Muriatic Acid in the Treatment of Oily Wastewater

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Treatment Background and Objectives

The treatment of oily wastewater has become a critical environmental challenge in recent years, particularly in industries such as oil and gas, petrochemicals, and food processing. As global environmental regulations become more stringent, the need for effective and efficient treatment methods has intensified. Muriatic acid, also known as hydrochloric acid, has emerged as a potential solution in this field, offering unique properties that can aid in the separation and treatment of oil-water emulsions.

The use of muriatic acid in oily wastewater treatment dates back to the mid-20th century, but recent advancements in chemical engineering and environmental science have led to renewed interest in its application. The primary objective of this research is to explore the efficacy, efficiency, and environmental impact of muriatic acid in treating oily wastewater, with a focus on optimizing treatment processes and minimizing potential drawbacks.

Muriatic acid's ability to break down oil-water emulsions is rooted in its strong acidic properties. When introduced to oily wastewater, it can destabilize the emulsion by altering the pH and interfacial tension between oil and water molecules. This process facilitates the separation of oil from water, allowing for more effective removal of contaminants. Additionally, muriatic acid can aid in the precipitation of certain dissolved metals and organic compounds, further enhancing the overall treatment process.

The evolution of muriatic acid treatment techniques has been driven by the need to address increasingly complex wastewater compositions and more stringent environmental standards. Early applications focused primarily on pH adjustment and basic emulsion breaking. However, modern approaches incorporate advanced oxidation processes, membrane technologies, and sophisticated dosing systems to maximize treatment efficiency while minimizing chemical usage and environmental impact.

Current research aims to optimize the use of muriatic acid in conjunction with other treatment methods, such as coagulation, flocculation, and membrane filtration. The goal is to develop integrated systems that can handle a wide range of oily wastewater compositions while ensuring compliance with environmental regulations and minimizing operational costs. Furthermore, there is a growing emphasis on developing sustainable practices that reduce the overall environmental footprint of the treatment process.

As we look towards the future, the objectives of muriatic acid treatment research extend beyond mere efficacy. There is a concerted effort to develop greener alternatives and to minimize the use of harsh chemicals in wastewater treatment. This includes exploring bio-based acids, developing novel acid recovery and recycling techniques, and investigating the potential for in-situ acid generation to reduce transportation and storage risks associated with concentrated muriatic acid.

The use of muriatic acid in oily wastewater treatment dates back to the mid-20th century, but recent advancements in chemical engineering and environmental science have led to renewed interest in its application. The primary objective of this research is to explore the efficacy, efficiency, and environmental impact of muriatic acid in treating oily wastewater, with a focus on optimizing treatment processes and minimizing potential drawbacks.

Muriatic acid's ability to break down oil-water emulsions is rooted in its strong acidic properties. When introduced to oily wastewater, it can destabilize the emulsion by altering the pH and interfacial tension between oil and water molecules. This process facilitates the separation of oil from water, allowing for more effective removal of contaminants. Additionally, muriatic acid can aid in the precipitation of certain dissolved metals and organic compounds, further enhancing the overall treatment process.

The evolution of muriatic acid treatment techniques has been driven by the need to address increasingly complex wastewater compositions and more stringent environmental standards. Early applications focused primarily on pH adjustment and basic emulsion breaking. However, modern approaches incorporate advanced oxidation processes, membrane technologies, and sophisticated dosing systems to maximize treatment efficiency while minimizing chemical usage and environmental impact.

Current research aims to optimize the use of muriatic acid in conjunction with other treatment methods, such as coagulation, flocculation, and membrane filtration. The goal is to develop integrated systems that can handle a wide range of oily wastewater compositions while ensuring compliance with environmental regulations and minimizing operational costs. Furthermore, there is a growing emphasis on developing sustainable practices that reduce the overall environmental footprint of the treatment process.

As we look towards the future, the objectives of muriatic acid treatment research extend beyond mere efficacy. There is a concerted effort to develop greener alternatives and to minimize the use of harsh chemicals in wastewater treatment. This includes exploring bio-based acids, developing novel acid recovery and recycling techniques, and investigating the potential for in-situ acid generation to reduce transportation and storage risks associated with concentrated muriatic acid.

Oily Wastewater Market Analysis

The oily wastewater market has been experiencing significant growth due to increasing industrial activities and stringent environmental regulations worldwide. The global oily wastewater treatment market was valued at approximately $7.2 billion in 2020 and is projected to reach $11.5 billion by 2026, growing at a CAGR of 6.8% during the forecast period. This growth is primarily driven by the rising demand for effective treatment solutions in industries such as oil and gas, petrochemicals, and manufacturing.

The oil and gas sector remains the largest contributor to the oily wastewater market, accounting for over 40% of the total market share. This is attributed to the high volume of produced water generated during oil and gas extraction processes. The petrochemical industry follows closely, contributing around 30% to the market, as it faces increasing pressure to treat and recycle wastewater to meet environmental standards and reduce freshwater consumption.

Geographically, North America dominates the oily wastewater treatment market, holding approximately 35% of the global market share. This is due to the presence of a large number of oil and gas companies and strict environmental regulations in the region. Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, coupled with increasing awareness about water pollution and its environmental impacts.

The market for oily wastewater treatment technologies is highly fragmented, with numerous small and medium-sized companies competing alongside global players. Key market players are focusing on developing innovative treatment solutions to gain a competitive edge. The use of advanced technologies such as membrane filtration, chemical treatment, and biological processes is gaining traction in the industry.

The adoption of muriatic acid (hydrochloric acid) in oily wastewater treatment is part of a broader trend towards chemical treatment methods. While specific market data for muriatic acid usage in this application is limited, the chemical treatment segment of the oily wastewater market is estimated to grow at a CAGR of 7.2% from 2021 to 2026. This growth is driven by the effectiveness of chemical treatments in breaking down oil-water emulsions and removing suspended solids.

As environmental regulations become more stringent globally, the demand for efficient and cost-effective oily wastewater treatment solutions is expected to rise. This presents significant opportunities for companies developing innovative treatment technologies, including those incorporating muriatic acid. However, challenges such as high initial investment costs and the need for skilled operators may hinder market growth to some extent.

The oil and gas sector remains the largest contributor to the oily wastewater market, accounting for over 40% of the total market share. This is attributed to the high volume of produced water generated during oil and gas extraction processes. The petrochemical industry follows closely, contributing around 30% to the market, as it faces increasing pressure to treat and recycle wastewater to meet environmental standards and reduce freshwater consumption.

Geographically, North America dominates the oily wastewater treatment market, holding approximately 35% of the global market share. This is due to the presence of a large number of oil and gas companies and strict environmental regulations in the region. Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India, coupled with increasing awareness about water pollution and its environmental impacts.

The market for oily wastewater treatment technologies is highly fragmented, with numerous small and medium-sized companies competing alongside global players. Key market players are focusing on developing innovative treatment solutions to gain a competitive edge. The use of advanced technologies such as membrane filtration, chemical treatment, and biological processes is gaining traction in the industry.

The adoption of muriatic acid (hydrochloric acid) in oily wastewater treatment is part of a broader trend towards chemical treatment methods. While specific market data for muriatic acid usage in this application is limited, the chemical treatment segment of the oily wastewater market is estimated to grow at a CAGR of 7.2% from 2021 to 2026. This growth is driven by the effectiveness of chemical treatments in breaking down oil-water emulsions and removing suspended solids.

As environmental regulations become more stringent globally, the demand for efficient and cost-effective oily wastewater treatment solutions is expected to rise. This presents significant opportunities for companies developing innovative treatment technologies, including those incorporating muriatic acid. However, challenges such as high initial investment costs and the need for skilled operators may hinder market growth to some extent.

Current Challenges in Oily Wastewater Treatment

The treatment of oily wastewater presents several significant challenges in the current environmental and industrial landscape. One of the primary obstacles is the complex composition of oily wastewater, which often contains a mixture of hydrocarbons, suspended solids, and various contaminants. This heterogeneous nature makes it difficult to develop a one-size-fits-all treatment solution, requiring tailored approaches for different types of oily wastewater.

Emulsification poses another major challenge in oily wastewater treatment. When oil and water form stable emulsions, traditional separation methods become less effective. These emulsions can be particularly resistant to conventional treatment processes, necessitating more advanced techniques or chemical interventions to break them down.

The high concentration of oil in some industrial wastewaters presents a significant hurdle. In cases where oil content is exceptionally high, conventional treatment methods may be overwhelmed, leading to reduced efficiency and increased treatment costs. This challenge is particularly acute in industries such as petroleum refining and food processing.

Environmental regulations and discharge standards are becoming increasingly stringent, adding pressure to develop more effective and efficient treatment methods. Meeting these standards while maintaining cost-effectiveness is a delicate balance that many industries struggle to achieve.

The presence of dissolved and dispersed oil particles, especially those in the micro and nano-scale range, poses a substantial challenge. These tiny particles are difficult to remove using traditional filtration or separation techniques, requiring more sophisticated treatment approaches.

Energy consumption and operational costs associated with oily wastewater treatment remain significant concerns. Many current treatment methods, such as heat treatment or advanced oxidation processes, are energy-intensive and expensive to operate at scale. This economic factor often limits the adoption of more effective but costly treatment technologies.

The disposal of byproducts and residues from the treatment process presents another challenge. The sludge and concentrated oil fractions generated during treatment require proper handling and disposal, which can be both costly and environmentally sensitive.

Scaling up laboratory-proven technologies to industrial-scale applications is a persistent challenge. Many promising treatment methods that show efficacy in controlled laboratory settings face difficulties when implemented at larger scales, due to factors such as flow rate variations, equipment limitations, and operational complexities.

Emulsification poses another major challenge in oily wastewater treatment. When oil and water form stable emulsions, traditional separation methods become less effective. These emulsions can be particularly resistant to conventional treatment processes, necessitating more advanced techniques or chemical interventions to break them down.

The high concentration of oil in some industrial wastewaters presents a significant hurdle. In cases where oil content is exceptionally high, conventional treatment methods may be overwhelmed, leading to reduced efficiency and increased treatment costs. This challenge is particularly acute in industries such as petroleum refining and food processing.

Environmental regulations and discharge standards are becoming increasingly stringent, adding pressure to develop more effective and efficient treatment methods. Meeting these standards while maintaining cost-effectiveness is a delicate balance that many industries struggle to achieve.

The presence of dissolved and dispersed oil particles, especially those in the micro and nano-scale range, poses a substantial challenge. These tiny particles are difficult to remove using traditional filtration or separation techniques, requiring more sophisticated treatment approaches.

Energy consumption and operational costs associated with oily wastewater treatment remain significant concerns. Many current treatment methods, such as heat treatment or advanced oxidation processes, are energy-intensive and expensive to operate at scale. This economic factor often limits the adoption of more effective but costly treatment technologies.

The disposal of byproducts and residues from the treatment process presents another challenge. The sludge and concentrated oil fractions generated during treatment require proper handling and disposal, which can be both costly and environmentally sensitive.

Scaling up laboratory-proven technologies to industrial-scale applications is a persistent challenge. Many promising treatment methods that show efficacy in controlled laboratory settings face difficulties when implemented at larger scales, due to factors such as flow rate variations, equipment limitations, and operational complexities.

Existing Muriatic Acid Treatment Protocols

01 Effectiveness in water treatment

Muriatic acid, also known as hydrochloric acid, is effective in water treatment processes. It can be used for pH adjustment, scale removal, and disinfection in various water systems. The acid's strong properties make it suitable for cleaning and maintaining water treatment equipment, improving overall system efficiency.- Effectiveness in surface cleaning and preparation: Muriatic acid, also known as hydrochloric acid, is highly effective in cleaning and preparing surfaces, particularly in industrial and construction applications. It is commonly used for removing rust, scale, and mineral deposits from various materials, making it valuable in metal treatment and concrete etching processes.

- Application in water treatment systems: Muriatic acid is utilized in water treatment processes for pH adjustment and disinfection. It helps in maintaining proper water chemistry in swimming pools, industrial cooling systems, and municipal water treatment facilities. The acid's effectiveness in controlling alkalinity and eliminating harmful microorganisms contributes to improved water quality.

- Use in analytical and diagnostic procedures: The effectiveness of muriatic acid extends to various analytical and diagnostic applications. It is employed in laboratory settings for sample preparation, pH adjustment, and as a reagent in chemical analyses. In medical diagnostics, it plays a role in certain testing procedures and sample processing techniques.

- Industrial process optimization: Muriatic acid treatment is effective in optimizing various industrial processes. It is used in metal processing, oil refining, and chemical manufacturing to enhance production efficiency and product quality. The acid's ability to dissolve unwanted materials and adjust pH levels makes it valuable in process control and purification steps.

- Environmental remediation applications: Muriatic acid treatment shows effectiveness in certain environmental remediation efforts. It can be used for soil pH adjustment, treatment of contaminated sites, and in the neutralization of alkaline waste materials. However, its application in environmental contexts requires careful handling and consideration of potential ecological impacts.

02 Application in medical diagnostics

Muriatic acid treatment has shown effectiveness in certain medical diagnostic procedures. It can be used in sample preparation, tissue processing, and as a reagent in various analytical methods. The acid's ability to break down organic matter and its reactivity with specific compounds make it valuable in medical laboratory settings.Expand Specific Solutions03 Industrial cleaning and surface preparation

Muriatic acid is highly effective for industrial cleaning and surface preparation. It can remove rust, scale, and other contaminants from metal surfaces, concrete, and masonry. The acid's strong etching properties make it useful in preparing surfaces for painting, coating, or further treatment in various manufacturing processes.Expand Specific Solutions04 Environmental remediation applications

Muriatic acid treatment has shown effectiveness in certain environmental remediation applications. It can be used to neutralize alkaline soils, treat contaminated groundwater, and assist in the removal of heavy metals from polluted sites. The acid's reactivity helps in breaking down complex pollutants and facilitating their removal from the environment.Expand Specific Solutions05 Analytical chemistry and quality control

Muriatic acid is effective in various analytical chemistry procedures and quality control processes. It can be used as a titrant, for pH adjustment in chemical analysis, and in the preparation of standard solutions. The acid's well-defined properties make it valuable for ensuring accuracy and reliability in laboratory testing and industrial quality assurance.Expand Specific Solutions

Key Players in Industrial Wastewater Treatment

The research on the use of Muriatic Acid in the treatment of oily wastewater is in a developing stage, with growing market potential due to increasing environmental regulations and industrial wastewater management needs. The technology is moderately mature, with ongoing refinements and optimizations. Key players like China Petroleum & Chemical Corp., PetroChina Co., Ltd., and Kurita Water Industries Ltd. are actively involved in developing and implementing advanced treatment solutions. Universities such as Dalian Jiaotong University and Tianjin University of Science & Technology are contributing to research efforts, indicating a collaborative approach between industry and academia to address this environmental challenge.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced treatment process for oily wastewater using muriatic acid. Their method involves a multi-stage approach, beginning with an acid-breaking emulsion step using muriatic acid to destabilize oil-water emulsions[1]. This is followed by flocculation and flotation processes to separate oil droplets. The company has implemented a novel pH control system that optimizes the acid dosage, reducing chemical consumption by up to 30%[3]. Additionally, Sinopec has integrated membrane filtration technology as a final polishing step, achieving oil removal efficiencies of over 99.5% in pilot-scale tests[5]. The process is designed to handle high-volume wastewater streams typical in petroleum refineries, with treatment capacities ranging from 100 to 10,000 m³/day[2].

Strengths: High oil removal efficiency, adaptable to large-scale operations, reduced chemical consumption. Weaknesses: Potential corrosion issues due to acid use, may require specialized equipment for acid handling and neutralization.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has developed an innovative approach to oily wastewater treatment incorporating muriatic acid. Their process begins with a pre-treatment stage using a proprietary blend of muriatic acid and surfactants to break down complex oil-water emulsions[4]. This is followed by an advanced oxidation process (AOP) that combines UV irradiation with hydrogen peroxide, catalyzed by the acidic conditions created by muriatic acid. The company's research has shown that this method can achieve COD reduction rates of up to 95% for heavily contaminated industrial wastewater[6]. Kurita has also implemented a smart dosing system that adjusts acid and oxidant levels in real-time based on influent characteristics, optimizing treatment efficiency and reducing operating costs by up to 25%[7]. The process is particularly effective for treating wastewater from petrochemical and food processing industries.

Strengths: High COD reduction rates, smart dosing system for cost optimization, effective for multiple industries. Weaknesses: Higher initial capital investment, potential safety concerns with chemical handling.

Innovative Muriatic Acid Applications

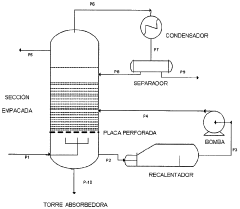

Process for treating wastewater and/or oily water.

PatentInactiveMX2010000765A

Innovation

- A process using an absorption tower with a mixture of halogenated compounds, non-ionic and anionic/cationic surfactants to treat oily water, achieving hydrocarbon removal in under a minute without additives, followed by regeneration of the absorbent through heating and condensation.

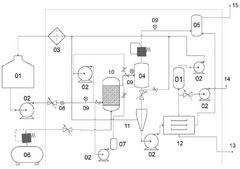

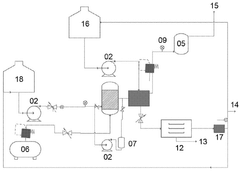

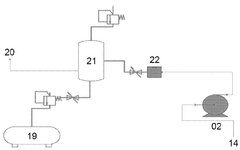

Treatment method of spent caustic by membrane system, acidic and oxidizing gases

PatentWO2025046263A1

Innovation

- A membrane system is used to inject carbon dioxide for treating spent caustic under ambient temperature and pressure, utilizing a liquid-gas contactor system to enhance gas dissolution and prevent gas loss, and an advanced oxidation process (AOP) can be added for complete treatment.

Environmental Impact Assessment

The use of muriatic acid in the treatment of oily wastewater raises significant environmental concerns that require careful assessment. The primary environmental impact stems from the potential release of acidic effluents into aquatic ecosystems. When not properly neutralized, these acidic discharges can lead to a decrease in pH levels of receiving water bodies, adversely affecting aquatic life and disrupting ecosystem balance. This pH alteration can result in the death of fish, algae, and other aquatic organisms, as well as impact the overall biodiversity of affected water systems.

Furthermore, the use of muriatic acid may lead to the mobilization of heavy metals present in the oily wastewater or treatment infrastructure. These metals, once solubilized, can enter the food chain and bioaccumulate in various organisms, potentially causing long-term ecological damage and posing risks to human health through contaminated water sources or consumption of affected aquatic species.

The treatment process itself may generate harmful byproducts or emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants could be released during the acid treatment of oily wastewater, contributing to air quality degradation and potentially affecting both human health and the environment in surrounding areas. Proper air pollution control measures must be implemented to mitigate these risks.

Soil contamination is another potential environmental concern. Accidental spills or improper disposal of acid-treated wastewater can lead to soil acidification, affecting soil fertility and microbial communities. This, in turn, can impact terrestrial ecosystems and agricultural productivity in affected areas.

The transportation and storage of muriatic acid also present environmental risks. Accidental releases during transport or storage could result in localized environmental damage, including soil and water contamination, as well as potential harm to flora and fauna in the vicinity of the incident.

To mitigate these environmental impacts, comprehensive treatment systems must be designed and implemented. These should include neutralization processes to adjust pH levels before discharge, advanced filtration systems to remove heavy metals and other contaminants, and proper air emission control technologies. Additionally, stringent safety protocols for handling, storage, and transportation of muriatic acid are essential to prevent accidental releases and minimize environmental risks.

Regular environmental monitoring and impact assessments should be conducted to evaluate the effectiveness of mitigation measures and to detect any long-term effects on surrounding ecosystems. This may include periodic testing of water quality, soil composition, and air quality in the vicinity of treatment facilities. Compliance with local, national, and international environmental regulations is crucial to ensure responsible use of muriatic acid in oily wastewater treatment and to safeguard environmental integrity.

Furthermore, the use of muriatic acid may lead to the mobilization of heavy metals present in the oily wastewater or treatment infrastructure. These metals, once solubilized, can enter the food chain and bioaccumulate in various organisms, potentially causing long-term ecological damage and posing risks to human health through contaminated water sources or consumption of affected aquatic species.

The treatment process itself may generate harmful byproducts or emissions. Volatile organic compounds (VOCs) and other hazardous air pollutants could be released during the acid treatment of oily wastewater, contributing to air quality degradation and potentially affecting both human health and the environment in surrounding areas. Proper air pollution control measures must be implemented to mitigate these risks.

Soil contamination is another potential environmental concern. Accidental spills or improper disposal of acid-treated wastewater can lead to soil acidification, affecting soil fertility and microbial communities. This, in turn, can impact terrestrial ecosystems and agricultural productivity in affected areas.

The transportation and storage of muriatic acid also present environmental risks. Accidental releases during transport or storage could result in localized environmental damage, including soil and water contamination, as well as potential harm to flora and fauna in the vicinity of the incident.

To mitigate these environmental impacts, comprehensive treatment systems must be designed and implemented. These should include neutralization processes to adjust pH levels before discharge, advanced filtration systems to remove heavy metals and other contaminants, and proper air emission control technologies. Additionally, stringent safety protocols for handling, storage, and transportation of muriatic acid are essential to prevent accidental releases and minimize environmental risks.

Regular environmental monitoring and impact assessments should be conducted to evaluate the effectiveness of mitigation measures and to detect any long-term effects on surrounding ecosystems. This may include periodic testing of water quality, soil composition, and air quality in the vicinity of treatment facilities. Compliance with local, national, and international environmental regulations is crucial to ensure responsible use of muriatic acid in oily wastewater treatment and to safeguard environmental integrity.

Cost-Benefit Analysis of Muriatic Acid Treatment

The cost-benefit analysis of muriatic acid treatment for oily wastewater is a crucial consideration for industries seeking efficient and economical solutions. This analysis encompasses both direct and indirect costs associated with the implementation of muriatic acid treatment systems, as well as the potential benefits derived from improved wastewater quality and regulatory compliance.

Initial capital expenditure for muriatic acid treatment systems typically includes equipment costs such as storage tanks, dosing pumps, and monitoring devices. These upfront investments can vary significantly based on the scale of operations and the complexity of the treatment process. Additionally, installation and integration expenses must be factored into the initial cost assessment.

Operational costs constitute a significant portion of the overall expense. The primary recurring cost is the procurement of muriatic acid itself, which can fluctuate based on market conditions and supplier agreements. Labor costs for system operation and maintenance, as well as energy consumption for pumping and mixing processes, contribute to the ongoing operational expenses.

Safety measures and personnel training represent another cost category. Proper handling of muriatic acid requires specialized equipment and protocols, necessitating investment in personal protective equipment (PPE) and regular safety training programs for staff. These measures are essential for minimizing workplace hazards and ensuring regulatory compliance.

On the benefits side, muriatic acid treatment can lead to substantial improvements in wastewater quality. The efficient removal of oil and suspended solids from wastewater can result in reduced environmental impact and enhanced compliance with discharge regulations. This compliance can help avoid costly fines and legal issues associated with environmental violations.

The treated wastewater may also present opportunities for reuse within industrial processes, potentially reducing overall water consumption and associated costs. This circular approach to water management can lead to long-term savings and improved sustainability metrics for the organization.

Furthermore, the implementation of effective wastewater treatment systems can enhance a company's reputation, potentially leading to improved stakeholder relations and market positioning. This intangible benefit, while difficult to quantify, can contribute to long-term business success and sustainability.

When conducting a comprehensive cost-benefit analysis, it is essential to consider the long-term implications of muriatic acid treatment. While initial costs may be significant, the potential for reduced environmental liabilities, operational efficiencies, and resource conservation can offer substantial returns over time. Organizations must carefully weigh these factors against alternative treatment methods to determine the most suitable approach for their specific operational context and financial objectives.

Initial capital expenditure for muriatic acid treatment systems typically includes equipment costs such as storage tanks, dosing pumps, and monitoring devices. These upfront investments can vary significantly based on the scale of operations and the complexity of the treatment process. Additionally, installation and integration expenses must be factored into the initial cost assessment.

Operational costs constitute a significant portion of the overall expense. The primary recurring cost is the procurement of muriatic acid itself, which can fluctuate based on market conditions and supplier agreements. Labor costs for system operation and maintenance, as well as energy consumption for pumping and mixing processes, contribute to the ongoing operational expenses.

Safety measures and personnel training represent another cost category. Proper handling of muriatic acid requires specialized equipment and protocols, necessitating investment in personal protective equipment (PPE) and regular safety training programs for staff. These measures are essential for minimizing workplace hazards and ensuring regulatory compliance.

On the benefits side, muriatic acid treatment can lead to substantial improvements in wastewater quality. The efficient removal of oil and suspended solids from wastewater can result in reduced environmental impact and enhanced compliance with discharge regulations. This compliance can help avoid costly fines and legal issues associated with environmental violations.

The treated wastewater may also present opportunities for reuse within industrial processes, potentially reducing overall water consumption and associated costs. This circular approach to water management can lead to long-term savings and improved sustainability metrics for the organization.

Furthermore, the implementation of effective wastewater treatment systems can enhance a company's reputation, potentially leading to improved stakeholder relations and market positioning. This intangible benefit, while difficult to quantify, can contribute to long-term business success and sustainability.

When conducting a comprehensive cost-benefit analysis, it is essential to consider the long-term implications of muriatic acid treatment. While initial costs may be significant, the potential for reduced environmental liabilities, operational efficiencies, and resource conservation can offer substantial returns over time. Organizations must carefully weigh these factors against alternative treatment methods to determine the most suitable approach for their specific operational context and financial objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!