Standards and processing guidelines for Nylon 6 industrial components

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nylon 6 Technology Evolution and Objectives

Nylon 6 emerged in the 1930s as a revolutionary synthetic polymer, developed as an alternative to natural fibers. The evolution of this material has been marked by continuous improvements in manufacturing processes, formulation techniques, and application methodologies. Initially utilized primarily in textile applications, Nylon 6 has progressively expanded into industrial components due to its exceptional mechanical properties, including high tensile strength, abrasion resistance, and thermal stability.

The technological trajectory of Nylon 6 has been characterized by several significant advancements. In the 1950s-1960s, the focus was on improving polymerization techniques to enhance molecular weight control and consistency. The 1970s-1980s witnessed the development of reinforcement technologies, particularly glass fiber and mineral additives, substantially expanding the material's performance envelope for industrial applications.

The 1990s brought sophisticated compounding technologies that enabled precise tailoring of Nylon 6 properties through specialized additives and modifiers. This period also saw the emergence of advanced processing techniques such as reaction injection molding and precision extrusion, allowing for more complex component geometries and improved dimensional stability.

Recent technological developments have centered on sustainability and performance optimization. Bio-based precursors for Nylon 6 production have been developed, reducing dependency on petroleum-derived raw materials. Concurrently, nanotechnology integration has created high-performance composites with enhanced mechanical properties and specialized functionalities such as electromagnetic interference shielding and improved flame retardancy.

The primary objective in Nylon 6 industrial component manufacturing is establishing comprehensive standards and processing guidelines that ensure consistent quality, predictable performance, and manufacturing efficiency. These standards must address the material's hygroscopic nature, which significantly impacts processing parameters and final component properties. Additionally, they must account for the relationship between processing conditions and crystallinity development, which directly influences mechanical performance.

Another critical objective is developing standardized methodologies for quality assessment that accurately predict long-term performance under various environmental conditions. This includes accelerated aging protocols, stress-strain relationship models under different loading scenarios, and chemical resistance evaluation frameworks tailored to specific industrial environments.

Future technological objectives include developing advanced simulation tools that can accurately predict part performance based on processing parameters, material formulation, and component geometry. Additionally, there is a growing focus on circular economy approaches, including standardized recycling protocols for post-industrial and post-consumer Nylon 6 components, addressing the increasing demand for sustainable manufacturing practices.

The technological trajectory of Nylon 6 has been characterized by several significant advancements. In the 1950s-1960s, the focus was on improving polymerization techniques to enhance molecular weight control and consistency. The 1970s-1980s witnessed the development of reinforcement technologies, particularly glass fiber and mineral additives, substantially expanding the material's performance envelope for industrial applications.

The 1990s brought sophisticated compounding technologies that enabled precise tailoring of Nylon 6 properties through specialized additives and modifiers. This period also saw the emergence of advanced processing techniques such as reaction injection molding and precision extrusion, allowing for more complex component geometries and improved dimensional stability.

Recent technological developments have centered on sustainability and performance optimization. Bio-based precursors for Nylon 6 production have been developed, reducing dependency on petroleum-derived raw materials. Concurrently, nanotechnology integration has created high-performance composites with enhanced mechanical properties and specialized functionalities such as electromagnetic interference shielding and improved flame retardancy.

The primary objective in Nylon 6 industrial component manufacturing is establishing comprehensive standards and processing guidelines that ensure consistent quality, predictable performance, and manufacturing efficiency. These standards must address the material's hygroscopic nature, which significantly impacts processing parameters and final component properties. Additionally, they must account for the relationship between processing conditions and crystallinity development, which directly influences mechanical performance.

Another critical objective is developing standardized methodologies for quality assessment that accurately predict long-term performance under various environmental conditions. This includes accelerated aging protocols, stress-strain relationship models under different loading scenarios, and chemical resistance evaluation frameworks tailored to specific industrial environments.

Future technological objectives include developing advanced simulation tools that can accurately predict part performance based on processing parameters, material formulation, and component geometry. Additionally, there is a growing focus on circular economy approaches, including standardized recycling protocols for post-industrial and post-consumer Nylon 6 components, addressing the increasing demand for sustainable manufacturing practices.

Market Analysis for Nylon 6 Industrial Applications

The global market for Nylon 6 industrial components has demonstrated robust growth over the past decade, with a compound annual growth rate exceeding 5% since 2015. This growth is primarily driven by increasing demand across automotive, electrical and electronics, consumer goods, and industrial machinery sectors. The automotive industry remains the largest consumer of Nylon 6 components, accounting for approximately 35% of total market consumption, particularly for under-hood components where heat resistance and durability are critical requirements.

Market research indicates that Asia-Pacific currently dominates the Nylon 6 industrial components market, representing nearly 45% of global consumption. This regional dominance is attributed to rapid industrialization, expanding manufacturing bases, and increasing automotive production in countries like China, India, and South Korea. North America and Europe follow with market shares of approximately 25% and 20% respectively, where demand is primarily driven by technological advancements and stringent quality standards.

The market segmentation for Nylon 6 industrial components reveals distinct application categories with varying growth trajectories. Mechanical parts such as gears, bearings, and bushings constitute about 30% of the market, while electrical components including connectors and insulators represent roughly 25%. Automotive components account for another significant segment at 35%, with the remaining 10% distributed across various specialized applications.

Price sensitivity analysis shows that while raw material costs for Nylon 6 fluctuate with petroleum prices, manufacturers are increasingly focused on value-added properties rather than competing solely on price. Premium-grade Nylon 6 components with enhanced properties such as glass-fiber reinforcement, flame retardancy, or improved heat stabilization command price premiums of 15-30% over standard grades.

Market forecasts project continued growth for Nylon 6 industrial components, with particular expansion in emerging economies. The push toward lightweight materials in automotive and aerospace applications presents significant opportunities, as Nylon 6 offers an excellent strength-to-weight ratio compared to traditional metals. Additionally, the growing emphasis on sustainable manufacturing practices is driving innovation in bio-based and recycled Nylon 6 formulations.

Customer demand trends indicate increasing requirements for customized Nylon 6 components with specific performance characteristics. Engineering-grade Nylon 6 with enhanced mechanical properties, chemical resistance, and dimensional stability is experiencing the highest growth rate within the market. Furthermore, the integration of Nylon 6 components into smart manufacturing systems and IoT applications is creating new market niches with premium pricing potential.

Market research indicates that Asia-Pacific currently dominates the Nylon 6 industrial components market, representing nearly 45% of global consumption. This regional dominance is attributed to rapid industrialization, expanding manufacturing bases, and increasing automotive production in countries like China, India, and South Korea. North America and Europe follow with market shares of approximately 25% and 20% respectively, where demand is primarily driven by technological advancements and stringent quality standards.

The market segmentation for Nylon 6 industrial components reveals distinct application categories with varying growth trajectories. Mechanical parts such as gears, bearings, and bushings constitute about 30% of the market, while electrical components including connectors and insulators represent roughly 25%. Automotive components account for another significant segment at 35%, with the remaining 10% distributed across various specialized applications.

Price sensitivity analysis shows that while raw material costs for Nylon 6 fluctuate with petroleum prices, manufacturers are increasingly focused on value-added properties rather than competing solely on price. Premium-grade Nylon 6 components with enhanced properties such as glass-fiber reinforcement, flame retardancy, or improved heat stabilization command price premiums of 15-30% over standard grades.

Market forecasts project continued growth for Nylon 6 industrial components, with particular expansion in emerging economies. The push toward lightweight materials in automotive and aerospace applications presents significant opportunities, as Nylon 6 offers an excellent strength-to-weight ratio compared to traditional metals. Additionally, the growing emphasis on sustainable manufacturing practices is driving innovation in bio-based and recycled Nylon 6 formulations.

Customer demand trends indicate increasing requirements for customized Nylon 6 components with specific performance characteristics. Engineering-grade Nylon 6 with enhanced mechanical properties, chemical resistance, and dimensional stability is experiencing the highest growth rate within the market. Furthermore, the integration of Nylon 6 components into smart manufacturing systems and IoT applications is creating new market niches with premium pricing potential.

Current Challenges in Nylon 6 Processing

Despite significant advancements in Nylon 6 processing technologies, manufacturers continue to face several critical challenges that impact product quality, production efficiency, and cost-effectiveness. One of the primary obstacles is moisture sensitivity during processing. Nylon 6 is highly hygroscopic, absorbing atmospheric moisture rapidly, which necessitates thorough drying before processing. Inadequate drying leads to hydrolytic degradation during high-temperature processing, resulting in reduced molecular weight, compromised mechanical properties, and visible surface defects in the final components.

Thermal degradation presents another significant challenge, particularly in processes requiring extended residence times at elevated temperatures. The processing window for Nylon 6 is relatively narrow, with degradation occurring at temperatures above 290°C, yet proper flow characteristics often require temperatures approaching this threshold. This creates a delicate balance between achieving adequate flow and preventing material breakdown.

Dimensional stability issues continue to plague manufacturers of precision components. Nylon 6's semi-crystalline nature results in significant shrinkage during cooling, with shrinkage rates varying based on processing conditions, part geometry, and crystallization kinetics. This variability makes it difficult to maintain tight tolerances, especially for complex geometries or components with varying wall thicknesses.

Additive compatibility and dispersion remain problematic areas. While additives such as glass fibers, flame retardants, and impact modifiers enhance specific properties, they often create processing complications. Achieving uniform dispersion without fiber breakage or additive degradation requires precise control of processing parameters that can be difficult to maintain consistently in industrial settings.

Surface quality defects, including flow marks, weld lines, and sink marks, continue to challenge manufacturers, particularly in visible or high-performance applications. These defects often result from suboptimal processing conditions, mold design limitations, or material inconsistencies, requiring extensive troubleshooting and process refinement.

Recycling and sustainability concerns have gained prominence as environmental regulations tighten globally. Processing recycled Nylon 6 presents unique challenges due to potential contamination, variable moisture content, and degradation from previous processing cycles. Maintaining consistent properties when incorporating recycled content demands sophisticated blending strategies and enhanced process controls.

Lastly, process standardization across different equipment platforms remains elusive. Variations in machine designs, control systems, and sensing capabilities create inconsistencies when transferring processes between production lines or facilities, necessitating extensive revalidation and adjustment of processing parameters.

Thermal degradation presents another significant challenge, particularly in processes requiring extended residence times at elevated temperatures. The processing window for Nylon 6 is relatively narrow, with degradation occurring at temperatures above 290°C, yet proper flow characteristics often require temperatures approaching this threshold. This creates a delicate balance between achieving adequate flow and preventing material breakdown.

Dimensional stability issues continue to plague manufacturers of precision components. Nylon 6's semi-crystalline nature results in significant shrinkage during cooling, with shrinkage rates varying based on processing conditions, part geometry, and crystallization kinetics. This variability makes it difficult to maintain tight tolerances, especially for complex geometries or components with varying wall thicknesses.

Additive compatibility and dispersion remain problematic areas. While additives such as glass fibers, flame retardants, and impact modifiers enhance specific properties, they often create processing complications. Achieving uniform dispersion without fiber breakage or additive degradation requires precise control of processing parameters that can be difficult to maintain consistently in industrial settings.

Surface quality defects, including flow marks, weld lines, and sink marks, continue to challenge manufacturers, particularly in visible or high-performance applications. These defects often result from suboptimal processing conditions, mold design limitations, or material inconsistencies, requiring extensive troubleshooting and process refinement.

Recycling and sustainability concerns have gained prominence as environmental regulations tighten globally. Processing recycled Nylon 6 presents unique challenges due to potential contamination, variable moisture content, and degradation from previous processing cycles. Maintaining consistent properties when incorporating recycled content demands sophisticated blending strategies and enhanced process controls.

Lastly, process standardization across different equipment platforms remains elusive. Variations in machine designs, control systems, and sensing capabilities create inconsistencies when transferring processes between production lines or facilities, necessitating extensive revalidation and adjustment of processing parameters.

Current Processing Methods and Guidelines

01 Manufacturing processes for Nylon 6

Various manufacturing processes have been developed for producing Nylon 6 with improved properties. These processes include polymerization techniques, extrusion methods, and specialized treatments to enhance the polymer's characteristics. The manufacturing processes focus on controlling molecular weight, crystallinity, and other parameters to achieve desired mechanical and thermal properties in the final product.- Manufacturing processes for Nylon 6: Various manufacturing processes have been developed for producing Nylon 6 with improved properties. These processes include specific polymerization techniques, catalyst systems, and reaction conditions that affect the molecular weight, crystallinity, and overall quality of the polymer. Innovations in this area focus on enhancing production efficiency, reducing energy consumption, and improving the consistency of the final product.

- Nylon 6 composite materials: Nylon 6 can be combined with various fillers, reinforcements, and other polymers to create composite materials with enhanced properties. These composites often exhibit improved mechanical strength, thermal stability, chemical resistance, or specific functional characteristics. Common additives include glass fibers, carbon fibers, clay nanoparticles, and other polymeric materials that create synergistic effects with the Nylon 6 matrix.

- Nylon 6 fiber applications: Nylon 6 fibers are widely used in textile applications due to their excellent mechanical properties, durability, and processability. Innovations in this area include specialized spinning techniques, fiber treatments, and modifications to enhance properties such as strength, elasticity, moisture management, and dyeability. These fibers are used in apparel, industrial textiles, carpets, and technical applications requiring high performance materials.

- Recycling and sustainability of Nylon 6: Methods for recycling Nylon 6 materials and improving the sustainability of Nylon 6 production have been developed. These include chemical recycling processes that break down the polymer into its monomer components, mechanical recycling techniques, and the use of bio-based feedstocks for more environmentally friendly production. These innovations aim to reduce the environmental impact of Nylon 6 throughout its lifecycle.

- Modified Nylon 6 with enhanced properties: Chemical and physical modifications of Nylon 6 can enhance its properties for specific applications. These modifications include copolymerization with other monomers, grafting of functional groups, and blending with other polymers. Such modifications can improve properties like flame retardancy, impact resistance, barrier properties, and thermal stability, expanding the range of applications for Nylon 6-based materials.

02 Nylon 6 composite materials

Nylon 6 is frequently used as a matrix for composite materials, combining it with various fillers and reinforcements to enhance its properties. These composites may incorporate glass fibers, carbon fibers, mineral fillers, or nanomaterials to improve mechanical strength, thermal stability, and dimensional stability. The resulting composite materials offer superior performance compared to pure Nylon 6 for specialized applications.Expand Specific Solutions03 Nylon 6 fiber applications

Nylon 6 fibers are widely used in textile applications due to their excellent mechanical properties, durability, and processability. These fibers can be modified through various treatments to enhance properties such as dyeability, moisture absorption, and UV resistance. Applications include apparel, industrial textiles, carpets, and technical fabrics where strength and durability are required.Expand Specific Solutions04 Recycling and sustainability of Nylon 6

Methods for recycling Nylon 6 materials have been developed to address environmental concerns and promote sustainability. These include chemical depolymerization to recover caprolactam monomer, mechanical recycling processes, and techniques to incorporate recycled Nylon 6 into new products without significant loss of properties. Sustainable approaches also include bio-based alternatives and reducing environmental impact during production.Expand Specific Solutions05 Nylon 6 blends and modifications

Nylon 6 can be blended with other polymers or modified with various additives to enhance specific properties. These modifications may include impact modifiers, flame retardants, plasticizers, and compatibilizers. Chemical modifications such as copolymerization or grafting can also be performed to tailor the polymer's properties for specific applications, resulting in materials with improved heat resistance, chemical resistance, or processing characteristics.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The Nylon 6 industrial components market is currently in a mature growth phase, characterized by established processing standards and widespread industrial adoption. The global market size for Nylon 6 components is substantial, estimated at several billion dollars annually with steady growth projections. From a technical maturity perspective, companies like Ascend Performance Materials, Kingfa Sci. & Tech., and SABIC Global Technologies lead with advanced processing capabilities and proprietary formulations. Chinese manufacturers including Shanghai PRET Composites and Zhejiang Pret Advanced Materials are rapidly advancing their technical expertise, while academic institutions such as Beijing University of Chemical Technology and Donghua University contribute significantly to standards development. The competitive landscape shows increasing focus on high-performance applications and sustainability, with companies like Kuraray and Fujian Highsun developing specialized processing techniques for emerging industrial applications.

Ascend Performance Materials Operations LLC

Technical Solution: Ascend Performance Materials has pioneered advanced processing guidelines for Nylon 6 industrial components through their HiDura™ platform, which incorporates precise molecular weight control (15,000-30,000 g/mol) and specialized nucleating agents to enhance crystallization kinetics. Their technical approach includes a proprietary three-stage drying protocol (80°C for 4 hours, followed by 100°C for 2 hours under vacuum) that achieves moisture content below 0.1%, significantly reducing hydrolytic degradation during processing. Ascend's standards specify injection molding parameters with precise pressure profiles (80-120 MPa injection pressure with 40-60 MPa holding pressure) and controlled cooling rates to achieve uniform crystallinity distribution. Their guidelines include detailed specifications for reinforced grades, with glass fiber orientation optimization techniques that maintain fiber length above 70% of original during processing, resulting in components with enhanced mechanical properties (tensile strength improvements of 30-40% compared to standard processing).

Strengths: Industry-leading moisture control technology resulting in superior dimensional stability; comprehensive quality control systems with real-time monitoring capabilities. Weaknesses: Implementation requires significant capital investment in specialized equipment; processing guidelines are complex and require extensive operator training.

Beijing University of Chemical Technology

Technical Solution: Beijing University of Chemical Technology has developed comprehensive processing standards for Nylon 6 industrial components through their polymer engineering research center. Their approach includes scientifically optimized processing parameters based on rheological characterization, with specific melt viscosity ranges (150-300 Pa·s at processing temperatures) correlated to molecular weight distribution. Their guidelines specify precise injection molding parameters with controlled injection speeds (50-100 mm/s) and holding pressures (40-70% of injection pressure) to minimize internal stresses. The university's research has established correlations between processing conditions and crystallinity development, with cooling rate recommendations (8-12°C/min) to achieve optimal crystalline structure (30-35% crystallinity) for maximum mechanical performance. Their standards include detailed quality control protocols with non-destructive testing methods (ultrasonic and infrared spectroscopy) to verify internal structure consistency. The university has also developed specialized processing guidelines for recycled Nylon 6, with recommendations for compatibilizers and processing aids to maintain properties comparable to virgin material.

Strengths: Research-backed processing parameters with scientific validation; comprehensive understanding of structure-property relationships in processed components. Weaknesses: Guidelines may require adaptation for industrial-scale implementation; less focus on production efficiency compared to commercial entities.

Key Patents and Technical Innovations

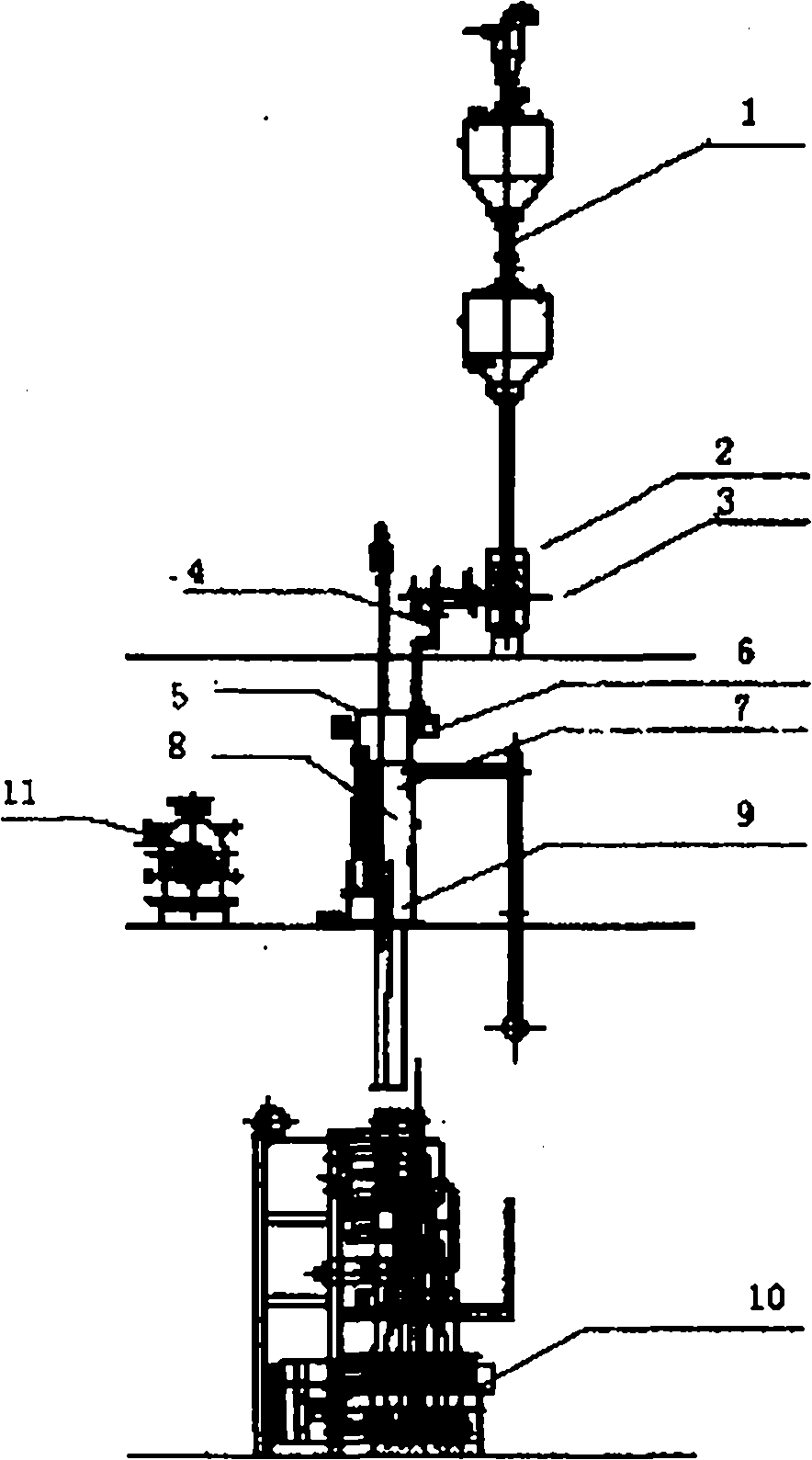

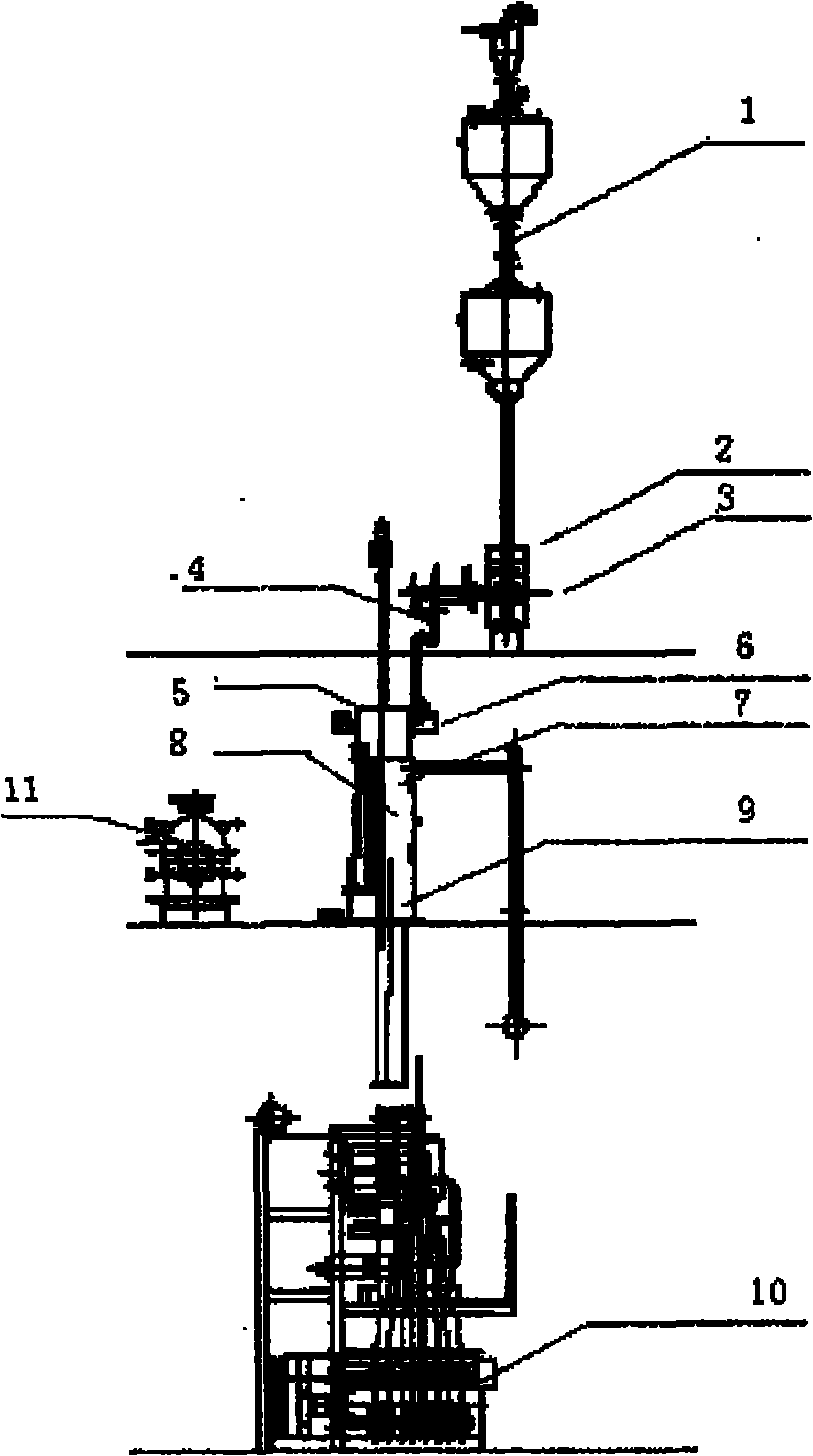

Production process of 9 to 14-dtex nylon-6 high-orientation fibers

PatentActiveCN101922054A

Innovation

- By controlling the heating temperature of nylon 6 slices, the extrusion process, the uniform distribution of the melt, cooling conditions and tension control, a 9-14 decitex production process is adopted, including dry nylon 6 slices being heated and melted in a screw extruder , then measured by the spinning metering pump and evenly distributed by the sand cup, the spinneret ejects the fiber at high pressure, and is cooled and formed in the side blowing air of constant temperature and humidity, and finally wound into a silk cake on the winding machine.

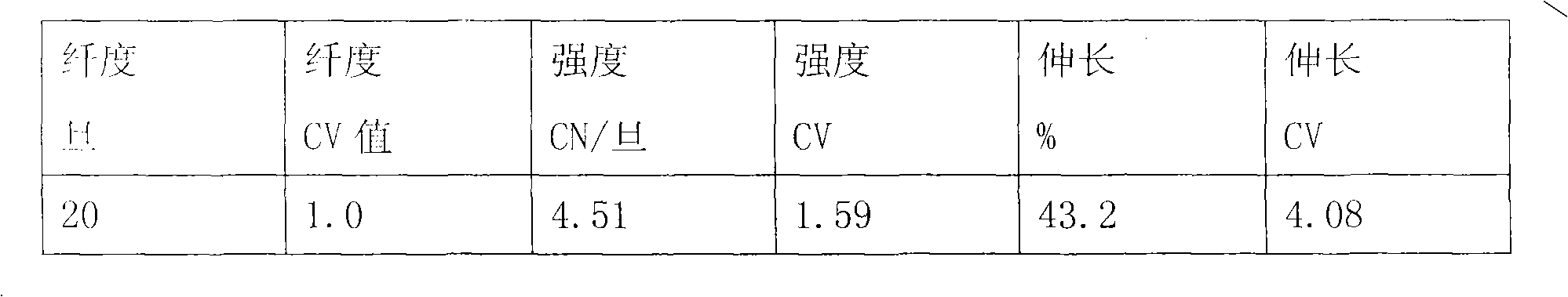

Process for producing 20-denier and 1-pore semi-dull fully-drawn fibers of nylon 6

PatentActiveCN102041560A

Innovation

- 20D nylon 6 semi-dull slices are heated, extruded and melted. They are delivered to the spinning box through equal-length pipes outside the box, evenly distributed into the spinning components, and ejected through the spinneret at high pressure to form fiber filaments. Under constant temperature and humidity conditions It is cooled and formed, and passed through a winding machine and a drafting roller to form a 20D nylon 6 semi-dull fully drafted fiber tow.

Environmental Impact and Sustainability Considerations

The environmental footprint of Nylon 6 industrial components has become increasingly significant as sustainability considerations gain prominence in manufacturing sectors. Life cycle assessment (LCA) studies indicate that Nylon 6 production generates substantial greenhouse gas emissions, primarily during the caprolactam synthesis phase, which accounts for approximately 70% of the total carbon footprint. Energy consumption during processing represents another critical environmental concern, with injection molding operations typically requiring 3-7 kWh per kilogram of processed material.

Water usage in Nylon 6 manufacturing presents additional sustainability challenges, particularly in the polymer washing and cooling processes. Industrial facilities typically consume 4-6 cubic meters of water per ton of Nylon 6 produced, with potential for contamination by caprolactam residues and other processing additives if wastewater treatment is inadequate.

Recent advancements in sustainable processing guidelines have focused on closed-loop manufacturing systems that recover and reuse process water, reducing consumption by up to 40% compared to traditional methods. Several industry leaders have implemented zero liquid discharge (ZLD) systems, establishing new benchmarks for water conservation in Nylon 6 component production.

Waste management represents another critical dimension of environmental impact. While Nylon 6 offers excellent recyclability compared to many other engineering plastics, industrial scrap rates typically range from 5-15% depending on component complexity and processing parameters. Standards such as ISO 14001 and industry-specific guidelines now mandate minimum recycled content requirements and establish protocols for in-process material recovery.

Energy efficiency improvements have been codified in recent processing guidelines, with recommendations for variable frequency drives on injection molding equipment, heat recovery systems, and optimized cooling cycles. These measures can reduce energy consumption by 15-30% while maintaining component quality and performance specifications.

Bio-based alternatives to traditional petroleum-derived caprolactam are emerging as promising pathways toward reduced environmental impact. Several manufacturers have developed partially bio-based Nylon 6 variants with up to 40% renewable content, though these materials often require modified processing parameters to maintain mechanical properties equivalent to conventional formulations.

End-of-life considerations have also been incorporated into recent standards, with design-for-disassembly principles becoming increasingly prominent in component specifications. This approach facilitates material recovery and supports circular economy objectives by ensuring that Nylon 6 components can be effectively separated from multi-material assemblies at end-of-life.

Water usage in Nylon 6 manufacturing presents additional sustainability challenges, particularly in the polymer washing and cooling processes. Industrial facilities typically consume 4-6 cubic meters of water per ton of Nylon 6 produced, with potential for contamination by caprolactam residues and other processing additives if wastewater treatment is inadequate.

Recent advancements in sustainable processing guidelines have focused on closed-loop manufacturing systems that recover and reuse process water, reducing consumption by up to 40% compared to traditional methods. Several industry leaders have implemented zero liquid discharge (ZLD) systems, establishing new benchmarks for water conservation in Nylon 6 component production.

Waste management represents another critical dimension of environmental impact. While Nylon 6 offers excellent recyclability compared to many other engineering plastics, industrial scrap rates typically range from 5-15% depending on component complexity and processing parameters. Standards such as ISO 14001 and industry-specific guidelines now mandate minimum recycled content requirements and establish protocols for in-process material recovery.

Energy efficiency improvements have been codified in recent processing guidelines, with recommendations for variable frequency drives on injection molding equipment, heat recovery systems, and optimized cooling cycles. These measures can reduce energy consumption by 15-30% while maintaining component quality and performance specifications.

Bio-based alternatives to traditional petroleum-derived caprolactam are emerging as promising pathways toward reduced environmental impact. Several manufacturers have developed partially bio-based Nylon 6 variants with up to 40% renewable content, though these materials often require modified processing parameters to maintain mechanical properties equivalent to conventional formulations.

End-of-life considerations have also been incorporated into recent standards, with design-for-disassembly principles becoming increasingly prominent in component specifications. This approach facilitates material recovery and supports circular economy objectives by ensuring that Nylon 6 components can be effectively separated from multi-material assemblies at end-of-life.

Quality Control and Testing Protocols

Quality control and testing protocols for Nylon 6 industrial components require systematic approaches to ensure consistent performance and reliability. The implementation of standardized testing methodologies begins with raw material verification, where incoming Nylon 6 resins undergo moisture content analysis, molecular weight distribution tests, and contaminant screening. These preliminary assessments establish baseline material properties that significantly influence downstream processing and final component quality.

Physical property testing constitutes a critical aspect of quality assurance, encompassing tensile strength measurements (ASTM D638), impact resistance evaluation (ASTM D256), and flexural modulus determination (ASTM D790). These standardized tests provide quantifiable metrics for comparing component performance against established specifications. Additionally, thermal property assessments including heat deflection temperature (ASTM D648) and melting point verification via Differential Scanning Calorimetry (DSC) ensure components meet operational temperature requirements.

Dimensional accuracy verification represents another essential protocol, particularly for precision-engineered components. Coordinate Measuring Machines (CMMs) and optical scanning technologies enable three-dimensional inspection with tolerances as tight as ±0.05mm. Statistical Process Control (SPC) methodologies applied to dimensional data help identify process drift before specification limits are exceeded.

Environmental resistance testing protocols evaluate component durability under various operational conditions. Accelerated aging chambers simulate UV exposure, temperature cycling, and chemical contact scenarios, while humidity resistance tests assess dimensional stability and mechanical property retention in moisture-rich environments. For components destined for automotive or aerospace applications, specialized fluid compatibility tests examine resistance to fuels, lubricants, and hydraulic fluids.

Non-destructive testing (NDT) techniques provide valuable quality insights without compromising component integrity. Ultrasonic inspection detects internal voids or inclusions, while X-ray computed tomography generates three-dimensional visualizations of internal structures. These advanced NDT methods complement traditional visual inspection protocols and are particularly valuable for safety-critical components.

Certification documentation represents the final element of comprehensive quality control systems. Each production batch requires traceability documentation linking raw material certifications, process parameters, and test results. This documentation chain enables root cause analysis of field failures and supports continuous improvement initiatives. Many industries now require digital quality management systems that maintain this documentation in searchable, secure databases accessible throughout the component lifecycle.

Physical property testing constitutes a critical aspect of quality assurance, encompassing tensile strength measurements (ASTM D638), impact resistance evaluation (ASTM D256), and flexural modulus determination (ASTM D790). These standardized tests provide quantifiable metrics for comparing component performance against established specifications. Additionally, thermal property assessments including heat deflection temperature (ASTM D648) and melting point verification via Differential Scanning Calorimetry (DSC) ensure components meet operational temperature requirements.

Dimensional accuracy verification represents another essential protocol, particularly for precision-engineered components. Coordinate Measuring Machines (CMMs) and optical scanning technologies enable three-dimensional inspection with tolerances as tight as ±0.05mm. Statistical Process Control (SPC) methodologies applied to dimensional data help identify process drift before specification limits are exceeded.

Environmental resistance testing protocols evaluate component durability under various operational conditions. Accelerated aging chambers simulate UV exposure, temperature cycling, and chemical contact scenarios, while humidity resistance tests assess dimensional stability and mechanical property retention in moisture-rich environments. For components destined for automotive or aerospace applications, specialized fluid compatibility tests examine resistance to fuels, lubricants, and hydraulic fluids.

Non-destructive testing (NDT) techniques provide valuable quality insights without compromising component integrity. Ultrasonic inspection detects internal voids or inclusions, while X-ray computed tomography generates three-dimensional visualizations of internal structures. These advanced NDT methods complement traditional visual inspection protocols and are particularly valuable for safety-critical components.

Certification documentation represents the final element of comprehensive quality control systems. Each production batch requires traceability documentation linking raw material certifications, process parameters, and test results. This documentation chain enables root cause analysis of field failures and supports continuous improvement initiatives. Many industries now require digital quality management systems that maintain this documentation in searchable, secure databases accessible throughout the component lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!