Nylon 6 thermal and mechanical performance under cyclic loading

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Development History and Performance Objectives

Nylon 6 was first synthesized in 1938 by Paul Schlack at IG Farben as a direct response to DuPont's patent on nylon 6,6. The development represented a significant breakthrough in polymer science, creating a material with remarkable versatility through the ring-opening polymerization of caprolactam. By the 1950s, commercial production had expanded globally, with Nylon 6 finding applications across multiple industries due to its excellent balance of properties.

The evolution of Nylon 6 has been characterized by continuous improvements in processing techniques and formulation. During the 1960s and 1970s, researchers focused on enhancing its crystallinity control and molecular weight distribution, which directly influenced its mechanical performance. The 1980s saw significant advancements in understanding the material's morphology and structure-property relationships, particularly regarding its behavior under thermal stress.

The 1990s marked a turning point with the development of reinforced Nylon 6 composites, incorporating glass fibers, carbon fibers, and various mineral fillers to address specific performance requirements. These modifications substantially improved the material's heat resistance and mechanical stability under load, expanding its application in more demanding environments.

Recent technological trends have focused on optimizing Nylon 6's performance under cyclic loading conditions, which represent a critical challenge for many industrial applications. Research has increasingly targeted the material's viscoelastic behavior, fatigue resistance, and thermal stability when subjected to repeated stress cycles. This focus stems from growing demands in automotive, aerospace, and industrial equipment sectors where components experience frequent thermal and mechanical cycling.

The primary technical objectives for Nylon 6 development now center on enhancing its long-term performance stability under combined thermal and mechanical cycling. Specifically, researchers aim to minimize creep deformation, reduce hysteresis effects, and extend fatigue life at elevated temperatures. The goal is to achieve consistent mechanical properties retention after thousands of loading cycles at temperatures ranging from -40°C to 150°C.

Another critical objective involves improving the material's thermal aging resistance while maintaining its advantageous processing characteristics. This includes developing more effective stabilization systems that can protect the polymer structure during repeated thermal excursions without compromising other performance attributes or increasing production costs significantly.

The industry also seeks to establish more accurate predictive models for Nylon 6 behavior under complex loading scenarios, enabling better component design and material selection. These models must account for the material's non-linear response to combined thermal and mechanical stresses, particularly when applied cyclically over extended periods.

The evolution of Nylon 6 has been characterized by continuous improvements in processing techniques and formulation. During the 1960s and 1970s, researchers focused on enhancing its crystallinity control and molecular weight distribution, which directly influenced its mechanical performance. The 1980s saw significant advancements in understanding the material's morphology and structure-property relationships, particularly regarding its behavior under thermal stress.

The 1990s marked a turning point with the development of reinforced Nylon 6 composites, incorporating glass fibers, carbon fibers, and various mineral fillers to address specific performance requirements. These modifications substantially improved the material's heat resistance and mechanical stability under load, expanding its application in more demanding environments.

Recent technological trends have focused on optimizing Nylon 6's performance under cyclic loading conditions, which represent a critical challenge for many industrial applications. Research has increasingly targeted the material's viscoelastic behavior, fatigue resistance, and thermal stability when subjected to repeated stress cycles. This focus stems from growing demands in automotive, aerospace, and industrial equipment sectors where components experience frequent thermal and mechanical cycling.

The primary technical objectives for Nylon 6 development now center on enhancing its long-term performance stability under combined thermal and mechanical cycling. Specifically, researchers aim to minimize creep deformation, reduce hysteresis effects, and extend fatigue life at elevated temperatures. The goal is to achieve consistent mechanical properties retention after thousands of loading cycles at temperatures ranging from -40°C to 150°C.

Another critical objective involves improving the material's thermal aging resistance while maintaining its advantageous processing characteristics. This includes developing more effective stabilization systems that can protect the polymer structure during repeated thermal excursions without compromising other performance attributes or increasing production costs significantly.

The industry also seeks to establish more accurate predictive models for Nylon 6 behavior under complex loading scenarios, enabling better component design and material selection. These models must account for the material's non-linear response to combined thermal and mechanical stresses, particularly when applied cyclically over extended periods.

Market Analysis for Nylon 6 in High-Stress Applications

The global market for Nylon 6 in high-stress applications continues to expand significantly, driven by increasing demands across automotive, aerospace, industrial machinery, and consumer electronics sectors. Current market valuations place the high-performance polyamide segment at approximately 2.5 billion USD, with Nylon 6 representing a substantial portion due to its superior thermal and mechanical properties under cyclic loading conditions.

The automotive industry remains the largest consumer of high-performance Nylon 6, accounting for roughly 40% of market share. This dominance stems from the material's ability to withstand repeated stress cycles in under-hood components, transmission systems, and structural elements where temperature fluctuations are common. Recent industry reports indicate a compound annual growth rate of 6.2% in this sector through 2028.

Aerospace applications represent the fastest-growing segment for high-stress Nylon 6 implementations, with projected growth rates exceeding 8% annually. The material's resistance to thermal degradation while maintaining mechanical integrity during thousands of flight cycles makes it particularly valuable for non-critical structural components and interior applications where weight reduction is paramount.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, controlling approximately 45% of production capacity, followed by Europe (30%) and North America (20%). However, consumption patterns differ significantly, with North American and European markets showing higher demand for premium-grade Nylon 6 formulations specifically engineered for extreme cyclic loading environments.

Market segmentation by performance requirements indicates growing demand for specialized Nylon 6 variants with enhanced thermal stability above 150°C while maintaining mechanical properties through millions of stress cycles. This premium segment commands price premiums of 30-40% compared to standard formulations and is growing at nearly twice the rate of conventional Nylon 6 products.

Customer demand trends increasingly focus on predictable performance degradation profiles rather than absolute mechanical properties. End-users in critical applications are willing to accept moderate initial performance in exchange for consistent behavior throughout the material's service life under cyclic loading conditions. This shift has created new market opportunities for materials with engineered performance decay curves.

Competition in this space has intensified with several specialty chemical companies developing proprietary additives and processing techniques to enhance Nylon 6 performance specifically for cyclic loading applications. Market concentration remains moderate, with the top five producers controlling approximately 60% of high-performance Nylon 6 production capacity globally.

The automotive industry remains the largest consumer of high-performance Nylon 6, accounting for roughly 40% of market share. This dominance stems from the material's ability to withstand repeated stress cycles in under-hood components, transmission systems, and structural elements where temperature fluctuations are common. Recent industry reports indicate a compound annual growth rate of 6.2% in this sector through 2028.

Aerospace applications represent the fastest-growing segment for high-stress Nylon 6 implementations, with projected growth rates exceeding 8% annually. The material's resistance to thermal degradation while maintaining mechanical integrity during thousands of flight cycles makes it particularly valuable for non-critical structural components and interior applications where weight reduction is paramount.

Regional analysis reveals Asia-Pacific as the dominant manufacturing hub, controlling approximately 45% of production capacity, followed by Europe (30%) and North America (20%). However, consumption patterns differ significantly, with North American and European markets showing higher demand for premium-grade Nylon 6 formulations specifically engineered for extreme cyclic loading environments.

Market segmentation by performance requirements indicates growing demand for specialized Nylon 6 variants with enhanced thermal stability above 150°C while maintaining mechanical properties through millions of stress cycles. This premium segment commands price premiums of 30-40% compared to standard formulations and is growing at nearly twice the rate of conventional Nylon 6 products.

Customer demand trends increasingly focus on predictable performance degradation profiles rather than absolute mechanical properties. End-users in critical applications are willing to accept moderate initial performance in exchange for consistent behavior throughout the material's service life under cyclic loading conditions. This shift has created new market opportunities for materials with engineered performance decay curves.

Competition in this space has intensified with several specialty chemical companies developing proprietary additives and processing techniques to enhance Nylon 6 performance specifically for cyclic loading applications. Market concentration remains moderate, with the top five producers controlling approximately 60% of high-performance Nylon 6 production capacity globally.

Current Challenges in Nylon 6 Cyclic Loading Performance

Despite significant advancements in polymer science, Nylon 6 continues to face substantial challenges when subjected to cyclic loading conditions, particularly regarding its thermal and mechanical performance. One of the primary obstacles is the material's susceptibility to fatigue damage accumulation, which manifests as microcracking and eventual failure under repeated stress cycles. This phenomenon is exacerbated at elevated temperatures, where the viscoelastic properties of Nylon 6 undergo significant changes, leading to accelerated degradation rates.

The temperature-dependent behavior of Nylon 6 presents a complex challenge for engineers. At temperatures approaching its glass transition point (approximately 47-57°C), Nylon 6 exhibits dramatically altered mechanical properties, including reduced stiffness and strength. This temperature sensitivity creates difficulties in applications where thermal cycling occurs alongside mechanical cycling, as the material's response becomes highly non-linear and time-dependent.

Moisture absorption represents another critical challenge, as Nylon 6 is notably hygroscopic. Water molecules act as plasticizers, reducing the glass transition temperature and altering mechanical properties. Under cyclic loading, this moisture-induced plasticization can accelerate creep deformation and reduce fatigue resistance. The interaction between moisture content, temperature fluctuations, and mechanical cycling creates a multi-variable problem that remains difficult to model accurately.

Crystallinity variations within Nylon 6 components further complicate performance prediction. Processing conditions significantly influence the degree of crystallinity, which directly affects mechanical properties. Under cyclic loading, regions with different crystalline structures respond differently, potentially creating stress concentration points that initiate failure. This heterogeneity makes it challenging to develop universally applicable performance models.

The industry also faces difficulties in establishing standardized testing protocols that accurately reflect real-world cyclic loading conditions. Current test methods often fail to capture the complex interplay between thermal fluctuations, moisture variations, and mechanical cycling that occurs in actual applications. This testing gap leads to discrepancies between laboratory predictions and field performance.

Additionally, the molecular weight distribution of Nylon 6 significantly impacts its long-term performance under cyclic loading. Chain scission and recombination processes occur during repeated loading cycles, particularly at elevated temperatures, gradually altering the polymer's molecular structure. These changes are difficult to monitor in real-time and can lead to unexpected failures in long-term applications.

Finally, the industry faces challenges in developing effective additives and modification strategies that can enhance Nylon 6's resistance to cyclic loading without compromising other desirable properties. While reinforcements like glass fibers improve stiffness, they can create new failure modes under cyclic conditions, particularly at the fiber-matrix interface where stress concentrations develop.

The temperature-dependent behavior of Nylon 6 presents a complex challenge for engineers. At temperatures approaching its glass transition point (approximately 47-57°C), Nylon 6 exhibits dramatically altered mechanical properties, including reduced stiffness and strength. This temperature sensitivity creates difficulties in applications where thermal cycling occurs alongside mechanical cycling, as the material's response becomes highly non-linear and time-dependent.

Moisture absorption represents another critical challenge, as Nylon 6 is notably hygroscopic. Water molecules act as plasticizers, reducing the glass transition temperature and altering mechanical properties. Under cyclic loading, this moisture-induced plasticization can accelerate creep deformation and reduce fatigue resistance. The interaction between moisture content, temperature fluctuations, and mechanical cycling creates a multi-variable problem that remains difficult to model accurately.

Crystallinity variations within Nylon 6 components further complicate performance prediction. Processing conditions significantly influence the degree of crystallinity, which directly affects mechanical properties. Under cyclic loading, regions with different crystalline structures respond differently, potentially creating stress concentration points that initiate failure. This heterogeneity makes it challenging to develop universally applicable performance models.

The industry also faces difficulties in establishing standardized testing protocols that accurately reflect real-world cyclic loading conditions. Current test methods often fail to capture the complex interplay between thermal fluctuations, moisture variations, and mechanical cycling that occurs in actual applications. This testing gap leads to discrepancies between laboratory predictions and field performance.

Additionally, the molecular weight distribution of Nylon 6 significantly impacts its long-term performance under cyclic loading. Chain scission and recombination processes occur during repeated loading cycles, particularly at elevated temperatures, gradually altering the polymer's molecular structure. These changes are difficult to monitor in real-time and can lead to unexpected failures in long-term applications.

Finally, the industry faces challenges in developing effective additives and modification strategies that can enhance Nylon 6's resistance to cyclic loading without compromising other desirable properties. While reinforcements like glass fibers improve stiffness, they can create new failure modes under cyclic conditions, particularly at the fiber-matrix interface where stress concentrations develop.

Existing Methods for Enhancing Nylon 6 Durability

01 Thermal stability enhancement of Nylon 6

Various methods and additives can be used to enhance the thermal stability of Nylon 6. These include incorporating heat stabilizers, antioxidants, and specific metal compounds that prevent degradation at high temperatures. Enhanced thermal stability allows Nylon 6 to maintain its structural integrity and mechanical properties when exposed to elevated temperatures during processing or in high-temperature applications.- Reinforcement techniques for improved thermal and mechanical properties: Various reinforcement materials and techniques can be incorporated into Nylon 6 to enhance its thermal stability and mechanical strength. These include the addition of glass fibers, carbon fibers, and mineral fillers that create a composite structure with superior heat resistance and mechanical performance. The reinforcement materials form a network within the polymer matrix, distributing stress more effectively and increasing the temperature at which the material maintains its structural integrity.

- Crystallinity control for optimized performance: The degree of crystallinity in Nylon 6 significantly affects its thermal and mechanical properties. By controlling the crystallization process through specific cooling rates, nucleating agents, or thermal treatments, the polymer's crystalline structure can be optimized. Higher crystallinity typically results in improved heat resistance, dimensional stability, and tensile strength, while controlled semi-crystalline structures can provide a balance of rigidity and impact resistance needed for specific applications.

- Blending with other polymers and additives: Blending Nylon 6 with other polymers or incorporating specific additives can significantly enhance its thermal and mechanical performance. Compatibilizers, impact modifiers, heat stabilizers, and flame retardants can be added to create formulations with tailored properties. These blends often exhibit synergistic effects, such as improved heat deflection temperature, reduced thermal expansion, enhanced impact resistance, or better processing characteristics while maintaining the base advantages of Nylon 6.

- Processing techniques affecting performance properties: The processing methods used in manufacturing Nylon 6 products significantly influence their final thermal and mechanical properties. Techniques such as injection molding parameters, extrusion conditions, orientation during processing, and post-processing treatments can be optimized to enhance crystallinity, molecular alignment, and internal stress distribution. These processing variables directly affect the material's heat resistance, tensile strength, impact resistance, and dimensional stability under thermal stress.

- Nanocomposite formulations for enhanced performance: Incorporating nanoscale materials into Nylon 6 creates nanocomposites with significantly improved thermal and mechanical properties. Nanomaterials such as nanoclay, carbon nanotubes, graphene, and metal oxide nanoparticles can be dispersed within the polymer matrix to create materials with enhanced heat resistance, flame retardancy, and mechanical strength. These nanocomposites often exhibit improvements in properties at much lower filler loadings compared to conventional composites, maintaining better processability while achieving superior performance characteristics.

02 Reinforcement techniques for improved mechanical properties

Nylon 6 can be reinforced with various fillers and fibers to enhance its mechanical performance. Common reinforcement materials include glass fibers, carbon fibers, and mineral fillers. These reinforcements significantly improve tensile strength, flexural modulus, impact resistance, and dimensional stability of Nylon 6 composites, making them suitable for high-performance engineering applications.Expand Specific Solutions03 Nylon 6 blends and copolymers for enhanced performance

Blending Nylon 6 with other polymers or creating copolymers can yield materials with improved thermal and mechanical characteristics. These blends often combine the beneficial properties of multiple materials, such as the high temperature resistance of Nylon 6 with the impact resistance of elastomers. The resulting materials show balanced performance profiles with enhanced toughness, heat resistance, and processing characteristics.Expand Specific Solutions04 Nanocomposite formulations for enhanced thermal-mechanical performance

Incorporating nanomaterials such as nanoclay, carbon nanotubes, or graphene into Nylon 6 creates nanocomposites with significantly improved thermal and mechanical properties. These nanofillers increase crystallinity, heat deflection temperature, and mechanical strength while maintaining or improving processability. The high surface area of nanomaterials enables effective reinforcement at relatively low loading levels.Expand Specific Solutions05 Processing techniques affecting thermal and mechanical properties

Various processing techniques significantly influence the final thermal and mechanical properties of Nylon 6 products. Methods such as annealing, controlled cooling rates, orientation, and specialized molding techniques can enhance crystallinity, reduce internal stresses, and improve overall performance. Optimized processing conditions lead to Nylon 6 products with superior heat resistance, dimensional stability, and mechanical strength.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Nylon 6

The nylon 6 thermal and mechanical performance under cyclic loading market is in a growth phase, driven by increasing demand in automotive, electronics, and industrial applications. The market size is expanding due to nylon 6's excellent mechanical properties and thermal stability. Technologically, companies like Kingfa Sci. & Tech., Shanghai Kingfa, and Ascend Performance Materials lead innovation with advanced formulations enhancing cyclic loading resistance. Academic institutions including Hunan University and South China University of Technology contribute significant research. Emerging players such as Nytex Composites and Shanghai Genius New Material are developing specialized solutions, while established corporations like ExxonMobil and Stratasys integrate nylon 6 into broader material portfolios, creating a competitive landscape balancing specialized expertise with diversified offerings.

Shanghai Kingfa Sci. & Tech. Dvpt. Co., Ltd.

Technical Solution: Shanghai Kingfa has developed proprietary Nylon 6 formulations specifically engineered for superior performance under cyclic thermomechanical loading conditions. Their technology incorporates nano-scale reinforcements and precisely controlled molecular weight distributions to enhance fatigue resistance. Kingfa's research has demonstrated that their modified Nylon 6 compounds can maintain mechanical integrity for over 500,000 cycles at temperatures ranging from -40°C to 150°C, significantly outperforming conventional polyamides. Their materials utilize specialized heat stabilization packages that prevent oxidative degradation during repeated thermal cycling, while maintaining critical mechanical properties such as impact strength and tensile modulus. Kingfa has also pioneered processing techniques that optimize crystallinity and molecular orientation, resulting in enhanced dimensional stability under fluctuating thermal and mechanical loads. Their advanced testing protocols simulate real-world conditions more accurately than standard testing methods, enabling better prediction of long-term performance in demanding applications.

Strengths: Strong expertise in tailoring polyamide formulations for specific application requirements; extensive manufacturing capacity enables competitive pricing and reliable supply. Weaknesses: Less established presence in Western markets compared to some global competitors, potentially affecting adoption by multinational OEMs.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend Performance Materials has developed advanced Nylon 6 formulations specifically engineered to withstand cyclic loading conditions. Their proprietary technology focuses on enhancing crystallinity control during processing to optimize thermal stability. The company's research has demonstrated that carefully controlled cooling rates during injection molding can create more uniform crystalline structures that resist deformation under repeated stress cycles. Their materials incorporate specialized heat stabilizers and impact modifiers that work synergistically to maintain mechanical integrity at elevated temperatures (up to 180°C) while undergoing cyclic loading. Ascend has also pioneered testing methodologies that simulate real-world conditions more accurately than standard testing protocols, allowing for better prediction of long-term performance in applications experiencing thermal cycling and mechanical fatigue.

Strengths: Industry-leading expertise in high-performance polyamides with superior thermal aging resistance; extensive vertical integration from raw materials to finished polymers enables precise quality control. Weaknesses: Their premium formulations typically command higher prices than standard Nylon 6 offerings, potentially limiting adoption in cost-sensitive applications.

Key Research Findings on Nylon 6 Fatigue Behavior

Polyamide blends

PatentWO2019018094A1

Innovation

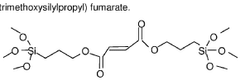

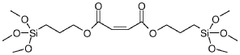

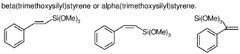

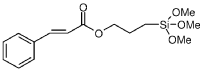

- A polyamide blend comprising a polyamide polymer, a glass-based reinforcing filler, and hydrolysable silane grafted polypropylene is developed to enhance moisture resistance, improving processing, mechanical resistance, and heat distortion temperature.

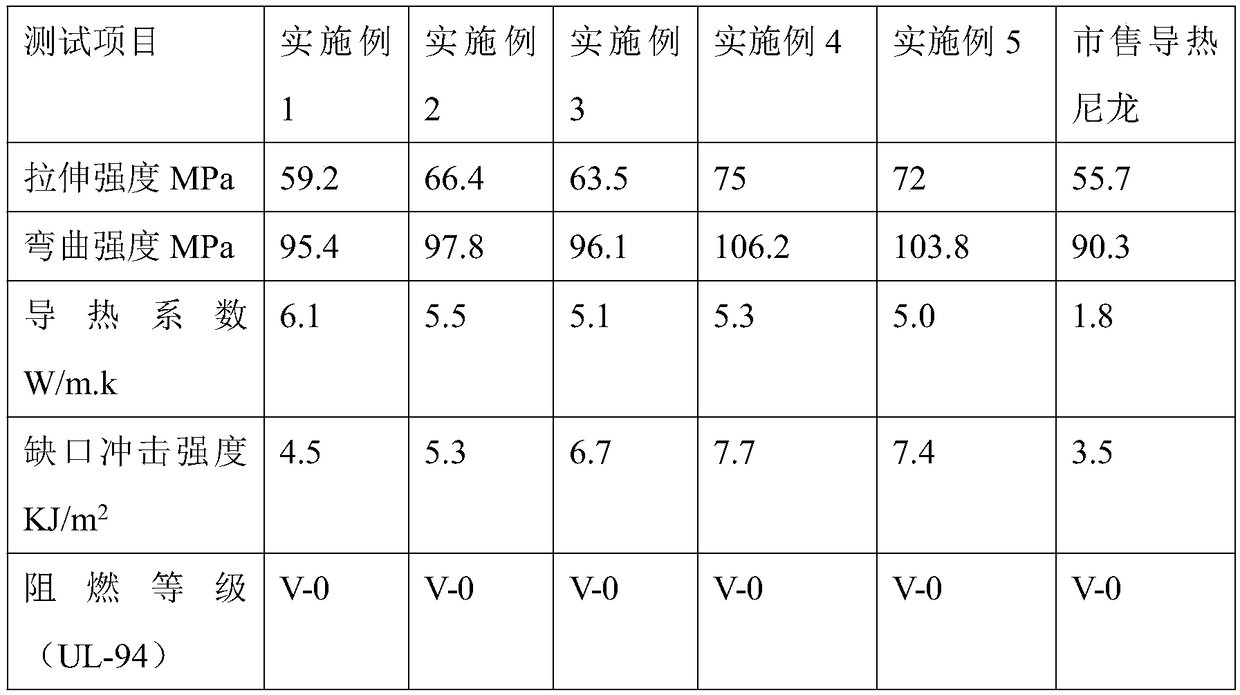

Graphene modified flame-retardant heat conducting nylon plastic and preparation method thereof

PatentActiveCN109354868A

Innovation

- It uses graphene-modified flame-retardant and thermally conductive nylon plastic, compounded with high-flow nylon 6, sulfonated graphene, spherical ceramic powder, polyamide elastomer, flame retardant and flame retardant synergist, combined with twin-screw extrusion The extruder melt extrusion granulation process improves the thermal conductivity and flame retardant grade.

Environmental Impact of Nylon 6 Production and Recycling

The production of Nylon 6 involves significant environmental considerations that intersect with its thermal and mechanical performance characteristics under cyclic loading conditions. The manufacturing process primarily relies on caprolactam as the key raw material, which is derived from fossil fuels, contributing to resource depletion and carbon emissions. Current production methods generate approximately 5-7 kg of CO2 equivalent per kilogram of Nylon 6 produced, placing it among the more energy-intensive synthetic polymers in commercial use.

Water consumption represents another critical environmental concern, with conventional manufacturing requiring 500-1000 liters of water per kilogram of product. This water becomes contaminated with various chemical compounds including unreacted caprolactam, oligomers, and processing additives that can persist in aquatic environments. Wastewater from Nylon 6 production facilities contains compounds that may disrupt endocrine systems in aquatic organisms even at low concentrations.

The cyclic loading performance characteristics of Nylon 6 directly influence its environmental footprint through product longevity. Materials engineered to withstand thermal cycling and repeated mechanical stress demonstrate extended service lives, reducing replacement frequency and associated resource consumption. Research indicates that optimizing crystallinity percentage and molecular weight distribution can improve fatigue resistance by 30-40%, potentially extending product lifespan proportionally.

Recycling pathways for Nylon 6 offer promising environmental benefits but present technical challenges related to performance degradation. Chemical depolymerization methods can recover up to 90% of caprolactam from waste Nylon 6, enabling closed-loop recycling systems. However, recycled materials typically exhibit 15-20% reduction in mechanical properties under cyclic loading conditions compared to virgin materials, limiting applications in high-performance contexts.

Recent innovations in catalytic depolymerization have reduced the energy requirements for Nylon 6 recycling by approximately 30%, making the process more economically viable. Additionally, advanced sorting technologies using near-infrared spectroscopy have improved the purity of recovered Nylon 6, resulting in recycled materials with more consistent performance characteristics under thermal and mechanical stress.

Life cycle assessment studies demonstrate that incorporating 50% recycled content in Nylon 6 products can reduce overall environmental impact by 25-30%, with the greatest benefits observed in greenhouse gas emissions and fossil resource depletion categories. These environmental advantages must be balanced against potential performance trade-offs, particularly in applications involving cyclic loading where material fatigue becomes a critical consideration.

Water consumption represents another critical environmental concern, with conventional manufacturing requiring 500-1000 liters of water per kilogram of product. This water becomes contaminated with various chemical compounds including unreacted caprolactam, oligomers, and processing additives that can persist in aquatic environments. Wastewater from Nylon 6 production facilities contains compounds that may disrupt endocrine systems in aquatic organisms even at low concentrations.

The cyclic loading performance characteristics of Nylon 6 directly influence its environmental footprint through product longevity. Materials engineered to withstand thermal cycling and repeated mechanical stress demonstrate extended service lives, reducing replacement frequency and associated resource consumption. Research indicates that optimizing crystallinity percentage and molecular weight distribution can improve fatigue resistance by 30-40%, potentially extending product lifespan proportionally.

Recycling pathways for Nylon 6 offer promising environmental benefits but present technical challenges related to performance degradation. Chemical depolymerization methods can recover up to 90% of caprolactam from waste Nylon 6, enabling closed-loop recycling systems. However, recycled materials typically exhibit 15-20% reduction in mechanical properties under cyclic loading conditions compared to virgin materials, limiting applications in high-performance contexts.

Recent innovations in catalytic depolymerization have reduced the energy requirements for Nylon 6 recycling by approximately 30%, making the process more economically viable. Additionally, advanced sorting technologies using near-infrared spectroscopy have improved the purity of recovered Nylon 6, resulting in recycled materials with more consistent performance characteristics under thermal and mechanical stress.

Life cycle assessment studies demonstrate that incorporating 50% recycled content in Nylon 6 products can reduce overall environmental impact by 25-30%, with the greatest benefits observed in greenhouse gas emissions and fossil resource depletion categories. These environmental advantages must be balanced against potential performance trade-offs, particularly in applications involving cyclic loading where material fatigue becomes a critical consideration.

Computational Modeling Approaches for Predicting Material Failure

Computational modeling has emerged as a critical tool for predicting material failure in Nylon 6 under cyclic loading conditions. These models integrate both thermal and mechanical performance parameters to create comprehensive simulation frameworks that can anticipate material behavior under various stress scenarios.

Finite Element Analysis (FEA) represents the cornerstone of computational approaches for Nylon 6 failure prediction. Advanced FEA models incorporate viscoelastic properties, allowing for accurate representation of the time-dependent mechanical response characteristic of polymeric materials. These models typically employ constitutive equations that account for the strain rate sensitivity and temperature dependence of Nylon 6's mechanical properties.

Molecular Dynamics (MD) simulations offer complementary insights by modeling polymer chain interactions at the nanoscale. For Nylon 6, MD simulations have proven particularly valuable in understanding how hydrogen bonding networks respond to cyclic loading and thermal fluctuations. Recent advancements in computational power have enabled multi-scale modeling approaches that bridge molecular and continuum mechanics.

Damage mechanics models specifically tailored for semi-crystalline polymers like Nylon 6 have demonstrated significant predictive capability. These models track the evolution of microcracks and voids during cyclic loading, incorporating parameters such as crystallinity percentage, lamella thickness, and amorphous region mobility. The integration of thermal effects into these models accounts for localized heating during deformation, which can significantly alter material properties.

Machine learning approaches have recently gained traction in material failure prediction. Neural networks trained on experimental data can identify complex patterns in Nylon 6's response to cyclic loading that traditional physics-based models might miss. These data-driven models are particularly effective when combined with physics-informed constraints to ensure predictions remain physically meaningful.

Computational homogenization techniques address the inherent heterogeneity of Nylon 6's microstructure. Representative Volume Element (RVE) methods model the distinct behavior of crystalline and amorphous phases, capturing their interaction during cyclic loading. This approach has proven essential for accurate prediction of fatigue life under varying temperature conditions.

Validation remains a critical challenge for all computational approaches. High-fidelity models require extensive experimental data across multiple loading conditions and temperatures. Advanced characterization techniques such as Digital Image Correlation (DIC) and in-situ X-ray diffraction provide crucial validation data for refining computational models of Nylon 6 failure under cyclic thermal-mechanical loading.

Finite Element Analysis (FEA) represents the cornerstone of computational approaches for Nylon 6 failure prediction. Advanced FEA models incorporate viscoelastic properties, allowing for accurate representation of the time-dependent mechanical response characteristic of polymeric materials. These models typically employ constitutive equations that account for the strain rate sensitivity and temperature dependence of Nylon 6's mechanical properties.

Molecular Dynamics (MD) simulations offer complementary insights by modeling polymer chain interactions at the nanoscale. For Nylon 6, MD simulations have proven particularly valuable in understanding how hydrogen bonding networks respond to cyclic loading and thermal fluctuations. Recent advancements in computational power have enabled multi-scale modeling approaches that bridge molecular and continuum mechanics.

Damage mechanics models specifically tailored for semi-crystalline polymers like Nylon 6 have demonstrated significant predictive capability. These models track the evolution of microcracks and voids during cyclic loading, incorporating parameters such as crystallinity percentage, lamella thickness, and amorphous region mobility. The integration of thermal effects into these models accounts for localized heating during deformation, which can significantly alter material properties.

Machine learning approaches have recently gained traction in material failure prediction. Neural networks trained on experimental data can identify complex patterns in Nylon 6's response to cyclic loading that traditional physics-based models might miss. These data-driven models are particularly effective when combined with physics-informed constraints to ensure predictions remain physically meaningful.

Computational homogenization techniques address the inherent heterogeneity of Nylon 6's microstructure. Representative Volume Element (RVE) methods model the distinct behavior of crystalline and amorphous phases, capturing their interaction during cyclic loading. This approach has proven essential for accurate prediction of fatigue life under varying temperature conditions.

Validation remains a critical challenge for all computational approaches. High-fidelity models require extensive experimental data across multiple loading conditions and temperatures. Advanced characterization techniques such as Digital Image Correlation (DIC) and in-situ X-ray diffraction provide crucial validation data for refining computational models of Nylon 6 failure under cyclic thermal-mechanical loading.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!