, which can trigger hydrolytic degradation during high-temperature processing. This necessitates stringent drying protocols that add complexity and cost to the recycling process. Failure to properly manage moisture content results in further molecular weight reduction and property deterioration.

The heterogeneity of recycled feedstock poses significant processing difficulties. Variations in the source, age, and prior processing history of collected Nylon 6 waste create inconsistencies in melt behavior, rheological properties, and crystallization kinetics. This variability makes it challenging to establish stable processing parameters and achieve consistent quality in recycled products.

Advanced analytical techniques are required to accurately characterize recycled Nylon 6 and predict its performance. Methods such as gel permeation chromatography for molecular weight distribution, differential scanning calorimetry for thermal properties, and spectroscopic techniques for chemical composition analysis are essential but add complexity to quality control processes.

Economically viable solutions for these technical challenges remain elusive. Current recycling technologies often struggle to produce recycled Nylon 6 that matches virgin material properties without significant cost increases. The development of more efficient separation technologies, stabilization additives specifically designed for recycled polyamides, and advanced processing techniques that can accommodate feedstock variability represent critical areas for innovation in this field.

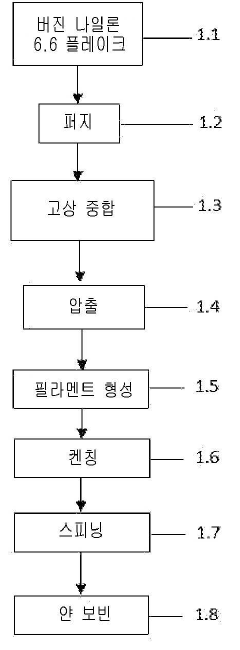

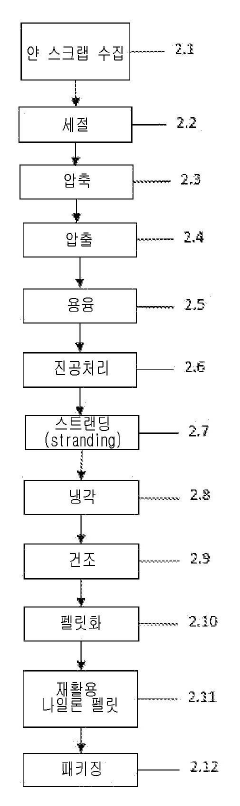

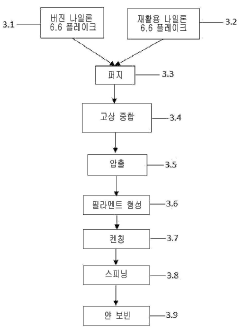

Current Methodologies for Nylon 6 Recycling

01 Mechanical properties of Nylon 6

Nylon 6 exhibits excellent mechanical properties including high tensile strength, good impact resistance, and flexibility. It maintains structural integrity under various load conditions and demonstrates good fatigue resistance. These properties make it suitable for applications requiring durability and mechanical stability. The material shows balanced stiffness and toughness characteristics, with the ability to withstand repeated stress cycles without significant degradation.- Mechanical properties of Nylon 6: Nylon 6 exhibits excellent mechanical properties including high tensile strength, good impact resistance, and flexibility. It maintains structural integrity under various load conditions and demonstrates good fatigue resistance. These properties make it suitable for applications requiring durability and mechanical stability. The material shows balanced stiffness and toughness characteristics, with the ability to withstand repeated stress cycles without significant degradation.

- Thermal properties and stability of Nylon 6: Nylon 6 possesses notable thermal properties including a melting point around 220°C and good heat resistance. It maintains dimensional stability across a wide temperature range and shows excellent resistance to thermal aging. The material has relatively low thermal conductivity, making it suitable for thermal insulation applications. Its heat deflection temperature allows for use in moderately high-temperature environments while maintaining structural integrity.

- Chemical resistance and barrier properties: Nylon 6 demonstrates good resistance to many chemicals, oils, greases, and hydrocarbons. It has excellent barrier properties against oxygen and other gases, making it suitable for packaging applications. The material shows moderate moisture absorption characteristics which can affect its dimensional stability and mechanical properties. Its chemical structure provides resistance to abrasion and wear in various environments, though it may be susceptible to degradation by strong acids and certain oxidizing agents.

- Modified Nylon 6 composites and blends: Modified Nylon 6 materials incorporate various additives, fillers, and reinforcements to enhance specific properties. Glass fiber reinforcement significantly improves mechanical strength and dimensional stability. Blending with other polymers creates materials with customized property profiles. Mineral fillers can enhance stiffness, flame retardancy, and thermal properties. These modifications allow for tailoring Nylon 6 to specific application requirements while maintaining its core beneficial characteristics.

- Processing characteristics and applications: Nylon 6 offers excellent processability through various manufacturing methods including injection molding, extrusion, and blow molding. It demonstrates good flow properties when melted and rapid solidification upon cooling. The material can be easily colored, textured, and finished. Its combination of properties makes it suitable for diverse applications in automotive components, electrical parts, consumer goods, industrial machinery, textiles, and packaging. The material's versatility in processing contributes to its widespread use across multiple industries.

02 Thermal properties and stability of Nylon 6

Nylon 6 possesses notable thermal properties including a melting point around 220°C and good heat resistance. It maintains dimensional stability across a wide temperature range and shows excellent resistance to thermal aging. The material can withstand continuous exposure to elevated temperatures without significant property degradation. Its thermal conductivity characteristics make it suitable for applications requiring heat management, while its low coefficient of thermal expansion contributes to dimensional stability in temperature-variable environments.Expand Specific Solutions03 Chemical resistance and barrier properties

Nylon 6 demonstrates good resistance to many chemicals including oils, greases, and various solvents. It has excellent barrier properties against oxygen, carbon dioxide, and hydrocarbon gases, making it suitable for packaging applications. The material shows moderate moisture absorption characteristics which can affect its dimensional stability and mechanical properties. Its resistance to hydrocarbons and many organic chemicals makes it valuable in automotive and industrial applications where exposure to such substances is common.Expand Specific Solutions04 Processing characteristics and manufacturability

Nylon 6 offers excellent processability through various manufacturing methods including injection molding, extrusion, and blow molding. It demonstrates good flow characteristics during processing, allowing for the production of complex shapes with fine details. The material shows consistent shrinkage rates, which facilitates dimensional control in manufacturing. Its compatibility with various additives enables property customization for specific applications, while its weldability and machinability further enhance its versatility in manufacturing processes.Expand Specific Solutions05 Surface properties and modification techniques

Nylon 6 exhibits good surface finish capabilities and can be modified through various techniques to enhance specific properties. Surface treatments can improve its adhesion characteristics, printability, and wear resistance. The material can be metallized, painted, or coated to achieve desired aesthetic or functional properties. Various modification techniques including plasma treatment, chemical etching, and the application of coupling agents can be employed to tailor surface properties for specific applications, enhancing its versatility across different industrial sectors.Expand Specific Solutions

Key Industry Players in Nylon 6 Recycling

The recycled Nylon 6 materials market is in a growth phase, driven by sustainability trends and increasing demand for eco-friendly alternatives. The global market size for recycled nylon is expanding rapidly, expected to reach significant volumes as major players invest in circular economy solutions. Technologically, the field shows moderate maturity with ongoing innovations to close performance gaps between recycled and virgin materials. Leading companies like Toray Industries and Kingfa Sci. & Tech. are advancing material science through proprietary technologies, while Solutia and Ascend Performance Materials contribute specialized expertise in nylon chemistry. Academic institutions such as Beijing University of Chemical Technology collaborate with industry to improve recycling processes and material properties, creating a competitive landscape where technical differentiation and sustainability credentials are key competitive advantages.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced recycling technologies for Nylon 6 that maintain up to 90% of virgin material properties. Their proprietary chemical recycling process depolymerizes waste Nylon 6 back to caprolactam, which is then repolymerized to create recycled Nylon 6 with minimal degradation. This closed-loop system allows for multiple recycling cycles without significant property loss. Toray's comparative studies show that their recycled Nylon 6 exhibits tensile strength within 5-7% of virgin material, and maintains similar thermal stability with only 2-3°C reduction in melting point. Their technology also addresses the yellowing issue common in recycled nylons through an advanced purification process that removes contaminants responsible for discoloration. Toray has implemented this technology in their CYCLEAD™ recycled nylon program, which has been adopted in automotive and textile applications.

Strengths: Superior property retention compared to mechanical recycling methods; closed-loop system enables multiple recycling cycles; excellent color quality control. Weaknesses: Higher energy consumption in chemical recycling process; requires sophisticated sorting and cleaning of feedstock; higher production cost compared to virgin material production.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has pioneered a hybrid recycling approach for Nylon 6 that combines mechanical and chemical treatment processes. Their comparative studies between virgin and recycled Nylon 6 have focused on optimizing the balance between processing efficiency and material property retention. Kingfa's technology employs a proprietary compatibilization system that allows recycled Nylon 6 to maintain approximately 85-90% of the mechanical properties of virgin material. Their process includes a multi-stage filtration and degassing system that removes contaminants and volatile compounds that typically cause property degradation. Kingfa has developed specialized additives that compensate for the molecular weight reduction in recycled materials, resulting in improved impact strength and elongation properties. Their research shows that properly formulated recycled Nylon 6 compounds can achieve comparable heat resistance to virgin materials, with heat deflection temperatures within 5-8°C of virgin nylon. Kingfa has successfully commercialized these materials in automotive, electrical, and consumer goods applications.

Strengths: Cost-effective balance between property retention and processing efficiency; specialized additive packages to compensate for recycled material deficiencies; broad application range. Weaknesses: Some color limitations compared to virgin materials; batch-to-batch consistency challenges; slightly lower long-term heat aging performance compared to virgin nylon.

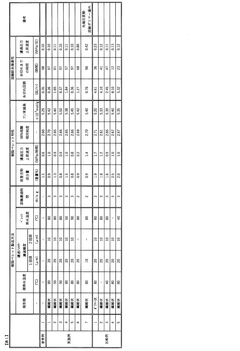

Critical Property Comparison Analysis

Tire grade high toughness and modulus recycled nylon 6.6 yarn and method for its production

PatentPendingKR1020240065292A

Innovation

- Recycled nylon 6.6 pellets are produced from tire-grade nylon 6.6 yarn scrap, and blended with virgin pellets to create tire-grade yarn with comparable properties through a solid state polymerization process, minimizing finishing oil levels and ensuring homogeneous mixing.

Nylon-6 fiber, and material-recycled polycaproamide resin pellets and method for production thereof

PatentWO2022196407A1

Innovation

- The development of material recycled polycaproamide resin pellets with a low polymer component content of 1.5% by weight or less, achieved through a process involving hot water extraction and multiple filtration steps, ensures a molecular weight distribution similar to virgin nylon 6 fibers, enhancing the quality and operability of recycled nylon 6 fibers.

Environmental Impact Assessment

The environmental impact assessment of recycled versus virgin Nylon 6 reveals significant differences in ecological footprints across their respective life cycles. Virgin Nylon 6 production requires substantial petroleum resources, consuming approximately 138 MJ of energy per kilogram produced, while generating 5.5-6.5 kg CO2 equivalent greenhouse gas emissions. This intensive process involves extraction of raw materials, chemical synthesis, and energy-demanding polymerization steps that contribute to resource depletion and atmospheric pollution.

In contrast, mechanical recycling of Nylon 6 demonstrates a 60-75% reduction in energy consumption compared to virgin production, with corresponding decreases in greenhouse gas emissions ranging from 45-55%. Chemical recycling methods, particularly depolymerization, show even greater potential with up to 85% energy savings when optimized at industrial scale, though current commercial implementations typically achieve 50-70% reductions.

Water usage metrics further highlight the environmental advantages of recycled Nylon 6, with virgin production requiring 500-1000 liters per kilogram compared to recycled processes that typically consume 150-300 liters. This represents a critical consideration in regions facing water scarcity challenges or where manufacturing facilities operate under stringent water management regulations.

Waste stream analysis indicates that recycled Nylon 6 production generates approximately 40% less solid waste than virgin manufacturing processes. However, the environmental benefits are partially offset by chemical treatments often required to restore material properties in recycled Nylon 6, particularly when addressing contamination or degradation issues in post-consumer waste streams.

Life Cycle Assessment (LCA) studies consistently demonstrate that recycled Nylon 6 offers superior environmental performance across multiple impact categories, including acidification potential, eutrophication, and photochemical ozone creation. These advantages become particularly pronounced when considering closed-loop recycling systems that can maintain material quality through multiple recycling cycles.

The environmental calculus becomes more complex when accounting for transportation impacts in global supply chains. Virgin Nylon 6 typically travels 1,500-2,500 kilometers from production to application, while recycled material supply chains can be more geographically dispersed due to collection infrastructure limitations, potentially offsetting some environmental gains through increased transportation emissions.

Recent policy developments, including Extended Producer Responsibility frameworks and carbon pricing mechanisms, are increasingly internalizing environmental externalities, thereby enhancing the economic viability of recycled Nylon 6 adoption. Industry forecasts suggest that improvements in collection infrastructure and recycling technologies could further amplify the environmental advantages of recycled Nylon 6 by an additional 15-25% over the next decade.

In contrast, mechanical recycling of Nylon 6 demonstrates a 60-75% reduction in energy consumption compared to virgin production, with corresponding decreases in greenhouse gas emissions ranging from 45-55%. Chemical recycling methods, particularly depolymerization, show even greater potential with up to 85% energy savings when optimized at industrial scale, though current commercial implementations typically achieve 50-70% reductions.

Water usage metrics further highlight the environmental advantages of recycled Nylon 6, with virgin production requiring 500-1000 liters per kilogram compared to recycled processes that typically consume 150-300 liters. This represents a critical consideration in regions facing water scarcity challenges or where manufacturing facilities operate under stringent water management regulations.

Waste stream analysis indicates that recycled Nylon 6 production generates approximately 40% less solid waste than virgin manufacturing processes. However, the environmental benefits are partially offset by chemical treatments often required to restore material properties in recycled Nylon 6, particularly when addressing contamination or degradation issues in post-consumer waste streams.

Life Cycle Assessment (LCA) studies consistently demonstrate that recycled Nylon 6 offers superior environmental performance across multiple impact categories, including acidification potential, eutrophication, and photochemical ozone creation. These advantages become particularly pronounced when considering closed-loop recycling systems that can maintain material quality through multiple recycling cycles.

The environmental calculus becomes more complex when accounting for transportation impacts in global supply chains. Virgin Nylon 6 typically travels 1,500-2,500 kilometers from production to application, while recycled material supply chains can be more geographically dispersed due to collection infrastructure limitations, potentially offsetting some environmental gains through increased transportation emissions.

Recent policy developments, including Extended Producer Responsibility frameworks and carbon pricing mechanisms, are increasingly internalizing environmental externalities, thereby enhancing the economic viability of recycled Nylon 6 adoption. Industry forecasts suggest that improvements in collection infrastructure and recycling technologies could further amplify the environmental advantages of recycled Nylon 6 by an additional 15-25% over the next decade.

Economic Viability Analysis

The economic viability of recycled Nylon 6 represents a critical factor in determining its market adoption compared to virgin materials. Current market analysis indicates that recycled Nylon 6 typically commands a price point 10-15% lower than virgin material, creating an initial cost advantage for manufacturers. However, this price differential must be evaluated against potential processing challenges and performance variations that may affect overall production economics.

Production cost analysis reveals that recycling Nylon 6 consumes approximately 70-80% less energy compared to manufacturing virgin material, translating to significant operational savings. The carbon footprint reduction is estimated at 50-60%, which increasingly translates to economic value as carbon pricing mechanisms expand globally. These sustainability benefits create tangible economic advantages beyond direct material costs.

Supply chain considerations significantly impact economic viability. The collection, sorting, and processing infrastructure for recycled Nylon 6 remains less developed than virgin material supply chains, creating potential volatility in material availability and pricing. Geographic disparities exist, with more mature recycling ecosystems in Western Europe and parts of Asia providing more stable supply conditions than emerging markets.

Scale economics present another crucial factor. Current recycling technologies demonstrate improved cost efficiency at larger scales, but many recycling operations have not yet reached optimal production volumes. Industry projections suggest that as recycling capacity increases over the next 3-5 years, production costs will decrease by an estimated 15-20%, further enhancing economic competitiveness.

Quality consistency variations in recycled Nylon 6 create downstream economic implications. Manufacturing processes using recycled material may require additional quality control measures, potentially offsetting some of the raw material cost advantages. However, technological advancements in recycling processes, particularly in contaminant removal and polymer chain preservation, are progressively minimizing these quality-related economic penalties.

Regulatory frameworks increasingly influence economic calculations. Extended producer responsibility regulations, plastic taxes, and recycled content mandates are being implemented across various markets, creating economic incentives that favor recycled materials. These policy instruments effectively internalize environmental externalities, improving the comparative economic position of recycled Nylon 6.

Long-term market forecasts indicate that as virgin petroleum-based feedstock prices continue their upward trajectory due to resource constraints and carbon pricing, the economic advantage of recycled Nylon 6 will likely strengthen. This trend, combined with technological improvements in recycling processes, suggests an increasingly favorable economic outlook for recycled Nylon 6 applications.

Production cost analysis reveals that recycling Nylon 6 consumes approximately 70-80% less energy compared to manufacturing virgin material, translating to significant operational savings. The carbon footprint reduction is estimated at 50-60%, which increasingly translates to economic value as carbon pricing mechanisms expand globally. These sustainability benefits create tangible economic advantages beyond direct material costs.

Supply chain considerations significantly impact economic viability. The collection, sorting, and processing infrastructure for recycled Nylon 6 remains less developed than virgin material supply chains, creating potential volatility in material availability and pricing. Geographic disparities exist, with more mature recycling ecosystems in Western Europe and parts of Asia providing more stable supply conditions than emerging markets.

Scale economics present another crucial factor. Current recycling technologies demonstrate improved cost efficiency at larger scales, but many recycling operations have not yet reached optimal production volumes. Industry projections suggest that as recycling capacity increases over the next 3-5 years, production costs will decrease by an estimated 15-20%, further enhancing economic competitiveness.

Quality consistency variations in recycled Nylon 6 create downstream economic implications. Manufacturing processes using recycled material may require additional quality control measures, potentially offsetting some of the raw material cost advantages. However, technological advancements in recycling processes, particularly in contaminant removal and polymer chain preservation, are progressively minimizing these quality-related economic penalties.

Regulatory frameworks increasingly influence economic calculations. Extended producer responsibility regulations, plastic taxes, and recycled content mandates are being implemented across various markets, creating economic incentives that favor recycled materials. These policy instruments effectively internalize environmental externalities, improving the comparative economic position of recycled Nylon 6.

Long-term market forecasts indicate that as virgin petroleum-based feedstock prices continue their upward trajectory due to resource constraints and carbon pricing, the economic advantage of recycled Nylon 6 will likely strengthen. This trend, combined with technological improvements in recycling processes, suggests an increasingly favorable economic outlook for recycled Nylon 6 applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!