How Muriatic Acid is Used in the Production of Ethanol

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid in Ethanol Production: Background and Objectives

Muriatic acid, also known as hydrochloric acid, plays a crucial role in the production of ethanol, a widely used biofuel and chemical compound. The use of muriatic acid in ethanol production has evolved over time, reflecting advancements in industrial processes and a growing demand for more efficient and sustainable fuel sources.

Historically, ethanol production relied on fermentation processes that did not involve muriatic acid. However, as the industry sought to improve yields and reduce costs, the integration of acid-based pretreatment methods became increasingly common. This shift marked a significant milestone in the evolution of ethanol production technology.

The primary objective of using muriatic acid in ethanol production is to enhance the efficiency of the overall process. Specifically, muriatic acid is employed in the pretreatment stage of lignocellulosic biomass, which is a key raw material for second-generation bioethanol production. The acid helps to break down the complex structure of plant materials, making cellulose and hemicellulose more accessible for subsequent enzymatic hydrolysis.

Another important goal is to increase the yield of fermentable sugars from biomass feedstocks. By effectively pretreating the raw materials with muriatic acid, a higher percentage of the available sugars can be extracted and converted into ethanol. This not only improves the overall production efficiency but also contributes to the economic viability of ethanol as a renewable fuel source.

Furthermore, the use of muriatic acid aims to reduce the formation of inhibitory compounds during the pretreatment process. These compounds can hinder fermentation and decrease ethanol yields. By optimizing the acid pretreatment conditions, producers can minimize the generation of these unwanted byproducts, leading to a more streamlined and effective production process.

The integration of muriatic acid in ethanol production also aligns with broader technological trends in the biofuel industry. As the sector moves towards more advanced and sustainable production methods, the role of chemical pretreatments like muriatic acid becomes increasingly important. This trend is driven by the need to utilize a wider range of feedstocks, including agricultural residues and dedicated energy crops, which often require more intensive pretreatment to release their fermentable sugars.

Looking ahead, the use of muriatic acid in ethanol production is expected to continue evolving. Research efforts are focused on optimizing acid concentrations, reaction times, and temperature conditions to further improve efficiency and reduce environmental impact. Additionally, there is growing interest in developing hybrid pretreatment methods that combine acid hydrolysis with other techniques, such as steam explosion or enzymatic treatments, to achieve even better results.

Historically, ethanol production relied on fermentation processes that did not involve muriatic acid. However, as the industry sought to improve yields and reduce costs, the integration of acid-based pretreatment methods became increasingly common. This shift marked a significant milestone in the evolution of ethanol production technology.

The primary objective of using muriatic acid in ethanol production is to enhance the efficiency of the overall process. Specifically, muriatic acid is employed in the pretreatment stage of lignocellulosic biomass, which is a key raw material for second-generation bioethanol production. The acid helps to break down the complex structure of plant materials, making cellulose and hemicellulose more accessible for subsequent enzymatic hydrolysis.

Another important goal is to increase the yield of fermentable sugars from biomass feedstocks. By effectively pretreating the raw materials with muriatic acid, a higher percentage of the available sugars can be extracted and converted into ethanol. This not only improves the overall production efficiency but also contributes to the economic viability of ethanol as a renewable fuel source.

Furthermore, the use of muriatic acid aims to reduce the formation of inhibitory compounds during the pretreatment process. These compounds can hinder fermentation and decrease ethanol yields. By optimizing the acid pretreatment conditions, producers can minimize the generation of these unwanted byproducts, leading to a more streamlined and effective production process.

The integration of muriatic acid in ethanol production also aligns with broader technological trends in the biofuel industry. As the sector moves towards more advanced and sustainable production methods, the role of chemical pretreatments like muriatic acid becomes increasingly important. This trend is driven by the need to utilize a wider range of feedstocks, including agricultural residues and dedicated energy crops, which often require more intensive pretreatment to release their fermentable sugars.

Looking ahead, the use of muriatic acid in ethanol production is expected to continue evolving. Research efforts are focused on optimizing acid concentrations, reaction times, and temperature conditions to further improve efficiency and reduce environmental impact. Additionally, there is growing interest in developing hybrid pretreatment methods that combine acid hydrolysis with other techniques, such as steam explosion or enzymatic treatments, to achieve even better results.

Market Analysis of Ethanol and Muriatic Acid

The ethanol and muriatic acid markets are closely intertwined, with muriatic acid playing a crucial role in ethanol production. The global ethanol market has been experiencing steady growth, driven by increasing demand for biofuels and renewable energy sources. In 2020, the global ethanol market was valued at approximately $89 billion, with projections indicating a compound annual growth rate (CAGR) of 4.8% from 2021 to 2028.

The United States and Brazil are the leading producers and consumers of ethanol, accounting for over 80% of global production. The U.S. ethanol industry alone contributes significantly to the economy, generating billions of dollars in revenue and supporting hundreds of thousands of jobs. The demand for ethanol is primarily driven by its use as a fuel additive, with the automotive sector being the largest end-user.

Muriatic acid, also known as hydrochloric acid, has a diverse range of industrial applications, including its use in ethanol production. The global muriatic acid market was valued at around $7.5 billion in 2020, with expectations of steady growth in the coming years. The market is segmented based on grade (food grade, industrial grade, and others) and application (food processing, steel pickling, oil well acidizing, and others).

In ethanol production, muriatic acid is used for pH adjustment and cleaning of equipment. The increasing demand for ethanol has consequently led to a rise in the demand for muriatic acid in this sector. However, the market for muriatic acid is not solely dependent on ethanol production, as it finds applications in various other industries such as chemicals, textiles, and water treatment.

The market dynamics of both ethanol and muriatic acid are influenced by factors such as government regulations, environmental concerns, and technological advancements. For instance, stringent environmental regulations have led to increased adoption of cleaner production processes in both industries. Additionally, the development of more efficient ethanol production methods has impacted the demand for muriatic acid in this sector.

Geographically, North America and Asia-Pacific are the largest markets for both ethanol and muriatic acid. The Asia-Pacific region, in particular, is expected to witness significant growth in both markets due to rapid industrialization and increasing energy demands in countries like China and India.

Looking ahead, the ethanol market is poised for further growth, driven by increasing environmental awareness and government mandates for blending ethanol with gasoline. This growth is expected to have a positive impact on the muriatic acid market, particularly in the ethanol production segment. However, challenges such as fluctuating raw material prices and environmental concerns regarding the production and handling of muriatic acid may impact market growth.

The United States and Brazil are the leading producers and consumers of ethanol, accounting for over 80% of global production. The U.S. ethanol industry alone contributes significantly to the economy, generating billions of dollars in revenue and supporting hundreds of thousands of jobs. The demand for ethanol is primarily driven by its use as a fuel additive, with the automotive sector being the largest end-user.

Muriatic acid, also known as hydrochloric acid, has a diverse range of industrial applications, including its use in ethanol production. The global muriatic acid market was valued at around $7.5 billion in 2020, with expectations of steady growth in the coming years. The market is segmented based on grade (food grade, industrial grade, and others) and application (food processing, steel pickling, oil well acidizing, and others).

In ethanol production, muriatic acid is used for pH adjustment and cleaning of equipment. The increasing demand for ethanol has consequently led to a rise in the demand for muriatic acid in this sector. However, the market for muriatic acid is not solely dependent on ethanol production, as it finds applications in various other industries such as chemicals, textiles, and water treatment.

The market dynamics of both ethanol and muriatic acid are influenced by factors such as government regulations, environmental concerns, and technological advancements. For instance, stringent environmental regulations have led to increased adoption of cleaner production processes in both industries. Additionally, the development of more efficient ethanol production methods has impacted the demand for muriatic acid in this sector.

Geographically, North America and Asia-Pacific are the largest markets for both ethanol and muriatic acid. The Asia-Pacific region, in particular, is expected to witness significant growth in both markets due to rapid industrialization and increasing energy demands in countries like China and India.

Looking ahead, the ethanol market is poised for further growth, driven by increasing environmental awareness and government mandates for blending ethanol with gasoline. This growth is expected to have a positive impact on the muriatic acid market, particularly in the ethanol production segment. However, challenges such as fluctuating raw material prices and environmental concerns regarding the production and handling of muriatic acid may impact market growth.

Technical Challenges in Ethanol Production Using Muriatic Acid

The use of muriatic acid, also known as hydrochloric acid, in ethanol production presents several technical challenges that require careful consideration and innovative solutions. One of the primary issues is the corrosive nature of muriatic acid, which can lead to significant equipment degradation over time. This necessitates the use of specialized materials and coatings for tanks, pipes, and other processing equipment, increasing both initial investment and maintenance costs.

Another challenge lies in maintaining precise pH levels throughout the production process. Muriatic acid is used to adjust pH during various stages, including pretreatment of biomass feedstocks and fermentation. However, even slight variations in acid concentration or distribution can significantly impact enzyme activity and microbial growth, potentially reducing ethanol yield and quality. Developing robust control systems and sensors for real-time pH monitoring and adjustment is crucial to address this challenge.

The handling and storage of muriatic acid pose safety concerns for workers and the environment. Proper containment, ventilation, and personal protective equipment are essential to prevent accidents and exposure. Additionally, the disposal of acid-containing waste streams requires careful management to comply with environmental regulations and minimize ecological impact.

Optimizing the acid pretreatment step presents another technical hurdle. While muriatic acid effectively breaks down lignocellulosic materials to release fermentable sugars, it can also produce inhibitory compounds that hinder subsequent fermentation. Balancing the severity of pretreatment with minimizing inhibitor formation is a delicate process that requires ongoing research and process optimization.

The recovery and recycling of muriatic acid from process streams is both an economic and environmental challenge. Developing efficient separation and purification techniques to reclaim and reuse the acid can significantly reduce operational costs and environmental footprint. However, this often involves complex separation processes and energy-intensive operations, which must be optimized for overall process efficiency.

Scaling up laboratory processes to industrial production levels introduces additional challenges. Maintaining consistent acid distribution and mixing in large-scale reactors, ensuring uniform heat transfer, and managing increased volumes of corrosive materials all require careful engineering and process design. Pilot-scale testing and gradual scale-up are often necessary to identify and address unforeseen issues.

Lastly, the integration of muriatic acid-based processes with other ethanol production steps, such as enzymatic hydrolysis and fermentation, requires careful optimization. Residual acid can interfere with downstream processes, necessitating neutralization or removal steps that add complexity and cost to the overall production system. Developing seamless integration strategies and potentially exploring alternative acid recovery methods are ongoing areas of research and development in the field.

Another challenge lies in maintaining precise pH levels throughout the production process. Muriatic acid is used to adjust pH during various stages, including pretreatment of biomass feedstocks and fermentation. However, even slight variations in acid concentration or distribution can significantly impact enzyme activity and microbial growth, potentially reducing ethanol yield and quality. Developing robust control systems and sensors for real-time pH monitoring and adjustment is crucial to address this challenge.

The handling and storage of muriatic acid pose safety concerns for workers and the environment. Proper containment, ventilation, and personal protective equipment are essential to prevent accidents and exposure. Additionally, the disposal of acid-containing waste streams requires careful management to comply with environmental regulations and minimize ecological impact.

Optimizing the acid pretreatment step presents another technical hurdle. While muriatic acid effectively breaks down lignocellulosic materials to release fermentable sugars, it can also produce inhibitory compounds that hinder subsequent fermentation. Balancing the severity of pretreatment with minimizing inhibitor formation is a delicate process that requires ongoing research and process optimization.

The recovery and recycling of muriatic acid from process streams is both an economic and environmental challenge. Developing efficient separation and purification techniques to reclaim and reuse the acid can significantly reduce operational costs and environmental footprint. However, this often involves complex separation processes and energy-intensive operations, which must be optimized for overall process efficiency.

Scaling up laboratory processes to industrial production levels introduces additional challenges. Maintaining consistent acid distribution and mixing in large-scale reactors, ensuring uniform heat transfer, and managing increased volumes of corrosive materials all require careful engineering and process design. Pilot-scale testing and gradual scale-up are often necessary to identify and address unforeseen issues.

Lastly, the integration of muriatic acid-based processes with other ethanol production steps, such as enzymatic hydrolysis and fermentation, requires careful optimization. Residual acid can interfere with downstream processes, necessitating neutralization or removal steps that add complexity and cost to the overall production system. Developing seamless integration strategies and potentially exploring alternative acid recovery methods are ongoing areas of research and development in the field.

Current Muriatic Acid-Based Ethanol Production Techniques

01 Chemical properties and applications of muriatic acid

Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and household applications. It is commonly used for cleaning, pH adjustment, and as a reagent in chemical processes. Its corrosive nature makes it effective for removing rust, scale, and other deposits.- Chemical properties and applications: Muriatic acid, also known as hydrochloric acid, is a strong mineral acid with various industrial and commercial applications. It is used in metal cleaning, pH adjustment, and as a reagent in chemical processes. Its corrosive nature and ability to dissolve certain metals make it useful in surface preparation and etching.

- Cleaning and surface treatment: Muriatic acid is widely used in cleaning and surface treatment applications. It is effective in removing rust, scale, and mineral deposits from various surfaces. In the construction industry, it is used for cleaning masonry, concrete, and tiles. The acid's ability to etch surfaces makes it useful in preparing substrates for coating or further treatment.

- Industrial processes and manufacturing: Muriatic acid plays a crucial role in various industrial processes and manufacturing. It is used in the production of chemicals, pharmaceuticals, and food additives. In the steel industry, it is employed for pickling and descaling metal surfaces. The acid is also utilized in water treatment, oil well acidizing, and as a catalyst in organic synthesis reactions.

- Safety and handling considerations: Due to its corrosive nature, proper safety measures and handling procedures are essential when working with muriatic acid. This includes using appropriate personal protective equipment, proper storage containers, and ventilation systems. Neutralization and disposal methods are important to prevent environmental contamination and ensure worker safety.

- Alternative formulations and applications: Research has been conducted on alternative formulations and applications of muriatic acid to enhance its effectiveness or reduce its environmental impact. This includes developing inhibited muriatic acid formulations, exploring its use in specialized cleaning products, and investigating its potential in emerging technologies such as fuel cells and energy storage systems.

02 Use of muriatic acid in water treatment

Muriatic acid plays a crucial role in water treatment processes. It is used for pH adjustment in swimming pools, industrial water systems, and municipal water treatment plants. The acid helps maintain proper water chemistry, prevents scale formation, and enhances the effectiveness of other treatment chemicals.Expand Specific Solutions03 Muriatic acid in metal processing and surface treatment

In metal processing, muriatic acid is used for pickling, etching, and cleaning metal surfaces. It effectively removes rust, scale, and other impurities from metals, preparing them for further treatment or coating. The acid is also used in electroplating processes and in the production of various metal compounds.Expand Specific Solutions04 Safety measures and handling of muriatic acid

Due to its corrosive nature, proper safety measures are essential when handling muriatic acid. This includes using appropriate personal protective equipment, proper storage containers, and ventilation systems. Neutralization techniques and spill control methods are also important aspects of safe muriatic acid handling and disposal.Expand Specific Solutions05 Environmental considerations and alternatives to muriatic acid

While muriatic acid is widely used, there are environmental concerns associated with its production and use. Research is ongoing to develop more environmentally friendly alternatives or to improve the efficiency of muriatic acid use. This includes exploring bio-based acids, developing closed-loop systems for acid recycling, and implementing advanced treatment technologies for acid-containing waste streams.Expand Specific Solutions

Key Industry Players in Ethanol and Chemical Production

The production of ethanol using muriatic acid is a mature technology within the broader biofuels industry, which is currently in a growth phase. The global ethanol market size is projected to reach $100 billion by 2025, driven by increasing demand for renewable fuels. Major players like Celanese, ExxonMobil, and LanzaTech are investing in advanced ethanol production technologies, including those utilizing muriatic acid. These companies, along with research institutions such as Korea Research Institute of Bioscience & Biotechnology and Tianjin University, are focusing on improving process efficiency and reducing production costs. The competitive landscape is characterized by a mix of established chemical companies and innovative biotech firms, with ongoing research and development efforts aimed at optimizing the use of muriatic acid in ethanol production.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) employs a multi-step process for ethanol production using muriatic acid (hydrochloric acid). The process involves acid hydrolysis of lignocellulosic biomass, where muriatic acid breaks down complex carbohydrates into simple sugars. Sinopec's method utilizes a dilute acid pretreatment step, typically using 0.5-2% muriatic acid at temperatures between 140-200°C [1]. This pretreatment enhances the accessibility of cellulose to enzymatic hydrolysis, improving overall ethanol yield. The company has also developed a novel acid recovery system, which recycles up to 97% of the muriatic acid, significantly reducing operational costs and environmental impact [3]. Sinopec's process integrates advanced fermentation techniques with genetically modified yeast strains capable of fermenting both hexose and pentose sugars, resulting in ethanol yields of up to 85% of the theoretical maximum [5].

Strengths: High efficiency in breaking down lignocellulosic biomass, cost-effective acid recovery system, and improved ethanol yields. Weaknesses: Potential equipment corrosion due to acid use and the need for acid-resistant materials, which may increase capital costs.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has developed an innovative approach to ethanol production utilizing muriatic acid in a two-stage hydrolysis process. The first stage involves a mild acid pretreatment using dilute muriatic acid (1-3% concentration) at moderate temperatures (100-140°C) to hydrolyze hemicellulose [2]. This is followed by a more severe acid hydrolysis step using concentrated muriatic acid (30-40%) at lower temperatures (30-50°C) to break down cellulose into glucose [4]. ExxonMobil's process incorporates a proprietary acid recovery system that achieves over 99% acid recovery, significantly reducing operational costs and environmental impact. The company has also developed a unique fermentation process using genetically engineered microorganisms capable of fermenting both C5 and C6 sugars, resulting in ethanol yields of up to 90% of the theoretical maximum [6]. Additionally, ExxonMobil has implemented an advanced distillation system that reduces energy consumption in the ethanol purification process by up to 30% compared to conventional methods [8].

Strengths: High ethanol yields, efficient acid recovery, and reduced energy consumption in purification. Weaknesses: Requires handling of concentrated acids, which may pose safety concerns and necessitate specialized equipment.

Innovative Approaches in Acid Catalysis for Ethanol Synthesis

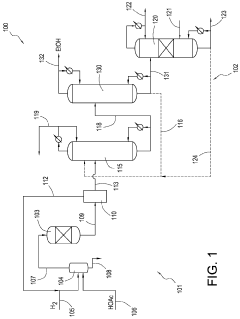

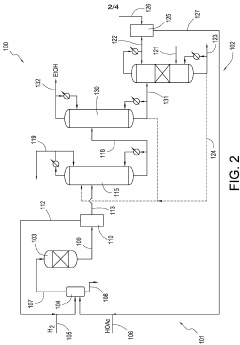

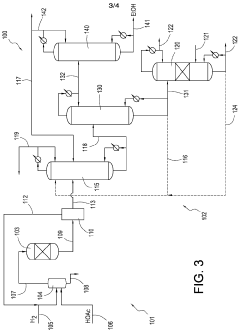

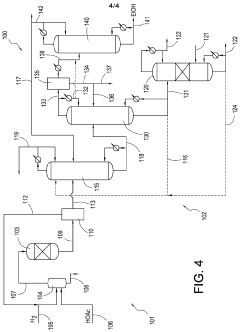

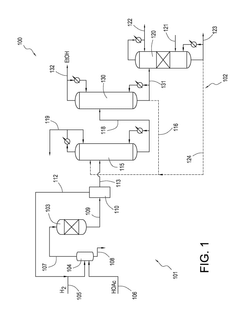

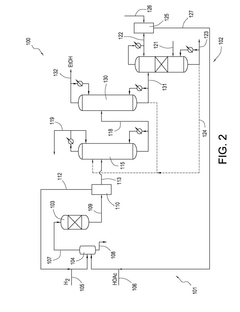

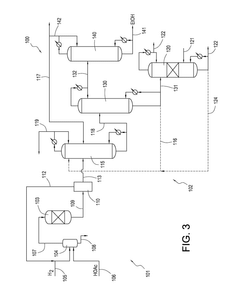

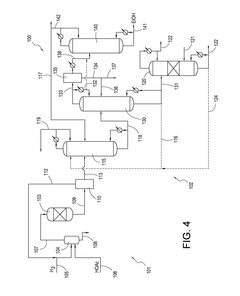

Process for producing ethanol and reducing acetic acid concentration

PatentWO2012149199A2

Innovation

- A process involving hydrogenation of acetic acid in the presence of a catalyst to produce a caide ethanol product, followed by distillation to separate acetic acid from ethanol, and subsequent esterification with alcohols to produce ester products that are easier to separate from water, thereby reducing acetic acid concentration in the ethanol stream.

Process for Producing Ethanol and Reducing Acetic Acid Concentration

PatentInactiveUS20120277496A1

Innovation

- A process involving hydrogenation of acetic acid in the presence of a catalyst to produce a crude ethanol product, followed by distillation to separate acetic acid from ethanol, and subsequent esterification with alcohols to produce ester products that are easier to separate from water, thereby improving the recovery of ethanol.

Environmental Impact and Sustainability Considerations

The use of muriatic acid in ethanol production raises significant environmental and sustainability concerns that warrant careful consideration. The production process involves the use of large quantities of water and chemicals, including muriatic acid, which can have detrimental effects on the environment if not properly managed.

One of the primary environmental concerns is the potential for water pollution. Muriatic acid, being a strong and corrosive substance, can contaminate water sources if not adequately contained or treated before disposal. This contamination can lead to acidification of water bodies, harming aquatic ecosystems and potentially affecting human health if it enters drinking water supplies.

Air pollution is another environmental issue associated with the use of muriatic acid in ethanol production. The acid can release harmful fumes and vapors during the manufacturing process, contributing to air quality degradation and potentially causing respiratory problems for workers and nearby communities if proper ventilation and safety measures are not implemented.

The production and transportation of muriatic acid also contribute to the carbon footprint of ethanol production. The energy-intensive processes involved in manufacturing the acid, as well as the emissions from transporting it to ethanol production facilities, add to the overall environmental impact of the industry.

From a sustainability perspective, the use of muriatic acid raises questions about resource depletion and long-term viability. The acid is derived from non-renewable resources, and its production consumes significant amounts of energy and raw materials. As global demand for ethanol increases, the sustainability of relying on such resource-intensive inputs becomes a pressing concern.

To address these environmental and sustainability challenges, the ethanol industry is exploring alternative production methods and more sustainable practices. Some companies are investigating the use of bio-based acids or enzymes as substitutes for muriatic acid, which could reduce the environmental impact and improve the overall sustainability of ethanol production.

Additionally, advancements in process efficiency and waste management are being pursued to minimize the environmental footprint of ethanol production. This includes implementing closed-loop systems to recycle and reuse chemicals, improving wastewater treatment processes, and adopting more energy-efficient production techniques.

Regulatory bodies are also playing a crucial role in addressing the environmental impact of ethanol production. Stricter regulations on emissions, waste disposal, and chemical handling are being implemented in many regions, forcing the industry to adopt more sustainable practices and invest in cleaner technologies.

One of the primary environmental concerns is the potential for water pollution. Muriatic acid, being a strong and corrosive substance, can contaminate water sources if not adequately contained or treated before disposal. This contamination can lead to acidification of water bodies, harming aquatic ecosystems and potentially affecting human health if it enters drinking water supplies.

Air pollution is another environmental issue associated with the use of muriatic acid in ethanol production. The acid can release harmful fumes and vapors during the manufacturing process, contributing to air quality degradation and potentially causing respiratory problems for workers and nearby communities if proper ventilation and safety measures are not implemented.

The production and transportation of muriatic acid also contribute to the carbon footprint of ethanol production. The energy-intensive processes involved in manufacturing the acid, as well as the emissions from transporting it to ethanol production facilities, add to the overall environmental impact of the industry.

From a sustainability perspective, the use of muriatic acid raises questions about resource depletion and long-term viability. The acid is derived from non-renewable resources, and its production consumes significant amounts of energy and raw materials. As global demand for ethanol increases, the sustainability of relying on such resource-intensive inputs becomes a pressing concern.

To address these environmental and sustainability challenges, the ethanol industry is exploring alternative production methods and more sustainable practices. Some companies are investigating the use of bio-based acids or enzymes as substitutes for muriatic acid, which could reduce the environmental impact and improve the overall sustainability of ethanol production.

Additionally, advancements in process efficiency and waste management are being pursued to minimize the environmental footprint of ethanol production. This includes implementing closed-loop systems to recycle and reuse chemicals, improving wastewater treatment processes, and adopting more energy-efficient production techniques.

Regulatory bodies are also playing a crucial role in addressing the environmental impact of ethanol production. Stricter regulations on emissions, waste disposal, and chemical handling are being implemented in many regions, forcing the industry to adopt more sustainable practices and invest in cleaner technologies.

Safety Protocols and Regulatory Compliance in Ethanol Manufacturing

The production of ethanol using muriatic acid requires strict adherence to safety protocols and regulatory compliance to ensure worker safety, environmental protection, and product quality. Ethanol manufacturing facilities must implement comprehensive safety management systems that address the specific risks associated with handling muriatic acid and other hazardous materials.

Personal protective equipment (PPE) is a critical component of safety protocols in ethanol production. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Proper training on the correct use and maintenance of PPE is essential to ensure its effectiveness in preventing chemical exposure.

Ventilation systems play a crucial role in maintaining a safe working environment. Ethanol manufacturing facilities must be equipped with adequate local exhaust ventilation to remove acid vapors and fumes from work areas. Regular maintenance and testing of these systems are necessary to ensure their optimal performance and compliance with regulatory standards.

Emergency response procedures are vital for addressing potential accidents or spills involving muriatic acid. Facilities must have clearly defined protocols for evacuation, spill containment, and decontamination. Emergency eyewash stations and safety showers should be readily accessible in areas where acid is handled or stored.

Storage and handling of muriatic acid require specific safety measures. Acid-resistant containment systems, proper labeling, and segregation from incompatible materials are essential. Regular inspections of storage areas and transfer equipment help prevent leaks and ensure the integrity of containment systems.

Regulatory compliance in ethanol manufacturing involves adherence to various national and international standards. In the United States, facilities must comply with Occupational Safety and Health Administration (OSHA) regulations, including the Process Safety Management (PSM) standard for highly hazardous chemicals. The Environmental Protection Agency (EPA) also enforces regulations related to air emissions, wastewater discharge, and hazardous waste management in ethanol production.

Employee training is a critical aspect of safety and compliance programs. Workers must receive comprehensive instruction on hazard recognition, proper handling procedures, emergency response, and the use of safety equipment. Regular refresher training and competency assessments help maintain a high level of safety awareness and preparedness.

Documentation and record-keeping are essential for demonstrating regulatory compliance. Ethanol manufacturers must maintain detailed records of safety procedures, employee training, equipment maintenance, and incident reports. These records are subject to review during regulatory inspections and audits.

Continuous improvement of safety protocols is necessary to address evolving risks and regulatory requirements. Regular safety audits, incident investigations, and risk assessments help identify areas for improvement and ensure that safety measures remain effective and up-to-date.

Personal protective equipment (PPE) is a critical component of safety protocols in ethanol production. Workers must wear appropriate chemical-resistant gloves, goggles, face shields, and protective clothing when handling muriatic acid. Proper training on the correct use and maintenance of PPE is essential to ensure its effectiveness in preventing chemical exposure.

Ventilation systems play a crucial role in maintaining a safe working environment. Ethanol manufacturing facilities must be equipped with adequate local exhaust ventilation to remove acid vapors and fumes from work areas. Regular maintenance and testing of these systems are necessary to ensure their optimal performance and compliance with regulatory standards.

Emergency response procedures are vital for addressing potential accidents or spills involving muriatic acid. Facilities must have clearly defined protocols for evacuation, spill containment, and decontamination. Emergency eyewash stations and safety showers should be readily accessible in areas where acid is handled or stored.

Storage and handling of muriatic acid require specific safety measures. Acid-resistant containment systems, proper labeling, and segregation from incompatible materials are essential. Regular inspections of storage areas and transfer equipment help prevent leaks and ensure the integrity of containment systems.

Regulatory compliance in ethanol manufacturing involves adherence to various national and international standards. In the United States, facilities must comply with Occupational Safety and Health Administration (OSHA) regulations, including the Process Safety Management (PSM) standard for highly hazardous chemicals. The Environmental Protection Agency (EPA) also enforces regulations related to air emissions, wastewater discharge, and hazardous waste management in ethanol production.

Employee training is a critical aspect of safety and compliance programs. Workers must receive comprehensive instruction on hazard recognition, proper handling procedures, emergency response, and the use of safety equipment. Regular refresher training and competency assessments help maintain a high level of safety awareness and preparedness.

Documentation and record-keeping are essential for demonstrating regulatory compliance. Ethanol manufacturers must maintain detailed records of safety procedures, employee training, equipment maintenance, and incident reports. These records are subject to review during regulatory inspections and audits.

Continuous improvement of safety protocols is necessary to address evolving risks and regulatory requirements. Regular safety audits, incident investigations, and risk assessments help identify areas for improvement and ensure that safety measures remain effective and up-to-date.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!