How moisture absorption affects mechanical stability of Nylon 6

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Hygroscopic Properties and Stability Goals

Nylon 6 is a semi-crystalline polyamide known for its excellent mechanical properties, including high tensile strength, good abrasion resistance, and durability. However, its hygroscopic nature presents significant challenges for applications requiring dimensional stability and consistent mechanical performance. Understanding and addressing these challenges is crucial for expanding the material's application scope in demanding environments.

The primary goal of this technical investigation is to comprehensively analyze how moisture absorption affects the mechanical stability of Nylon 6 and to establish performance targets that maintain structural integrity under varying humidity conditions. We aim to quantify the relationship between moisture content and key mechanical properties, including tensile strength, impact resistance, and dimensional stability.

Historically, Nylon 6 has demonstrated moisture absorption rates of 2.7-3.2% at equilibrium under standard conditions (23°C, 50% RH), significantly higher than many competing engineering plastics. This absorption fundamentally alters the material's properties through plasticization effects, where water molecules interfere with hydrogen bonding between polymer chains, increasing chain mobility.

Current industry standards typically accept a 15-20% reduction in tensile strength and a 10-15% decrease in modulus when Nylon 6 transitions from dry to moisture-equilibrated states. Our technical objectives include developing strategies to maintain mechanical property variations within 10% across the full range of expected service environments.

The evolution of Nylon 6 technology shows promising trends in moisture resistance improvement. Recent advancements in polymer chemistry have yielded modified grades with reduced moisture sensitivity through techniques such as end-group capping, incorporation of hydrophobic comonomers, and specialized compounding with mineral fillers or glass fiber reinforcement.

For critical applications, we aim to achieve dimensional stability with maximum linear expansion below 0.2% across the full range of service humidity conditions. This represents a significant improvement over conventional Nylon 6, which typically exhibits 0.5-0.8% dimensional changes when transitioning from dry to saturated states.

Our technical roadmap includes investigating novel surface treatments, exploring hybrid composite structures, and developing predictive models for long-term mechanical performance under cyclic humidity conditions. These efforts align with the broader industry trend toward more environmentally resilient engineering plastics that maintain consistent performance across diverse operating environments.

The ultimate goal is to establish clear engineering guidelines for Nylon 6 application in moisture-variable environments, with particular focus on quantifying safety factors needed for structural applications and developing accelerated testing protocols that accurately predict long-term mechanical stability.

The primary goal of this technical investigation is to comprehensively analyze how moisture absorption affects the mechanical stability of Nylon 6 and to establish performance targets that maintain structural integrity under varying humidity conditions. We aim to quantify the relationship between moisture content and key mechanical properties, including tensile strength, impact resistance, and dimensional stability.

Historically, Nylon 6 has demonstrated moisture absorption rates of 2.7-3.2% at equilibrium under standard conditions (23°C, 50% RH), significantly higher than many competing engineering plastics. This absorption fundamentally alters the material's properties through plasticization effects, where water molecules interfere with hydrogen bonding between polymer chains, increasing chain mobility.

Current industry standards typically accept a 15-20% reduction in tensile strength and a 10-15% decrease in modulus when Nylon 6 transitions from dry to moisture-equilibrated states. Our technical objectives include developing strategies to maintain mechanical property variations within 10% across the full range of expected service environments.

The evolution of Nylon 6 technology shows promising trends in moisture resistance improvement. Recent advancements in polymer chemistry have yielded modified grades with reduced moisture sensitivity through techniques such as end-group capping, incorporation of hydrophobic comonomers, and specialized compounding with mineral fillers or glass fiber reinforcement.

For critical applications, we aim to achieve dimensional stability with maximum linear expansion below 0.2% across the full range of service humidity conditions. This represents a significant improvement over conventional Nylon 6, which typically exhibits 0.5-0.8% dimensional changes when transitioning from dry to saturated states.

Our technical roadmap includes investigating novel surface treatments, exploring hybrid composite structures, and developing predictive models for long-term mechanical performance under cyclic humidity conditions. These efforts align with the broader industry trend toward more environmentally resilient engineering plastics that maintain consistent performance across diverse operating environments.

The ultimate goal is to establish clear engineering guidelines for Nylon 6 application in moisture-variable environments, with particular focus on quantifying safety factors needed for structural applications and developing accelerated testing protocols that accurately predict long-term mechanical stability.

Market Analysis of Moisture-Resistant Nylon Applications

The global market for moisture-resistant nylon applications has experienced significant growth in recent years, driven by increasing demand across multiple industries where mechanical stability under varying environmental conditions is critical. The market size for specialized nylon 6 formulations with enhanced moisture resistance properties is currently valued at approximately $3.2 billion, with projections indicating a compound annual growth rate of 5.7% through 2028.

Automotive and transportation sectors represent the largest application segment, accounting for roughly 32% of the total market share. In these industries, moisture-resistant nylon components are essential for under-hood applications, fuel systems, and structural elements where dimensional stability and mechanical performance must be maintained despite exposure to humidity and temperature fluctuations.

The electronics and electrical industry follows closely as the second-largest consumer of moisture-resistant nylon materials, comprising about 27% of market demand. This sector's growth is primarily fueled by the expanding need for reliable insulation materials in consumer electronics, telecommunications equipment, and electrical connectors that must maintain consistent performance regardless of environmental moisture conditions.

Consumer goods and industrial equipment manufacturers collectively represent approximately 25% of the market, with applications ranging from sporting equipment and household appliances to industrial machinery components. These sectors value nylon formulations that can maintain their mechanical properties despite repeated moisture absorption and desorption cycles.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, driven by robust manufacturing activities in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, where advanced engineering applications and stringent performance requirements fuel demand for high-performance moisture-resistant nylon variants.

Market trends indicate growing demand for specialized nylon 6 formulations with enhanced moisture resistance achieved through various technical approaches, including copolymerization, compounding with hydrophobic additives, and surface treatments. Premium pricing is observed for solutions that can demonstrate consistent mechanical stability under fluctuating humidity conditions, with price premiums of 15-30% compared to standard nylon 6 materials.

Customer requirements are increasingly focused on predictable performance metrics, with many end-users willing to pay premium prices for materials that offer quantifiable reductions in moisture sensitivity. This trend is particularly evident in high-value applications where component failure due to moisture-induced dimensional changes or mechanical property degradation would result in significant downstream costs.

Automotive and transportation sectors represent the largest application segment, accounting for roughly 32% of the total market share. In these industries, moisture-resistant nylon components are essential for under-hood applications, fuel systems, and structural elements where dimensional stability and mechanical performance must be maintained despite exposure to humidity and temperature fluctuations.

The electronics and electrical industry follows closely as the second-largest consumer of moisture-resistant nylon materials, comprising about 27% of market demand. This sector's growth is primarily fueled by the expanding need for reliable insulation materials in consumer electronics, telecommunications equipment, and electrical connectors that must maintain consistent performance regardless of environmental moisture conditions.

Consumer goods and industrial equipment manufacturers collectively represent approximately 25% of the market, with applications ranging from sporting equipment and household appliances to industrial machinery components. These sectors value nylon formulations that can maintain their mechanical properties despite repeated moisture absorption and desorption cycles.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, driven by robust manufacturing activities in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, where advanced engineering applications and stringent performance requirements fuel demand for high-performance moisture-resistant nylon variants.

Market trends indicate growing demand for specialized nylon 6 formulations with enhanced moisture resistance achieved through various technical approaches, including copolymerization, compounding with hydrophobic additives, and surface treatments. Premium pricing is observed for solutions that can demonstrate consistent mechanical stability under fluctuating humidity conditions, with price premiums of 15-30% compared to standard nylon 6 materials.

Customer requirements are increasingly focused on predictable performance metrics, with many end-users willing to pay premium prices for materials that offer quantifiable reductions in moisture sensitivity. This trend is particularly evident in high-value applications where component failure due to moisture-induced dimensional changes or mechanical property degradation would result in significant downstream costs.

Current Challenges in Nylon 6 Moisture Management

Despite significant advancements in polymer science, moisture management in Nylon 6 remains a persistent challenge for manufacturers and end-users alike. The hydrophilic nature of Nylon 6, attributed to its amide groups, creates a fundamental vulnerability to moisture absorption that continues to complicate industrial applications. Current moisture management approaches struggle with the inherent trade-off between maintaining mechanical properties and controlling water uptake.

The primary challenge lies in the molecular-level interaction between water molecules and the polymer chains. When moisture penetrates Nylon 6, it disrupts hydrogen bonding between polymer chains, acting as a plasticizer that significantly reduces glass transition temperature. This plasticization effect can decrease tensile strength by up to 30% and impact resistance by 15-20% at moisture saturation levels, creating unpredictable performance variations in critical applications.

Manufacturing processes further complicate moisture management. During injection molding and extrusion, residual moisture can cause hydrolysis reactions that degrade the polymer chains, reducing molecular weight and compromising long-term mechanical stability. Current drying protocols often prove inadequate, with studies showing that conventional drying methods may leave residual moisture of 0.1-0.2%, still sufficient to initiate degradation during high-temperature processing.

Environmental cycling presents another significant challenge. Components exposed to fluctuating humidity conditions experience repeated absorption and desorption cycles, leading to dimensional instability and internal stress accumulation. This cycling effect is particularly problematic in precision engineering applications where dimensional tolerances are critical, with documented dimensional changes of 0.2-0.5% possible between dry and saturated states.

Surface treatments and coatings offer partial solutions but introduce their own complications. Hydrophobic coatings can reduce initial moisture uptake rates but typically do not prevent long-term absorption. Additionally, adhesion issues between coatings and the Nylon 6 substrate often lead to delamination under mechanical stress or thermal cycling, negating their protective benefits over time.

The development of moisture-resistant Nylon 6 composites represents a promising direction, but current formulations face challenges in maintaining the base polymer's desirable properties. Incorporating hydrophobic fillers often increases brittleness or reduces processability, while chemical modifications to reduce hydrophilicity can negatively impact other mechanical properties or increase production costs substantially.

Quantification and prediction of moisture effects remain imprecise, with existing models struggling to account for the complex interplay between environmental conditions, material history, and mechanical loading. This predictive gap hampers design engineers' ability to accurately compensate for moisture-induced property changes, often resulting in over-engineering or unexpected field failures.

The primary challenge lies in the molecular-level interaction between water molecules and the polymer chains. When moisture penetrates Nylon 6, it disrupts hydrogen bonding between polymer chains, acting as a plasticizer that significantly reduces glass transition temperature. This plasticization effect can decrease tensile strength by up to 30% and impact resistance by 15-20% at moisture saturation levels, creating unpredictable performance variations in critical applications.

Manufacturing processes further complicate moisture management. During injection molding and extrusion, residual moisture can cause hydrolysis reactions that degrade the polymer chains, reducing molecular weight and compromising long-term mechanical stability. Current drying protocols often prove inadequate, with studies showing that conventional drying methods may leave residual moisture of 0.1-0.2%, still sufficient to initiate degradation during high-temperature processing.

Environmental cycling presents another significant challenge. Components exposed to fluctuating humidity conditions experience repeated absorption and desorption cycles, leading to dimensional instability and internal stress accumulation. This cycling effect is particularly problematic in precision engineering applications where dimensional tolerances are critical, with documented dimensional changes of 0.2-0.5% possible between dry and saturated states.

Surface treatments and coatings offer partial solutions but introduce their own complications. Hydrophobic coatings can reduce initial moisture uptake rates but typically do not prevent long-term absorption. Additionally, adhesion issues between coatings and the Nylon 6 substrate often lead to delamination under mechanical stress or thermal cycling, negating their protective benefits over time.

The development of moisture-resistant Nylon 6 composites represents a promising direction, but current formulations face challenges in maintaining the base polymer's desirable properties. Incorporating hydrophobic fillers often increases brittleness or reduces processability, while chemical modifications to reduce hydrophilicity can negatively impact other mechanical properties or increase production costs substantially.

Quantification and prediction of moisture effects remain imprecise, with existing models struggling to account for the complex interplay between environmental conditions, material history, and mechanical loading. This predictive gap hampers design engineers' ability to accurately compensate for moisture-induced property changes, often resulting in over-engineering or unexpected field failures.

Existing Moisture Control Technologies for Nylon 6

01 Reinforcement with fillers and additives

Various fillers and additives can be incorporated into Nylon 6 to enhance its mechanical stability. These include glass fibers, carbon fibers, mineral fillers, and nanomaterials that significantly improve tensile strength, impact resistance, and dimensional stability. The reinforcement materials create a composite structure that distributes stress more effectively throughout the polymer matrix, resulting in superior mechanical properties compared to pure Nylon 6.- Reinforcement with fillers and additives: Various fillers and additives can be incorporated into Nylon 6 to enhance its mechanical stability. These include glass fibers, carbon fibers, mineral fillers, and nanomaterials that significantly improve tensile strength, impact resistance, and dimensional stability. The reinforcement materials create a composite structure that distributes mechanical stress more effectively throughout the polymer matrix, resulting in superior mechanical properties compared to pure Nylon 6.

- Blending with other polymers: Blending Nylon 6 with other polymers creates materials with enhanced mechanical stability. Compatible polymers like polyolefins, elastomers, or other engineering plastics can be combined with Nylon 6 to achieve specific mechanical property improvements. These polymer blends often exhibit synergistic effects, resulting in better impact resistance, flexibility, or tensile strength while maintaining the beneficial properties of Nylon 6.

- Crystallinity control and heat treatment: The mechanical stability of Nylon 6 can be significantly improved through controlling its crystallinity and applying appropriate heat treatments. Processes such as annealing, controlled cooling, and thermal conditioning affect the polymer's crystalline structure, which directly influences mechanical properties. Higher crystallinity typically results in greater stiffness and tensile strength, while controlled cooling can optimize the balance between toughness and rigidity.

- Surface modification and coating techniques: Surface treatments and coating techniques can enhance the mechanical stability of Nylon 6 components. Methods include plasma treatment, chemical modification, and application of specialized coatings that improve surface hardness, wear resistance, and environmental stability. These modifications create a protective layer that shields the base material from mechanical stress and environmental factors that could otherwise compromise its structural integrity.

- Processing parameters optimization: Optimizing processing parameters during Nylon 6 manufacturing significantly impacts its mechanical stability. Factors such as injection molding temperature, pressure, cooling rate, and extrusion conditions affect the polymer's molecular orientation, internal stress distribution, and overall mechanical performance. Proper control of these parameters can minimize defects and enhance the material's resistance to mechanical failure under various loading conditions.

02 Blending with other polymers

Blending Nylon 6 with other polymers creates materials with enhanced mechanical stability. Compatible polymers like polyolefins, elastomers, or other engineering plastics can be combined with Nylon 6 to achieve specific property improvements such as increased impact resistance, reduced water absorption, or improved dimensional stability. The resulting polymer blends often exhibit synergistic effects that overcome the inherent limitations of pure Nylon 6.Expand Specific Solutions03 Modification of crystalline structure

The mechanical stability of Nylon 6 can be significantly improved by modifying its crystalline structure. Techniques such as controlled cooling, annealing, and nucleation can optimize the crystallinity level and crystal morphology. Higher crystallinity typically results in greater stiffness and tensile strength, while specific crystal structures can enhance impact resistance and dimensional stability under varying temperature and humidity conditions.Expand Specific Solutions04 Surface treatments and coatings

Surface treatments and specialized coatings can enhance the mechanical stability of Nylon 6 components. Techniques such as plasma treatment, chemical modification, or application of protective coatings improve surface hardness, wear resistance, and environmental stability. These treatments can create cross-linked surface layers or hydrophobic barriers that protect the underlying Nylon 6 from degradation while maintaining or enhancing its mechanical properties.Expand Specific Solutions05 Processing techniques for improved stability

Advanced processing techniques can significantly enhance the mechanical stability of Nylon 6 products. Methods such as orientation during extrusion, optimized injection molding parameters, and specialized heat treatment processes align polymer chains to increase strength in specific directions. Controlled cooling rates and processing under specific pressure conditions can also minimize internal stresses and voids, resulting in components with superior mechanical properties and long-term dimensional stability.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The moisture absorption in Nylon 6 presents a complex competitive landscape within the materials science industry. Currently in a mature growth phase, the market for moisture-resistant nylon solutions is expanding steadily, with an estimated global value exceeding $2 billion. Leading companies like DuPont, Ascend Performance Materials, and Kingfa Sci. & Tech. have developed advanced technologies to mitigate hygroscopic effects, while academic institutions such as Beijing University of Chemical Technology and Hebei University of Technology contribute significant research. Mitsubishi Gas Chemical and GS Caltex are advancing moisture-barrier technologies, while Stratasys addresses moisture concerns in 3D printing applications. The technical maturity varies across sectors, with automotive and aerospace applications (supported by companies like Parker-Hannifin and Eaton) showing higher sophistication than consumer applications.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend Performance Materials has developed proprietary moisture management technologies for their Nylon 6 products, focusing on reducing hygroscopic properties through advanced polymer modification. Their approach involves incorporating hydrophobic additives and specialized surface treatments that create a moisture barrier while maintaining the core mechanical properties of Nylon 6. The company has implemented a multi-layer molecular structure that limits water absorption to less than 2.5% (compared to traditional Nylon 6's 8-10%) while preserving tensile strength. Their research has demonstrated that controlled crystallinity levels between 35-40% provide optimal balance between moisture resistance and mechanical stability. Ascend's technology also includes specialized drying protocols that establish precise moisture equilibrium points to prevent internal stress development during processing and end-use applications.

Strengths: Superior moisture resistance while maintaining mechanical properties; comprehensive understanding of crystallinity-moisture relationships; established industrial-scale production capabilities. Weaknesses: Higher production costs compared to standard Nylon 6; potential reduction in some mechanical properties like impact resistance; requires specialized processing equipment for optimal results.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered advanced moisture-resistant Nylon 6 formulations through their proprietary Zytel® technology platform. Their approach combines molecular weight optimization with specialized nucleating agents that create a more ordered crystalline structure, reducing interstitial spaces where water molecules can penetrate. DuPont's research has established that controlling the amorphous-to-crystalline ratio is critical, with their engineered materials achieving a 40-45% crystallinity that reduces moisture absorption by up to 50% compared to conventional Nylon 6. Their technology incorporates hydrophobic nanoparticles that are chemically bonded to the polymer chains, creating permanent moisture barriers throughout the material matrix. DuPont has also developed specialized heat treatment processes that realign polymer chains to minimize moisture-induced dimensional changes, maintaining mechanical stability even in high-humidity environments where traditional Nylon 6 would experience significant property degradation.

Strengths: Extensive research infrastructure and polymer science expertise; established global manufacturing capabilities; comprehensive material characterization facilities. Weaknesses: Premium pricing compared to standard polyamides; potential processing challenges requiring specialized equipment; some formulations may have reduced elongation properties.

Key Scientific Findings on Hygroscopic Mechanical Degradation

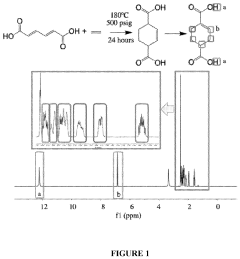

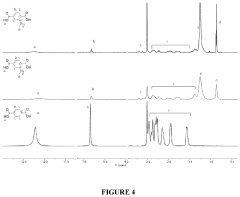

Isomerization of cyclohexenedicarboxylic acid and its derivatives

PatentPendingUS20230373895A1

Innovation

- The synthesis of hydrophobic cyclic diacids through Diels-Alder chemistry with muconic acid derivatives, specifically shifting the unsaturation from the beta-gamma to the alpha-beta position, which allows for the production of novel polyamides with improved water resistance and surface properties.

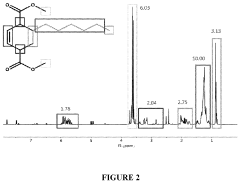

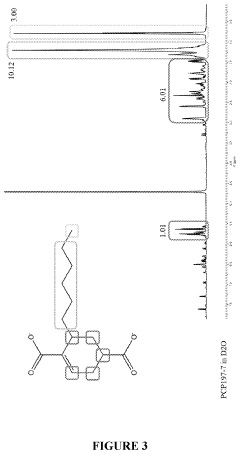

Functionalization of trans-3-hexenedioic acid for the production of hydrophobic polyamides and chemical resistance thereof

PatentInactiveUS20190153156A1

Innovation

- The development of a hydrophobic and chemically resistant Bio-Advantaged Nylon (BAN) through the functionalization of trans-3-hexenedioic acid, achieved by reacting 3-(dodecylthio)hexanedioic acid with hexamethylenediamine and adipic acid, resulting in a polymer with reduced water absorption and enhanced chemical resistance.

Environmental Factors Affecting Nylon 6 Performance

Nylon 6 performance is significantly influenced by various environmental factors, with moisture absorption being particularly critical to its mechanical stability. The hygroscopic nature of Nylon 6 allows it to absorb up to 9-10% of its weight in moisture under high humidity conditions, which substantially alters its dimensional stability and mechanical properties. This absorption occurs primarily due to the hydrogen bonding between water molecules and the amide groups in the polymer chain.

Temperature fluctuations exacerbate moisture-related issues, as higher temperatures accelerate the rate of moisture absorption while simultaneously reducing mechanical strength. Research indicates that for every 1% increase in moisture content, there can be a corresponding 10-15% decrease in tensile strength and up to 20% reduction in flexural modulus. This relationship is non-linear, with the most dramatic property changes occurring during the initial stages of moisture absorption.

UV radiation presents another significant environmental challenge, particularly when combined with moisture exposure. The photodegradation process initiated by UV exposure creates free radicals within the polymer structure, which can accelerate hydrolysis reactions in the presence of moisture. Long-term studies demonstrate that Nylon 6 components exposed to both high humidity and UV radiation show accelerated aging, with mechanical property degradation occurring at rates 2-3 times faster than those observed under single-factor exposure conditions.

Chemical exposure further complicates the moisture-mechanical stability relationship. Acidic environments can catalyze the hydrolysis of amide bonds when moisture is present, leading to chain scission and molecular weight reduction. Alkaline environments, while less damaging than acidic ones, can still promote surface degradation when combined with moisture. Industrial environments containing specific chemical contaminants such as chlorides or sulfates can form aggressive microenvironments on the polymer surface, creating localized areas of accelerated degradation.

Cyclic environmental conditions pose perhaps the most challenging scenario for Nylon 6 stability. Repeated moisture absorption and desorption cycles create internal stresses within the material as it undergoes dimensional changes. These hygrothermal cycles can lead to microcracking, particularly at stress concentration points, ultimately resulting in premature mechanical failure. Testing protocols that incorporate such cycling have shown that as few as 50-100 moisture cycles can reduce the fatigue life of Nylon 6 components by up to 40% compared to stable environmental conditions.

Temperature fluctuations exacerbate moisture-related issues, as higher temperatures accelerate the rate of moisture absorption while simultaneously reducing mechanical strength. Research indicates that for every 1% increase in moisture content, there can be a corresponding 10-15% decrease in tensile strength and up to 20% reduction in flexural modulus. This relationship is non-linear, with the most dramatic property changes occurring during the initial stages of moisture absorption.

UV radiation presents another significant environmental challenge, particularly when combined with moisture exposure. The photodegradation process initiated by UV exposure creates free radicals within the polymer structure, which can accelerate hydrolysis reactions in the presence of moisture. Long-term studies demonstrate that Nylon 6 components exposed to both high humidity and UV radiation show accelerated aging, with mechanical property degradation occurring at rates 2-3 times faster than those observed under single-factor exposure conditions.

Chemical exposure further complicates the moisture-mechanical stability relationship. Acidic environments can catalyze the hydrolysis of amide bonds when moisture is present, leading to chain scission and molecular weight reduction. Alkaline environments, while less damaging than acidic ones, can still promote surface degradation when combined with moisture. Industrial environments containing specific chemical contaminants such as chlorides or sulfates can form aggressive microenvironments on the polymer surface, creating localized areas of accelerated degradation.

Cyclic environmental conditions pose perhaps the most challenging scenario for Nylon 6 stability. Repeated moisture absorption and desorption cycles create internal stresses within the material as it undergoes dimensional changes. These hygrothermal cycles can lead to microcracking, particularly at stress concentration points, ultimately resulting in premature mechanical failure. Testing protocols that incorporate such cycling have shown that as few as 50-100 moisture cycles can reduce the fatigue life of Nylon 6 components by up to 40% compared to stable environmental conditions.

Lifecycle Assessment of Moisture-Exposed Nylon Components

The lifecycle of Nylon 6 components exposed to moisture presents significant challenges for engineering applications requiring long-term mechanical stability. When examining the complete service life of these components, moisture absorption emerges as a critical factor affecting performance degradation over time. Initially, newly manufactured Nylon 6 parts exhibit optimal mechanical properties with tensile strength typically ranging from 70-85 MPa and flexural modulus between 2.5-3.0 GPa under controlled environmental conditions.

As these components enter service environments with varying humidity levels, they begin absorbing moisture at rates dependent on ambient conditions, component thickness, and surface treatments. Research indicates that Nylon 6 can absorb up to 9-10% moisture by weight at saturation in high-humidity environments, with approximately 50% of this absorption occurring within the first 24-48 hours of exposure.

The progressive moisture absorption triggers several degradation mechanisms that compromise mechanical stability throughout the component's lifecycle. Dimensional changes become evident within days of deployment, with swelling of 0.2-0.3% per 1% moisture absorption. This dimensional instability creates particular challenges for precision-engineered components with tight tolerances.

Mid-lifecycle assessment typically reveals significant reductions in mechanical properties, with tensile strength decreasing by 30-40% and modulus of elasticity dropping by 25-35% at moisture saturation. These changes correlate directly with increased molecular mobility as water molecules disrupt hydrogen bonding between polymer chains, effectively plasticizing the material and lowering its glass transition temperature by approximately 5-10°C per 1% moisture content.

Accelerated aging studies demonstrate that cyclic moisture absorption and desorption—common in real-world applications—can lead to more severe degradation than constant humidity exposure. Each absorption-desorption cycle introduces microstresses within the polymer matrix, potentially creating microvoids and accelerating mechanical failure through environmental stress cracking.

End-of-life analysis of moisture-exposed Nylon 6 components frequently reveals permanent changes to the polymer structure, including reduced crystallinity and molecular weight degradation through hydrolysis reactions. These irreversible changes mean that even after drying, components rarely return to their original mechanical properties, retaining only 85-90% of initial performance values.

Lifecycle assessment methodologies must therefore incorporate moisture history as a key parameter when predicting remaining service life of Nylon 6 components. Modern predictive models now integrate time-dependent moisture diffusion calculations with mechanical property degradation curves to provide more accurate lifecycle estimations for components operating in variable humidity environments.

As these components enter service environments with varying humidity levels, they begin absorbing moisture at rates dependent on ambient conditions, component thickness, and surface treatments. Research indicates that Nylon 6 can absorb up to 9-10% moisture by weight at saturation in high-humidity environments, with approximately 50% of this absorption occurring within the first 24-48 hours of exposure.

The progressive moisture absorption triggers several degradation mechanisms that compromise mechanical stability throughout the component's lifecycle. Dimensional changes become evident within days of deployment, with swelling of 0.2-0.3% per 1% moisture absorption. This dimensional instability creates particular challenges for precision-engineered components with tight tolerances.

Mid-lifecycle assessment typically reveals significant reductions in mechanical properties, with tensile strength decreasing by 30-40% and modulus of elasticity dropping by 25-35% at moisture saturation. These changes correlate directly with increased molecular mobility as water molecules disrupt hydrogen bonding between polymer chains, effectively plasticizing the material and lowering its glass transition temperature by approximately 5-10°C per 1% moisture content.

Accelerated aging studies demonstrate that cyclic moisture absorption and desorption—common in real-world applications—can lead to more severe degradation than constant humidity exposure. Each absorption-desorption cycle introduces microstresses within the polymer matrix, potentially creating microvoids and accelerating mechanical failure through environmental stress cracking.

End-of-life analysis of moisture-exposed Nylon 6 components frequently reveals permanent changes to the polymer structure, including reduced crystallinity and molecular weight degradation through hydrolysis reactions. These irreversible changes mean that even after drying, components rarely return to their original mechanical properties, retaining only 85-90% of initial performance values.

Lifecycle assessment methodologies must therefore incorporate moisture history as a key parameter when predicting remaining service life of Nylon 6 components. Modern predictive models now integrate time-dependent moisture diffusion calculations with mechanical property degradation curves to provide more accurate lifecycle estimations for components operating in variable humidity environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!