Nylon 6 composites reinforced with glass and carbon fibers

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Composites Evolution and Research Objectives

Nylon 6, a synthetic polymer first developed in the 1930s by Wallace Carothers at DuPont, has evolved significantly over decades to become a cornerstone material in various industrial applications. The journey of Nylon 6 composites represents a fascinating intersection of polymer science and materials engineering, with continuous innovations driving its performance capabilities to new heights.

The evolution of Nylon 6 composites began with basic reinforcement techniques in the 1950s, primarily focusing on improving mechanical properties. By the 1970s, glass fiber reinforcement emerged as a standard approach to enhance strength and stiffness while maintaining the polymer's inherent processability advantages. The 1990s witnessed a paradigm shift with the introduction of carbon fiber reinforcements, opening new frontiers for high-performance applications where weight reduction and superior mechanical properties were paramount.

Recent advancements in nanotechnology have further revolutionized Nylon 6 composites, with nanoscale fillers and hybrid reinforcement systems creating materials with unprecedented property combinations. The integration of computational modeling and simulation tools has accelerated development cycles, allowing for more precise tailoring of composite properties to specific application requirements.

The global push toward sustainability has also influenced Nylon 6 composite evolution, with increasing research focused on bio-based alternatives, recycling technologies, and environmentally friendly processing methods. This represents a significant departure from traditional petroleum-based production pathways and addresses growing environmental concerns.

The primary research objectives in this field now center on several key areas. First, optimizing the interface between Nylon 6 matrices and reinforcing fibers (both glass and carbon) to maximize load transfer efficiency and minimize failure mechanisms. Second, developing cost-effective processing techniques that can maintain fiber integrity while achieving uniform dispersion throughout the polymer matrix.

Another critical research objective involves understanding and controlling the crystallization behavior of Nylon 6 in the presence of different fiber types, as this significantly impacts the final mechanical and thermal properties of the composite. Researchers are also exploring multi-functional composites that combine mechanical reinforcement with additional properties such as electrical conductivity, thermal management capabilities, or self-healing characteristics.

The ultimate goal of current research efforts is to develop next-generation Nylon 6 composites that offer superior performance-to-weight ratios, enhanced durability under extreme conditions, improved recyclability, and reduced environmental footprint. These objectives align with broader industry trends toward lightweighting in transportation, sustainable manufacturing practices, and materials with extended service lifetimes.

The evolution of Nylon 6 composites began with basic reinforcement techniques in the 1950s, primarily focusing on improving mechanical properties. By the 1970s, glass fiber reinforcement emerged as a standard approach to enhance strength and stiffness while maintaining the polymer's inherent processability advantages. The 1990s witnessed a paradigm shift with the introduction of carbon fiber reinforcements, opening new frontiers for high-performance applications where weight reduction and superior mechanical properties were paramount.

Recent advancements in nanotechnology have further revolutionized Nylon 6 composites, with nanoscale fillers and hybrid reinforcement systems creating materials with unprecedented property combinations. The integration of computational modeling and simulation tools has accelerated development cycles, allowing for more precise tailoring of composite properties to specific application requirements.

The global push toward sustainability has also influenced Nylon 6 composite evolution, with increasing research focused on bio-based alternatives, recycling technologies, and environmentally friendly processing methods. This represents a significant departure from traditional petroleum-based production pathways and addresses growing environmental concerns.

The primary research objectives in this field now center on several key areas. First, optimizing the interface between Nylon 6 matrices and reinforcing fibers (both glass and carbon) to maximize load transfer efficiency and minimize failure mechanisms. Second, developing cost-effective processing techniques that can maintain fiber integrity while achieving uniform dispersion throughout the polymer matrix.

Another critical research objective involves understanding and controlling the crystallization behavior of Nylon 6 in the presence of different fiber types, as this significantly impacts the final mechanical and thermal properties of the composite. Researchers are also exploring multi-functional composites that combine mechanical reinforcement with additional properties such as electrical conductivity, thermal management capabilities, or self-healing characteristics.

The ultimate goal of current research efforts is to develop next-generation Nylon 6 composites that offer superior performance-to-weight ratios, enhanced durability under extreme conditions, improved recyclability, and reduced environmental footprint. These objectives align with broader industry trends toward lightweighting in transportation, sustainable manufacturing practices, and materials with extended service lifetimes.

Market Analysis for Fiber-Reinforced Nylon 6 Applications

The global market for fiber-reinforced Nylon 6 composites has experienced significant growth over the past decade, driven primarily by increasing demand from automotive, aerospace, and industrial sectors. The market value reached approximately $2.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2028.

Automotive applications represent the largest market segment, accounting for nearly 40% of total consumption. This dominance stems from the automotive industry's continuous pursuit of lightweight materials to improve fuel efficiency and reduce emissions. Glass fiber-reinforced Nylon 6 components have become standard in engine covers, intake manifolds, and structural components, while carbon fiber variants are increasingly adopted in premium and performance vehicles.

The aerospace sector, though smaller in volume, shows the highest growth rate at 8.2% annually. The superior strength-to-weight ratio of carbon fiber-reinforced Nylon 6 makes it particularly valuable for interior components, ducting systems, and non-critical structural elements where weight reduction directly impacts fuel consumption and operational costs.

Regional analysis reveals Asia-Pacific as the dominant market, representing 45% of global consumption, with China and India as primary growth engines. North America and Europe follow with 28% and 22% market shares respectively, characterized by higher adoption rates of premium carbon fiber composites in specialized applications.

Consumer electronics has emerged as a rapidly expanding application area, growing at 7.5% annually. The thermal stability, dimensional precision, and aesthetic qualities of fiber-reinforced Nylon 6 make it ideal for smartphone frames, laptop components, and other portable device housings where durability and weight are critical factors.

Market dynamics are increasingly influenced by sustainability concerns, with 65% of surveyed manufacturers citing environmental regulations as a significant factor in material selection decisions. This has accelerated research into recycling technologies for these composites and the development of bio-based Nylon 6 variants reinforced with natural fibers.

Price sensitivity varies significantly across application sectors. While automotive manufacturers prioritize cost-effectiveness of glass fiber reinforcements, aerospace and high-performance sports equipment manufacturers demonstrate willingness to pay premium prices for carbon fiber variants, creating a tiered market structure based on performance requirements and budget constraints.

The COVID-19 pandemic temporarily disrupted supply chains in 2020, causing a 12% market contraction, but recovery has been robust with most segments returning to pre-pandemic growth trajectories by mid-2022. This resilience underscores the essential nature of these materials in modern manufacturing processes.

Automotive applications represent the largest market segment, accounting for nearly 40% of total consumption. This dominance stems from the automotive industry's continuous pursuit of lightweight materials to improve fuel efficiency and reduce emissions. Glass fiber-reinforced Nylon 6 components have become standard in engine covers, intake manifolds, and structural components, while carbon fiber variants are increasingly adopted in premium and performance vehicles.

The aerospace sector, though smaller in volume, shows the highest growth rate at 8.2% annually. The superior strength-to-weight ratio of carbon fiber-reinforced Nylon 6 makes it particularly valuable for interior components, ducting systems, and non-critical structural elements where weight reduction directly impacts fuel consumption and operational costs.

Regional analysis reveals Asia-Pacific as the dominant market, representing 45% of global consumption, with China and India as primary growth engines. North America and Europe follow with 28% and 22% market shares respectively, characterized by higher adoption rates of premium carbon fiber composites in specialized applications.

Consumer electronics has emerged as a rapidly expanding application area, growing at 7.5% annually. The thermal stability, dimensional precision, and aesthetic qualities of fiber-reinforced Nylon 6 make it ideal for smartphone frames, laptop components, and other portable device housings where durability and weight are critical factors.

Market dynamics are increasingly influenced by sustainability concerns, with 65% of surveyed manufacturers citing environmental regulations as a significant factor in material selection decisions. This has accelerated research into recycling technologies for these composites and the development of bio-based Nylon 6 variants reinforced with natural fibers.

Price sensitivity varies significantly across application sectors. While automotive manufacturers prioritize cost-effectiveness of glass fiber reinforcements, aerospace and high-performance sports equipment manufacturers demonstrate willingness to pay premium prices for carbon fiber variants, creating a tiered market structure based on performance requirements and budget constraints.

The COVID-19 pandemic temporarily disrupted supply chains in 2020, causing a 12% market contraction, but recovery has been robust with most segments returning to pre-pandemic growth trajectories by mid-2022. This resilience underscores the essential nature of these materials in modern manufacturing processes.

Technical Challenges in Fiber-Reinforced Polymer Development

Despite significant advancements in fiber-reinforced polymer technology, the development of Nylon 6 composites reinforced with glass and carbon fibers faces several persistent technical challenges. One of the primary obstacles is achieving optimal fiber-matrix interfacial adhesion. The inherently hydrophilic nature of Nylon 6 often contrasts with the relatively hydrophobic characteristics of carbon fibers, resulting in weak interfacial bonding that compromises mechanical properties and long-term durability of the composite.

Processing difficulties represent another significant challenge, particularly in maintaining consistent fiber dispersion and orientation during manufacturing. High-temperature processing required for Nylon 6 (melting point ~220°C) can potentially damage sizing agents on fibers, reducing their effectiveness as reinforcement. Additionally, the high viscosity of molten Nylon 6 creates difficulties in achieving thorough fiber wetting, especially at higher fiber loading percentages.

Moisture absorption remains a critical concern for Nylon 6 composites. The material's hygroscopic nature leads to dimensional instability and potential degradation of mechanical properties over time. When reinforced with glass fibers, this issue becomes particularly problematic as moisture can weaken the fiber-matrix interface through hydrolysis mechanisms, accelerating composite failure under load.

The balance between stiffness and impact resistance presents ongoing engineering challenges. While carbon fiber reinforcement significantly enhances stiffness and strength, it often reduces impact resistance and introduces brittle failure modes. Conversely, glass fiber reinforcement provides better impact properties but lower specific strength and modulus compared to carbon fiber variants.

Cost-performance optimization continues to challenge widespread adoption. Carbon fiber reinforcement, while technically superior in many aspects, adds substantial cost to the final composite. Glass fibers offer a more economical alternative but with performance trade-offs that must be carefully evaluated for specific applications.

Thermal management issues arise from the coefficient of thermal expansion (CTE) mismatch between Nylon 6 and reinforcing fibers. This mismatch generates internal stresses during thermal cycling, potentially leading to microcracking and accelerated aging of the composite structure. The challenge is particularly pronounced in applications experiencing wide temperature fluctuations.

Environmental concerns and recyclability present growing challenges as sustainability becomes increasingly important. The heterogeneous nature of fiber-reinforced Nylon 6 composites complicates end-of-life recycling processes, with fiber extraction and matrix separation remaining technically difficult and economically questionable at industrial scales.

Processing difficulties represent another significant challenge, particularly in maintaining consistent fiber dispersion and orientation during manufacturing. High-temperature processing required for Nylon 6 (melting point ~220°C) can potentially damage sizing agents on fibers, reducing their effectiveness as reinforcement. Additionally, the high viscosity of molten Nylon 6 creates difficulties in achieving thorough fiber wetting, especially at higher fiber loading percentages.

Moisture absorption remains a critical concern for Nylon 6 composites. The material's hygroscopic nature leads to dimensional instability and potential degradation of mechanical properties over time. When reinforced with glass fibers, this issue becomes particularly problematic as moisture can weaken the fiber-matrix interface through hydrolysis mechanisms, accelerating composite failure under load.

The balance between stiffness and impact resistance presents ongoing engineering challenges. While carbon fiber reinforcement significantly enhances stiffness and strength, it often reduces impact resistance and introduces brittle failure modes. Conversely, glass fiber reinforcement provides better impact properties but lower specific strength and modulus compared to carbon fiber variants.

Cost-performance optimization continues to challenge widespread adoption. Carbon fiber reinforcement, while technically superior in many aspects, adds substantial cost to the final composite. Glass fibers offer a more economical alternative but with performance trade-offs that must be carefully evaluated for specific applications.

Thermal management issues arise from the coefficient of thermal expansion (CTE) mismatch between Nylon 6 and reinforcing fibers. This mismatch generates internal stresses during thermal cycling, potentially leading to microcracking and accelerated aging of the composite structure. The challenge is particularly pronounced in applications experiencing wide temperature fluctuations.

Environmental concerns and recyclability present growing challenges as sustainability becomes increasingly important. The heterogeneous nature of fiber-reinforced Nylon 6 composites complicates end-of-life recycling processes, with fiber extraction and matrix separation remaining technically difficult and economically questionable at industrial scales.

Current Reinforcement Methodologies for Nylon 6 Composites

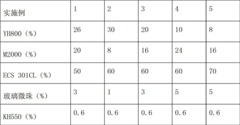

01 Composition and preparation methods of nylon 6 composites with glass and carbon fibers

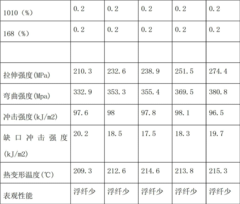

Nylon 6 composites can be reinforced with both glass and carbon fibers to enhance mechanical properties. These composites typically contain specific ratios of nylon 6 matrix with glass fibers and carbon fibers as reinforcement materials. The preparation methods often involve melt blending, extrusion, and injection molding processes to ensure proper dispersion of the reinforcing fibers within the polymer matrix. The resulting composites exhibit improved strength, stiffness, and dimensional stability compared to unreinforced nylon 6.- Composition and preparation methods of nylon 6 composites with glass and carbon fibers: Nylon 6 composites can be reinforced with both glass and carbon fibers to enhance mechanical properties. These composites typically contain specific ratios of nylon 6 matrix with glass fibers and carbon fibers as reinforcement materials. The preparation methods often involve melt blending, extrusion, and injection molding processes to ensure proper dispersion of the reinforcing fibers within the polymer matrix.

- Mechanical property enhancement in hybrid fiber reinforced nylon 6: The combination of glass and carbon fibers in nylon 6 creates synergistic effects that significantly improve mechanical properties. These hybrid composites demonstrate enhanced tensile strength, flexural modulus, impact resistance, and dimensional stability compared to single-fiber reinforced composites. The different fiber types complement each other, with carbon fibers providing high strength and stiffness while glass fibers contribute to impact resistance and cost efficiency.

- Surface treatment and interfacial compatibility improvement: Surface treatments of glass and carbon fibers are crucial for enhancing the interfacial adhesion between the fibers and nylon 6 matrix. Various coupling agents, sizing materials, and chemical modifications are applied to the fiber surfaces to improve compatibility. These treatments create stronger chemical bonds at the interface, leading to better stress transfer, reduced void formation, and improved overall composite performance.

- Processing techniques for fiber orientation and distribution control: Specialized processing techniques are employed to control the orientation and distribution of glass and carbon fibers within nylon 6 composites. These include optimized injection molding parameters, extrusion conditions, and compression molding processes. Proper fiber alignment and distribution are essential for maximizing mechanical properties and ensuring consistent performance across the composite material.

- Applications and performance in specific environments: Nylon 6 composites reinforced with glass and carbon fibers find applications in automotive components, industrial parts, consumer goods, and aerospace structures. These materials exhibit excellent performance under various environmental conditions, including high temperature resistance, chemical stability, and long-term durability. The combination of different fiber types allows for customization of properties to meet specific application requirements while maintaining a balance between performance and cost.

02 Surface treatment and modification of reinforcing fibers

Surface treatments and modifications of glass and carbon fibers are essential for improving the interfacial adhesion between the fibers and nylon 6 matrix. Various coupling agents, such as silanes for glass fibers and oxidative treatments for carbon fibers, can be applied to enhance the fiber-matrix interaction. These treatments modify the surface chemistry of the fibers, promoting better wetting and adhesion with the polymer matrix, which results in improved mechanical properties and reduced water absorption in the final composite.Expand Specific Solutions03 Hybrid reinforcement effects and synergistic properties

The combination of glass and carbon fibers in nylon 6 creates hybrid composites with synergistic properties. While carbon fibers provide high strength and stiffness with low weight, glass fibers offer cost-effectiveness and good impact resistance. The hybrid approach allows for tailoring specific properties by adjusting the ratio of different fiber types. This synergistic effect can result in composites with balanced mechanical properties, improved thermal stability, and enhanced dimensional stability under varying environmental conditions.Expand Specific Solutions04 Processing techniques for fiber orientation and distribution

Specialized processing techniques are crucial for controlling fiber orientation and distribution in nylon 6 composites. Methods such as injection molding with specific gate designs, compression molding, and extrusion with specialized screws can be employed to achieve desired fiber alignment. The processing parameters, including temperature, pressure, and cooling rate, significantly influence the microstructure and consequently the mechanical properties of the composites. Proper fiber distribution prevents agglomeration and ensures uniform reinforcement throughout the matrix.Expand Specific Solutions05 Applications and performance enhancements

Nylon 6 composites reinforced with glass and carbon fibers find applications in automotive components, industrial parts, sporting goods, and electronic housings. These composites offer enhanced mechanical properties, including higher tensile strength, flexural modulus, and impact resistance compared to unreinforced nylon. Additionally, they exhibit improved thermal stability, reduced warpage, and better dimensional stability under varying temperature and humidity conditions. The performance can be further enhanced by incorporating additives such as impact modifiers, flame retardants, and heat stabilizers.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Composite Materials

The nylon 6 composites reinforced with glass and carbon fibers market is in a growth phase, driven by increasing demand for lightweight, high-strength materials across automotive, aerospace, and industrial applications. The global market size is estimated to exceed $2 billion, with projected annual growth of 6-8%. Technologically, the field shows moderate maturity with ongoing innovation. Key players include Kingfa Sci. & Tech. and its subsidiaries, demonstrating strong R&D capabilities in modified plastics and composite materials. Shanghai PRET Composites and Johns Manville bring significant expertise in fiber reinforcement technologies, while academic-industrial collaborations with institutions like Beijing University of Chemical Technology and University of Southern Mississippi are advancing material performance. Companies like Hyundai Motor and Rolls Royce represent major end-users driving application-specific developments.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa has developed advanced Nylon 6 composite formulations incorporating both short and long glass fibers with proprietary coupling agents to enhance fiber-matrix interfacial adhesion. Their technology involves a specialized twin-screw extrusion process with precise temperature control zones (260-290°C) that minimizes thermal degradation while ensuring optimal fiber dispersion. The company has pioneered a multi-stage compounding technique that maintains longer fiber lengths (averaging 0.8-1.2mm) compared to conventional processes, resulting in composites with tensile strengths exceeding 180 MPa and notched impact strengths of 12-15 kJ/m². Their glass fiber reinforced Nylon 6 grades (GF30-GF60) feature modified sizing agents specifically designed for polyamide matrices, enhancing long-term heat aging resistance up to 180°C.

Strengths: Superior fiber-matrix adhesion through proprietary coupling agents; excellent fiber length preservation during processing; comprehensive product range with fiber loadings from 15-60%. Weaknesses: Higher production costs compared to standard compounds; potential for increased water absorption affecting dimensional stability; limited carbon fiber offerings compared to their glass fiber portfolio.

Johns Manville Corp.

Technical Solution: Johns Manville has developed specialized glass fiber technologies specifically engineered for reinforcing Nylon 6 composites. Their StarRov® series features proprietary sizing chemistries that create strong covalent bonds with polyamide matrices, resulting in superior interfacial adhesion. The company employs a multi-end roving manufacturing process that produces fibers with consistent diameter (10-13 μm) and tensile strengths exceeding 3.5 GPa. Their chopped strand products undergo a thermal treatment process at precisely controlled temperatures (280-320°C) to optimize fiber surface characteristics for Nylon 6 compatibility. Johns Manville's glass fiber reinforcements enable Nylon 6 composites to achieve flexural moduli of 9-12 GPa and heat deflection temperatures above 200°C, making them suitable for demanding automotive and industrial applications. Their latest innovation includes hybrid reinforcement systems combining E-glass with specialty glass formulations to enhance both mechanical properties and dimensional stability.

Strengths: Industry-leading expertise in glass fiber sizing chemistry specifically for polyamide matrices; extensive product range with tailored solutions for different processing methods; global manufacturing capabilities ensuring consistent supply. Weaknesses: Limited focus on carbon fiber technologies; higher cost compared to standard glass fibers; primarily a materials supplier rather than a finished composite manufacturer.

Key Patents and Innovations in Fiber-Matrix Interface Engineering

High glazing and high liquidity glass fiber-reinforced nylon 6 composite material and preparation method thereof

PatentActiveCN101104735A

Innovation

- By adding high-gloss masterbatch, the flow characteristics of the resin are changed, the exposure of glass fiber on the surface of the part is suppressed, the processing performance is improved, and the mechanical properties of the glass fiber-reinforced nylon 6 composite material are improved. The specific method includes using nylon 6 resin, compatibilizer, glass fiber, high-gloss masterbatch and other additives, preparing through a twin-screw extrusion process, and optimizing the component ratio and processing temperature.

Glass fiber reinforced nylon 6 composite material with superhigh content and preparation method thereof

PatentActiveCN103044910A

Innovation

- By adjusting the viscosity of nylon 6 resin to improve the wettability of resin and glass fiber, and adding glass beads to improve apparent quality, ultra-high content glass fiber reinforced nylon 6 was prepared using a twin-screw extruder and injection molding mechanism sampling strip. composite materials.

Environmental Impact and Sustainability Considerations

The environmental impact of Nylon 6 composites reinforced with glass and carbon fibers presents significant considerations for sustainable manufacturing and product lifecycle management. These composite materials, while offering superior mechanical properties, raise concerns regarding resource consumption during production. The manufacturing of glass fibers requires substantial energy inputs, with estimates suggesting approximately 30-50 MJ/kg, while carbon fiber production demands even higher energy expenditure, typically ranging from 200-400 MJ/kg, contributing to considerable carbon emissions.

Waste management challenges are particularly pronounced with these composites due to their inherent difficulty in separation and recycling. The heterogeneous nature of fiber-reinforced polymers creates substantial barriers to conventional recycling methods, resulting in most end-of-life products being directed to landfills or incineration facilities. Current recycling rates for these materials remain below 10% globally, highlighting a critical sustainability gap.

Water pollution represents another environmental concern, as the manufacturing processes for both Nylon 6 and its reinforcing fibers involve chemical treatments that can generate contaminated wastewater. Without proper treatment, these effluents may introduce harmful substances into aquatic ecosystems, including sizing agents, coupling compounds, and polymer residues.

Recent sustainability initiatives have focused on developing bio-based alternatives to traditional Nylon 6 composites. Research indicates that partially bio-derived polyamides can reduce the carbon footprint by 15-30% compared to petroleum-based counterparts. Additionally, natural fiber reinforcements such as flax, hemp, or jute are being explored as potential substitutes for glass fibers in less demanding applications, offering reduced environmental impact and enhanced biodegradability.

Life Cycle Assessment (LCA) studies reveal that the environmental footprint of these composites is dominated by the production phase, with fiber manufacturing accounting for 60-70% of total impacts. However, these impacts may be offset during the use phase in transportation applications, where the lightweight properties of these composites contribute to fuel efficiency improvements of 5-8% compared to traditional materials.

Emerging technologies for composite recycling show promise, including solvolysis and pyrolysis processes that can recover both fiber reinforcements and polymer precursors. These advanced recycling methods have demonstrated fiber recovery rates of up to 80% with retention of 70-90% of original mechanical properties, potentially creating closed-loop material systems for future applications of reinforced Nylon 6 composites.

Waste management challenges are particularly pronounced with these composites due to their inherent difficulty in separation and recycling. The heterogeneous nature of fiber-reinforced polymers creates substantial barriers to conventional recycling methods, resulting in most end-of-life products being directed to landfills or incineration facilities. Current recycling rates for these materials remain below 10% globally, highlighting a critical sustainability gap.

Water pollution represents another environmental concern, as the manufacturing processes for both Nylon 6 and its reinforcing fibers involve chemical treatments that can generate contaminated wastewater. Without proper treatment, these effluents may introduce harmful substances into aquatic ecosystems, including sizing agents, coupling compounds, and polymer residues.

Recent sustainability initiatives have focused on developing bio-based alternatives to traditional Nylon 6 composites. Research indicates that partially bio-derived polyamides can reduce the carbon footprint by 15-30% compared to petroleum-based counterparts. Additionally, natural fiber reinforcements such as flax, hemp, or jute are being explored as potential substitutes for glass fibers in less demanding applications, offering reduced environmental impact and enhanced biodegradability.

Life Cycle Assessment (LCA) studies reveal that the environmental footprint of these composites is dominated by the production phase, with fiber manufacturing accounting for 60-70% of total impacts. However, these impacts may be offset during the use phase in transportation applications, where the lightweight properties of these composites contribute to fuel efficiency improvements of 5-8% compared to traditional materials.

Emerging technologies for composite recycling show promise, including solvolysis and pyrolysis processes that can recover both fiber reinforcements and polymer precursors. These advanced recycling methods have demonstrated fiber recovery rates of up to 80% with retention of 70-90% of original mechanical properties, potentially creating closed-loop material systems for future applications of reinforced Nylon 6 composites.

Performance Comparison Between Glass and Carbon Fiber Reinforcements

When comparing glass fiber reinforcement (GFR) and carbon fiber reinforcement (CFR) in Nylon 6 composites, several key performance metrics reveal significant differences. Mechanical properties stand as the most notable distinction, with carbon fiber reinforcements consistently demonstrating superior tensile strength—typically 30-40% higher than glass fiber alternatives in equivalent loading conditions. Carbon fiber reinforced Nylon 6 composites achieve tensile strengths ranging from 150-220 MPa compared to 100-160 MPa for glass fiber reinforcements at similar fiber loading percentages.

Modulus of elasticity follows a similar pattern, with carbon fiber reinforcements providing substantially higher stiffness. CFR Nylon 6 composites exhibit elastic moduli between 15-25 GPa, while GFR variants typically range from 7-12 GPa. This difference becomes particularly pronounced in applications requiring dimensional stability under load.

Impact resistance presents a more nuanced comparison. While glass fiber reinforcements generally offer superior impact strength in standard testing (typically 20-30% higher notched Izod values), carbon fiber composites demonstrate better retention of mechanical properties after impact events. This characteristic proves especially valuable in applications experiencing repeated stress cycles or impact loading.

Thermal performance represents another critical differentiator. Carbon fiber reinforced Nylon 6 maintains mechanical integrity at higher temperatures, with heat deflection temperatures approximately 15-25°C higher than glass fiber variants. Additionally, CFR composites exhibit lower coefficients of thermal expansion (CTE), providing enhanced dimensional stability across temperature fluctuations—a crucial factor in precision engineering applications.

Weight considerations heavily favor carbon fiber reinforcements, which deliver comparable or superior mechanical performance at 25-40% lower weight than glass fiber alternatives. This weight advantage translates directly to improved specific strength and stiffness metrics, making CFR composites particularly valuable in transportation and aerospace applications where weight reduction directly impacts energy efficiency.

Electrical and thermal conductivity properties also differ significantly. Carbon fiber reinforcements impart moderate electrical conductivity to otherwise insulating Nylon 6, enabling applications requiring electrostatic discharge protection. Glass fiber reinforcements maintain the electrical insulating properties of the base polymer. Similarly, carbon fiber composites demonstrate approximately 30-50% higher thermal conductivity, enhancing heat dissipation in electronic housing applications.

Cost-performance analysis reveals glass fiber reinforcements' significant economic advantage, with raw material costs typically 60-75% lower than carbon fiber alternatives. This cost differential often determines material selection in high-volume, cost-sensitive applications where the performance advantages of carbon fiber cannot justify the price premium.

Modulus of elasticity follows a similar pattern, with carbon fiber reinforcements providing substantially higher stiffness. CFR Nylon 6 composites exhibit elastic moduli between 15-25 GPa, while GFR variants typically range from 7-12 GPa. This difference becomes particularly pronounced in applications requiring dimensional stability under load.

Impact resistance presents a more nuanced comparison. While glass fiber reinforcements generally offer superior impact strength in standard testing (typically 20-30% higher notched Izod values), carbon fiber composites demonstrate better retention of mechanical properties after impact events. This characteristic proves especially valuable in applications experiencing repeated stress cycles or impact loading.

Thermal performance represents another critical differentiator. Carbon fiber reinforced Nylon 6 maintains mechanical integrity at higher temperatures, with heat deflection temperatures approximately 15-25°C higher than glass fiber variants. Additionally, CFR composites exhibit lower coefficients of thermal expansion (CTE), providing enhanced dimensional stability across temperature fluctuations—a crucial factor in precision engineering applications.

Weight considerations heavily favor carbon fiber reinforcements, which deliver comparable or superior mechanical performance at 25-40% lower weight than glass fiber alternatives. This weight advantage translates directly to improved specific strength and stiffness metrics, making CFR composites particularly valuable in transportation and aerospace applications where weight reduction directly impacts energy efficiency.

Electrical and thermal conductivity properties also differ significantly. Carbon fiber reinforcements impart moderate electrical conductivity to otherwise insulating Nylon 6, enabling applications requiring electrostatic discharge protection. Glass fiber reinforcements maintain the electrical insulating properties of the base polymer. Similarly, carbon fiber composites demonstrate approximately 30-50% higher thermal conductivity, enhancing heat dissipation in electronic housing applications.

Cost-performance analysis reveals glass fiber reinforcements' significant economic advantage, with raw material costs typically 60-75% lower than carbon fiber alternatives. This cost differential often determines material selection in high-volume, cost-sensitive applications where the performance advantages of carbon fiber cannot justify the price premium.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!