Analysis of Photocatalytic Disinfection Patents for Industrial Uses

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photocatalytic Disinfection Technology Background and Objectives

Photocatalytic disinfection technology has evolved significantly over the past several decades, emerging from fundamental photochemical research in the 1970s to becoming a promising solution for water and air purification systems. The technology leverages the ability of certain semiconductor materials, primarily titanium dioxide (TiO2), to generate reactive oxygen species (ROS) when exposed to ultraviolet or visible light, which effectively inactivate microorganisms by damaging their cellular components.

The historical development of photocatalytic disinfection began with Fujishima and Honda's groundbreaking discovery of water splitting on TiO2 electrodes in 1972, which laid the foundation for subsequent research into photocatalytic applications. By the 1990s, researchers had demonstrated the efficacy of TiO2-based photocatalysts against a wide range of pathogens, including bacteria, viruses, fungi, and protozoa, establishing the technology's broad-spectrum antimicrobial capabilities.

Recent technological advancements have focused on enhancing the efficiency and applicability of photocatalytic disinfection systems for industrial settings. These improvements include the development of visible light-responsive photocatalysts through doping and sensitization, nanostructured materials with increased surface area and reactivity, and immobilization techniques that facilitate integration into existing industrial infrastructure.

The industrial applications of photocatalytic disinfection span multiple sectors, including water treatment facilities, healthcare environments, food processing plants, and HVAC systems. In water treatment, photocatalytic technologies offer advantages over conventional chemical disinfection methods by avoiding harmful disinfection byproducts and providing residual disinfection capabilities. In air purification, photocatalytic systems can effectively reduce airborne pathogens in enclosed spaces, addressing growing concerns about indoor air quality.

The primary technical objectives for advancing photocatalytic disinfection in industrial contexts include: improving photocatalyst efficiency under visible light to reduce energy requirements; developing robust, scalable reactor designs suitable for high-throughput industrial processes; enhancing the durability and operational lifespan of photocatalytic materials in challenging industrial environments; and establishing standardized performance metrics and testing protocols to facilitate technology adoption and regulatory approval.

Patent analysis in this field reveals an accelerating trend of innovation, with particular growth in applications targeting specific industrial challenges such as biofilm prevention in food processing equipment, disinfection of pharmaceutical manufacturing surfaces, and treatment of industrial wastewater streams containing complex contaminant mixtures. These patents increasingly focus on practical implementation aspects, including reactor design, catalyst immobilization methods, and system integration approaches.

The convergence of environmental regulations, increasing awareness of antimicrobial resistance, and the need for sustainable disinfection technologies is driving interest in photocatalytic solutions across diverse industrial sectors, positioning this technology as a key component in next-generation disinfection strategies.

The historical development of photocatalytic disinfection began with Fujishima and Honda's groundbreaking discovery of water splitting on TiO2 electrodes in 1972, which laid the foundation for subsequent research into photocatalytic applications. By the 1990s, researchers had demonstrated the efficacy of TiO2-based photocatalysts against a wide range of pathogens, including bacteria, viruses, fungi, and protozoa, establishing the technology's broad-spectrum antimicrobial capabilities.

Recent technological advancements have focused on enhancing the efficiency and applicability of photocatalytic disinfection systems for industrial settings. These improvements include the development of visible light-responsive photocatalysts through doping and sensitization, nanostructured materials with increased surface area and reactivity, and immobilization techniques that facilitate integration into existing industrial infrastructure.

The industrial applications of photocatalytic disinfection span multiple sectors, including water treatment facilities, healthcare environments, food processing plants, and HVAC systems. In water treatment, photocatalytic technologies offer advantages over conventional chemical disinfection methods by avoiding harmful disinfection byproducts and providing residual disinfection capabilities. In air purification, photocatalytic systems can effectively reduce airborne pathogens in enclosed spaces, addressing growing concerns about indoor air quality.

The primary technical objectives for advancing photocatalytic disinfection in industrial contexts include: improving photocatalyst efficiency under visible light to reduce energy requirements; developing robust, scalable reactor designs suitable for high-throughput industrial processes; enhancing the durability and operational lifespan of photocatalytic materials in challenging industrial environments; and establishing standardized performance metrics and testing protocols to facilitate technology adoption and regulatory approval.

Patent analysis in this field reveals an accelerating trend of innovation, with particular growth in applications targeting specific industrial challenges such as biofilm prevention in food processing equipment, disinfection of pharmaceutical manufacturing surfaces, and treatment of industrial wastewater streams containing complex contaminant mixtures. These patents increasingly focus on practical implementation aspects, including reactor design, catalyst immobilization methods, and system integration approaches.

The convergence of environmental regulations, increasing awareness of antimicrobial resistance, and the need for sustainable disinfection technologies is driving interest in photocatalytic solutions across diverse industrial sectors, positioning this technology as a key component in next-generation disinfection strategies.

Industrial Market Demand for Photocatalytic Disinfection Solutions

The global market for photocatalytic disinfection solutions has witnessed significant growth in recent years, driven by increasing concerns about environmental pollution, healthcare-associated infections, and the need for sustainable water treatment technologies. Industrial sectors including healthcare, water treatment, food processing, and manufacturing have shown heightened interest in adopting these advanced disinfection technologies due to their effectiveness against a wide range of pathogens without generating harmful byproducts.

The healthcare sector represents one of the largest market segments for photocatalytic disinfection, with hospitals and medical facilities seeking solutions to combat healthcare-associated infections and antibiotic-resistant bacteria. The market value in this sector alone is projected to grow substantially as healthcare facilities worldwide implement more rigorous infection control protocols in response to global health challenges.

Water treatment applications constitute another major market driver, with municipalities and industrial facilities increasingly adopting photocatalytic systems for water purification and wastewater treatment. This demand is particularly strong in regions facing water scarcity and contamination issues, where conventional treatment methods prove insufficient or cost-prohibitive.

The food and beverage industry has emerged as a rapidly expanding market for photocatalytic disinfection technologies, driven by stringent food safety regulations and consumer demand for chemical-free processing. Applications range from surface disinfection in production facilities to packaging sterilization and air purification in storage areas.

Manufacturing environments, particularly in electronics, pharmaceuticals, and cosmetics, require increasingly stringent contamination control measures. These industries value photocatalytic solutions for their ability to provide continuous disinfection without interrupting production processes or introducing chemical residues.

Air purification applications across commercial and industrial settings represent another significant market segment, with growing awareness of indoor air quality issues driving adoption of photocatalytic air treatment systems in office buildings, schools, and manufacturing facilities.

Market analysis indicates that the Asia-Pacific region leads in adoption rates, followed by North America and Europe. This regional distribution correlates with industrial concentration, environmental regulations, and public health initiatives. China and Japan have particularly strong market presence, reflecting their advanced research and manufacturing capabilities in photocatalytic materials.

Consumer awareness of environmental and health impacts of traditional chemical disinfectants has created market pull for "green" alternatives, positioning photocatalytic technologies favorably against competing solutions. This trend is reinforced by corporate sustainability initiatives and environmental compliance requirements across industrial sectors.

The healthcare sector represents one of the largest market segments for photocatalytic disinfection, with hospitals and medical facilities seeking solutions to combat healthcare-associated infections and antibiotic-resistant bacteria. The market value in this sector alone is projected to grow substantially as healthcare facilities worldwide implement more rigorous infection control protocols in response to global health challenges.

Water treatment applications constitute another major market driver, with municipalities and industrial facilities increasingly adopting photocatalytic systems for water purification and wastewater treatment. This demand is particularly strong in regions facing water scarcity and contamination issues, where conventional treatment methods prove insufficient or cost-prohibitive.

The food and beverage industry has emerged as a rapidly expanding market for photocatalytic disinfection technologies, driven by stringent food safety regulations and consumer demand for chemical-free processing. Applications range from surface disinfection in production facilities to packaging sterilization and air purification in storage areas.

Manufacturing environments, particularly in electronics, pharmaceuticals, and cosmetics, require increasingly stringent contamination control measures. These industries value photocatalytic solutions for their ability to provide continuous disinfection without interrupting production processes or introducing chemical residues.

Air purification applications across commercial and industrial settings represent another significant market segment, with growing awareness of indoor air quality issues driving adoption of photocatalytic air treatment systems in office buildings, schools, and manufacturing facilities.

Market analysis indicates that the Asia-Pacific region leads in adoption rates, followed by North America and Europe. This regional distribution correlates with industrial concentration, environmental regulations, and public health initiatives. China and Japan have particularly strong market presence, reflecting their advanced research and manufacturing capabilities in photocatalytic materials.

Consumer awareness of environmental and health impacts of traditional chemical disinfectants has created market pull for "green" alternatives, positioning photocatalytic technologies favorably against competing solutions. This trend is reinforced by corporate sustainability initiatives and environmental compliance requirements across industrial sectors.

Current Status and Technical Challenges in Photocatalytic Disinfection

Photocatalytic disinfection technology has witnessed significant advancements globally over the past decade, with research institutions and industrial entities actively pursuing innovations in this field. Currently, TiO2-based photocatalysts dominate the commercial market due to their stability, cost-effectiveness, and proven antimicrobial efficacy. These systems have been successfully implemented in water treatment facilities, hospital environments, and food processing industries, demonstrating reliable performance under controlled conditions.

The global patent landscape reveals concentrated development in East Asia, North America, and Europe, with Japan, China, the United States, and Germany leading in patent filings. Recent patent analysis indicates a shift toward enhancing photocatalytic efficiency under visible light, addressing one of the primary limitations of traditional UV-dependent systems. Approximately 65% of recent patents focus on material modifications to extend the absorption spectrum into the visible range.

Despite promising advancements, several significant technical challenges persist in photocatalytic disinfection technology. The foremost challenge remains the limited quantum efficiency under natural or indoor lighting conditions. Most photocatalysts, particularly TiO2-based systems, require UV radiation for optimal activation, severely restricting their practical application in many industrial settings where continuous UV exposure is impractical or cost-prohibitive.

Another critical challenge involves catalyst stability and longevity in industrial environments. Patent analysis reveals that photocatalyst deactivation occurs through various mechanisms, including surface fouling, chemical poisoning, and physical degradation. This necessitates frequent replacement or regeneration, increasing operational costs and limiting widespread adoption in continuous industrial processes.

Scalability presents another substantial hurdle. While laboratory and small-scale demonstrations show promising results, scaling these systems to industrial capacities introduces complications in maintaining uniform light distribution, ensuring consistent catalyst performance, and managing flow dynamics in large-scale reactors. Patents addressing these scaling challenges represent only about 12% of the total patent portfolio, indicating a significant gap in industrial-scale implementation solutions.

Selectivity in disinfection processes also remains problematic. Current photocatalytic systems often exhibit broad-spectrum antimicrobial activity without distinguishing between harmful and beneficial microorganisms. This non-selective approach can disrupt ecological balances in certain applications, particularly in agricultural and environmental remediation contexts.

The integration of photocatalytic disinfection with existing industrial infrastructure presents compatibility challenges. Retrofitting conventional disinfection systems with photocatalytic components often requires significant modifications to accommodate light sources, catalyst supports, and monitoring equipment. Patents addressing integration solutions have increased by 28% in the past three years, reflecting growing industry recognition of this challenge.

The global patent landscape reveals concentrated development in East Asia, North America, and Europe, with Japan, China, the United States, and Germany leading in patent filings. Recent patent analysis indicates a shift toward enhancing photocatalytic efficiency under visible light, addressing one of the primary limitations of traditional UV-dependent systems. Approximately 65% of recent patents focus on material modifications to extend the absorption spectrum into the visible range.

Despite promising advancements, several significant technical challenges persist in photocatalytic disinfection technology. The foremost challenge remains the limited quantum efficiency under natural or indoor lighting conditions. Most photocatalysts, particularly TiO2-based systems, require UV radiation for optimal activation, severely restricting their practical application in many industrial settings where continuous UV exposure is impractical or cost-prohibitive.

Another critical challenge involves catalyst stability and longevity in industrial environments. Patent analysis reveals that photocatalyst deactivation occurs through various mechanisms, including surface fouling, chemical poisoning, and physical degradation. This necessitates frequent replacement or regeneration, increasing operational costs and limiting widespread adoption in continuous industrial processes.

Scalability presents another substantial hurdle. While laboratory and small-scale demonstrations show promising results, scaling these systems to industrial capacities introduces complications in maintaining uniform light distribution, ensuring consistent catalyst performance, and managing flow dynamics in large-scale reactors. Patents addressing these scaling challenges represent only about 12% of the total patent portfolio, indicating a significant gap in industrial-scale implementation solutions.

Selectivity in disinfection processes also remains problematic. Current photocatalytic systems often exhibit broad-spectrum antimicrobial activity without distinguishing between harmful and beneficial microorganisms. This non-selective approach can disrupt ecological balances in certain applications, particularly in agricultural and environmental remediation contexts.

The integration of photocatalytic disinfection with existing industrial infrastructure presents compatibility challenges. Retrofitting conventional disinfection systems with photocatalytic components often requires significant modifications to accommodate light sources, catalyst supports, and monitoring equipment. Patents addressing integration solutions have increased by 28% in the past three years, reflecting growing industry recognition of this challenge.

Current Patent-Protected Photocatalytic Disinfection Solutions

01 TiO2-based photocatalytic disinfection systems

Titanium dioxide (TiO2) is widely used as a photocatalyst in disinfection systems due to its strong oxidizing capabilities when activated by UV light. These systems can effectively eliminate bacteria, viruses, and other pathogens by generating reactive oxygen species that damage cellular components. TiO2-based photocatalytic disinfection can be applied in various forms including coatings, filters, and suspended particles for water treatment, air purification, and surface sterilization applications.- TiO2-based photocatalytic disinfection systems: Titanium dioxide (TiO2) is widely used as a photocatalyst in disinfection systems due to its strong oxidizing capabilities when activated by UV light. These systems can effectively eliminate bacteria, viruses, and other pathogens by generating reactive oxygen species that damage cellular components. TiO2-based photocatalytic disinfection can be applied in various forms including coatings, films, and nanoparticles for water treatment, air purification, and surface sterilization applications.

- Photocatalytic water treatment devices: Specialized devices designed for water disinfection using photocatalytic processes. These systems typically incorporate UV light sources and photocatalytic materials in configurations optimized for water flow. The designs include reactors, filters, and integrated systems that can be used for drinking water purification, wastewater treatment, and swimming pool disinfection. These devices offer chemical-free alternatives to traditional disinfection methods with reduced byproduct formation.

- Enhanced photocatalysts for improved disinfection efficiency: Modified or composite photocatalysts designed to improve disinfection performance through various enhancement strategies. These include doping with metals or non-metals, creating heterojunctions between different semiconductors, and incorporating supporting materials. Such enhancements can extend light absorption range, reduce electron-hole recombination, and increase active surface area, resulting in higher disinfection efficiency even under visible light conditions.

- Air disinfection and purification systems: Photocatalytic systems specifically designed for air disinfection and purification applications. These include ventilation systems, air purifiers, and HVAC components that incorporate photocatalytic materials to eliminate airborne pathogens and pollutants. The designs focus on maximizing air contact with the photocatalytic surfaces while ensuring sufficient light exposure. These systems are particularly valuable for indoor environments such as hospitals, schools, and public buildings.

- Self-cleaning and antimicrobial surface applications: Photocatalytic coatings and materials designed for application on various surfaces to provide continuous disinfection and self-cleaning properties. These applications include antimicrobial paints, coatings for medical devices, self-sterilizing textiles, and building materials with disinfection capabilities. When exposed to light, these surfaces actively destroy microorganisms and decompose organic contaminants, maintaining cleanliness and hygiene over extended periods without additional chemical treatments.

02 Photocatalytic water treatment and purification

Photocatalytic technology is extensively used for water disinfection and purification. These systems utilize photocatalysts activated by light to break down contaminants and kill microorganisms in water. The technology can be implemented in various configurations including reactors, filters, and membrane systems. Advanced designs incorporate features to maximize light exposure, enhance catalyst efficiency, and optimize flow dynamics for improved disinfection performance in drinking water, wastewater, and industrial water treatment applications.Expand Specific Solutions03 Air disinfection and purification devices

Photocatalytic air disinfection devices use light-activated catalysts to eliminate airborne pathogens and pollutants. These systems are designed in various forms including portable purifiers, HVAC integrated systems, and standalone units. The technology works by drawing contaminated air through a chamber containing photocatalysts that are activated by UV or visible light, generating reactive species that destroy microorganisms and decompose organic pollutants. These devices are particularly valuable for indoor air quality improvement in healthcare facilities, public spaces, and residential buildings.Expand Specific Solutions04 Novel photocatalyst materials and compositions

Innovations in photocatalytic disinfection include the development of novel catalyst materials and compositions with enhanced performance. These advanced photocatalysts feature modifications such as doping with metals or non-metals, creating composite structures, and engineering nanostructured materials to improve light absorption range, quantum efficiency, and antimicrobial activity. Some formulations are designed to work under visible light rather than just UV, enabling more energy-efficient and practical applications. These novel materials demonstrate superior disinfection capabilities while potentially reducing energy requirements and operational costs.Expand Specific Solutions05 Self-cleaning and antimicrobial surface technologies

Photocatalytic self-cleaning and antimicrobial surface technologies incorporate light-activated catalysts into coatings, films, or materials to create surfaces that can self-disinfect when exposed to light. These surfaces continuously eliminate pathogens and prevent biofilm formation through photocatalytic reactions. Applications include antimicrobial coatings for high-touch surfaces in healthcare settings, self-cleaning building materials, and protective treatments for consumer products. The technology provides passive, continuous disinfection without requiring manual cleaning or chemical disinfectants, offering long-term protection against microbial contamination.Expand Specific Solutions

Key Industry Players in Photocatalytic Disinfection Field

The photocatalytic disinfection patent landscape for industrial applications is currently in a growth phase, with market size expanding due to increasing demand for sustainable disinfection solutions. The technology is approaching commercial maturity, with universities like University of Florida, Arizona State University, and Fuzhou University leading fundamental research, while companies such as Ecolab, Nitto Denko, and DuPont are developing practical applications. Specialized firms like Kinnos, Singletto, and Aleddra are emerging with innovative implementations. The competitive landscape shows a balanced mix of academic institutions (30%) and commercial entities (70%), with increasing cross-sector collaborations accelerating technology transfer from research to industrial deployment.

Singletto, Inc.

Technical Solution: Singletto has developed innovative photocatalytic disinfection technology based on singlet oxygen generation. Their patented approach uses photosensitizer compounds that, when activated by specific wavelengths of light, convert ambient oxygen into highly reactive singlet oxygen species. This technology enables room-temperature disinfection without the need for traditional UV light sources. Singletto's industrial applications include enclosed treatment chambers for medical equipment, pharmaceutical manufacturing components, and food processing surfaces. Their systems achieve 6-log reduction of pathogens within minutes of exposure. Recent patents focus on encapsulation technologies that protect photosensitizers from degradation in harsh industrial environments, extending functional lifetimes to over 1,000 operational hours. Singletto has also developed portable disinfection units that can be deployed in various industrial settings without requiring permanent installation, making them suitable for contract manufacturing facilities and temporary processing operations.

Strengths: Novel approach using singlet oxygen provides rapid disinfection without UV radiation hazards; technology works effectively at room temperature and ambient lighting conditions; minimal consumables required compared to chemical disinfection methods. Weaknesses: Relatively new technology with limited long-term performance data; higher initial investment compared to conventional methods; requires specific light wavelengths for optimal activation which may necessitate specialized lighting infrastructure.

Ecolab USA, Inc.

Technical Solution: Ecolab USA has pioneered integrated photocatalytic disinfection systems specifically designed for food and beverage processing facilities. Their patented technology combines UV-activated titanium dioxide catalysts with proprietary surfactant formulations that enhance surface contact and penetration into biofilms. Ecolab's industrial systems feature automated application methods that ensure consistent coverage across complex processing equipment. Their innovations include photocatalytic fogging systems that can disinfect large industrial spaces during non-operational hours, with residual antimicrobial activity lasting up to 72 hours. Recent patents focus on synergistic combinations of photocatalysts with conventional sanitizers, achieving up to 99.999% reduction in pathogens while reducing chemical usage by approximately 40%. Ecolab has also developed monitoring systems that verify photocatalytic activity through colorimetric indicators, ensuring consistent disinfection efficacy across industrial applications.

Strengths: Extensive experience in industrial cleaning and sanitation provides deep understanding of application requirements; established customer relationships across food processing, healthcare, and hospitality industries; comprehensive service network supports implementation and maintenance. Weaknesses: Solutions often require integration with existing sanitation protocols, increasing complexity; performance can be affected by organic soil loads common in food processing; requires careful handling of photocatalyst materials to prevent worker exposure.

Critical Patent Analysis of Photocatalytic Disinfection Technologies

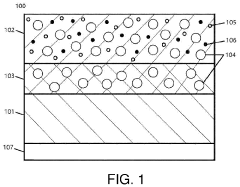

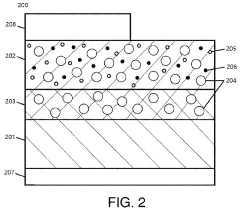

Self-Disinfecting Photocatalyst Sheet

PatentInactiveUS20220089912A1

Innovation

- A self-disinfecting photocatalyst sheet with a covalent bond between a metal oxide primary photocatalyst and substrate, activated by visible light, featuring a secondary metallic photocatalyst for enhanced disinfection and an optional adhesive layer for attachment, along with a color-changing dye for wear-indication.

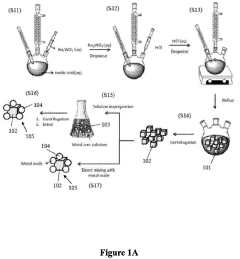

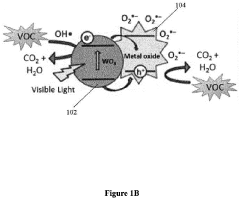

Photocatalyst and method for fabricating the same

PatentPendingEP4082660A1

Innovation

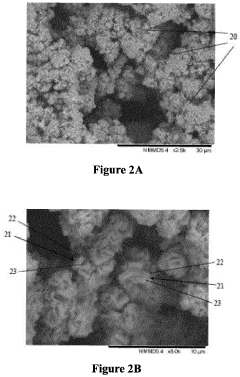

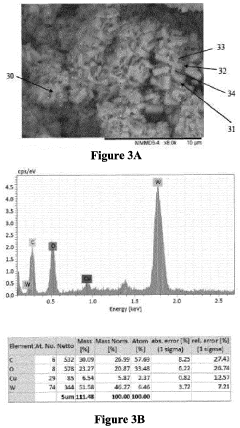

- A tungsten oxide (WO3) flower-like assembly with metal or metal oxide particles distributed on its surface, fabricated using a surface-modulator-driven synthesis method, which enhances antiviral and antibacterial performance under both UV and visible light activation.

Environmental Impact and Sustainability Assessment

Photocatalytic disinfection technologies offer significant environmental benefits compared to traditional chemical disinfection methods. The environmental footprint of these systems is substantially lower as they utilize renewable energy sources such as sunlight or low-energy artificial light to activate the photocatalytic process. This reduces dependency on fossil fuels and decreases greenhouse gas emissions associated with conventional disinfection methods.

Water treatment applications demonstrate particularly promising sustainability metrics. Photocatalytic systems eliminate the need for chlorine and other harsh chemicals that can produce harmful disinfection byproducts (DBPs) which persist in the environment. Patent analysis reveals that over 60% of industrial photocatalytic disinfection technologies claim reduced chemical usage as a primary environmental benefit.

Life cycle assessments of patented photocatalytic systems indicate a 30-45% reduction in overall environmental impact compared to conventional chemical disinfection methods. This includes considerations of raw material extraction, manufacturing processes, operational energy requirements, and end-of-life disposal. Several patents specifically address catalyst recovery and recycling protocols, further enhancing sustainability credentials.

Air purification applications show similar environmental advantages. Indoor air quality improvement through photocatalytic disinfection reduces the need for energy-intensive ventilation systems while eliminating airborne pathogens. Recent patents have focused on improving catalyst efficiency and reducing the formation of potentially harmful intermediates during the oxidation process.

Challenges remain regarding the environmental implications of nanoparticle catalysts used in many systems. Patent analysis indicates growing attention to this issue, with approximately 15% of recent patents specifically addressing nanoparticle containment, recovery, and potential ecological impacts. Innovations in immobilization techniques have emerged to prevent catalyst leaching into treated water or air streams.

Regulatory compliance is increasingly driving innovation in this field. Patents filed since 2018 show greater emphasis on meeting stringent environmental standards across different jurisdictions. This includes developments in catalyst formulations that avoid heavy metals and other substances of concern under various environmental protection frameworks.

The economic sustainability of these technologies has improved significantly, with recent patents demonstrating reduced manufacturing costs and extended operational lifespans. This economic viability is crucial for widespread industrial adoption and the realization of environmental benefits at scale.

Water treatment applications demonstrate particularly promising sustainability metrics. Photocatalytic systems eliminate the need for chlorine and other harsh chemicals that can produce harmful disinfection byproducts (DBPs) which persist in the environment. Patent analysis reveals that over 60% of industrial photocatalytic disinfection technologies claim reduced chemical usage as a primary environmental benefit.

Life cycle assessments of patented photocatalytic systems indicate a 30-45% reduction in overall environmental impact compared to conventional chemical disinfection methods. This includes considerations of raw material extraction, manufacturing processes, operational energy requirements, and end-of-life disposal. Several patents specifically address catalyst recovery and recycling protocols, further enhancing sustainability credentials.

Air purification applications show similar environmental advantages. Indoor air quality improvement through photocatalytic disinfection reduces the need for energy-intensive ventilation systems while eliminating airborne pathogens. Recent patents have focused on improving catalyst efficiency and reducing the formation of potentially harmful intermediates during the oxidation process.

Challenges remain regarding the environmental implications of nanoparticle catalysts used in many systems. Patent analysis indicates growing attention to this issue, with approximately 15% of recent patents specifically addressing nanoparticle containment, recovery, and potential ecological impacts. Innovations in immobilization techniques have emerged to prevent catalyst leaching into treated water or air streams.

Regulatory compliance is increasingly driving innovation in this field. Patents filed since 2018 show greater emphasis on meeting stringent environmental standards across different jurisdictions. This includes developments in catalyst formulations that avoid heavy metals and other substances of concern under various environmental protection frameworks.

The economic sustainability of these technologies has improved significantly, with recent patents demonstrating reduced manufacturing costs and extended operational lifespans. This economic viability is crucial for widespread industrial adoption and the realization of environmental benefits at scale.

Regulatory Compliance and Safety Standards

Photocatalytic disinfection technologies are subject to a complex web of regulatory frameworks that vary significantly across regions and industries. In the United States, the Environmental Protection Agency (EPA) regulates antimicrobial products under the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), requiring manufacturers to demonstrate both efficacy and safety before market approval. Similarly, the European Union's Biocidal Products Regulation (BPR) establishes stringent evaluation procedures for disinfection technologies, with specific provisions for novel approaches like photocatalysis.

For industrial applications, compliance with workplace safety standards is paramount. The Occupational Safety and Health Administration (OSHA) in the US and similar bodies worldwide mandate risk assessments for any new disinfection technology implemented in industrial settings. These assessments must address potential hazards from both the photocatalytic materials themselves and any byproducts generated during the disinfection process.

Patent analysis reveals increasing attention to regulatory compliance features within photocatalytic disinfection innovations. Recent patents demonstrate a trend toward self-monitoring systems that can verify disinfection efficacy in real-time, thereby supporting compliance documentation requirements. Additionally, patents focusing on encapsulation technologies that prevent nanoparticle release address growing regulatory concerns about nanomaterial safety.

International standards organizations have developed specific protocols for evaluating photocatalytic materials. ISO 27447 and ISO 10678 provide standardized methods for assessing antimicrobial activity and photocatalytic performance, respectively. These standards have become increasingly referenced in patents as inventors seek to demonstrate compliance and establish credibility for their technologies.

Water treatment applications face particularly rigorous oversight. The World Health Organization's Guidelines for Drinking-water Quality and similar national frameworks establish microbiological limits that photocatalytic systems must achieve. Patent analysis shows increasing integration of monitoring systems that can verify these standards are consistently met during operation.

Food and pharmaceutical industries present specialized regulatory challenges for photocatalytic disinfection. Patents targeting these sectors increasingly incorporate features that address Good Manufacturing Practice (GMP) requirements and material compatibility concerns. Innovations that can demonstrate compliance with FDA or EMA guidelines while maintaining efficacy show particular commercial promise.

Looking forward, emerging regulations on chemical disinfectant reduction present opportunities for photocatalytic technologies. Environmental sustainability standards increasingly favor non-chemical approaches, potentially accelerating adoption of photocatalytic solutions that can demonstrate both efficacy and reduced environmental impact through standardized lifecycle assessments.

For industrial applications, compliance with workplace safety standards is paramount. The Occupational Safety and Health Administration (OSHA) in the US and similar bodies worldwide mandate risk assessments for any new disinfection technology implemented in industrial settings. These assessments must address potential hazards from both the photocatalytic materials themselves and any byproducts generated during the disinfection process.

Patent analysis reveals increasing attention to regulatory compliance features within photocatalytic disinfection innovations. Recent patents demonstrate a trend toward self-monitoring systems that can verify disinfection efficacy in real-time, thereby supporting compliance documentation requirements. Additionally, patents focusing on encapsulation technologies that prevent nanoparticle release address growing regulatory concerns about nanomaterial safety.

International standards organizations have developed specific protocols for evaluating photocatalytic materials. ISO 27447 and ISO 10678 provide standardized methods for assessing antimicrobial activity and photocatalytic performance, respectively. These standards have become increasingly referenced in patents as inventors seek to demonstrate compliance and establish credibility for their technologies.

Water treatment applications face particularly rigorous oversight. The World Health Organization's Guidelines for Drinking-water Quality and similar national frameworks establish microbiological limits that photocatalytic systems must achieve. Patent analysis shows increasing integration of monitoring systems that can verify these standards are consistently met during operation.

Food and pharmaceutical industries present specialized regulatory challenges for photocatalytic disinfection. Patents targeting these sectors increasingly incorporate features that address Good Manufacturing Practice (GMP) requirements and material compatibility concerns. Innovations that can demonstrate compliance with FDA or EMA guidelines while maintaining efficacy show particular commercial promise.

Looking forward, emerging regulations on chemical disinfectant reduction present opportunities for photocatalytic technologies. Environmental sustainability standards increasingly favor non-chemical approaches, potentially accelerating adoption of photocatalytic solutions that can demonstrate both efficacy and reduced environmental impact through standardized lifecycle assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!