Anode-free batteries and their impact on electrode kinetics

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-free Battery Technology Background and Objectives

The evolution of battery technology has been a cornerstone of modern technological advancement, with lithium-ion batteries dominating the market since their commercial introduction in the early 1990s. However, as demands for higher energy density, longer lifespan, and improved safety continue to grow, conventional battery architectures face significant limitations. Anode-free battery technology represents a revolutionary approach that addresses these challenges by eliminating the traditional graphite or silicon anode, instead utilizing lithium metal directly deposited on the current collector during the initial charging process.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in electrolyte formulations and separator technologies have revitalized interest in this architecture. By removing the anode host material, these batteries can theoretically achieve energy densities approaching 500 Wh/kg, nearly double that of conventional lithium-ion batteries. This dramatic improvement stems from the elimination of "dead weight" in the form of graphite or silicon that typically serves as the host for lithium ions.

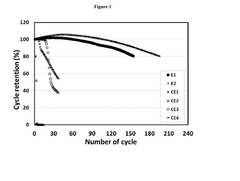

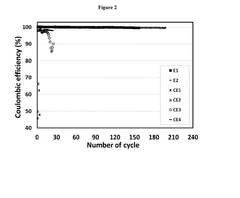

The technical evolution trajectory shows accelerating development since 2015, with significant publications and patents emerging from research institutions and industry leaders alike. The primary technical objective of anode-free battery research is to achieve stable lithium plating and stripping processes that maintain high Coulombic efficiency over hundreds of cycles. Current state-of-the-art systems demonstrate approximately 80-90% Coulombic efficiency, whereas commercial viability requires >99.9%.

Electrode kinetics represents a critical challenge in anode-free systems. Without a host structure to guide lithium deposition, the metal tends to form dendrites—needle-like structures that can penetrate the separator and cause short circuits. Understanding and controlling the interfacial reactions between the lithium metal and electrolyte is essential for improving cycle life and safety. Recent research focuses on electrolyte engineering and the development of artificial solid-electrolyte interphases (SEI) to regulate lithium deposition morphology.

The overarching goal of anode-free battery technology is to create a commercially viable energy storage solution that maximizes energy density while maintaining acceptable cycle life, rate capability, and safety characteristics. This requires interdisciplinary approaches combining materials science, electrochemistry, and engineering. Success in this field could revolutionize portable electronics, electric vehicles, and grid storage applications by enabling longer device operation, extended driving ranges, and more efficient energy management systems.

The concept of anode-free batteries dates back to the 1970s, but recent breakthroughs in electrolyte formulations and separator technologies have revitalized interest in this architecture. By removing the anode host material, these batteries can theoretically achieve energy densities approaching 500 Wh/kg, nearly double that of conventional lithium-ion batteries. This dramatic improvement stems from the elimination of "dead weight" in the form of graphite or silicon that typically serves as the host for lithium ions.

The technical evolution trajectory shows accelerating development since 2015, with significant publications and patents emerging from research institutions and industry leaders alike. The primary technical objective of anode-free battery research is to achieve stable lithium plating and stripping processes that maintain high Coulombic efficiency over hundreds of cycles. Current state-of-the-art systems demonstrate approximately 80-90% Coulombic efficiency, whereas commercial viability requires >99.9%.

Electrode kinetics represents a critical challenge in anode-free systems. Without a host structure to guide lithium deposition, the metal tends to form dendrites—needle-like structures that can penetrate the separator and cause short circuits. Understanding and controlling the interfacial reactions between the lithium metal and electrolyte is essential for improving cycle life and safety. Recent research focuses on electrolyte engineering and the development of artificial solid-electrolyte interphases (SEI) to regulate lithium deposition morphology.

The overarching goal of anode-free battery technology is to create a commercially viable energy storage solution that maximizes energy density while maintaining acceptable cycle life, rate capability, and safety characteristics. This requires interdisciplinary approaches combining materials science, electrochemistry, and engineering. Success in this field could revolutionize portable electronics, electric vehicles, and grid storage applications by enabling longer device operation, extended driving ranges, and more efficient energy management systems.

Market Demand Analysis for Next-Generation Energy Storage

The global energy storage market is experiencing unprecedented growth, driven by the increasing adoption of renewable energy sources and the electrification of transportation. Current projections indicate the energy storage market will reach $546 billion by 2035, with a compound annual growth rate of approximately 20% between 2023 and 2035. Within this expanding landscape, next-generation battery technologies, particularly anode-free batteries, are positioned to capture significant market share due to their potential for higher energy density and lower production costs.

Consumer electronics manufacturers are actively seeking battery solutions that can extend device runtime while maintaining or reducing form factors. This demand is evidenced by the 15% year-over-year increase in research and development investments from major electronics companies into advanced battery technologies during 2022-2023.

The electric vehicle (EV) sector represents perhaps the most substantial market opportunity for anode-free battery technology. With global EV sales projected to constitute 45% of all vehicle sales by 2035, automotive manufacturers are prioritizing battery innovations that address range anxiety and charging speed limitations. Anode-free designs, with their theoretical energy density improvements of 50-60% over conventional lithium-ion batteries, directly address these market requirements.

Grid-scale energy storage represents another significant growth vector, with installed capacity expected to increase tenfold by 2030. Utility companies and grid operators are specifically seeking storage solutions with improved cycle life, safety profiles, and reduced dependency on critical materials – all potential advantages of advanced anode-free configurations when electrode kinetics challenges are properly addressed.

Market analysis reveals that consumers and industrial buyers are willing to pay a 15-25% premium for energy storage solutions that deliver substantive improvements in energy density, charging speed, and operational lifetime. This pricing flexibility creates a viable commercialization pathway for anode-free technologies despite their current higher manufacturing costs.

Regional market assessment indicates particularly strong demand growth in Asia-Pacific and European markets, driven by aggressive electrification policies and renewable energy targets. North American markets show increasing demand signals following recent legislative support for domestic battery manufacturing and deployment.

Industry surveys indicate that 78% of battery manufacturers have initiated research programs focused on anode-free or anode-light battery architectures, signaling broad recognition of this technology's market potential. However, these same surveys highlight concerns regarding electrode kinetics as the primary technical barrier to commercialization, with 65% of respondents identifying this specific challenge as critical to market adoption.

Consumer electronics manufacturers are actively seeking battery solutions that can extend device runtime while maintaining or reducing form factors. This demand is evidenced by the 15% year-over-year increase in research and development investments from major electronics companies into advanced battery technologies during 2022-2023.

The electric vehicle (EV) sector represents perhaps the most substantial market opportunity for anode-free battery technology. With global EV sales projected to constitute 45% of all vehicle sales by 2035, automotive manufacturers are prioritizing battery innovations that address range anxiety and charging speed limitations. Anode-free designs, with their theoretical energy density improvements of 50-60% over conventional lithium-ion batteries, directly address these market requirements.

Grid-scale energy storage represents another significant growth vector, with installed capacity expected to increase tenfold by 2030. Utility companies and grid operators are specifically seeking storage solutions with improved cycle life, safety profiles, and reduced dependency on critical materials – all potential advantages of advanced anode-free configurations when electrode kinetics challenges are properly addressed.

Market analysis reveals that consumers and industrial buyers are willing to pay a 15-25% premium for energy storage solutions that deliver substantive improvements in energy density, charging speed, and operational lifetime. This pricing flexibility creates a viable commercialization pathway for anode-free technologies despite their current higher manufacturing costs.

Regional market assessment indicates particularly strong demand growth in Asia-Pacific and European markets, driven by aggressive electrification policies and renewable energy targets. North American markets show increasing demand signals following recent legislative support for domestic battery manufacturing and deployment.

Industry surveys indicate that 78% of battery manufacturers have initiated research programs focused on anode-free or anode-light battery architectures, signaling broad recognition of this technology's market potential. However, these same surveys highlight concerns regarding electrode kinetics as the primary technical barrier to commercialization, with 65% of respondents identifying this specific challenge as critical to market adoption.

Current State and Challenges in Anode-free Battery Development

Anode-free battery technology represents a significant paradigm shift in energy storage systems, eliminating the traditional graphite or silicon anode in favor of using the lithium metal directly deposited on the current collector during charging. The current state of development shows promising theoretical energy density improvements of 60-70% compared to conventional lithium-ion batteries, with potential energy densities exceeding 500 Wh/kg at the cell level.

Despite these advantages, several critical challenges impede widespread commercialization. The most significant obstacle remains the formation and growth of lithium dendrites during cycling, which can penetrate the separator and cause catastrophic short circuits. Recent research indicates that dendrite formation is directly linked to electrode kinetics, with uneven lithium deposition occurring due to heterogeneous current distribution across the electrode surface.

Electrolyte stability presents another major challenge, as most conventional electrolytes decompose when in contact with highly reactive lithium metal. This decomposition forms an unstable solid electrolyte interphase (SEI) that continuously consumes both electrolyte and active lithium, leading to rapid capacity fade. Advanced electrolyte formulations incorporating fluorinated solvents and high-concentration salt systems have shown improved performance but remain insufficient for long-term cycling stability.

The absence of a host structure for lithium deposition creates significant volume expansion issues during charging, with dimensional changes exceeding 20% in some cell designs. This expansion stresses the cell components and can lead to mechanical failures. Current research focuses on developing three-dimensional current collectors and artificial interphases to guide uniform lithium deposition.

Coulombic efficiency in anode-free batteries typically ranges from 95-98%, significantly lower than the 99.9%+ required for commercial viability. Each cycle irreversibly consumes lithium through side reactions, rapidly depleting the limited lithium inventory. Recent innovations using single-ion conducting solid electrolytes have improved efficiency but introduce new manufacturing challenges.

Globally, research institutions in North America, East Asia, and Europe lead development efforts, with notable progress at Stanford University, PNNL, and various Chinese academic institutions. Industrial players including QuantumScape, SolidEnergy Systems, and SES have demonstrated prototype cells with cycle lives approaching 400-500 cycles, still below the 1000+ cycles needed for automotive applications.

The electrode kinetics in anode-free systems differ fundamentally from conventional batteries, with lithium nucleation and growth mechanisms heavily influenced by current density, temperature, and pressure. Understanding these complex relationships remains incomplete, with computational models still struggling to accurately predict long-term performance under real-world conditions.

Despite these advantages, several critical challenges impede widespread commercialization. The most significant obstacle remains the formation and growth of lithium dendrites during cycling, which can penetrate the separator and cause catastrophic short circuits. Recent research indicates that dendrite formation is directly linked to electrode kinetics, with uneven lithium deposition occurring due to heterogeneous current distribution across the electrode surface.

Electrolyte stability presents another major challenge, as most conventional electrolytes decompose when in contact with highly reactive lithium metal. This decomposition forms an unstable solid electrolyte interphase (SEI) that continuously consumes both electrolyte and active lithium, leading to rapid capacity fade. Advanced electrolyte formulations incorporating fluorinated solvents and high-concentration salt systems have shown improved performance but remain insufficient for long-term cycling stability.

The absence of a host structure for lithium deposition creates significant volume expansion issues during charging, with dimensional changes exceeding 20% in some cell designs. This expansion stresses the cell components and can lead to mechanical failures. Current research focuses on developing three-dimensional current collectors and artificial interphases to guide uniform lithium deposition.

Coulombic efficiency in anode-free batteries typically ranges from 95-98%, significantly lower than the 99.9%+ required for commercial viability. Each cycle irreversibly consumes lithium through side reactions, rapidly depleting the limited lithium inventory. Recent innovations using single-ion conducting solid electrolytes have improved efficiency but introduce new manufacturing challenges.

Globally, research institutions in North America, East Asia, and Europe lead development efforts, with notable progress at Stanford University, PNNL, and various Chinese academic institutions. Industrial players including QuantumScape, SolidEnergy Systems, and SES have demonstrated prototype cells with cycle lives approaching 400-500 cycles, still below the 1000+ cycles needed for automotive applications.

The electrode kinetics in anode-free systems differ fundamentally from conventional batteries, with lithium nucleation and growth mechanisms heavily influenced by current density, temperature, and pressure. Understanding these complex relationships remains incomplete, with computational models still struggling to accurately predict long-term performance under real-world conditions.

Current Technical Solutions for Electrode Kinetics Enhancement

01 Anode-free battery design and architecture

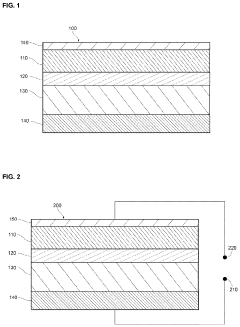

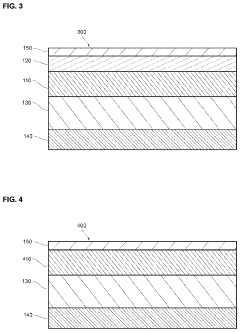

Anode-free batteries eliminate the traditional anode material, instead using a current collector where lithium is deposited during charging. This design significantly increases energy density by removing the weight and volume of the anode substrate. The architecture typically involves a lithium metal electrode that forms in situ during the first charge cycle, with special attention to the interface between the current collector and electrolyte to ensure uniform lithium deposition and prevent dendrite formation.- Anode-free battery design and architecture: Anode-free batteries eliminate the traditional anode material, instead utilizing lithium metal that plates directly onto the current collector during charging. This design significantly increases energy density while reducing weight and volume. The architecture typically includes specialized current collectors, separators, and electrolyte systems that facilitate controlled lithium plating and stripping, which is critical for electrode kinetics and overall battery performance.

- Electrolyte formulations for improved electrode kinetics: Advanced electrolyte formulations play a crucial role in enhancing electrode kinetics in anode-free batteries. These formulations often include additives that form stable solid electrolyte interphases (SEI), facilitate faster ion transport, and prevent dendrite formation. Specialized solvents, salts, and functional additives work synergistically to improve lithium ion mobility, reduce interfacial resistance, and enhance the rate capability of the battery system.

- Surface modification techniques for current collectors: Surface modification of current collectors is essential for optimizing electrode kinetics in anode-free batteries. These techniques include applying protective coatings, creating nanostructured surfaces, or introducing functional groups that enhance lithium nucleation and adhesion. Modified surfaces help achieve uniform lithium deposition, prevent dendrite formation, and improve cycling stability by controlling the interfacial reactions between the plated lithium and the current collector.

- Cathode materials and structures for balanced kinetics: Specialized cathode materials and structures are developed to balance the electrode kinetics in anode-free batteries. These include high-capacity cathode materials with optimized porosity, particle size distribution, and conductive networks that facilitate rapid ion diffusion and electron transfer. Advanced cathode designs incorporate gradient compositions or hierarchical structures that maintain stable performance during the unique charging and discharging processes of anode-free systems.

- In-situ monitoring and control of electrode kinetics: In-situ monitoring and control systems are implemented to optimize electrode kinetics in anode-free batteries. These technologies include advanced sensors, electrochemical impedance spectroscopy, and real-time analysis methods that track lithium plating/stripping behavior, interfacial resistance changes, and degradation mechanisms. The data collected enables adaptive charging protocols and battery management systems that dynamically adjust operating conditions to maintain optimal electrode kinetics throughout battery life.

02 Electrode kinetics enhancement strategies

Various approaches are employed to improve electrode kinetics in anode-free batteries, including surface modification of current collectors, incorporation of functional additives in electrolytes, and development of novel interfacial layers. These strategies aim to facilitate faster ion transport, reduce charge transfer resistance, and promote uniform lithium deposition/dissolution. Enhanced electrode kinetics leads to improved rate capability, reduced polarization, and better cycling stability in anode-free battery systems.Expand Specific Solutions03 Electrolyte formulations for improved kinetics

Specialized electrolyte formulations play a crucial role in anode-free battery performance by influencing the electrode kinetics. These formulations often include combinations of solvents, salts, and additives designed to form stable solid electrolyte interphases, suppress dendrite growth, and enhance lithium ion transport. Advanced electrolytes can incorporate ionic liquids, high-concentration salt systems, or fluorinated compounds to improve the electrochemical stability window and interfacial properties at the electrode-electrolyte interface.Expand Specific Solutions04 Characterization and modeling of electrode kinetics

Advanced characterization techniques and computational modeling are essential for understanding electrode kinetics in anode-free batteries. These include electrochemical impedance spectroscopy, scanning electron microscopy, X-ray diffraction, and various spectroscopic methods to analyze the electrode-electrolyte interface. Computational models help predict lithium deposition behavior, ion transport mechanisms, and degradation pathways, enabling the rational design of improved battery components with enhanced kinetic properties.Expand Specific Solutions05 Novel materials for current collectors and interfaces

Development of advanced materials for current collectors and interfacial layers is critical for optimizing electrode kinetics in anode-free batteries. These materials include nanostructured metals, carbon-based composites, and hybrid structures with tailored surface properties. Novel coating technologies and surface treatments are employed to modify the electrochemical properties of current collectors, promoting uniform lithium nucleation and growth while minimizing side reactions that could impede kinetics and cycle life.Expand Specific Solutions

Key Patents and Research on Anode-free Battery Interfaces

Anode-less lithium battery

PatentPendingIN202217059976A

Innovation

- An anode-less lithium ion battery design utilizing a liquid electrolyte composition comprising at least 70% by volume of a solvent mixture with a combination of fluorinated and non-fluorinated ether compounds and a lithium salt, which reduces dendrite growth and enhances cycling performance by optimizing the electrolyte composition and the formation of a stable solid electrolyte interface.

Lithium secondary battery, and anode free battery

PatentPendingUS20230238539A1

Innovation

- Incorporating an anion-absorbing conductive polymer between the positive electrode current collector and the separator or solid electrolyte in lithium secondary batteries without a negative electrode active material, allowing lithium metal deposition and consumption from both positive electrode and counter ions, which slows the deposition rate and enhances cycle characteristics.

Sustainability and Resource Implications of Anode-free Batteries

Anode-free battery technology represents a significant advancement in sustainable energy storage solutions, offering substantial environmental and resource benefits compared to conventional lithium-ion batteries. By eliminating the traditional graphite or silicon anode, these batteries reduce material consumption and manufacturing complexity while potentially increasing energy density. This design approach directly addresses critical sustainability challenges facing the battery industry, particularly regarding resource scarcity and environmental impact.

The removal of the anode substrate significantly reduces the consumption of critical materials, decreasing the overall ecological footprint of battery production. Conventional lithium-ion batteries require substantial amounts of graphite, copper, and other materials for anode construction, contributing to resource depletion and environmental degradation through mining and processing activities. Anode-free designs minimize these impacts by utilizing lithium metal directly as the active material, without requiring additional substrate materials.

From a lifecycle perspective, anode-free batteries offer promising advantages in terms of resource efficiency. The simplified battery architecture reduces the complexity of manufacturing processes, potentially lowering energy consumption during production. Additionally, the reduced material content may facilitate more efficient recycling processes, enabling better recovery of valuable materials at end-of-life. This closed-loop potential aligns with circular economy principles increasingly prioritized in sustainable technology development.

However, several sustainability challenges remain unresolved. The increased reliance on lithium metal in anode-free designs raises concerns about lithium supply chain sustainability, particularly as global demand for lithium continues to rise. Current lithium extraction methods, including brine evaporation and hard rock mining, present significant environmental challenges including water consumption, habitat disruption, and chemical pollution. Addressing these upstream sustainability issues will be crucial for realizing the full environmental benefits of anode-free technology.

The electrode kinetics of anode-free batteries also influence their sustainability profile through impacts on battery lifespan and performance stability. Current challenges with dendrite formation and electrolyte degradation can lead to shortened cycle life, potentially offsetting material savings through more frequent battery replacement. Improving electrode kinetics to enhance longevity represents a critical research direction that would significantly strengthen the sustainability case for anode-free technology.

Manufacturing scalability presents another important consideration in the sustainability assessment. While anode-free designs theoretically simplify production, they also introduce new manufacturing challenges related to handling reactive lithium metal and maintaining precise electrochemical interfaces. Developing environmentally responsible, energy-efficient manufacturing processes will be essential for maximizing the sustainability benefits of this promising technology.

The removal of the anode substrate significantly reduces the consumption of critical materials, decreasing the overall ecological footprint of battery production. Conventional lithium-ion batteries require substantial amounts of graphite, copper, and other materials for anode construction, contributing to resource depletion and environmental degradation through mining and processing activities. Anode-free designs minimize these impacts by utilizing lithium metal directly as the active material, without requiring additional substrate materials.

From a lifecycle perspective, anode-free batteries offer promising advantages in terms of resource efficiency. The simplified battery architecture reduces the complexity of manufacturing processes, potentially lowering energy consumption during production. Additionally, the reduced material content may facilitate more efficient recycling processes, enabling better recovery of valuable materials at end-of-life. This closed-loop potential aligns with circular economy principles increasingly prioritized in sustainable technology development.

However, several sustainability challenges remain unresolved. The increased reliance on lithium metal in anode-free designs raises concerns about lithium supply chain sustainability, particularly as global demand for lithium continues to rise. Current lithium extraction methods, including brine evaporation and hard rock mining, present significant environmental challenges including water consumption, habitat disruption, and chemical pollution. Addressing these upstream sustainability issues will be crucial for realizing the full environmental benefits of anode-free technology.

The electrode kinetics of anode-free batteries also influence their sustainability profile through impacts on battery lifespan and performance stability. Current challenges with dendrite formation and electrolyte degradation can lead to shortened cycle life, potentially offsetting material savings through more frequent battery replacement. Improving electrode kinetics to enhance longevity represents a critical research direction that would significantly strengthen the sustainability case for anode-free technology.

Manufacturing scalability presents another important consideration in the sustainability assessment. While anode-free designs theoretically simplify production, they also introduce new manufacturing challenges related to handling reactive lithium metal and maintaining precise electrochemical interfaces. Developing environmentally responsible, energy-efficient manufacturing processes will be essential for maximizing the sustainability benefits of this promising technology.

Safety and Performance Standards for Advanced Battery Technologies

The evolution of battery technologies has necessitated the development of comprehensive safety and performance standards to ensure reliable operation and consumer protection. For anode-free batteries, which represent a significant advancement in energy storage technology, these standards are particularly crucial due to their unique electrode kinetics and potential safety challenges.

Current safety standards for conventional lithium-ion batteries, such as IEC 62133 and UL 1642, provide baseline requirements but require substantial adaptation to address the specific characteristics of anode-free systems. These batteries, lacking a dedicated anode structure, exhibit distinct failure modes and thermal behavior that necessitate specialized testing protocols. The absence of traditional anode materials alters the electrochemical dynamics, requiring modified safety parameters for overcharge protection, thermal runaway prevention, and short-circuit management.

Performance standards must also evolve to accurately benchmark anode-free technologies. Traditional metrics like cycle life and capacity retention require recalibration to account for the unique electrode kinetics observed in these systems. The direct lithium plating mechanism in anode-free batteries creates distinctive performance profiles that cannot be adequately evaluated using conventional testing methodologies.

Regulatory bodies including the International Electrotechnical Commission (IEC) and ASTM International are currently developing specialized standards for next-generation battery technologies. These emerging frameworks incorporate advanced characterization techniques such as operando electrochemical impedance spectroscopy and high-resolution microscopy to evaluate the dynamic interface formation and lithium plating behavior critical to anode-free battery performance.

Industry consortia are simultaneously establishing voluntary standards that address the unique challenges of anode-free systems. These include enhanced protocols for evaluating dendrite formation risk, electrolyte stability under various operating conditions, and accelerated aging tests that specifically target the failure mechanisms most relevant to anode-free architectures.

The integration of these batteries into commercial applications will require harmonized global standards that balance innovation with safety requirements. Current efforts focus on developing testing methodologies that can accurately predict long-term performance and safety margins while accounting for the distinctive electrode kinetics of anode-free systems. This standardization process represents a critical enabler for market adoption, providing manufacturers and consumers with reliable benchmarks for evaluating this promising technology.

Current safety standards for conventional lithium-ion batteries, such as IEC 62133 and UL 1642, provide baseline requirements but require substantial adaptation to address the specific characteristics of anode-free systems. These batteries, lacking a dedicated anode structure, exhibit distinct failure modes and thermal behavior that necessitate specialized testing protocols. The absence of traditional anode materials alters the electrochemical dynamics, requiring modified safety parameters for overcharge protection, thermal runaway prevention, and short-circuit management.

Performance standards must also evolve to accurately benchmark anode-free technologies. Traditional metrics like cycle life and capacity retention require recalibration to account for the unique electrode kinetics observed in these systems. The direct lithium plating mechanism in anode-free batteries creates distinctive performance profiles that cannot be adequately evaluated using conventional testing methodologies.

Regulatory bodies including the International Electrotechnical Commission (IEC) and ASTM International are currently developing specialized standards for next-generation battery technologies. These emerging frameworks incorporate advanced characterization techniques such as operando electrochemical impedance spectroscopy and high-resolution microscopy to evaluate the dynamic interface formation and lithium plating behavior critical to anode-free battery performance.

Industry consortia are simultaneously establishing voluntary standards that address the unique challenges of anode-free systems. These include enhanced protocols for evaluating dendrite formation risk, electrolyte stability under various operating conditions, and accelerated aging tests that specifically target the failure mechanisms most relevant to anode-free architectures.

The integration of these batteries into commercial applications will require harmonized global standards that balance innovation with safety requirements. Current efforts focus on developing testing methodologies that can accurately predict long-term performance and safety margins while accounting for the distinctive electrode kinetics of anode-free systems. This standardization process represents a critical enabler for market adoption, providing manufacturers and consumers with reliable benchmarks for evaluating this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!