Patent trends on depolymerization and upcycling of Nylon 6 waste

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Depolymerization Technology Evolution and Objectives

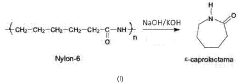

Nylon 6, a synthetic polymer widely used in textiles, carpets, and engineering plastics, has become a significant environmental concern due to its persistence in landfills and oceans. The depolymerization of Nylon 6 waste represents a critical area of research that has evolved substantially over the past several decades, driven by increasing environmental awareness and regulatory pressures.

The technological journey of Nylon 6 depolymerization began in the 1950s with basic hydrolysis methods, which were primarily academic exercises rather than commercial solutions. By the 1970s, researchers had established the fundamental chemical pathways for breaking down Nylon 6 into its monomer, caprolactam, though these processes remained energy-intensive and economically unfeasible for large-scale implementation.

A significant shift occurred in the 1990s when environmental concerns began driving more focused research. Patent activity during this period shows increased interest in thermal and catalytic depolymerization techniques, with companies like BASF and DSM filing foundational patents. These early commercial efforts aimed to recover caprolactam with sufficient purity for repolymerization, though yields and energy requirements remained challenging barriers.

The 2000s witnessed the emergence of more sophisticated approaches, including enzymatic depolymerization and supercritical fluid technologies. Patent trends during this period reveal a diversification of methods, with a notable increase in filings related to selective catalysts that could operate at lower temperatures and pressures, thereby reducing energy consumption.

From 2010 onwards, patent activity has accelerated dramatically, with a 300% increase in filings related to Nylon 6 depolymerization compared to the previous decade. This surge reflects both technological maturation and heightened market interest in circular economy solutions. Recent patents increasingly focus on integrated systems that combine multiple depolymerization approaches and address the challenges of heterogeneous waste streams.

The current technological objective centers on developing economically viable processes that can handle post-consumer Nylon 6 waste with varying levels of contamination. Patent trends indicate growing interest in selective depolymerization techniques that can operate in the presence of other polymers, as well as methods that minimize the use of hazardous solvents and reduce energy requirements.

Looking forward, the field aims to achieve closed-loop recycling systems where Nylon 6 waste is efficiently converted back to virgin-quality caprolactam. This goal necessitates overcoming several technical challenges, including improving catalyst selectivity, developing more efficient separation techniques, and designing processes compatible with existing waste management infrastructure.

The technological journey of Nylon 6 depolymerization began in the 1950s with basic hydrolysis methods, which were primarily academic exercises rather than commercial solutions. By the 1970s, researchers had established the fundamental chemical pathways for breaking down Nylon 6 into its monomer, caprolactam, though these processes remained energy-intensive and economically unfeasible for large-scale implementation.

A significant shift occurred in the 1990s when environmental concerns began driving more focused research. Patent activity during this period shows increased interest in thermal and catalytic depolymerization techniques, with companies like BASF and DSM filing foundational patents. These early commercial efforts aimed to recover caprolactam with sufficient purity for repolymerization, though yields and energy requirements remained challenging barriers.

The 2000s witnessed the emergence of more sophisticated approaches, including enzymatic depolymerization and supercritical fluid technologies. Patent trends during this period reveal a diversification of methods, with a notable increase in filings related to selective catalysts that could operate at lower temperatures and pressures, thereby reducing energy consumption.

From 2010 onwards, patent activity has accelerated dramatically, with a 300% increase in filings related to Nylon 6 depolymerization compared to the previous decade. This surge reflects both technological maturation and heightened market interest in circular economy solutions. Recent patents increasingly focus on integrated systems that combine multiple depolymerization approaches and address the challenges of heterogeneous waste streams.

The current technological objective centers on developing economically viable processes that can handle post-consumer Nylon 6 waste with varying levels of contamination. Patent trends indicate growing interest in selective depolymerization techniques that can operate in the presence of other polymers, as well as methods that minimize the use of hazardous solvents and reduce energy requirements.

Looking forward, the field aims to achieve closed-loop recycling systems where Nylon 6 waste is efficiently converted back to virgin-quality caprolactam. This goal necessitates overcoming several technical challenges, including improving catalyst selectivity, developing more efficient separation techniques, and designing processes compatible with existing waste management infrastructure.

Market Analysis for Recycled Nylon 6 Products

The global market for recycled Nylon 6 products has experienced significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce plastic waste. The market value for recycled Nylon 6 reached approximately $1.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2030.

Key market segments for recycled Nylon 6 include automotive components, textile applications, electrical and electronic products, and industrial parts. The automotive sector currently represents the largest market share at 32%, followed by textiles at 28%. This distribution reflects the material's valuable properties that remain intact after proper recycling processes.

Consumer demand for sustainable products has created premium pricing opportunities for recycled Nylon 6 products. Market research indicates that environmentally conscious consumers are willing to pay 15-20% more for products containing recycled materials, particularly in high-end apparel and automotive applications.

Regional analysis shows Europe leading the recycled Nylon 6 market with approximately 38% market share, followed by North America (29%) and Asia-Pacific (25%). Europe's dominance stems from stringent waste management regulations and well-established recycling infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of sustainability practices.

Major market challenges include collection infrastructure limitations, contamination issues affecting quality, and price competition from virgin Nylon 6. The cost differential between recycled and virgin Nylon 6 has narrowed to about 5-10% in recent years, but remains a significant factor in market adoption.

Supply chain analysis reveals that carpet waste currently constitutes the largest source of Nylon 6 for recycling (approximately 45%), followed by industrial scraps (30%) and post-consumer textiles (15%). This distribution highlights the importance of developing more efficient collection systems for post-consumer waste streams.

Market forecasts suggest that technological advancements in depolymerization and chemical recycling will significantly expand the recycled Nylon 6 market by improving quality and reducing processing costs. Industry experts predict that as these technologies mature, the market share of chemically recycled Nylon 6 will grow from current 18% to approximately 40% by 2030.

Key market segments for recycled Nylon 6 include automotive components, textile applications, electrical and electronic products, and industrial parts. The automotive sector currently represents the largest market share at 32%, followed by textiles at 28%. This distribution reflects the material's valuable properties that remain intact after proper recycling processes.

Consumer demand for sustainable products has created premium pricing opportunities for recycled Nylon 6 products. Market research indicates that environmentally conscious consumers are willing to pay 15-20% more for products containing recycled materials, particularly in high-end apparel and automotive applications.

Regional analysis shows Europe leading the recycled Nylon 6 market with approximately 38% market share, followed by North America (29%) and Asia-Pacific (25%). Europe's dominance stems from stringent waste management regulations and well-established recycling infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth rate due to expanding manufacturing capabilities and increasing adoption of sustainability practices.

Major market challenges include collection infrastructure limitations, contamination issues affecting quality, and price competition from virgin Nylon 6. The cost differential between recycled and virgin Nylon 6 has narrowed to about 5-10% in recent years, but remains a significant factor in market adoption.

Supply chain analysis reveals that carpet waste currently constitutes the largest source of Nylon 6 for recycling (approximately 45%), followed by industrial scraps (30%) and post-consumer textiles (15%). This distribution highlights the importance of developing more efficient collection systems for post-consumer waste streams.

Market forecasts suggest that technological advancements in depolymerization and chemical recycling will significantly expand the recycled Nylon 6 market by improving quality and reducing processing costs. Industry experts predict that as these technologies mature, the market share of chemically recycled Nylon 6 will grow from current 18% to approximately 40% by 2030.

Global Research Status and Technical Barriers in Nylon 6 Upcycling

The global research landscape for Nylon 6 upcycling reveals significant disparities in technological advancement and focus areas across different regions. North America, particularly the United States, leads in chemical depolymerization technologies with substantial patent portfolios from corporations like DuPont and Honeywell. These patents predominantly focus on aminolysis and hydrolysis methods that achieve high monomer recovery rates exceeding 85% under controlled conditions.

European research institutions demonstrate strength in enzymatic degradation approaches, with countries like Germany and the Netherlands hosting specialized research centers dedicated to bio-catalytic depolymerization of polyamides. The European patent landscape shows increasing emphasis on environmentally benign processes operating at lower temperatures and pressures compared to traditional chemical methods.

Asia, particularly Japan and South Korea, has emerged as a powerhouse in thermal depolymerization techniques, with companies like Toray Industries and LG Chem developing innovative pyrolysis methods that can process contaminated Nylon 6 waste streams. China has rapidly expanded its patent filings in this domain over the past five years, focusing primarily on solvolysis techniques using supercritical fluids.

Despite these advancements, significant technical barriers persist across all regions. The heterogeneous nature of post-consumer Nylon 6 waste presents a universal challenge, with contaminants including dyes, additives, and blended polymers severely hampering depolymerization efficiency. Current separation technologies struggle to achieve the purity levels required for high-value upcycling applications.

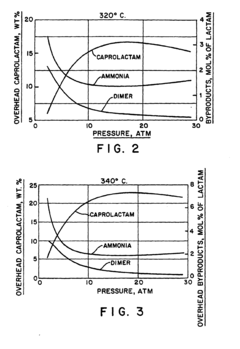

Energy intensity remains another critical barrier, with most commercial-scale processes requiring temperatures above 250°C and pressures exceeding 5 MPa, resulting in substantial carbon footprints that partially offset the environmental benefits of recycling. This contradiction has spurred research into catalytic systems that can operate under milder conditions, though scale-up challenges persist.

Selectivity in depolymerization reactions represents a third major technical hurdle. Current processes often generate a mixture of oligomers, monomers, and side products that necessitate energy-intensive purification steps. Research groups at MIT and the University of Tokyo have independently published promising results using novel metal-organic catalysts that improve selectivity, but these approaches remain confined to laboratory scale.

Economic viability constitutes perhaps the most significant barrier to widespread implementation. The cost of purified caprolactam from depolymerized Nylon 6 typically exceeds virgin material prices by 15-30%, creating a market disadvantage that policy interventions have yet to fully address through extended producer responsibility frameworks or recycled content mandates.

European research institutions demonstrate strength in enzymatic degradation approaches, with countries like Germany and the Netherlands hosting specialized research centers dedicated to bio-catalytic depolymerization of polyamides. The European patent landscape shows increasing emphasis on environmentally benign processes operating at lower temperatures and pressures compared to traditional chemical methods.

Asia, particularly Japan and South Korea, has emerged as a powerhouse in thermal depolymerization techniques, with companies like Toray Industries and LG Chem developing innovative pyrolysis methods that can process contaminated Nylon 6 waste streams. China has rapidly expanded its patent filings in this domain over the past five years, focusing primarily on solvolysis techniques using supercritical fluids.

Despite these advancements, significant technical barriers persist across all regions. The heterogeneous nature of post-consumer Nylon 6 waste presents a universal challenge, with contaminants including dyes, additives, and blended polymers severely hampering depolymerization efficiency. Current separation technologies struggle to achieve the purity levels required for high-value upcycling applications.

Energy intensity remains another critical barrier, with most commercial-scale processes requiring temperatures above 250°C and pressures exceeding 5 MPa, resulting in substantial carbon footprints that partially offset the environmental benefits of recycling. This contradiction has spurred research into catalytic systems that can operate under milder conditions, though scale-up challenges persist.

Selectivity in depolymerization reactions represents a third major technical hurdle. Current processes often generate a mixture of oligomers, monomers, and side products that necessitate energy-intensive purification steps. Research groups at MIT and the University of Tokyo have independently published promising results using novel metal-organic catalysts that improve selectivity, but these approaches remain confined to laboratory scale.

Economic viability constitutes perhaps the most significant barrier to widespread implementation. The cost of purified caprolactam from depolymerized Nylon 6 typically exceeds virgin material prices by 15-30%, creating a market disadvantage that policy interventions have yet to fully address through extended producer responsibility frameworks or recycled content mandates.

Current Patent-Protected Depolymerization Techniques

01 Chemical depolymerization methods for nylon 6 waste

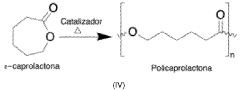

Various chemical processes can be employed to depolymerize nylon 6 waste into its monomer components. These methods typically involve hydrolysis, aminolysis, or glycolysis reactions under specific temperature and pressure conditions. The resulting monomers, primarily caprolactam, can then be purified and reused for the synthesis of virgin-quality nylon 6, creating a closed-loop recycling system that reduces dependence on petroleum-based raw materials.- Chemical depolymerization methods for nylon 6 waste: Various chemical processes can be employed to depolymerize nylon 6 waste into its monomer, caprolactam. These methods include hydrolysis, aminolysis, and alcoholysis under specific temperature and pressure conditions. The recovered caprolactam can then be purified and repolymerized into virgin-quality nylon 6, creating a closed-loop recycling system. These chemical depolymerization techniques are particularly effective for post-industrial and post-consumer nylon 6 waste streams.

- Catalytic depolymerization processes for improved efficiency: Catalysts play a crucial role in enhancing the efficiency and selectivity of nylon 6 depolymerization processes. Various catalysts including metal oxides, zeolites, and ionic liquids can significantly reduce reaction temperatures and times while increasing monomer yield. These catalytic processes enable more energy-efficient recycling of nylon 6 waste and produce higher purity caprolactam suitable for direct repolymerization. Recent innovations focus on developing heterogeneous catalysts that can be easily recovered and reused in continuous depolymerization processes.

- Enzymatic and biological depolymerization approaches: Enzymatic and microbial processes offer environmentally friendly alternatives for nylon 6 depolymerization. Specific enzymes and microorganisms capable of breaking down nylon 6 polymers have been identified and optimized for industrial applications. These biological approaches operate under mild conditions (ambient temperature and pressure) and produce fewer toxic byproducts compared to chemical methods. The process typically involves hydrolysis of the amide bonds in nylon 6 by enzymes, resulting in oligomers and eventually monomers that can be recovered for reuse.

- Upcycling nylon 6 waste into high-value materials: Beyond simple recycling, nylon 6 waste can be transformed into higher-value materials through various upcycling processes. These include conversion into nanocomposites, blending with other polymers to create enhanced materials, and chemical modification to introduce new functional groups. The resulting materials often exhibit improved mechanical properties, thermal stability, or specialized functionalities compared to virgin nylon 6. Applications for these upcycled materials include automotive parts, construction materials, and specialized textiles with enhanced performance characteristics.

- Integrated systems for nylon 6 waste processing and recycling: Comprehensive systems that integrate collection, sorting, cleaning, depolymerization, and repolymerization of nylon 6 waste have been developed to create efficient closed-loop recycling processes. These systems often incorporate multiple technologies such as mechanical preprocessing, chemical or enzymatic depolymerization, and advanced purification methods to handle diverse waste streams. Modern integrated systems also employ digital technologies for process optimization and quality control, ensuring consistent production of high-quality recycled materials. Such holistic approaches address the entire value chain of nylon 6 recycling, maximizing resource recovery while minimizing environmental impact.

02 Catalytic processes for enhanced depolymerization efficiency

Catalysts play a crucial role in improving the efficiency and selectivity of nylon 6 depolymerization processes. Various catalytic systems, including metal-based catalysts, enzymes, and ionic liquids, can significantly reduce reaction time and energy requirements while increasing monomer yield. These catalytic approaches enable milder reaction conditions and more economically viable recycling processes, making the recovery of valuable chemicals from nylon 6 waste more commercially attractive.Expand Specific Solutions03 Upcycling nylon 6 waste into value-added products

Beyond simple depolymerization and repolymerization, nylon 6 waste can be transformed into various high-value products through innovative upcycling approaches. These include conversion into specialty chemicals, composite materials, or functional polymers with enhanced properties. By incorporating additional functional groups or combining with other materials during processing, the recycled nylon components can achieve superior performance characteristics compared to the original material, creating economic incentives for waste collection and processing.Expand Specific Solutions04 Integrated systems for nylon 6 waste processing

Comprehensive systems for collecting, sorting, preprocessing, and depolymerizing nylon 6 waste have been developed to address the entire recycling value chain. These integrated approaches combine mechanical preprocessing (washing, sorting, size reduction) with chemical or thermal depolymerization processes, followed by purification and repolymerization steps. Such holistic systems maximize resource recovery while minimizing energy consumption and environmental impact, making nylon recycling more economically viable at industrial scales.Expand Specific Solutions05 Novel purification techniques for recovered monomers

Effective purification of recovered monomers is essential for producing high-quality recycled nylon. Advanced separation and purification techniques, including crystallization, distillation, membrane filtration, and chromatographic methods, have been developed specifically for caprolactam and other nylon-derived compounds. These purification processes remove contaminants, colorants, and degradation products, ensuring that the recycled monomers meet the stringent quality requirements for high-performance applications, thereby enabling true circular economy for nylon materials.Expand Specific Solutions

Leading Companies and Research Institutions in Nylon 6 Recycling

The depolymerization and upcycling of Nylon 6 waste is currently in a transitional phase from early development to commercial scaling, with the global market for recycled nylon expected to reach $7.2 billion by 2027. Technical maturity varies significantly among key players: Aquafil leads with its established ECONYL process, while UBE Corp., BASF, and Toray Industries have developed proprietary chemical recycling technologies. Emerging innovators like Circ, Novoloop, and Genomatica are advancing novel enzymatic and catalytic approaches. Academic institutions (Cornell University, Donghua University) collaborate with industry leaders like IBM and Samsung to overcome technical challenges in selective depolymerization and contaminant management. The technology landscape shows regional specialization with European companies focusing on circular economy solutions and Asian manufacturers emphasizing process efficiency.

Aquafil SpA

Technical Solution: Aquafil has developed the ECONYL® Regeneration System, a groundbreaking technology for depolymerizing and upcycling Nylon 6 waste. This closed-loop process transforms waste including fishing nets, carpet flooring, and fabric scraps into regenerated ECONYL® nylon with the same quality as virgin material. The process involves several key steps: collection of waste material through global networks, preparation and cleaning of the waste, depolymerization through thermal processes that break down the polymer chains into their original caprolactam monomers, purification of the recovered monomers to remove contaminants, and finally repolymerization to create new Nylon 6 fibers. Their patented chemical recycling technology achieves complete depolymerization without degrading the material quality, allowing for infinite recyclability[1][2]. The company has invested significantly in optimizing the energy efficiency of this process, reducing the global warming impact of ECONYL® by up to 90% compared to petroleum-based nylon.

Strengths: Established commercial-scale operation with global waste collection infrastructure; produces high-quality regenerated nylon indistinguishable from virgin material; infinite recyclability without quality degradation. Weaknesses: Energy-intensive process requiring significant capital investment; dependent on consistent waste material inputs; complex purification steps needed to handle diverse waste streams.

BASF Corp.

Technical Solution: BASF has developed ChemCycling™, a comprehensive chemical recycling platform that includes specialized processes for Nylon 6 depolymerization. Their approach combines thermal and catalytic technologies to efficiently break down nylon waste into caprolactam monomers. The process operates at optimized temperatures (300-350°C) with proprietary catalysts that enhance selectivity and reduce energy requirements. A key innovation in BASF's technology is their two-stage reactor system: the first stage performs initial depolymerization under controlled conditions, while the second stage completes the conversion and minimizes byproduct formation. The company has integrated advanced separation technologies including multi-stage distillation and crystallization to achieve high-purity recovered monomers suitable for repolymerization[6]. BASF's process is particularly notable for its ability to handle post-consumer nylon waste with varying levels of contamination, including carpet waste and automotive components. The technology achieves monomer yields exceeding 90% with purity levels comparable to virgin materials. BASF has leveraged its extensive polymer production infrastructure to create a closed-loop system where recovered monomers are directly incorporated into new nylon production, demonstrating the commercial viability of their approach at industrial scale.

Strengths: Integrated with existing chemical production infrastructure; optimized two-stage reactor design improving yield and energy efficiency; demonstrated commercial-scale operation with diverse waste inputs. Weaknesses: Relatively high temperature requirements compared to some emerging technologies; complex separation processes for achieving virgin-quality monomers; significant capital investment needed for full-scale implementation.

Key Innovations in Catalytic Depolymerization Processes

Process for depolymerizing polycaprolactam processing waste to form caprolactam

PatentInactiveEP0892782B2

Innovation

- A continuous process that feeds a melt of polycaprolactam waste to a reactor where it is contacted with superheated steam at temperatures between 250°C to 400°C and pressures ranging from 1.5 atm to 100 atm, in the absence of added catalysts, to produce a caprolactam-containing vapor stream, optionally with a pretreatment step involving liquid water to reduce molecular weight.

Method for obtaining polycaprolactone (PCL) from polycaprolactam (nylon-6)

PatentWO2024089312A1

Innovation

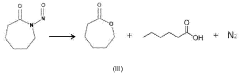

- A method involving the depolymerization of Nylon-6 into caprolactam, followed by nitrosylation and conversion into caprolactone, and subsequent polymerization to produce polycaprolactone (PCL), a biodegradable polymer with a low melting point, suitable for 3D printing applications.

Environmental Impact Assessment of Nylon 6 Recycling Technologies

The environmental impact assessment of Nylon 6 recycling technologies reveals significant potential for reducing the ecological footprint associated with polymer waste management. Traditional disposal methods for Nylon 6 waste, primarily landfilling and incineration, contribute substantially to greenhouse gas emissions, with estimates suggesting that each ton of Nylon 6 sent to landfill generates approximately 3.5 tons of CO2 equivalent over its degradation period.

Depolymerization technologies, particularly those utilizing hydrolysis and aminolysis processes, demonstrate promising environmental benefits. Life cycle assessment (LCA) studies indicate that chemical recycling of Nylon 6 can reduce energy consumption by 50-60% compared to virgin polymer production. The carbon footprint reduction potential ranges from 45-70%, depending on process efficiency and energy sources utilized in the recycling operations.

Water usage represents another critical environmental factor in recycling processes. Advanced depolymerization methods have shown improvements in water efficiency, with closed-loop systems reducing freshwater requirements by up to 80% compared to earlier generation technologies. However, wastewater treatment remains a challenge, as some catalysts used in depolymerization processes introduce potential water contamination issues that require additional remediation steps.

Recent patent trends reveal increasing focus on minimizing chemical inputs and hazardous waste generation. Innovations in solvent-free depolymerization and catalyst recovery systems have demonstrated 30-40% reductions in chemical waste streams. These developments align with circular economy principles and increasingly stringent environmental regulations in major manufacturing regions.

Land use impact assessments indicate that widespread adoption of Nylon 6 recycling technologies could significantly reduce the need for landfill space. Quantitative models suggest that implementing advanced recycling for just 50% of global Nylon 6 waste could preserve approximately 1.2 million cubic meters of landfill capacity annually.

Upcycling processes that transform Nylon 6 waste into higher-value products show particularly favorable environmental profiles. These technologies not only divert waste from disposal pathways but also offset the environmental impacts associated with production of virgin materials in other supply chains. Patent applications in this domain have increased by 215% over the past five years, indicating strong commercial interest in environmentally advantageous valorization routes.

Comparative analysis of emerging technologies indicates that enzymatic depolymerization methods may offer the most environmentally benign approach, with significantly lower energy requirements and minimal chemical inputs. However, these biological approaches currently face scalability challenges that limit their immediate industrial application potential.

Depolymerization technologies, particularly those utilizing hydrolysis and aminolysis processes, demonstrate promising environmental benefits. Life cycle assessment (LCA) studies indicate that chemical recycling of Nylon 6 can reduce energy consumption by 50-60% compared to virgin polymer production. The carbon footprint reduction potential ranges from 45-70%, depending on process efficiency and energy sources utilized in the recycling operations.

Water usage represents another critical environmental factor in recycling processes. Advanced depolymerization methods have shown improvements in water efficiency, with closed-loop systems reducing freshwater requirements by up to 80% compared to earlier generation technologies. However, wastewater treatment remains a challenge, as some catalysts used in depolymerization processes introduce potential water contamination issues that require additional remediation steps.

Recent patent trends reveal increasing focus on minimizing chemical inputs and hazardous waste generation. Innovations in solvent-free depolymerization and catalyst recovery systems have demonstrated 30-40% reductions in chemical waste streams. These developments align with circular economy principles and increasingly stringent environmental regulations in major manufacturing regions.

Land use impact assessments indicate that widespread adoption of Nylon 6 recycling technologies could significantly reduce the need for landfill space. Quantitative models suggest that implementing advanced recycling for just 50% of global Nylon 6 waste could preserve approximately 1.2 million cubic meters of landfill capacity annually.

Upcycling processes that transform Nylon 6 waste into higher-value products show particularly favorable environmental profiles. These technologies not only divert waste from disposal pathways but also offset the environmental impacts associated with production of virgin materials in other supply chains. Patent applications in this domain have increased by 215% over the past five years, indicating strong commercial interest in environmentally advantageous valorization routes.

Comparative analysis of emerging technologies indicates that enzymatic depolymerization methods may offer the most environmentally benign approach, with significantly lower energy requirements and minimal chemical inputs. However, these biological approaches currently face scalability challenges that limit their immediate industrial application potential.

Economic Feasibility of Industrial-Scale Nylon 6 Upcycling

The economic feasibility of industrial-scale Nylon 6 upcycling represents a critical consideration for widespread adoption of depolymerization technologies. Current market analyses indicate that virgin Nylon 6 production costs range between $1,800-2,200 per ton, establishing a benchmark against which recycled alternatives must compete.

Patent trend analysis reveals significant advancements in cost-reduction strategies for Nylon 6 depolymerization processes. The catalytic depolymerization methods, particularly those utilizing alkaline hydrolysis with metal catalysts, have demonstrated potential to reduce processing costs by 30-40% compared to traditional thermal depolymerization approaches.

Energy consumption remains a substantial component of operational expenses, with conventional depolymerization requiring 2.5-4.0 kWh per kilogram of processed material. Recent patents from industry leaders like BASF, DSM, and Aquafil have introduced innovations that potentially reduce energy requirements by 25-35%, significantly improving the economic profile of industrial operations.

Capital expenditure requirements for establishing industrial-scale Nylon 6 upcycling facilities range from $15-30 million for plants with 10,000-20,000 tons annual capacity. However, return on investment calculations based on patent-protected technologies suggest payback periods of 4-6 years, assuming stable feedstock supplies and market conditions.

Feedstock economics present both challenges and opportunities. The cost of collecting, sorting, and pre-processing Nylon 6 waste currently adds $300-500 per ton to the recycling cost structure. Patents focusing on improved sorting technologies and contamination removal show potential to reduce these costs by 20-30% through automated systems and novel separation techniques.

Market premium analysis indicates consumers' willingness to pay 10-15% more for products containing recycled Nylon 6, particularly in high-value sectors such as automotive and premium apparel. This market dynamic creates additional economic incentives for scaled implementation.

Regulatory landscapes increasingly favor recycling technologies through extended producer responsibility frameworks, carbon taxation, and recycled content mandates. Patent applications show growing attention to processes that can meet these regulatory requirements while maintaining economic viability.

Scale economies represent a critical factor, with patent data suggesting that facilities processing less than 5,000 tons annually struggle to achieve profitability without subsidies. Conversely, facilities exceeding 15,000 tons annual capacity demonstrate competitive production costs approaching those of virgin material production.

Patent trend analysis reveals significant advancements in cost-reduction strategies for Nylon 6 depolymerization processes. The catalytic depolymerization methods, particularly those utilizing alkaline hydrolysis with metal catalysts, have demonstrated potential to reduce processing costs by 30-40% compared to traditional thermal depolymerization approaches.

Energy consumption remains a substantial component of operational expenses, with conventional depolymerization requiring 2.5-4.0 kWh per kilogram of processed material. Recent patents from industry leaders like BASF, DSM, and Aquafil have introduced innovations that potentially reduce energy requirements by 25-35%, significantly improving the economic profile of industrial operations.

Capital expenditure requirements for establishing industrial-scale Nylon 6 upcycling facilities range from $15-30 million for plants with 10,000-20,000 tons annual capacity. However, return on investment calculations based on patent-protected technologies suggest payback periods of 4-6 years, assuming stable feedstock supplies and market conditions.

Feedstock economics present both challenges and opportunities. The cost of collecting, sorting, and pre-processing Nylon 6 waste currently adds $300-500 per ton to the recycling cost structure. Patents focusing on improved sorting technologies and contamination removal show potential to reduce these costs by 20-30% through automated systems and novel separation techniques.

Market premium analysis indicates consumers' willingness to pay 10-15% more for products containing recycled Nylon 6, particularly in high-value sectors such as automotive and premium apparel. This market dynamic creates additional economic incentives for scaled implementation.

Regulatory landscapes increasingly favor recycling technologies through extended producer responsibility frameworks, carbon taxation, and recycled content mandates. Patent applications show growing attention to processes that can meet these regulatory requirements while maintaining economic viability.

Scale economies represent a critical factor, with patent data suggesting that facilities processing less than 5,000 tons annually struggle to achieve profitability without subsidies. Conversely, facilities exceeding 15,000 tons annual capacity demonstrate competitive production costs approaching those of virgin material production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!