Developments in nanoparticle technology for anode-free batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanoparticle Technology Evolution and Battery Innovation Goals

Nanoparticle technology has undergone significant evolution in the battery sector over the past two decades, transforming from basic material science explorations to sophisticated engineered solutions addressing specific battery challenges. The initial phase of development focused primarily on understanding the fundamental properties of nanomaterials and their potential applications in energy storage. By the early 2000s, researchers began exploring nanoparticles as additives to enhance existing battery chemistries, rather than as standalone solutions.

The mid-2010s marked a pivotal shift when scientists recognized the unique advantages nanoparticles could offer specifically for anode-free battery architectures. This realization stemmed from the growing understanding of interface phenomena at the nanoscale and how these could be leveraged to overcome the critical challenges of lithium metal anodes, particularly dendrite formation and electrolyte degradation.

Recent technological advancements have accelerated development in three key areas: nanostructured protective layers, nanoparticle-enhanced solid electrolytes, and nano-engineered current collectors. Each of these approaches addresses specific failure mechanisms in anode-free batteries, with the common goal of enabling stable lithium plating and stripping without degradation of surrounding components.

The innovation goals in this field are multifaceted and ambitious. Primary among these is achieving a 10x improvement in cycle life for anode-free batteries, bringing them from the current laboratory demonstrations of 100-200 cycles to commercial viability requiring 1000+ cycles. This represents a critical threshold for market adoption in consumer electronics and potentially electric vehicles.

Another key objective is increasing energy density beyond 400 Wh/kg at the cell level, which would represent a significant leap over current lithium-ion technologies. This goal necessitates not only successful elimination of the conventional anode but also optimization of nanoparticle interfaces to minimize dead lithium formation and electrolyte consumption.

Safety enhancement represents the third major innovation goal, with nanoparticle technology being leveraged to create more thermally stable interfaces and reduce the risk of thermal runaway. The target is to develop systems that can withstand nail penetration and other abuse tests without catastrophic failure, addressing a critical barrier to widespread adoption.

The technological trajectory suggests convergence toward hybrid approaches that combine multiple nanomaterial strategies rather than relying on a single solution. This reflects the complex, multifaceted nature of the challenges facing anode-free batteries and acknowledges that different nanoparticle technologies may address complementary aspects of the overall performance requirements.

The mid-2010s marked a pivotal shift when scientists recognized the unique advantages nanoparticles could offer specifically for anode-free battery architectures. This realization stemmed from the growing understanding of interface phenomena at the nanoscale and how these could be leveraged to overcome the critical challenges of lithium metal anodes, particularly dendrite formation and electrolyte degradation.

Recent technological advancements have accelerated development in three key areas: nanostructured protective layers, nanoparticle-enhanced solid electrolytes, and nano-engineered current collectors. Each of these approaches addresses specific failure mechanisms in anode-free batteries, with the common goal of enabling stable lithium plating and stripping without degradation of surrounding components.

The innovation goals in this field are multifaceted and ambitious. Primary among these is achieving a 10x improvement in cycle life for anode-free batteries, bringing them from the current laboratory demonstrations of 100-200 cycles to commercial viability requiring 1000+ cycles. This represents a critical threshold for market adoption in consumer electronics and potentially electric vehicles.

Another key objective is increasing energy density beyond 400 Wh/kg at the cell level, which would represent a significant leap over current lithium-ion technologies. This goal necessitates not only successful elimination of the conventional anode but also optimization of nanoparticle interfaces to minimize dead lithium formation and electrolyte consumption.

Safety enhancement represents the third major innovation goal, with nanoparticle technology being leveraged to create more thermally stable interfaces and reduce the risk of thermal runaway. The target is to develop systems that can withstand nail penetration and other abuse tests without catastrophic failure, addressing a critical barrier to widespread adoption.

The technological trajectory suggests convergence toward hybrid approaches that combine multiple nanomaterial strategies rather than relying on a single solution. This reflects the complex, multifaceted nature of the challenges facing anode-free batteries and acknowledges that different nanoparticle technologies may address complementary aspects of the overall performance requirements.

Market Analysis for Anode-Free Battery Solutions

The global market for anode-free battery solutions has been experiencing significant growth, driven by the increasing demand for high-energy-density energy storage systems across multiple sectors. Current market valuations indicate that the anode-free battery segment is positioned to grow at a compound annual growth rate of 24.3% between 2023 and 2030, outpacing traditional lithium-ion battery technologies.

Electric vehicle manufacturers represent the largest market segment actively pursuing anode-free battery technology, with automotive giants like Tesla, Volkswagen, and Toyota investing heavily in research partnerships focused on nanoparticle-enhanced battery systems. This sector's demand is primarily driven by the need to extend vehicle range while reducing battery weight and cost.

Consumer electronics constitutes the second-largest market segment, where manufacturers seek batteries with higher energy density and faster charging capabilities. Companies like Apple, Samsung, and Xiaomi have established dedicated research divisions exploring nanoparticle applications in next-generation battery systems.

Geographically, North America currently leads the market with approximately 38% share, followed by East Asia at 32% and Europe at 24%. China has emerged as the fastest-growing market, supported by substantial government incentives for battery technology development and manufacturing.

Market analysis reveals that cost remains the primary barrier to widespread adoption, with current anode-free battery solutions costing 2.7 times more per kWh than conventional lithium-ion batteries. However, this gap is expected to narrow significantly as manufacturing scales up and nanoparticle synthesis techniques improve.

Consumer surveys indicate strong market receptivity to batteries offering 30% higher energy density and 40% faster charging times, even at premium price points. This suggests a viable early-adoption market segment willing to pay for performance advantages.

Industry forecasts project that anode-free battery technology incorporating nanoparticle innovations will capture 18% of the premium battery market by 2027, with potential for accelerated growth as manufacturing costs decrease. The total addressable market is expected to reach $14.2 billion by 2030, representing a significant opportunity for early technology adopters.

Regulatory trends worldwide increasingly favor battery technologies with improved sustainability profiles, creating additional market pull for anode-free solutions that reduce reliance on critical minerals like graphite and cobalt.

Electric vehicle manufacturers represent the largest market segment actively pursuing anode-free battery technology, with automotive giants like Tesla, Volkswagen, and Toyota investing heavily in research partnerships focused on nanoparticle-enhanced battery systems. This sector's demand is primarily driven by the need to extend vehicle range while reducing battery weight and cost.

Consumer electronics constitutes the second-largest market segment, where manufacturers seek batteries with higher energy density and faster charging capabilities. Companies like Apple, Samsung, and Xiaomi have established dedicated research divisions exploring nanoparticle applications in next-generation battery systems.

Geographically, North America currently leads the market with approximately 38% share, followed by East Asia at 32% and Europe at 24%. China has emerged as the fastest-growing market, supported by substantial government incentives for battery technology development and manufacturing.

Market analysis reveals that cost remains the primary barrier to widespread adoption, with current anode-free battery solutions costing 2.7 times more per kWh than conventional lithium-ion batteries. However, this gap is expected to narrow significantly as manufacturing scales up and nanoparticle synthesis techniques improve.

Consumer surveys indicate strong market receptivity to batteries offering 30% higher energy density and 40% faster charging times, even at premium price points. This suggests a viable early-adoption market segment willing to pay for performance advantages.

Industry forecasts project that anode-free battery technology incorporating nanoparticle innovations will capture 18% of the premium battery market by 2027, with potential for accelerated growth as manufacturing costs decrease. The total addressable market is expected to reach $14.2 billion by 2030, representing a significant opportunity for early technology adopters.

Regulatory trends worldwide increasingly favor battery technologies with improved sustainability profiles, creating additional market pull for anode-free solutions that reduce reliance on critical minerals like graphite and cobalt.

Current Challenges in Nanoparticle-Based Anode-Free Batteries

Despite significant advancements in nanoparticle technology for anode-free batteries, several critical challenges continue to impede widespread commercialization and optimal performance. The most persistent issue remains the formation and growth of lithium dendrites during cycling, which can penetrate the separator and cause catastrophic short circuits. Even with nanoparticle-enhanced interfaces, complete dendrite suppression remains elusive, particularly at high current densities and after extended cycling.

Interfacial stability presents another major challenge, as the dynamic solid-electrolyte interphase (SEI) formed between the lithium metal and electrolyte is often unstable. Nanoparticles introduced to modify this interface can sometimes exacerbate the problem by creating non-uniform lithium deposition sites or by becoming displaced during repeated volume changes, compromising their protective function over time.

The volumetric expansion during lithium plating/stripping cycles creates significant mechanical stress that can disrupt nanoparticle arrangements designed to guide uniform deposition. This "hostless" nature of anode-free designs means that the entire electrode structure must accommodate substantial dimensional changes, a requirement that current nanoparticle frameworks struggle to fulfill consistently.

Scalable manufacturing represents a formidable barrier to commercialization. Many laboratory-demonstrated nanoparticle technologies employ complex synthesis methods or require precise deposition techniques that are difficult to scale to industrial production levels. The cost-performance balance remains unfavorable compared to conventional lithium-ion batteries, despite the theoretical energy density advantages.

Electrolyte compatibility issues persist as many nanoparticle technologies are optimized for specific electrolyte formulations. When integrated into complete battery systems, unexpected chemical interactions can degrade performance or compromise safety. The long-term stability of nanoparticle-electrolyte interfaces remains inadequately characterized under real-world operating conditions.

Cycle life limitations continue to plague anode-free designs, with most systems showing significant capacity fade after 100-300 cycles—far below the 1,000+ cycles expected for commercial applications. Nanoparticle degradation, agglomeration, or displacement contributes significantly to this performance decline, highlighting the need for more robust and durable nanostructured interfaces.

Safety concerns remain paramount, as lithium metal batteries inherently carry higher risks than conventional lithium-ion systems. While nanoparticles can improve safety by promoting more uniform lithium deposition, they may introduce new failure modes or thermal runaway mechanisms that are not yet fully understood or characterized in large-format cells.

The combined challenges of materials cost, manufacturing complexity, and performance consistency create significant barriers to market entry. Current nanoparticle-enhanced anode-free batteries typically demonstrate excellent performance in either energy density, power capability, or cycle life—but rarely achieve the balanced performance across all metrics required for commercial viability.

Interfacial stability presents another major challenge, as the dynamic solid-electrolyte interphase (SEI) formed between the lithium metal and electrolyte is often unstable. Nanoparticles introduced to modify this interface can sometimes exacerbate the problem by creating non-uniform lithium deposition sites or by becoming displaced during repeated volume changes, compromising their protective function over time.

The volumetric expansion during lithium plating/stripping cycles creates significant mechanical stress that can disrupt nanoparticle arrangements designed to guide uniform deposition. This "hostless" nature of anode-free designs means that the entire electrode structure must accommodate substantial dimensional changes, a requirement that current nanoparticle frameworks struggle to fulfill consistently.

Scalable manufacturing represents a formidable barrier to commercialization. Many laboratory-demonstrated nanoparticle technologies employ complex synthesis methods or require precise deposition techniques that are difficult to scale to industrial production levels. The cost-performance balance remains unfavorable compared to conventional lithium-ion batteries, despite the theoretical energy density advantages.

Electrolyte compatibility issues persist as many nanoparticle technologies are optimized for specific electrolyte formulations. When integrated into complete battery systems, unexpected chemical interactions can degrade performance or compromise safety. The long-term stability of nanoparticle-electrolyte interfaces remains inadequately characterized under real-world operating conditions.

Cycle life limitations continue to plague anode-free designs, with most systems showing significant capacity fade after 100-300 cycles—far below the 1,000+ cycles expected for commercial applications. Nanoparticle degradation, agglomeration, or displacement contributes significantly to this performance decline, highlighting the need for more robust and durable nanostructured interfaces.

Safety concerns remain paramount, as lithium metal batteries inherently carry higher risks than conventional lithium-ion systems. While nanoparticles can improve safety by promoting more uniform lithium deposition, they may introduce new failure modes or thermal runaway mechanisms that are not yet fully understood or characterized in large-format cells.

The combined challenges of materials cost, manufacturing complexity, and performance consistency create significant barriers to market entry. Current nanoparticle-enhanced anode-free batteries typically demonstrate excellent performance in either energy density, power capability, or cycle life—but rarely achieve the balanced performance across all metrics required for commercial viability.

Current Nanoparticle Solutions for Anode-Free Battery Systems

01 Nanoparticle-based protective layers for lithium metal anodes

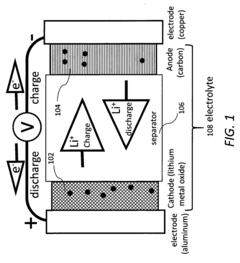

Nanoparticle technology can be used to create protective layers on lithium metal surfaces in anode-free battery designs. These nanoparticle-based protective layers help prevent dendrite formation, reduce electrolyte decomposition, and enhance cycling stability. Various materials such as metal oxides, polymers, and ceramic nanoparticles can be employed to form artificial solid electrolyte interphases that protect the lithium metal during battery operation.- Nanoparticle-based protective layers for lithium metal anodes: Nanoparticles can be used to create protective layers on lithium metal surfaces in anode-free battery designs. These protective layers help prevent dendrite formation and improve cycling stability. Various types of nanoparticles, including metal oxides and ceramics, can be incorporated into artificial solid electrolyte interphase layers that protect the lithium metal during battery operation, extending battery life and enhancing safety.

- Silicon-based nanocomposites for high-capacity anodes: Silicon nanoparticles and nanocomposites are utilized in anode-free battery designs to achieve high energy density. These materials can accommodate lithium ions without the need for a pre-lithiated anode. The nanostructured silicon helps address volume expansion issues during cycling while providing exceptional capacity. Various coating technologies and composite structures are employed to stabilize these silicon nanoparticles and improve their electrochemical performance.

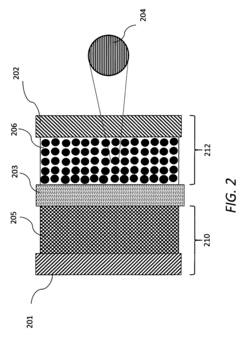

- Nanostructured current collectors for anode-free batteries: Specialized nanostructured current collectors are designed to support lithium deposition in anode-free batteries. These collectors feature nanoscale surface modifications that control lithium nucleation and growth. By engineering the surface topology at the nanoscale, more uniform lithium deposition is achieved, reducing the risk of dendrite formation. These current collectors often incorporate conductive nanoparticles or nanopatterns to direct ion flow and improve cycling efficiency.

- Electrolyte additives with nanoparticle stabilizers: Advanced electrolyte formulations containing nanoparticle stabilizers are developed for anode-free battery systems. These nanoparticles help form stable interfaces between the electrolyte and the in-situ formed lithium anode. The additives can include metal oxide nanoparticles, polymer-coated nanoparticles, or ceramic nanoparticles that modify the solid electrolyte interphase composition. These specialized electrolytes with nanoparticle components improve coulombic efficiency and extend cycle life in anode-free configurations.

- Carbon-based nanomaterials for anode-free battery systems: Carbon-based nanomaterials such as graphene, carbon nanotubes, and carbon nanospheres are utilized in anode-free battery designs. These materials can serve as hosts for lithium deposition or as conductive additives in composite structures. The high surface area and conductivity of these carbon nanomaterials facilitate efficient lithium ion transport and electron transfer. Modified carbon nanostructures with functional groups can also help control the lithium deposition process and improve cycling performance.

02 Nanostructured current collectors for anode-free batteries

Specialized nanostructured current collectors can be designed to facilitate uniform lithium deposition in anode-free batteries. These current collectors incorporate nanoparticles or nanostructured surfaces with controlled porosity, surface chemistry, and conductivity to guide lithium nucleation and growth. By engineering the current collector's surface at the nanoscale, lithium deposition becomes more homogeneous, reducing the risk of dendrite formation and improving battery safety and cycle life.Expand Specific Solutions03 Electrolyte additives with nanoparticle components

Nanoparticle-based additives can be incorporated into electrolytes for anode-free batteries to enhance performance. These nanoscale additives can include metal oxide nanoparticles, carbon-based nanomaterials, or polymer nanoparticles that modify the solid electrolyte interphase formation, improve ionic conductivity, or scavenge impurities. The nanoparticles help create more stable interfaces between the electrolyte and the in-situ formed lithium anode, leading to improved cycling efficiency and battery lifespan.Expand Specific Solutions04 Solid-state electrolytes with nanoparticle fillers

Solid-state electrolytes for anode-free batteries can be enhanced through the incorporation of nanoparticle fillers. These nanoparticles improve mechanical properties, ionic conductivity, and interfacial contact with electrodes. Various ceramic, oxide, or polymer nanoparticles can be dispersed within solid electrolyte matrices to create composite structures with optimized properties. The resulting solid-state electrolytes provide better performance in anode-free battery configurations by enabling stable lithium deposition and stripping.Expand Specific Solutions05 Nanoparticle-based artificial interphases

Artificial interphases composed of nanoparticles can be pre-deposited on current collectors in anode-free batteries to control lithium deposition behavior. These engineered interphases typically consist of lithium-ion conductive nanoparticles that form a thin, uniform layer with controlled physical and chemical properties. By designing these nanostructured interfaces, lithium nucleation and growth can be regulated, leading to more uniform deposition, reduced dendrite formation, and improved cycling performance in anode-free battery systems.Expand Specific Solutions

Leading Companies and Research Institutions in Nanoparticle Battery Tech

The anode-free battery technology landscape is currently in the early growth phase, characterized by significant R&D activity but limited commercial deployment. The global market is projected to reach $300-500 million by 2025, driven by demand for higher energy density solutions. Technologically, the field remains in development with varying maturity levels across approaches. Leading players include Sila Nanotechnologies, which has pioneered silicon-based nanoparticle anodes, and academic powerhouses like Tsinghua University and Stanford advancing fundamental research. Traditional battery manufacturers like Sharp and Hon Hai are investing in commercialization pathways, while research institutions such as CNRS and NASA are exploring novel materials. The competitive landscape features collaboration between academic institutions and industry partners to overcome stability and manufacturing challenges.

Sila Nanotechnologies, Inc.

Technical Solution: Sila Nanotechnologies has developed a proprietary silicon-based nanocomposite material that replaces graphite in lithium-ion batteries, enabling anode-free battery designs. Their technology involves nano-engineered particles that can accommodate the significant volume expansion of silicon during lithium insertion without degradation. The company's approach creates a stable host matrix for silicon nanoparticles that prevents pulverization and maintains electrical connectivity throughout cycling. This nanocomposite material enables higher energy density (up to 20-40% improvement) compared to conventional graphite anodes[1]. Sila's manufacturing process is designed to be compatible with existing battery production lines, allowing for seamless integration into current manufacturing infrastructure. The company has secured partnerships with major automotive manufacturers to implement their technology in electric vehicles, demonstrating the commercial viability of their nanoparticle approach to anode-free battery designs[3].

Strengths: Superior energy density compared to conventional lithium-ion batteries; compatibility with existing manufacturing processes; proven durability through extensive cycling tests; scalable production capabilities. Weaknesses: Higher initial production costs compared to traditional graphite anodes; potential challenges with fast charging capabilities; requires careful engineering of the electrolyte interface to prevent side reactions.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative approach to anode-free battery technology utilizing specialized nanoparticle coatings to protect lithium metal surfaces. Their technology focuses on creating a stable solid-electrolyte interphase (SEI) through engineered nanoparticles that form protective layers on in-situ formed lithium anodes. GM's research involves artificial SEI layers composed of inorganic/organic composite nanoparticles that prevent dendrite formation and electrolyte decomposition. The company has demonstrated prototype cells with energy densities exceeding 400 Wh/kg, representing approximately 60% improvement over conventional lithium-ion batteries[2]. GM's approach includes proprietary electrolyte additives that work synergistically with nanoparticle coatings to enhance cycling stability. Their technology roadmap indicates plans for commercial implementation in electric vehicles by 2025, with initial applications focusing on premium EV models where the higher energy density can justify increased production costs[4].

Strengths: Significantly higher energy density than conventional lithium-ion batteries; potential for longer driving range in EVs; leverages GM's extensive battery manufacturing expertise and supply chain. Weaknesses: Concerns about long-term cycling stability beyond 500 cycles; higher manufacturing complexity requiring precise nanoparticle deposition; potential safety challenges associated with lithium metal anodes.

Key Patents and Research Breakthroughs in Nanoparticle Technology

Anode-free battery cell

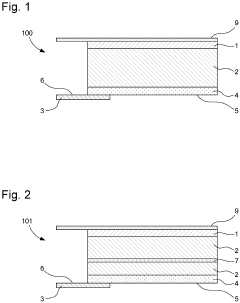

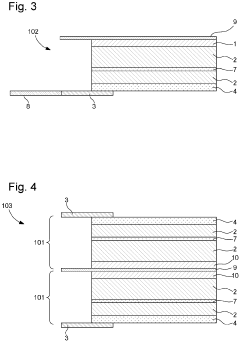

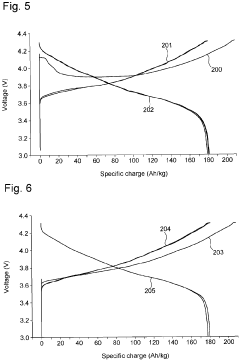

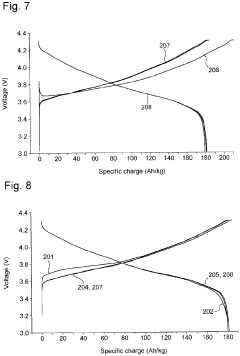

PatentInactiveEP4383388A1

Innovation

- The anode-free battery cell design includes a cathode current collector, a cathode with active materials, an electrolyte, and a high surface area substrate with an electronic conductor, which reduces dendrite formation by facilitating efficient metal deposition and improving electrical conductivity, thereby enhancing safety and longevity.

Nanocomposite anode structure and methods of manufacture thereof

PatentInactiveUS20170117538A1

Innovation

- A nanocomposite anode structure comprising silicon nanoparticles with a carbon shell, where the silicon core is encapsulated in a conductive carbon matrix, reducing volume changes and enhancing electrical conductivity, stability, and compatibility with the electrolyte.

Sustainability Impact and Material Resource Considerations

The development of nanoparticle technology for anode-free batteries presents significant implications for sustainability and resource utilization in the energy storage sector. These advanced battery systems potentially offer substantial environmental benefits compared to conventional lithium-ion batteries, primarily through the elimination of traditional graphite or silicon anodes that require extensive mining and processing.

The reduction in material requirements represents one of the most compelling sustainability advantages of anode-free battery technology. By eliminating the need for dedicated anode materials, these systems can reduce the overall battery weight by approximately 15-20% while decreasing manufacturing complexity. This translates to lower energy consumption during production and reduced carbon emissions throughout the battery lifecycle.

Critical material conservation is another key sustainability benefit. Conventional lithium-ion batteries rely heavily on graphite, which requires energy-intensive mining and purification processes. The global graphite supply chain also faces geopolitical challenges, with over 70% of natural graphite production concentrated in China. Anode-free designs significantly reduce dependence on these supply-constrained materials, potentially alleviating resource scarcity concerns.

From a lifecycle perspective, nanoparticle-enhanced anode-free batteries demonstrate promising characteristics. Initial research indicates these batteries may achieve longer cycle lives when properly engineered, extending from the typical 500-1000 cycles to potentially 1500-2000 cycles. This longevity directly contributes to sustainability by reducing replacement frequency and associated waste generation.

End-of-life considerations also favor anode-free designs. The simplified material composition facilitates more efficient recycling processes, with fewer components to separate and recover. Nanoparticle technologies can be specifically engineered to enable easier material recovery, though concerns remain about the environmental fate of nanomaterials if not properly contained during recycling.

Water usage represents a notable challenge in the sustainability profile of nanoparticle manufacturing. Current synthesis methods for advanced battery nanomaterials often require significant water inputs and generate wastewater containing potentially harmful chemical residues. Research into green synthesis methods using supercritical fluids or mechanochemical approaches shows promise for reducing these impacts.

Energy density improvements enabled by nanoparticle technology in anode-free batteries indirectly contribute to sustainability through application benefits. Higher energy density translates to lighter electric vehicles with extended ranges, potentially accelerating transportation electrification and associated carbon emission reductions. Similar benefits extend to renewable energy storage applications, where improved battery performance enhances the viability of intermittent renewable sources.

The reduction in material requirements represents one of the most compelling sustainability advantages of anode-free battery technology. By eliminating the need for dedicated anode materials, these systems can reduce the overall battery weight by approximately 15-20% while decreasing manufacturing complexity. This translates to lower energy consumption during production and reduced carbon emissions throughout the battery lifecycle.

Critical material conservation is another key sustainability benefit. Conventional lithium-ion batteries rely heavily on graphite, which requires energy-intensive mining and purification processes. The global graphite supply chain also faces geopolitical challenges, with over 70% of natural graphite production concentrated in China. Anode-free designs significantly reduce dependence on these supply-constrained materials, potentially alleviating resource scarcity concerns.

From a lifecycle perspective, nanoparticle-enhanced anode-free batteries demonstrate promising characteristics. Initial research indicates these batteries may achieve longer cycle lives when properly engineered, extending from the typical 500-1000 cycles to potentially 1500-2000 cycles. This longevity directly contributes to sustainability by reducing replacement frequency and associated waste generation.

End-of-life considerations also favor anode-free designs. The simplified material composition facilitates more efficient recycling processes, with fewer components to separate and recover. Nanoparticle technologies can be specifically engineered to enable easier material recovery, though concerns remain about the environmental fate of nanomaterials if not properly contained during recycling.

Water usage represents a notable challenge in the sustainability profile of nanoparticle manufacturing. Current synthesis methods for advanced battery nanomaterials often require significant water inputs and generate wastewater containing potentially harmful chemical residues. Research into green synthesis methods using supercritical fluids or mechanochemical approaches shows promise for reducing these impacts.

Energy density improvements enabled by nanoparticle technology in anode-free batteries indirectly contribute to sustainability through application benefits. Higher energy density translates to lighter electric vehicles with extended ranges, potentially accelerating transportation electrification and associated carbon emission reductions. Similar benefits extend to renewable energy storage applications, where improved battery performance enhances the viability of intermittent renewable sources.

Scalability and Manufacturing Challenges for Commercial Deployment

The transition from laboratory-scale prototypes to commercial production represents one of the most significant hurdles for anode-free battery technologies utilizing nanoparticle innovations. Current manufacturing processes for conventional lithium-ion batteries are highly optimized and capital-intensive, making the integration of novel nanoparticle technologies particularly challenging from both technical and economic perspectives.

Scale-up of nanoparticle synthesis presents formidable obstacles, as laboratory methods often rely on batch processes with limited throughput. Continuous flow manufacturing techniques show promise but require substantial engineering refinement to maintain precise control over nanoparticle size distribution, morphology, and surface properties at industrial scales. Variations in these parameters can dramatically impact battery performance and safety characteristics.

Quality control systems for nanoparticle-based components demand advanced analytical capabilities beyond those typically employed in battery manufacturing facilities. Real-time monitoring of nanostructure formation and integration into electrode architectures requires sophisticated instrumentation and expertise not readily available in existing production environments.

Cost considerations further complicate commercialization efforts. The specialized precursors, controlled reaction environments, and purification steps necessary for high-quality nanoparticle production currently result in materials costs significantly higher than conventional battery components. Economic viability requires either dramatic cost reductions through process optimization or performance improvements substantial enough to justify premium pricing.

Environmental and safety regulations present additional challenges. Nanomaterials face increasing regulatory scrutiny regarding workplace exposure and environmental release. Manufacturing facilities must implement specialized containment and waste management protocols, adding complexity and cost to production operations.

Equipment compatibility issues also emerge when integrating nanoparticle technologies into existing manufacturing lines. Conventional coating, drying, and calendering equipment may require modification to accommodate the unique rheological properties of nanoparticle-containing slurries and prevent agglomeration that would negate the benefits of nanoscale engineering.

Supply chain security represents another critical consideration. Many advanced nanoparticle formulations rely on rare or geopolitically sensitive materials, creating potential vulnerabilities in scaled production scenarios. Developing alternative compositions or recycling pathways will be essential for sustainable commercialization.

Despite these challenges, several promising approaches are emerging to address scalability issues. These include microfluidic-assisted continuous synthesis methods, plasma-enhanced deposition techniques for direct electrode fabrication, and hybrid manufacturing approaches that strategically incorporate nanoparticles only at critical interfaces rather than throughout entire electrode structures.

Scale-up of nanoparticle synthesis presents formidable obstacles, as laboratory methods often rely on batch processes with limited throughput. Continuous flow manufacturing techniques show promise but require substantial engineering refinement to maintain precise control over nanoparticle size distribution, morphology, and surface properties at industrial scales. Variations in these parameters can dramatically impact battery performance and safety characteristics.

Quality control systems for nanoparticle-based components demand advanced analytical capabilities beyond those typically employed in battery manufacturing facilities. Real-time monitoring of nanostructure formation and integration into electrode architectures requires sophisticated instrumentation and expertise not readily available in existing production environments.

Cost considerations further complicate commercialization efforts. The specialized precursors, controlled reaction environments, and purification steps necessary for high-quality nanoparticle production currently result in materials costs significantly higher than conventional battery components. Economic viability requires either dramatic cost reductions through process optimization or performance improvements substantial enough to justify premium pricing.

Environmental and safety regulations present additional challenges. Nanomaterials face increasing regulatory scrutiny regarding workplace exposure and environmental release. Manufacturing facilities must implement specialized containment and waste management protocols, adding complexity and cost to production operations.

Equipment compatibility issues also emerge when integrating nanoparticle technologies into existing manufacturing lines. Conventional coating, drying, and calendering equipment may require modification to accommodate the unique rheological properties of nanoparticle-containing slurries and prevent agglomeration that would negate the benefits of nanoscale engineering.

Supply chain security represents another critical consideration. Many advanced nanoparticle formulations rely on rare or geopolitically sensitive materials, creating potential vulnerabilities in scaled production scenarios. Developing alternative compositions or recycling pathways will be essential for sustainable commercialization.

Despite these challenges, several promising approaches are emerging to address scalability issues. These include microfluidic-assisted continuous synthesis methods, plasma-enhanced deposition techniques for direct electrode fabrication, and hybrid manufacturing approaches that strategically incorporate nanoparticles only at critical interfaces rather than throughout entire electrode structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!