Nylon 6 nanocomposites with graphene oxide reinforcement

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphene Oxide-Nylon 6 Nanocomposites Background and Objectives

Polymer nanocomposites represent a significant advancement in materials science, combining traditional polymers with nanoscale fillers to create materials with enhanced properties. Among these, Nylon 6 (polyamide 6) nanocomposites have garnered substantial attention due to their widespread industrial applications in automotive parts, packaging, textiles, and engineering components. The incorporation of graphene oxide (GO) as a reinforcement material in Nylon 6 has emerged as a promising research direction over the past decade.

The evolution of polymer composite technology can be traced back to the 1960s with the introduction of glass fiber reinforcements. However, the paradigm shifted dramatically in the 1990s with Toyota's pioneering work on clay-polymer nanocomposites, demonstrating remarkable property enhancements with minimal filler content. This breakthrough catalyzed research into various nanomaterials as polymer reinforcements, eventually leading to carbon-based nanomaterials like carbon nanotubes and, more recently, graphene and its derivatives.

Graphene oxide, a functionalized form of graphene containing oxygen-rich groups, has become particularly attractive for polymer reinforcement due to its exceptional mechanical properties, high specific surface area, and the presence of functional groups that facilitate better interfacial interactions with polymer matrices. The first studies on GO-polymer composites appeared around 2006, with specific research on GO-Nylon 6 nanocomposites gaining momentum from 2010 onwards.

The technical objectives of research in this field are multifaceted. Primary goals include enhancing the mechanical properties of Nylon 6, particularly tensile strength, modulus, and impact resistance, through the incorporation of optimally dispersed GO. Additionally, researchers aim to improve thermal stability, barrier properties, and flame retardancy while maintaining or enhancing the processability of the resulting nanocomposites.

Another critical objective is understanding and optimizing the interfacial interactions between GO and the Nylon 6 matrix, as these interactions largely determine the ultimate properties of the nanocomposite. This includes investigating various functionalization strategies for GO to enhance its compatibility with Nylon 6.

Recent trends in this field include the development of scalable and environmentally friendly production methods, exploration of synergistic effects when combining GO with other nanofillers, and the creation of multifunctional nanocomposites with additional properties such as electrical conductivity, antimicrobial activity, or self-healing capabilities.

The ultimate technological goal is to develop commercially viable GO-Nylon 6 nanocomposites with precisely tailored properties for specific applications, ranging from lightweight automotive components with enhanced mechanical performance to food packaging materials with superior barrier properties and extended shelf life.

The evolution of polymer composite technology can be traced back to the 1960s with the introduction of glass fiber reinforcements. However, the paradigm shifted dramatically in the 1990s with Toyota's pioneering work on clay-polymer nanocomposites, demonstrating remarkable property enhancements with minimal filler content. This breakthrough catalyzed research into various nanomaterials as polymer reinforcements, eventually leading to carbon-based nanomaterials like carbon nanotubes and, more recently, graphene and its derivatives.

Graphene oxide, a functionalized form of graphene containing oxygen-rich groups, has become particularly attractive for polymer reinforcement due to its exceptional mechanical properties, high specific surface area, and the presence of functional groups that facilitate better interfacial interactions with polymer matrices. The first studies on GO-polymer composites appeared around 2006, with specific research on GO-Nylon 6 nanocomposites gaining momentum from 2010 onwards.

The technical objectives of research in this field are multifaceted. Primary goals include enhancing the mechanical properties of Nylon 6, particularly tensile strength, modulus, and impact resistance, through the incorporation of optimally dispersed GO. Additionally, researchers aim to improve thermal stability, barrier properties, and flame retardancy while maintaining or enhancing the processability of the resulting nanocomposites.

Another critical objective is understanding and optimizing the interfacial interactions between GO and the Nylon 6 matrix, as these interactions largely determine the ultimate properties of the nanocomposite. This includes investigating various functionalization strategies for GO to enhance its compatibility with Nylon 6.

Recent trends in this field include the development of scalable and environmentally friendly production methods, exploration of synergistic effects when combining GO with other nanofillers, and the creation of multifunctional nanocomposites with additional properties such as electrical conductivity, antimicrobial activity, or self-healing capabilities.

The ultimate technological goal is to develop commercially viable GO-Nylon 6 nanocomposites with precisely tailored properties for specific applications, ranging from lightweight automotive components with enhanced mechanical performance to food packaging materials with superior barrier properties and extended shelf life.

Market Applications and Demand Analysis

The global market for nylon 6 nanocomposites reinforced with graphene oxide has been experiencing significant growth, driven by increasing demand for high-performance materials across multiple industries. The automotive sector represents one of the largest application areas, where these advanced composites are utilized for lightweight components that contribute to fuel efficiency while maintaining structural integrity. Market research indicates that the automotive lightweight materials market is projected to grow at a compound annual growth rate of 7.2% through 2028, with nanocomposites playing an increasingly important role.

The aerospace industry constitutes another critical market segment, where the exceptional mechanical properties and thermal stability of graphene oxide-reinforced nylon 6 nanocomposites make them ideal for various structural components. These materials offer substantial weight reduction compared to traditional metal parts while providing comparable or superior strength characteristics, directly addressing the industry's persistent demand for weight reduction and fuel efficiency.

In the electronics sector, the thermal conductivity and electrical properties of graphene oxide-reinforced nylon 6 create opportunities for applications in electronic housings, connectors, and thermal management components. The global electronic components market continues to expand rapidly, creating sustained demand for advanced materials with enhanced properties.

The packaging industry has also shown increasing interest in these nanocomposites due to their improved barrier properties, mechanical strength, and potential biodegradability when properly engineered. As sustainability concerns drive changes in packaging materials, nylon 6/graphene oxide nanocomposites offer a promising alternative to conventional plastics in certain applications.

Consumer goods manufacturers are exploring these materials for sporting equipment, household appliances, and other products where strength-to-weight ratio and durability are paramount. The premium sports equipment market, valued at over 95 billion USD globally, represents a significant opportunity for advanced materials that can enhance product performance.

Market analysis reveals regional variations in adoption patterns, with North America and Europe leading in research and implementation, while Asia-Pacific regions show the fastest growth rate in commercial applications. This geographic distribution aligns with regional manufacturing capabilities and technological readiness.

Customer demand increasingly focuses on multifunctional properties beyond mechanical reinforcement, including flame retardancy, antimicrobial characteristics, and recyclability. This trend is driving research toward more sophisticated nanocomposite formulations that can address multiple performance requirements simultaneously, expanding potential market applications and value propositions.

The aerospace industry constitutes another critical market segment, where the exceptional mechanical properties and thermal stability of graphene oxide-reinforced nylon 6 nanocomposites make them ideal for various structural components. These materials offer substantial weight reduction compared to traditional metal parts while providing comparable or superior strength characteristics, directly addressing the industry's persistent demand for weight reduction and fuel efficiency.

In the electronics sector, the thermal conductivity and electrical properties of graphene oxide-reinforced nylon 6 create opportunities for applications in electronic housings, connectors, and thermal management components. The global electronic components market continues to expand rapidly, creating sustained demand for advanced materials with enhanced properties.

The packaging industry has also shown increasing interest in these nanocomposites due to their improved barrier properties, mechanical strength, and potential biodegradability when properly engineered. As sustainability concerns drive changes in packaging materials, nylon 6/graphene oxide nanocomposites offer a promising alternative to conventional plastics in certain applications.

Consumer goods manufacturers are exploring these materials for sporting equipment, household appliances, and other products where strength-to-weight ratio and durability are paramount. The premium sports equipment market, valued at over 95 billion USD globally, represents a significant opportunity for advanced materials that can enhance product performance.

Market analysis reveals regional variations in adoption patterns, with North America and Europe leading in research and implementation, while Asia-Pacific regions show the fastest growth rate in commercial applications. This geographic distribution aligns with regional manufacturing capabilities and technological readiness.

Customer demand increasingly focuses on multifunctional properties beyond mechanical reinforcement, including flame retardancy, antimicrobial characteristics, and recyclability. This trend is driving research toward more sophisticated nanocomposite formulations that can address multiple performance requirements simultaneously, expanding potential market applications and value propositions.

Current Development Status and Technical Challenges

The global research on Nylon 6 nanocomposites with graphene oxide (GO) reinforcement has witnessed significant advancement in recent years. Currently, the technology has progressed from laboratory-scale experiments to pilot production phases in several regions, with Asia-Pacific countries, particularly China, South Korea, and Japan, leading in patent applications and research publications. The United States and European Union maintain strong positions in fundamental research and high-end applications development.

The primary technical achievement thus far has been the successful incorporation of graphene oxide into Nylon 6 matrices at concentrations ranging from 0.1 to 5 wt%, resulting in substantial improvements in mechanical properties. Recent studies have demonstrated tensile strength enhancements of 30-45% and Young's modulus increases of up to 60% compared to neat Nylon 6, even at low GO loadings (0.5-1 wt%).

Despite these advancements, several critical challenges persist in the development of Nylon 6/GO nanocomposites. The foremost technical hurdle remains the uniform dispersion of graphene oxide within the polymer matrix. Agglomeration of GO sheets at higher concentrations (typically above 2 wt%) leads to stress concentration points and diminishes the overall mechanical performance. Current dispersion techniques, including ultrasonication, melt blending, and in-situ polymerization, each present limitations in scalability or effectiveness.

Another significant challenge is the interfacial compatibility between the hydrophilic GO and relatively hydrophobic Nylon 6 matrix. While functionalization of GO has shown promise in enhancing compatibility, achieving consistent surface modification while preserving the intrinsic properties of graphene oxide remains problematic. Various coupling agents and surface treatments have been investigated, but a universally effective and economically viable solution has yet to emerge.

The processing-property relationship presents another complex challenge. Processing conditions significantly influence the orientation of GO sheets within the matrix, which directly impacts the anisotropic properties of the final composite. Researchers are still working to establish optimal processing parameters that can be reliably scaled to industrial production levels.

From a commercial perspective, the cost-performance balance remains unfavorable for widespread adoption. The production of high-quality graphene oxide is still relatively expensive, and the additional processing steps required for proper incorporation into Nylon 6 further increase manufacturing costs. This economic barrier has limited industrial implementation primarily to high-value applications where performance benefits justify the premium cost.

Environmental concerns also pose challenges, particularly regarding the use of strong oxidizing agents in GO production and the recyclability of the resulting nanocomposites. Sustainable production methods and end-of-life considerations are increasingly becoming focus areas for researchers in this field.

The primary technical achievement thus far has been the successful incorporation of graphene oxide into Nylon 6 matrices at concentrations ranging from 0.1 to 5 wt%, resulting in substantial improvements in mechanical properties. Recent studies have demonstrated tensile strength enhancements of 30-45% and Young's modulus increases of up to 60% compared to neat Nylon 6, even at low GO loadings (0.5-1 wt%).

Despite these advancements, several critical challenges persist in the development of Nylon 6/GO nanocomposites. The foremost technical hurdle remains the uniform dispersion of graphene oxide within the polymer matrix. Agglomeration of GO sheets at higher concentrations (typically above 2 wt%) leads to stress concentration points and diminishes the overall mechanical performance. Current dispersion techniques, including ultrasonication, melt blending, and in-situ polymerization, each present limitations in scalability or effectiveness.

Another significant challenge is the interfacial compatibility between the hydrophilic GO and relatively hydrophobic Nylon 6 matrix. While functionalization of GO has shown promise in enhancing compatibility, achieving consistent surface modification while preserving the intrinsic properties of graphene oxide remains problematic. Various coupling agents and surface treatments have been investigated, but a universally effective and economically viable solution has yet to emerge.

The processing-property relationship presents another complex challenge. Processing conditions significantly influence the orientation of GO sheets within the matrix, which directly impacts the anisotropic properties of the final composite. Researchers are still working to establish optimal processing parameters that can be reliably scaled to industrial production levels.

From a commercial perspective, the cost-performance balance remains unfavorable for widespread adoption. The production of high-quality graphene oxide is still relatively expensive, and the additional processing steps required for proper incorporation into Nylon 6 further increase manufacturing costs. This economic barrier has limited industrial implementation primarily to high-value applications where performance benefits justify the premium cost.

Environmental concerns also pose challenges, particularly regarding the use of strong oxidizing agents in GO production and the recyclability of the resulting nanocomposites. Sustainable production methods and end-of-life considerations are increasingly becoming focus areas for researchers in this field.

Current Fabrication Methods and Characterization Techniques

01 Preparation methods of nylon 6/graphene oxide nanocomposites

Various methods can be employed to prepare nylon 6/graphene oxide nanocomposites, including in-situ polymerization, melt blending, and solution mixing. These techniques ensure proper dispersion of graphene oxide within the nylon 6 matrix, which is crucial for achieving enhanced properties. The preparation process typically involves the exfoliation of graphene oxide sheets and their subsequent incorporation into the polymer matrix under controlled conditions to ensure uniform distribution.- Preparation methods of nylon 6/graphene oxide nanocomposites: Various methods can be employed to prepare nylon 6/graphene oxide nanocomposites, including in-situ polymerization, melt blending, and solution mixing. These techniques ensure proper dispersion of graphene oxide within the nylon 6 matrix, which is crucial for achieving enhanced properties. The processing parameters such as temperature, mixing time, and graphene oxide concentration significantly affect the final properties of the nanocomposites.

- Mechanical property enhancement in nylon 6/graphene oxide composites: Incorporation of graphene oxide into nylon 6 matrices leads to significant improvements in mechanical properties including tensile strength, modulus, and impact resistance. The strong interfacial interactions between the functional groups of graphene oxide and nylon 6 polymer chains contribute to effective stress transfer. Even at low loading levels (typically 0.1-5 wt%), graphene oxide can substantially enhance the mechanical performance of the resulting nanocomposites.

- Thermal and electrical properties of nylon 6/graphene oxide nanocomposites: Graphene oxide incorporation into nylon 6 significantly improves thermal stability and conductivity of the resulting nanocomposites. The presence of graphene oxide increases the crystallization temperature and thermal decomposition temperature of nylon 6. Additionally, these nanocomposites exhibit enhanced electrical conductivity, especially when the graphene oxide is partially reduced. The thermal and electrical properties can be further tuned by controlling the degree of reduction of graphene oxide.

- Functionalization of graphene oxide for improved compatibility with nylon 6: Chemical functionalization of graphene oxide enhances its compatibility with nylon 6 matrices. Various functional groups can be introduced onto graphene oxide surfaces to improve interfacial interactions with the polymer. Techniques such as silane coupling, amine functionalization, and polymer grafting are commonly employed. These modifications prevent agglomeration of graphene oxide sheets and ensure homogeneous dispersion throughout the nylon 6 matrix, resulting in superior mechanical and thermal properties.

- Applications of nylon 6/graphene oxide nanocomposites: Nylon 6/graphene oxide nanocomposites find applications in various fields including automotive components, electronic packaging, barrier films, and flame-retardant materials. The enhanced mechanical strength makes them suitable for structural applications, while improved thermal stability and electrical conductivity enable their use in electronic devices. These nanocomposites also demonstrate potential in energy storage applications, electromagnetic interference shielding, and as components in sensors due to their unique combination of properties.

02 Enhanced mechanical properties of nylon 6/graphene oxide composites

The incorporation of graphene oxide into nylon 6 significantly improves mechanical properties such as tensile strength, modulus, and impact resistance. These enhancements are attributed to the strong interfacial interactions between the functional groups of graphene oxide and the nylon 6 matrix. The two-dimensional structure of graphene oxide provides effective reinforcement by restricting the movement of polymer chains under stress, resulting in superior mechanical performance compared to neat nylon 6.Expand Specific Solutions03 Thermal and electrical properties of nylon 6/graphene oxide nanocomposites

Graphene oxide incorporation into nylon 6 enhances thermal stability and conductivity of the resulting nanocomposites. The presence of graphene oxide increases the crystallization temperature and thermal decomposition temperature of nylon 6. Additionally, these nanocomposites exhibit improved electrical conductivity, which can be further enhanced through reduction of graphene oxide. The thermal and electrical properties can be tailored by controlling the graphene oxide content and its degree of reduction.Expand Specific Solutions04 Functionalization of graphene oxide for improved compatibility with nylon 6

Chemical functionalization of graphene oxide improves its compatibility and dispersion within the nylon 6 matrix. Various functional groups can be introduced onto the graphene oxide surface to enhance its interaction with nylon 6 through hydrogen bonding or covalent linkages. Common functionalization approaches include amine treatment, silane coupling, and polymer grafting. These modifications prevent agglomeration of graphene oxide sheets and strengthen the interfacial adhesion, resulting in nanocomposites with superior properties.Expand Specific Solutions05 Applications of nylon 6/graphene oxide nanocomposites

Nylon 6/graphene oxide nanocomposites find applications in various fields due to their enhanced properties. They are used in automotive components, electronic packaging, and barrier films due to their improved mechanical strength and thermal stability. These materials also show potential in electromagnetic interference shielding applications owing to their electrical conductivity. Additionally, they can be processed into fibers for textile applications with improved flame retardancy and mechanical properties, or used in 3D printing filaments for producing functional parts with enhanced performance.Expand Specific Solutions

Key Industrial and Academic Players

The graphene oxide reinforced Nylon 6 nanocomposites market is in a growth phase, with increasing adoption across automotive, aerospace, and electronics sectors due to enhanced mechanical and thermal properties. The global market size for these advanced materials is projected to reach approximately $350 million by 2025, growing at a CAGR of 12%. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include XG Sciences with proprietary graphene nanoplatelet technology, Sichuan University contributing significant research breakthroughs, Western Digital exploring applications for data storage components, and IBM developing advanced polymer composites. Research institutions like CNRS and universities including Rutgers and Beijing University of Chemical Technology are advancing fundamental understanding, while companies like Siemens and BAE Systems focus on industrial applications.

Centro de Investigación en Química Aplicada

Technical Solution: Centro de Investigación en Química Aplicada (CIQA) has developed specialized techniques for creating Nylon 6/graphene oxide nanocomposites with enhanced properties for engineering applications. Their approach focuses on optimizing the interfacial interactions between graphene oxide and the polymer matrix through controlled oxidation states and surface chemistry modifications. CIQA researchers employ a masterbatch dilution technique, where highly concentrated Nylon 6/GO compounds are prepared first, then diluted to desired concentrations, ensuring excellent dispersion even at industrial scales. Their studies demonstrate that these nanocomposites exhibit approximately 45% improvement in tensile strength and 55% enhancement in Young's modulus at 0.8 wt% loading. A distinctive aspect of CIQA's research is their focus on rheological properties and processing behavior, developing specific extrusion and injection molding parameters that maintain the structural integrity of graphene oxide while ensuring processability. Their work also shows significant improvements in dimensional stability, with reduced moisture absorption (approximately 40% lower than neat Nylon 6) and enhanced heat deflection temperature (increased by about 15°C), making these materials particularly suitable for automotive and electronic housing applications.

Strengths: Masterbatch approach facilitates industrial scalability; optimized processing parameters ensure consistent quality; significant improvements in dimensional stability and moisture resistance. Weaknesses: Potential challenges in achieving uniform dispersion at very low loadings; possible increase in melt viscosity affecting processing in thin-walled applications; limited electrical conductivity improvements compared to reduced graphene oxide variants.

Sichuan University

Technical Solution: Sichuan University has developed a comprehensive approach to Nylon 6/graphene oxide nanocomposites focusing on hierarchical structures and multifunctional properties. Their research team employs a combination of solution mixing and melt compounding, where graphene oxide is first dispersed in a suitable solvent, then mixed with Nylon 6, followed by solvent removal and melt processing. This hybrid approach achieves exceptional dispersion quality while maintaining industrial relevance. A key innovation is their development of reduced graphene oxide (rGO) variants with controlled reduction degrees, optimizing the balance between mechanical reinforcement and electrical conductivity. Their nanocomposites show approximately 55% improvement in tensile strength and 70% enhancement in modulus at 1 wt% loading. Additionally, Sichuan University researchers have developed flame-retardant Nylon 6/GO nanocomposites by incorporating phosphorus-containing compounds onto graphene oxide surfaces, achieving UL-94 V-0 ratings with significantly reduced peak heat release rates during combustion. Their work also demonstrates remarkable improvements in gas barrier properties, with oxygen permeability reduced by up to 60% compared to neat Nylon 6.

Strengths: Hybrid processing approach combines benefits of solution and melt methods; multifunctional properties including mechanical, electrical, and flame retardancy; excellent barrier properties particularly valuable for packaging applications. Weaknesses: Complex processing may increase production costs; potential challenges in maintaining consistent reduction degree of graphene oxide at scale; trade-offs between different functional properties may require application-specific optimization.

Critical Patents and Research Breakthroughs

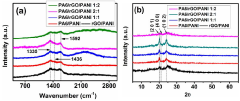

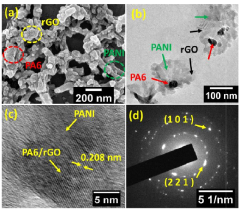

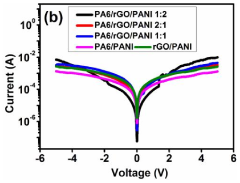

Pa6/RGO/PANI ternary nanocomposites and fabrication of symmetric supercapacitors for electrochemical energy storage applications

PatentActiveIN201931053416A

Innovation

- A ternary nanocomposite of polyaniline (PANI), Nylon-6 (PA6), and reduced graphene oxide (rGO) with a compositional ratio of PA6:PANI at 1:2, formed through in-situ polymerization, creating an inter-crosslinked matrix with PANI fragments encapsulating PA6 and rGO, enhancing specific capacitance and cyclic stability.

Graphene oxide reinforced coumarin based polyamide nanocomposite material and preparation method thereof

PatentPendingIN201921048181A

Innovation

- The process of in situ hydrolytic polymerization is used to disperse graphene oxide powder within a polyamide matrix, forming a reinforced nanocomposite material with improved mechanical and thermal properties through pre-polymerization treatment and polymerization reactions at controlled temperatures.

Environmental Impact and Sustainability Considerations

The integration of graphene oxide (GO) into Nylon 6 matrices presents significant environmental implications that warrant careful consideration. The production of conventional polymer composites typically involves energy-intensive processes and petroleum-based raw materials, contributing substantially to carbon emissions and environmental degradation. In contrast, GO-reinforced Nylon 6 nanocomposites offer potential sustainability advantages through enhanced material efficiency and extended product lifecycles.

The incorporation of minimal amounts of GO (typically 0.1-5 wt%) can dramatically improve the mechanical, thermal, and barrier properties of Nylon 6, potentially reducing the overall material requirements for specific applications. This material efficiency translates to reduced resource consumption and waste generation throughout the product lifecycle. Furthermore, the enhanced durability and performance characteristics of these nanocomposites can extend product service life, decreasing replacement frequency and associated environmental impacts.

However, the environmental benefits must be balanced against potential concerns in the production phase. GO synthesis often involves chemical oxidation processes utilizing strong acids and oxidants, which can generate hazardous waste streams if not properly managed. Recent research has focused on developing greener synthesis routes for GO, including electrochemical exfoliation and environmentally benign oxidation methods, which significantly reduce the environmental footprint of GO production.

End-of-life considerations for GO-reinforced Nylon 6 nanocomposites present both challenges and opportunities. The strong interfacial interactions between GO and the polymer matrix may complicate traditional recycling processes. However, emerging research indicates that these nanocomposites can be effectively recycled through specialized mechanical and chemical recycling techniques, preserving material value and reducing waste. Additionally, the thermal stability imparted by GO may enhance the efficiency of energy recovery processes when recycling is not feasible.

Life cycle assessment (LCA) studies comparing GO-reinforced Nylon 6 nanocomposites with conventional alternatives demonstrate potential environmental benefits, particularly in applications where material lightweighting leads to energy savings during use. For instance, in automotive applications, the reduced weight and enhanced properties can contribute to fuel efficiency improvements, offsetting the environmental impacts of production.

Regulatory frameworks governing nanomaterials in consumer products continue to evolve, with increasing emphasis on safety assessment and environmental impact. Manufacturers developing GO-reinforced Nylon 6 nanocomposites must navigate these regulatory landscapes while implementing responsible manufacturing practices that minimize environmental risks and maximize sustainability benefits throughout the product lifecycle.

The incorporation of minimal amounts of GO (typically 0.1-5 wt%) can dramatically improve the mechanical, thermal, and barrier properties of Nylon 6, potentially reducing the overall material requirements for specific applications. This material efficiency translates to reduced resource consumption and waste generation throughout the product lifecycle. Furthermore, the enhanced durability and performance characteristics of these nanocomposites can extend product service life, decreasing replacement frequency and associated environmental impacts.

However, the environmental benefits must be balanced against potential concerns in the production phase. GO synthesis often involves chemical oxidation processes utilizing strong acids and oxidants, which can generate hazardous waste streams if not properly managed. Recent research has focused on developing greener synthesis routes for GO, including electrochemical exfoliation and environmentally benign oxidation methods, which significantly reduce the environmental footprint of GO production.

End-of-life considerations for GO-reinforced Nylon 6 nanocomposites present both challenges and opportunities. The strong interfacial interactions between GO and the polymer matrix may complicate traditional recycling processes. However, emerging research indicates that these nanocomposites can be effectively recycled through specialized mechanical and chemical recycling techniques, preserving material value and reducing waste. Additionally, the thermal stability imparted by GO may enhance the efficiency of energy recovery processes when recycling is not feasible.

Life cycle assessment (LCA) studies comparing GO-reinforced Nylon 6 nanocomposites with conventional alternatives demonstrate potential environmental benefits, particularly in applications where material lightweighting leads to energy savings during use. For instance, in automotive applications, the reduced weight and enhanced properties can contribute to fuel efficiency improvements, offsetting the environmental impacts of production.

Regulatory frameworks governing nanomaterials in consumer products continue to evolve, with increasing emphasis on safety assessment and environmental impact. Manufacturers developing GO-reinforced Nylon 6 nanocomposites must navigate these regulatory landscapes while implementing responsible manufacturing practices that minimize environmental risks and maximize sustainability benefits throughout the product lifecycle.

Mechanical and Thermal Property Enhancement Mechanisms

The mechanical and thermal property enhancement in Nylon 6/graphene oxide (GO) nanocomposites occurs through several key mechanisms. At the molecular level, the exceptional mechanical strength of GO sheets (Young's modulus ~1 TPa) provides significant reinforcement when properly dispersed within the Nylon 6 matrix. The two-dimensional structure of GO creates an extensive interfacial area with the polymer chains, enabling efficient stress transfer from the matrix to the nanofiller during mechanical loading.

The presence of oxygen-containing functional groups on GO surfaces (hydroxyl, epoxy, and carboxyl groups) facilitates strong interfacial interactions with Nylon 6 through hydrogen bonding and potential covalent linkages. These interactions restrict polymer chain mobility near the GO interfaces, creating "interphase regions" with altered molecular dynamics compared to the bulk polymer. This phenomenon contributes to increased stiffness and strength in the nanocomposite system.

GO nanosheets also act as effective nucleating agents for Nylon 6 crystallization, promoting the formation of more ordered crystalline structures with enhanced mechanical properties. The crystallization kinetics are accelerated, and the resulting crystalline morphology often exhibits higher perfection and orientation, further contributing to mechanical reinforcement.

From a thermal perspective, GO incorporation enhances thermal stability through several mechanisms. The high thermal conductivity of graphene-based materials (up to 5000 W/m·K for pristine graphene) facilitates more efficient heat dissipation throughout the nanocomposite. This prevents localized thermal degradation and improves overall thermal resistance.

The barrier effect of GO nanosheets creates a "tortuous path" that impedes the diffusion of volatile degradation products during thermal decomposition. This physical barrier mechanism delays mass loss during thermal degradation processes, effectively increasing the thermal decomposition temperature of the nanocomposite.

Additionally, GO can act as a radical scavenger during thermal oxidation processes, neutralizing free radicals that would otherwise propagate polymer chain degradation. The oxygen-containing functional groups on GO surfaces may participate in complex reactions that interrupt the thermal degradation pathways of Nylon 6.

The synergistic combination of these mechanical and thermal enhancement mechanisms depends critically on achieving optimal GO dispersion within the polymer matrix and tailoring the interfacial chemistry between the components. Processing methods that prevent GO agglomeration and promote strong interfacial adhesion are essential for maximizing these property enhancements.

The presence of oxygen-containing functional groups on GO surfaces (hydroxyl, epoxy, and carboxyl groups) facilitates strong interfacial interactions with Nylon 6 through hydrogen bonding and potential covalent linkages. These interactions restrict polymer chain mobility near the GO interfaces, creating "interphase regions" with altered molecular dynamics compared to the bulk polymer. This phenomenon contributes to increased stiffness and strength in the nanocomposite system.

GO nanosheets also act as effective nucleating agents for Nylon 6 crystallization, promoting the formation of more ordered crystalline structures with enhanced mechanical properties. The crystallization kinetics are accelerated, and the resulting crystalline morphology often exhibits higher perfection and orientation, further contributing to mechanical reinforcement.

From a thermal perspective, GO incorporation enhances thermal stability through several mechanisms. The high thermal conductivity of graphene-based materials (up to 5000 W/m·K for pristine graphene) facilitates more efficient heat dissipation throughout the nanocomposite. This prevents localized thermal degradation and improves overall thermal resistance.

The barrier effect of GO nanosheets creates a "tortuous path" that impedes the diffusion of volatile degradation products during thermal decomposition. This physical barrier mechanism delays mass loss during thermal degradation processes, effectively increasing the thermal decomposition temperature of the nanocomposite.

Additionally, GO can act as a radical scavenger during thermal oxidation processes, neutralizing free radicals that would otherwise propagate polymer chain degradation. The oxygen-containing functional groups on GO surfaces may participate in complex reactions that interrupt the thermal degradation pathways of Nylon 6.

The synergistic combination of these mechanical and thermal enhancement mechanisms depends critically on achieving optimal GO dispersion within the polymer matrix and tailoring the interfacial chemistry between the components. Processing methods that prevent GO agglomeration and promote strong interfacial adhesion are essential for maximizing these property enhancements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!