Analyzing Muriatic Acid's Effectiveness in Scale Removal

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Scale Removal Background and Objectives

Muriatic acid, also known as hydrochloric acid, has been a cornerstone in industrial and domestic scale removal applications for decades. The use of this powerful acid for descaling purposes dates back to the early 20th century when industries began to recognize its effectiveness in dissolving mineral deposits. Over time, its application has expanded from industrial settings to residential use, particularly in pool maintenance and household cleaning.

The evolution of muriatic acid usage in scale removal has been driven by the increasing need for efficient and cost-effective solutions to combat mineral buildup in various systems. As water-based technologies advanced, so did the challenges associated with scale formation, prompting further research and development in descaling methods. The acid's ability to rapidly dissolve calcium carbonate, the primary component of most scale deposits, has made it a preferred choice in many applications.

Recent technological advancements have focused on improving the safety and efficiency of muriatic acid applications. This includes the development of buffered formulations that reduce fumes and corrosivity while maintaining effectiveness. Additionally, there has been a growing emphasis on understanding the optimal concentration and application methods for different types of scale and surfaces.

The primary objective of analyzing muriatic acid's effectiveness in scale removal is to quantify its performance across various scenarios and compare it with alternative descaling agents. This analysis aims to provide a comprehensive understanding of the acid's capabilities, limitations, and potential improvements. Key areas of investigation include reaction rates with different types of scale, the impact of concentration on effectiveness, and the long-term effects on treated surfaces.

Furthermore, this analysis seeks to address environmental and safety concerns associated with muriatic acid use. As regulations become more stringent, there is a pressing need to evaluate the acid's ecological impact and explore more sustainable alternatives or application methods. This includes assessing the potential for recycling or neutralizing the acid after use, as well as developing protocols for safe handling and disposal.

Another crucial objective is to optimize the use of muriatic acid in various industrial and domestic settings. This involves determining the most effective application techniques, such as circulation methods in closed systems or spray applications for open surfaces. The goal is to maximize scale removal efficiency while minimizing the amount of acid used, thereby reducing costs and environmental impact.

The evolution of muriatic acid usage in scale removal has been driven by the increasing need for efficient and cost-effective solutions to combat mineral buildup in various systems. As water-based technologies advanced, so did the challenges associated with scale formation, prompting further research and development in descaling methods. The acid's ability to rapidly dissolve calcium carbonate, the primary component of most scale deposits, has made it a preferred choice in many applications.

Recent technological advancements have focused on improving the safety and efficiency of muriatic acid applications. This includes the development of buffered formulations that reduce fumes and corrosivity while maintaining effectiveness. Additionally, there has been a growing emphasis on understanding the optimal concentration and application methods for different types of scale and surfaces.

The primary objective of analyzing muriatic acid's effectiveness in scale removal is to quantify its performance across various scenarios and compare it with alternative descaling agents. This analysis aims to provide a comprehensive understanding of the acid's capabilities, limitations, and potential improvements. Key areas of investigation include reaction rates with different types of scale, the impact of concentration on effectiveness, and the long-term effects on treated surfaces.

Furthermore, this analysis seeks to address environmental and safety concerns associated with muriatic acid use. As regulations become more stringent, there is a pressing need to evaluate the acid's ecological impact and explore more sustainable alternatives or application methods. This includes assessing the potential for recycling or neutralizing the acid after use, as well as developing protocols for safe handling and disposal.

Another crucial objective is to optimize the use of muriatic acid in various industrial and domestic settings. This involves determining the most effective application techniques, such as circulation methods in closed systems or spray applications for open surfaces. The goal is to maximize scale removal efficiency while minimizing the amount of acid used, thereby reducing costs and environmental impact.

Market Analysis for Scale Removal Solutions

The scale removal solutions market has been experiencing steady growth due to increasing demand across various industries, including water treatment, oil and gas, manufacturing, and residential applications. The global market for scale removal products and services is projected to reach significant value in the coming years, driven by the growing awareness of the detrimental effects of scale buildup on equipment efficiency and lifespan.

In the industrial sector, scale removal solutions are crucial for maintaining the performance of heat exchangers, boilers, cooling towers, and other critical equipment. The power generation industry, in particular, has been a major contributor to market growth, as scale formation in power plant equipment can lead to reduced energy efficiency and increased maintenance costs.

The water treatment industry has also been a key driver of market demand, with municipalities and water utilities seeking effective solutions to address scale buildup in distribution systems and treatment facilities. Additionally, the oil and gas sector has shown increased interest in scale removal products, particularly for offshore operations where scale formation can significantly impact production rates.

In the residential market, there has been a growing trend towards the use of eco-friendly and chemical-free scale removal solutions. This shift is driven by consumer preferences for safer and more sustainable household products. As a result, manufacturers are developing new formulations that are both effective and environmentally friendly.

Geographically, North America and Europe have been the largest markets for scale removal solutions, owing to their well-established industrial sectors and stringent regulations regarding equipment maintenance and water quality. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization and increasing investments in infrastructure development.

The competitive landscape of the scale removal solutions market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the market have been focusing on product innovation and strategic partnerships to gain a competitive edge. There is also a growing emphasis on developing customized solutions to meet specific industry requirements.

Looking ahead, the market for scale removal solutions is expected to continue its growth trajectory, driven by factors such as increasing industrialization, stricter environmental regulations, and the need for improved energy efficiency across various sectors. The development of advanced technologies, such as nanotechnology-based scale inhibitors and smart monitoring systems, is likely to shape the future of the market and create new opportunities for industry players.

In the industrial sector, scale removal solutions are crucial for maintaining the performance of heat exchangers, boilers, cooling towers, and other critical equipment. The power generation industry, in particular, has been a major contributor to market growth, as scale formation in power plant equipment can lead to reduced energy efficiency and increased maintenance costs.

The water treatment industry has also been a key driver of market demand, with municipalities and water utilities seeking effective solutions to address scale buildup in distribution systems and treatment facilities. Additionally, the oil and gas sector has shown increased interest in scale removal products, particularly for offshore operations where scale formation can significantly impact production rates.

In the residential market, there has been a growing trend towards the use of eco-friendly and chemical-free scale removal solutions. This shift is driven by consumer preferences for safer and more sustainable household products. As a result, manufacturers are developing new formulations that are both effective and environmentally friendly.

Geographically, North America and Europe have been the largest markets for scale removal solutions, owing to their well-established industrial sectors and stringent regulations regarding equipment maintenance and water quality. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, fueled by rapid industrialization and increasing investments in infrastructure development.

The competitive landscape of the scale removal solutions market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the market have been focusing on product innovation and strategic partnerships to gain a competitive edge. There is also a growing emphasis on developing customized solutions to meet specific industry requirements.

Looking ahead, the market for scale removal solutions is expected to continue its growth trajectory, driven by factors such as increasing industrialization, stricter environmental regulations, and the need for improved energy efficiency across various sectors. The development of advanced technologies, such as nanotechnology-based scale inhibitors and smart monitoring systems, is likely to shape the future of the market and create new opportunities for industry players.

Current Challenges in Scale Removal Techniques

Scale removal techniques in industrial and domestic settings face several significant challenges that hinder their effectiveness and efficiency. One of the primary issues is the diversity of scale compositions encountered in various applications. Scales can range from calcium carbonate and magnesium hydroxide to more complex mineral deposits, each requiring specific treatment approaches. This variability makes it difficult to develop a one-size-fits-all solution for scale removal.

Another challenge lies in the accessibility of scaled surfaces. In many industrial applications, such as heat exchangers, boilers, and pipelines, scale forms in hard-to-reach areas. This limited access complicates the application of removal techniques and often necessitates system shutdowns for thorough cleaning, leading to increased downtime and operational costs.

The environmental impact of scale removal processes is an increasingly pressing concern. Many traditional descaling agents, including strong acids and chelating agents, can be harmful to aquatic ecosystems if not properly managed. This has led to stricter regulations on the use and disposal of these chemicals, pushing the industry to seek more environmentally friendly alternatives.

Corrosion of underlying surfaces during scale removal is another significant challenge. Aggressive cleaning methods or strong acids can damage the base material, particularly in sensitive equipment or thin-walled structures. Balancing the need for effective scale removal with the preservation of equipment integrity is a delicate task that requires careful consideration of material compatibility and treatment parameters.

Time and cost efficiency also pose challenges in scale removal techniques. Many current methods are labor-intensive and time-consuming, particularly for large-scale industrial applications. This not only increases operational costs but also extends the duration of equipment downtime, impacting overall productivity.

The formation of secondary scales during the removal process is an often-overlooked challenge. Some removal techniques can inadvertently create conditions that promote the rapid reformation of scale, necessitating more frequent treatments and reducing the long-term effectiveness of the cleaning process.

Lastly, the safety concerns associated with handling and applying scale removal chemicals present ongoing challenges. Many effective descaling agents are hazardous, requiring specialized training, personal protective equipment, and strict safety protocols. This increases the complexity of scale removal operations and can limit the applicability of certain techniques in sensitive environments.

Another challenge lies in the accessibility of scaled surfaces. In many industrial applications, such as heat exchangers, boilers, and pipelines, scale forms in hard-to-reach areas. This limited access complicates the application of removal techniques and often necessitates system shutdowns for thorough cleaning, leading to increased downtime and operational costs.

The environmental impact of scale removal processes is an increasingly pressing concern. Many traditional descaling agents, including strong acids and chelating agents, can be harmful to aquatic ecosystems if not properly managed. This has led to stricter regulations on the use and disposal of these chemicals, pushing the industry to seek more environmentally friendly alternatives.

Corrosion of underlying surfaces during scale removal is another significant challenge. Aggressive cleaning methods or strong acids can damage the base material, particularly in sensitive equipment or thin-walled structures. Balancing the need for effective scale removal with the preservation of equipment integrity is a delicate task that requires careful consideration of material compatibility and treatment parameters.

Time and cost efficiency also pose challenges in scale removal techniques. Many current methods are labor-intensive and time-consuming, particularly for large-scale industrial applications. This not only increases operational costs but also extends the duration of equipment downtime, impacting overall productivity.

The formation of secondary scales during the removal process is an often-overlooked challenge. Some removal techniques can inadvertently create conditions that promote the rapid reformation of scale, necessitating more frequent treatments and reducing the long-term effectiveness of the cleaning process.

Lastly, the safety concerns associated with handling and applying scale removal chemicals present ongoing challenges. Many effective descaling agents are hazardous, requiring specialized training, personal protective equipment, and strict safety protocols. This increases the complexity of scale removal operations and can limit the applicability of certain techniques in sensitive environments.

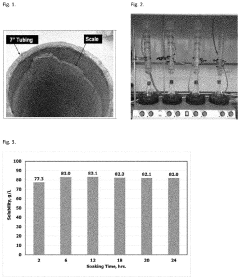

Existing Muriatic Acid Application Methods

01 Cleaning and etching applications

Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. The acid's strong corrosive properties make it suitable for preparing surfaces for painting or further treatment.- Cleaning and etching applications: Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and etching various surfaces. It is commonly used for removing rust, scale, and mineral deposits from metal surfaces, concrete, and masonry. The acid's strong corrosive properties make it suitable for preparing surfaces for painting or further treatment.

- pH adjustment in industrial processes: Muriatic acid is widely used in industrial processes for pH adjustment. Its effectiveness in lowering pH makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid can be precisely controlled to achieve desired pH levels in various applications.

- Metal surface treatment: The effectiveness of muriatic acid in metal surface treatment is well-established. It is used for pickling steel and other metals to remove oxide layers and prepare surfaces for further processing. The acid's ability to dissolve metal oxides makes it an essential component in metal finishing and galvanization processes.

- Swimming pool maintenance: Muriatic acid is effective in maintaining proper pH levels in swimming pools. It is used to lower the pH when it becomes too high, helping to prevent scale formation and ensure the effectiveness of chlorine-based disinfectants. The acid's quick action and affordability make it a popular choice for pool maintenance.

- Pharmaceutical and chemical synthesis: In pharmaceutical and chemical industries, muriatic acid's effectiveness is utilized in various synthesis processes. It serves as a reagent or catalyst in the production of drugs, dyes, and other chemical compounds. The acid's strong proton-donating ability makes it valuable in organic synthesis reactions.

02 pH adjustment in industrial processes

Muriatic acid is widely used in industrial processes for pH adjustment. Its effectiveness in lowering pH levels makes it valuable in water treatment, chemical manufacturing, and food processing industries. The acid helps maintain optimal pH conditions for various reactions and processes.Expand Specific Solutions03 Swimming pool maintenance

In swimming pool maintenance, muriatic acid is effective for balancing water chemistry. It helps lower the pH and total alkalinity of pool water, preventing scale formation and ensuring proper sanitizer effectiveness. The acid's ability to quickly adjust water parameters makes it a popular choice among pool owners and maintenance professionals.Expand Specific Solutions04 Metal treatment and processing

Muriatic acid is highly effective in metal treatment and processing applications. It is used for pickling steel and other metals to remove surface oxides and impurities. The acid's ability to dissolve metal oxides makes it valuable in the production and finishing of various metal products.Expand Specific Solutions05 Pharmaceutical and chemical synthesis

In pharmaceutical and chemical industries, muriatic acid is an effective reagent for various synthesis processes. It serves as a catalyst, pH regulator, and reactant in the production of numerous compounds. The acid's strong proton-donating properties make it valuable in organic and inorganic synthesis reactions.Expand Specific Solutions

Key Players in Industrial Cleaning Industry

The market for muriatic acid in scale removal is in a mature stage, with established players and proven technologies. The global market size for industrial cleaning chemicals, including scale removers, is estimated to be in the billions of dollars. Technologically, the use of muriatic acid for scale removal is well-understood, with ongoing research focused on improving efficiency and environmental impact. Key players like Ecolab, Kurita Water Industries, and Mitsubishi Heavy Industries are investing in R&D to develop more effective and eco-friendly solutions. Emerging companies such as FQE Chemicals are also contributing to innovation in this field, while established petrochemical giants like Petróleo Brasileiro SA and China Petroleum & Chemical Corp. maintain a significant market presence.

Ecolab USA, Inc.

Technical Solution: Ecolab has developed a comprehensive approach to scale removal using muriatic acid, focusing on optimizing the concentration and application method. Their technology involves a controlled-release system that gradually introduces the acid into the affected areas, ensuring maximum effectiveness while minimizing corrosion risks. The company has conducted extensive research on the kinetics of scale dissolution, allowing them to tailor the acid treatment to specific types of scale deposits[1]. Ecolab's method also incorporates inhibitors and surfactants to enhance the acid's penetration and reduce potential damage to underlying surfaces[3].

Strengths: Precise control over acid application, reduced corrosion risks, and tailored solutions for different scale types. Weaknesses: May require specialized equipment and trained personnel for optimal results.

Kurita Water Industries Ltd.

Technical Solution: Kurita has pioneered a hybrid approach combining muriatic acid with advanced chelating agents for scale removal. Their technology utilizes a proprietary blend of hydrochloric acid and organic chelators, which synergistically dissolve scale deposits while protecting metal surfaces. The company's research has shown that this combination can effectively remove up to 95% of common scale types, including calcium carbonate and iron oxides[2]. Kurita's method also incorporates real-time monitoring systems to adjust acid concentration and flow rates dynamically, ensuring optimal scale removal efficiency[4].

Strengths: High efficiency in scale removal, reduced environmental impact, and protection of equipment surfaces. Weaknesses: Potentially higher cost due to specialized chemical formulations.

Core Research on Muriatic Acid Efficacy

Scale cleaning method by using acid

PatentInactiveJP2013049035A

Innovation

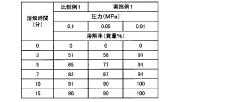

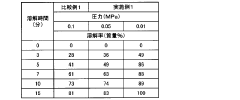

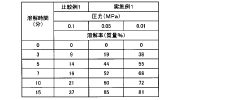

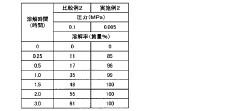

- A method involving the use of an acid as a cleaning agent that foams the scale under reduced pressure, with a pressure range of 0.001 to 0.09 MPa and a pH of 5 or less, to enhance scale dissolution by accelerating the reaction with generated gases under reduced pressure.

Method of removing iron-containing scale from a wellbore, pipe, or surface using a biodegradable descaler solution

PatentActiveUS20210207019A1

Innovation

- A biodegradable descaler solution comprising hydrochloric acid, formic acid, citric acid, a corrosion inhibitor, a corrosion inhibitor intensifier, and a surfactant is used to contact and dissolve iron-containing scale, achieving high removal efficiency while minimizing steel corrosion.

Environmental Impact Assessment

The use of muriatic acid for scale removal raises significant environmental concerns that require careful consideration. When released into aquatic ecosystems, muriatic acid can cause severe pH imbalances, potentially harming fish, plants, and other aquatic organisms. The acid's corrosive nature can also damage infrastructure and equipment if not properly contained or neutralized.

Soil contamination is another potential risk associated with muriatic acid use. Improper disposal or accidental spills can lead to soil acidification, affecting plant growth and soil microbial communities. This can have long-lasting impacts on local ecosystems and agricultural productivity.

Air quality is also a concern, as muriatic acid can release harmful fumes. These emissions can contribute to air pollution and pose health risks to workers and nearby communities if not adequately controlled. Proper ventilation and personal protective equipment are essential to mitigate these risks.

The production and transportation of muriatic acid also have environmental implications. Manufacturing processes can generate greenhouse gas emissions and other pollutants, while transportation risks include potential spills or accidents that could harm ecosystems along distribution routes.

Waste management is a critical aspect of environmental impact assessment for muriatic acid use. Neutralization and proper disposal of acid waste are necessary to prevent environmental contamination. Recycling and reuse strategies can help minimize the overall environmental footprint of scale removal operations.

Water consumption is another factor to consider, as large-scale cleaning operations may require significant amounts of water for dilution and rinsing. This can strain local water resources, particularly in water-scarce regions.

To mitigate these environmental impacts, several strategies can be employed. Using lower concentrations of acid, implementing closed-loop systems for acid recovery and reuse, and exploring alternative, less harmful descaling agents are potential approaches. Additionally, adopting best practices for handling, storage, and disposal can significantly reduce the risk of environmental contamination.

Regulatory compliance is crucial in managing the environmental impacts of muriatic acid use. Adhering to local, national, and international environmental regulations ensures that proper safeguards are in place to protect ecosystems and human health. Regular environmental monitoring and impact assessments can help identify and address potential issues before they become significant problems.

Soil contamination is another potential risk associated with muriatic acid use. Improper disposal or accidental spills can lead to soil acidification, affecting plant growth and soil microbial communities. This can have long-lasting impacts on local ecosystems and agricultural productivity.

Air quality is also a concern, as muriatic acid can release harmful fumes. These emissions can contribute to air pollution and pose health risks to workers and nearby communities if not adequately controlled. Proper ventilation and personal protective equipment are essential to mitigate these risks.

The production and transportation of muriatic acid also have environmental implications. Manufacturing processes can generate greenhouse gas emissions and other pollutants, while transportation risks include potential spills or accidents that could harm ecosystems along distribution routes.

Waste management is a critical aspect of environmental impact assessment for muriatic acid use. Neutralization and proper disposal of acid waste are necessary to prevent environmental contamination. Recycling and reuse strategies can help minimize the overall environmental footprint of scale removal operations.

Water consumption is another factor to consider, as large-scale cleaning operations may require significant amounts of water for dilution and rinsing. This can strain local water resources, particularly in water-scarce regions.

To mitigate these environmental impacts, several strategies can be employed. Using lower concentrations of acid, implementing closed-loop systems for acid recovery and reuse, and exploring alternative, less harmful descaling agents are potential approaches. Additionally, adopting best practices for handling, storage, and disposal can significantly reduce the risk of environmental contamination.

Regulatory compliance is crucial in managing the environmental impacts of muriatic acid use. Adhering to local, national, and international environmental regulations ensures that proper safeguards are in place to protect ecosystems and human health. Regular environmental monitoring and impact assessments can help identify and address potential issues before they become significant problems.

Safety Protocols and Regulations

When handling muriatic acid for scale removal, strict safety protocols and regulations must be adhered to due to its highly corrosive nature. Personal protective equipment (PPE) is mandatory, including chemical-resistant gloves, goggles, face shields, and protective clothing. Proper ventilation is crucial to prevent the accumulation of harmful fumes. Workers must be trained in the safe handling and use of muriatic acid, including proper dilution techniques and emergency procedures.

Storage and transportation of muriatic acid require special considerations. It must be kept in properly labeled, acid-resistant containers and stored in a cool, dry, well-ventilated area away from incompatible materials. Secondary containment systems are often required to prevent spills from spreading. During transportation, vehicles must be equipped with appropriate placards and documentation as per hazardous materials regulations.

Disposal of muriatic acid and its waste products must comply with local, state, and federal environmental regulations. Neutralization is typically required before disposal, and the process must be carried out by trained personnel. Many jurisdictions require detailed record-keeping of acid usage and disposal.

Emergency response plans are essential when working with muriatic acid. These plans should include procedures for spill containment, neutralization, and decontamination. Eyewash stations and safety showers must be readily accessible in areas where the acid is used or stored. First aid protocols specific to acid exposure should be established and communicated to all personnel.

Regulatory compliance extends to workplace safety standards set by organizations such as OSHA in the United States. These standards outline permissible exposure limits, required safety equipment, and training requirements. Regular safety audits and inspections are necessary to ensure ongoing compliance with these regulations.

Environmental considerations are also critical when using muriatic acid for scale removal. Measures must be in place to prevent acid runoff into water systems or soil. In some cases, permits may be required for large-scale use of muriatic acid, particularly in industrial settings or near sensitive environmental areas.

Lastly, proper documentation and labeling are essential components of safety protocols. Material Safety Data Sheets (MSDS) must be readily available, and all containers and work areas should be clearly labeled with appropriate hazard warnings. Regular training and refresher courses on safety procedures and regulations should be conducted to ensure all personnel remain up-to-date on best practices and legal requirements when working with muriatic acid.

Storage and transportation of muriatic acid require special considerations. It must be kept in properly labeled, acid-resistant containers and stored in a cool, dry, well-ventilated area away from incompatible materials. Secondary containment systems are often required to prevent spills from spreading. During transportation, vehicles must be equipped with appropriate placards and documentation as per hazardous materials regulations.

Disposal of muriatic acid and its waste products must comply with local, state, and federal environmental regulations. Neutralization is typically required before disposal, and the process must be carried out by trained personnel. Many jurisdictions require detailed record-keeping of acid usage and disposal.

Emergency response plans are essential when working with muriatic acid. These plans should include procedures for spill containment, neutralization, and decontamination. Eyewash stations and safety showers must be readily accessible in areas where the acid is used or stored. First aid protocols specific to acid exposure should be established and communicated to all personnel.

Regulatory compliance extends to workplace safety standards set by organizations such as OSHA in the United States. These standards outline permissible exposure limits, required safety equipment, and training requirements. Regular safety audits and inspections are necessary to ensure ongoing compliance with these regulations.

Environmental considerations are also critical when using muriatic acid for scale removal. Measures must be in place to prevent acid runoff into water systems or soil. In some cases, permits may be required for large-scale use of muriatic acid, particularly in industrial settings or near sensitive environmental areas.

Lastly, proper documentation and labeling are essential components of safety protocols. Material Safety Data Sheets (MSDS) must be readily available, and all containers and work areas should be clearly labeled with appropriate hazard warnings. Regular training and refresher courses on safety procedures and regulations should be conducted to ensure all personnel remain up-to-date on best practices and legal requirements when working with muriatic acid.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!