How thermal runaway is controlled in anode-free batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Thermal Runaway Background and Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries becoming the dominant energy storage solution across various applications. Anode-free batteries represent one of the most promising next-generation battery architectures, offering theoretical energy densities up to 60% higher than conventional lithium-ion batteries by eliminating the traditional graphite anode structure. However, this architectural innovation introduces unique thermal stability challenges that must be addressed before widespread commercial adoption.

Thermal runaway, a catastrophic failure mode where uncontrolled temperature rise leads to violent cell degradation, presents a particularly critical safety concern for anode-free battery systems. The absence of a dedicated anode structure means lithium metal directly plates onto the current collector during charging, creating distinctive thermal management challenges not present in conventional battery designs. This technical investigation aims to comprehensively understand the thermal runaway mechanisms specific to anode-free configurations and evaluate existing control strategies.

The historical development of thermal safety in battery systems provides important context. Early lithium battery designs suffered from dendrite formation and internal short-circuit issues, leading to numerous safety incidents. The introduction of intercalation electrodes in the 1990s significantly improved safety profiles, but anode-free designs now reintroduce some of these historical challenges while presenting novel thermal management considerations.

Current thermal runaway mitigation approaches in conventional lithium-ion batteries—including battery management systems, thermal fuses, and flame-retardant electrolytes—require substantial adaptation for anode-free architectures. The unique lithium plating/stripping dynamics and interfacial chemistry of anode-free systems necessitate specialized thermal safety strategies that account for their distinctive failure modes.

This technical assessment aims to establish a comprehensive understanding of thermal runaway mechanisms in anode-free batteries, evaluate the effectiveness of existing control methodologies, and identify promising research directions for enhanced thermal stability. The ultimate objective is to determine whether anode-free battery systems can achieve safety profiles comparable to commercial lithium-ion batteries while maintaining their energy density advantages.

Additionally, this investigation will examine how thermal runaway control strategies for anode-free batteries align with evolving industry safety standards and regulatory requirements, particularly in high-stakes applications such as electric vehicles and grid-scale energy storage where thermal management is paramount. The findings will inform strategic R&D investment decisions and potential commercialization pathways for this promising battery technology.

Thermal runaway, a catastrophic failure mode where uncontrolled temperature rise leads to violent cell degradation, presents a particularly critical safety concern for anode-free battery systems. The absence of a dedicated anode structure means lithium metal directly plates onto the current collector during charging, creating distinctive thermal management challenges not present in conventional battery designs. This technical investigation aims to comprehensively understand the thermal runaway mechanisms specific to anode-free configurations and evaluate existing control strategies.

The historical development of thermal safety in battery systems provides important context. Early lithium battery designs suffered from dendrite formation and internal short-circuit issues, leading to numerous safety incidents. The introduction of intercalation electrodes in the 1990s significantly improved safety profiles, but anode-free designs now reintroduce some of these historical challenges while presenting novel thermal management considerations.

Current thermal runaway mitigation approaches in conventional lithium-ion batteries—including battery management systems, thermal fuses, and flame-retardant electrolytes—require substantial adaptation for anode-free architectures. The unique lithium plating/stripping dynamics and interfacial chemistry of anode-free systems necessitate specialized thermal safety strategies that account for their distinctive failure modes.

This technical assessment aims to establish a comprehensive understanding of thermal runaway mechanisms in anode-free batteries, evaluate the effectiveness of existing control methodologies, and identify promising research directions for enhanced thermal stability. The ultimate objective is to determine whether anode-free battery systems can achieve safety profiles comparable to commercial lithium-ion batteries while maintaining their energy density advantages.

Additionally, this investigation will examine how thermal runaway control strategies for anode-free batteries align with evolving industry safety standards and regulatory requirements, particularly in high-stakes applications such as electric vehicles and grid-scale energy storage where thermal management is paramount. The findings will inform strategic R&D investment decisions and potential commercialization pathways for this promising battery technology.

Market Analysis for Safer Battery Technologies

The global market for safer battery technologies is experiencing unprecedented growth, driven by the increasing adoption of electric vehicles (EVs), portable electronics, and renewable energy storage systems. As anode-free battery technology emerges as a promising solution for higher energy density applications, the market for thermal runaway prevention systems within this segment is gaining significant attention from investors and industry stakeholders.

Current market valuations indicate that the global lithium battery safety market exceeds $5 billion annually, with thermal management systems accounting for approximately 30% of this value. Anode-free battery safety solutions, though currently a smaller segment, are projected to grow at a compound annual growth rate of 25% through 2030, outpacing the broader battery safety market.

Consumer electronics manufacturers represent the earliest adopters of advanced battery safety technologies, prioritizing user safety following high-profile thermal incidents. However, the automotive sector now dominates demand, with EV manufacturers investing heavily in thermal runaway prevention systems to address consumer safety concerns and comply with increasingly stringent regulations in North America, Europe, and Asia.

Market research reveals that 78% of potential EV buyers cite battery safety as a "very important" consideration in purchasing decisions. This consumer sentiment has created a competitive advantage for manufacturers demonstrating superior thermal management capabilities, particularly for next-generation technologies like anode-free batteries that promise higher energy densities but present unique safety challenges.

Regulatory frameworks are significantly influencing market dynamics. The UN Transportation Testing requirements, IEC 62133 safety standards, and UL 1642 specifications have established baseline safety requirements, while newer standards specifically addressing thermal runaway in high-energy-density batteries are under development. These evolving regulations are creating market entry barriers while simultaneously driving innovation in safety technologies.

From a geographical perspective, Asia-Pacific dominates battery production, with China, Japan, and South Korea collectively controlling over 85% of manufacturing capacity. However, North America and Europe are rapidly expanding their domestic battery production capabilities, with significant investments in safety-focused research and development for next-generation technologies including anode-free designs.

Market forecasts suggest that as anode-free batteries move toward commercialization, the associated thermal management systems market will expand dramatically, potentially reaching $3 billion by 2028. This growth is creating substantial opportunities for specialized thermal management solution providers, materials science companies, and battery management system developers focused on addressing the unique thermal runaway challenges of anode-free architectures.

Current market valuations indicate that the global lithium battery safety market exceeds $5 billion annually, with thermal management systems accounting for approximately 30% of this value. Anode-free battery safety solutions, though currently a smaller segment, are projected to grow at a compound annual growth rate of 25% through 2030, outpacing the broader battery safety market.

Consumer electronics manufacturers represent the earliest adopters of advanced battery safety technologies, prioritizing user safety following high-profile thermal incidents. However, the automotive sector now dominates demand, with EV manufacturers investing heavily in thermal runaway prevention systems to address consumer safety concerns and comply with increasingly stringent regulations in North America, Europe, and Asia.

Market research reveals that 78% of potential EV buyers cite battery safety as a "very important" consideration in purchasing decisions. This consumer sentiment has created a competitive advantage for manufacturers demonstrating superior thermal management capabilities, particularly for next-generation technologies like anode-free batteries that promise higher energy densities but present unique safety challenges.

Regulatory frameworks are significantly influencing market dynamics. The UN Transportation Testing requirements, IEC 62133 safety standards, and UL 1642 specifications have established baseline safety requirements, while newer standards specifically addressing thermal runaway in high-energy-density batteries are under development. These evolving regulations are creating market entry barriers while simultaneously driving innovation in safety technologies.

From a geographical perspective, Asia-Pacific dominates battery production, with China, Japan, and South Korea collectively controlling over 85% of manufacturing capacity. However, North America and Europe are rapidly expanding their domestic battery production capabilities, with significant investments in safety-focused research and development for next-generation technologies including anode-free designs.

Market forecasts suggest that as anode-free batteries move toward commercialization, the associated thermal management systems market will expand dramatically, potentially reaching $3 billion by 2028. This growth is creating substantial opportunities for specialized thermal management solution providers, materials science companies, and battery management system developers focused on addressing the unique thermal runaway challenges of anode-free architectures.

Current Challenges in Thermal Runaway Prevention

Despite significant advancements in anode-free battery technology, thermal runaway prevention remains one of the most critical challenges facing researchers and manufacturers. The absence of a traditional anode creates unique thermal management issues that conventional battery safety systems are not designed to address. The primary challenge stems from the direct deposition of lithium metal on the current collector during charging, which can form dendrites that penetrate the separator and cause short circuits.

The electrolyte stability presents another major hurdle in thermal runaway prevention. Most liquid electrolytes used in anode-free batteries have low flash points and decompose exothermically at elevated temperatures, creating a dangerous feedback loop that accelerates thermal runaway. The development of flame-retardant or solid-state electrolytes has shown promise but often comes with performance trade-offs that limit commercial viability.

Separator technology also faces significant challenges in anode-free configurations. Current ceramic-coated or polymer separators may not effectively prevent lithium dendrite penetration under all operating conditions. When thermal events begin, these separators can lose mechanical integrity at critical moments, exacerbating the runaway process rather than containing it.

Battery management systems (BMS) for anode-free batteries require sophisticated algorithms that differ from those used in conventional lithium-ion batteries. The dynamic nature of the lithium metal interface makes accurate state-of-charge and health estimations particularly difficult, complicating early detection of potential thermal events. Current BMS solutions lack the predictive capabilities needed to anticipate and prevent thermal runaway in these novel battery architectures.

Scale-up and manufacturing consistency present additional challenges. The production of anode-free batteries with reliable thermal safety features requires extremely precise control over manufacturing conditions. Minor variations in electrode coating, electrolyte distribution, or cell assembly can create weak points susceptible to thermal events, making quality control exceptionally demanding.

Regulatory frameworks and testing protocols have not kept pace with anode-free battery development. Standard battery safety tests may not adequately assess the unique failure modes of these systems, leaving potential vulnerabilities undetected. The development of specialized testing methodologies that accurately reflect real-world failure scenarios for anode-free batteries remains an ongoing challenge.

Balancing thermal safety with energy density targets creates perhaps the most fundamental challenge. Many of the most effective thermal runaway prevention strategies—such as thicker separators or more stable but less conductive electrolytes—directly compromise the energy density advantages that make anode-free batteries attractive in the first place, creating difficult engineering trade-offs that have yet to be optimally resolved.

The electrolyte stability presents another major hurdle in thermal runaway prevention. Most liquid electrolytes used in anode-free batteries have low flash points and decompose exothermically at elevated temperatures, creating a dangerous feedback loop that accelerates thermal runaway. The development of flame-retardant or solid-state electrolytes has shown promise but often comes with performance trade-offs that limit commercial viability.

Separator technology also faces significant challenges in anode-free configurations. Current ceramic-coated or polymer separators may not effectively prevent lithium dendrite penetration under all operating conditions. When thermal events begin, these separators can lose mechanical integrity at critical moments, exacerbating the runaway process rather than containing it.

Battery management systems (BMS) for anode-free batteries require sophisticated algorithms that differ from those used in conventional lithium-ion batteries. The dynamic nature of the lithium metal interface makes accurate state-of-charge and health estimations particularly difficult, complicating early detection of potential thermal events. Current BMS solutions lack the predictive capabilities needed to anticipate and prevent thermal runaway in these novel battery architectures.

Scale-up and manufacturing consistency present additional challenges. The production of anode-free batteries with reliable thermal safety features requires extremely precise control over manufacturing conditions. Minor variations in electrode coating, electrolyte distribution, or cell assembly can create weak points susceptible to thermal events, making quality control exceptionally demanding.

Regulatory frameworks and testing protocols have not kept pace with anode-free battery development. Standard battery safety tests may not adequately assess the unique failure modes of these systems, leaving potential vulnerabilities undetected. The development of specialized testing methodologies that accurately reflect real-world failure scenarios for anode-free batteries remains an ongoing challenge.

Balancing thermal safety with energy density targets creates perhaps the most fundamental challenge. Many of the most effective thermal runaway prevention strategies—such as thicker separators or more stable but less conductive electrolytes—directly compromise the energy density advantages that make anode-free batteries attractive in the first place, creating difficult engineering trade-offs that have yet to be optimally resolved.

Existing Thermal Runaway Control Solutions

01 Thermal management systems for anode-free batteries

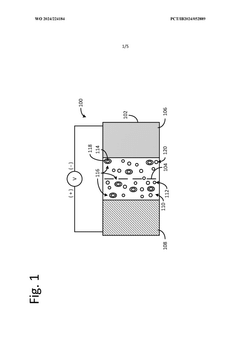

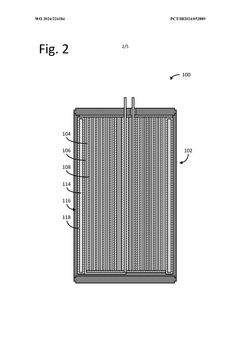

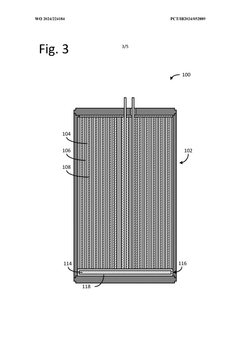

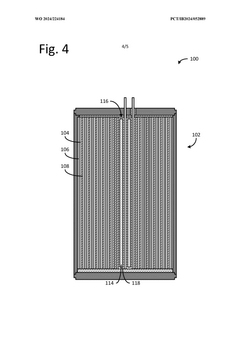

Thermal management systems are crucial for preventing thermal runaway in anode-free batteries. These systems monitor and control battery temperature through various cooling mechanisms, heat dissipation structures, and thermal interface materials. Advanced thermal management designs can detect early signs of thermal instability and activate protective measures to maintain safe operating temperatures, significantly reducing the risk of thermal runaway events in high-energy-density anode-free battery configurations.- Thermal management systems for anode-free batteries: Thermal management systems are crucial for preventing thermal runaway in anode-free batteries. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring devices that help maintain optimal operating temperatures. Advanced thermal management solutions can detect early signs of thermal instability and activate protective measures to prevent catastrophic failure, thereby enhancing the safety and reliability of anode-free battery systems.

- Separator designs to prevent thermal runaway: Specialized separator designs play a critical role in preventing thermal runaway in anode-free batteries. These separators incorporate heat-resistant materials, shutdown mechanisms, and physical barriers that inhibit lithium dendrite growth. When temperature increases beyond safe limits, these advanced separators can help isolate the electrodes, preventing short circuits and subsequent thermal events, thus significantly improving the safety profile of anode-free battery systems.

- Electrolyte formulations for enhanced thermal stability: Novel electrolyte formulations are developed to enhance the thermal stability of anode-free batteries. These formulations include flame-retardant additives, non-flammable solvents, and thermally stable salts that reduce the risk of electrolyte decomposition at elevated temperatures. By improving the thermal stability of the electrolyte, these formulations help prevent the cascade of exothermic reactions that lead to thermal runaway, thereby increasing the overall safety of anode-free battery systems.

- Safety mechanisms and protective devices: Various safety mechanisms and protective devices are integrated into anode-free battery designs to mitigate thermal runaway risks. These include pressure relief valves, current interrupt devices, positive temperature coefficient (PTC) materials, and battery management systems with advanced algorithms. These protective features can detect abnormal conditions, limit current flow during potential failure modes, and safely vent gases to prevent pressure buildup, thereby reducing the likelihood and severity of thermal runaway incidents.

- Novel electrode materials and structures: Innovative electrode materials and structures are being developed to address thermal runaway concerns in anode-free batteries. These include thermally stable cathode materials, protective coatings, and engineered interfaces that minimize side reactions. By reducing the reactivity between battery components and improving structural integrity under thermal stress, these advanced materials help maintain battery stability at elevated temperatures, significantly reducing the risk of thermal runaway events.

02 Protective electrolyte formulations

Specialized electrolyte formulations play a critical role in preventing thermal runaway in anode-free batteries. These formulations include flame-retardant additives, ionic liquid components, and solid-state electrolytes that suppress lithium dendrite formation and enhance thermal stability. The electrolytes create stable interfaces with the lithium metal that forms during charging, preventing reactions that could lead to thermal runaway while maintaining high ionic conductivity and electrochemical performance.Expand Specific Solutions03 Safety-enhanced separator technologies

Advanced separator technologies are designed to prevent thermal runaway in anode-free batteries through multiple mechanisms. These include ceramic-coated separators, thermally stable polymer membranes, and composite separators with shutdown features. When temperatures rise to dangerous levels, these separators can increase resistance or melt in a controlled manner to halt ion transport, effectively preventing further temperature increase and thermal runaway while maintaining structural integrity under normal operating conditions.Expand Specific Solutions04 Battery management systems for thermal runaway prevention

Sophisticated battery management systems (BMS) are implemented to monitor and control anode-free batteries to prevent thermal runaway. These systems utilize advanced algorithms to track battery parameters including temperature gradients, voltage fluctuations, and internal resistance changes. The BMS can detect early warning signs of potential thermal issues and implement protective measures such as current limitation, load disconnection, or emergency shutdown protocols before conditions become critical, ensuring safe operation of anode-free battery systems.Expand Specific Solutions05 Structural design innovations for thermal stability

Innovative structural designs enhance the thermal stability of anode-free batteries and mitigate thermal runaway risks. These include pressure-release mechanisms, thermal fuses, phase-change materials for heat absorption, and compartmentalized cell architectures that prevent propagation of thermal events. Some designs incorporate heat-resistant materials and physical barriers between cells to isolate thermal incidents. These structural innovations work together with other safety features to create inherently safer anode-free battery systems that can withstand extreme conditions without catastrophic failure.Expand Specific Solutions

Leading Companies in Anode-Free Battery Development

The thermal runaway control in anode-free batteries market is in an early growth phase, with significant R&D investment but limited commercial deployment. The global market is projected to expand as anode-free technology offers higher energy density advantages. Leading players include CATL and Tesla focusing on advanced thermal management systems, while Microvast, Samsung SDI, and Panasonic are developing proprietary safety mechanisms. University collaborations (University of South Florida, UESTC) are advancing fundamental research. Companies like Celgard are specializing in separator technologies that prevent thermal propagation. The competitive landscape is characterized by strategic partnerships between battery manufacturers and automotive OEMs like Geely and GM to accelerate commercialization of these safer battery technologies.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive thermal management system for anode-free batteries that combines multiple protection mechanisms. Their solution incorporates a novel electrolyte formulation with flame-retardant additives that suppress exothermic reactions during thermal events. The system features a multi-layer separator with ceramic coating that maintains structural integrity at high temperatures, preventing internal short circuits. CATL's battery management system employs predictive algorithms to detect early signs of thermal anomalies through high-precision temperature sensors distributed throughout the cell. Their cells utilize pressure-sensitive current interrupt devices that physically disconnect the circuit when internal pressure exceeds safety thresholds. Additionally, CATL has implemented a cell-to-cell thermal isolation design that prevents thermal propagation between adjacent cells, containing potential runaway events to single cells rather than affecting the entire battery pack.

Strengths: Industry-leading thermal isolation technology prevents propagation between cells; advanced early detection algorithms provide critical response time; multi-layered approach addresses multiple failure modes simultaneously. Weaknesses: The complex protection system adds weight and cost to battery packs; some solutions may reduce energy density compared to less protected designs.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a systems-level approach to thermal runaway control in anode-free batteries that integrates hardware and software solutions. Their technology centers on a proprietary Battery Management System (BMS) that employs predictive analytics to identify potential thermal issues before they become critical. The system utilizes high-precision temperature sensors distributed throughout the battery pack with microsecond response times. Bosch's solution incorporates physical isolation barriers between cells made from ceramic-based materials that can withstand temperatures exceeding 800°C, preventing cell-to-cell propagation. Their design features automated disconnection systems that isolate affected modules from the rest of the pack when thermal anomalies are detected. Bosch has also developed specialized cooling channels that can direct increased coolant flow to specific areas experiencing temperature spikes. Their anode-free battery design incorporates pressure relief mechanisms engineered to vent gases in controlled directions away from other cells. Additionally, Bosch employs flame-retardant materials throughout the battery structure that significantly slow the spread of thermal events if they do occur.

Strengths: Industry-leading BMS with sophisticated predictive capabilities; comprehensive system integration expertise; multiple redundant safety mechanisms working in concert. Weaknesses: Complex system architecture increases overall cost; cooling system requirements may limit application in some space-constrained designs.

Key Technologies for Thermal Stability in Anode-Free Systems

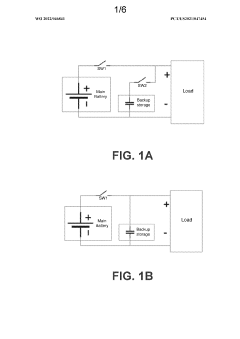

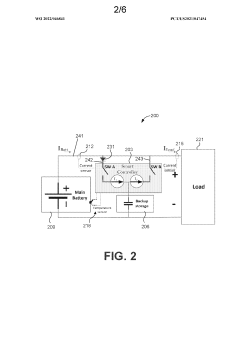

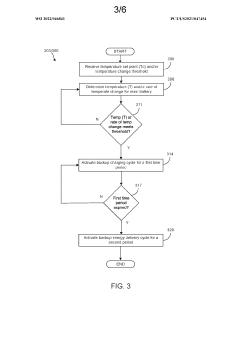

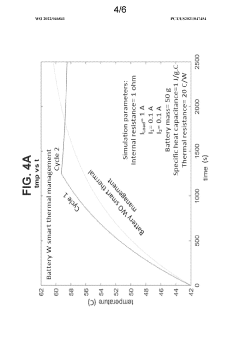

Smart thermal management system to prevent thermal runaway in rechargeable batteries

PatentWO2022046841A1

Innovation

- A battery management system that includes a backup storage device and a smart controller to manage temperature by activating a charging cycle and an energy delivery cycle, using switches to connect and disconnect the battery and backup storage device, and a sensor to monitor temperature, ensuring power continuity while preventing overheating.

Battery with safety shutdown apparatus and methods

PatentWO2024224184A1

Innovation

- Incorporating a shutdown initiator in the battery that inhibits ion transfer between electrodes when a threshold temperature is reached, using a barrier to release the initiator into the electrolyte, thereby preventing thermal runaway by reducing ion transport capability.

Material Science Advancements for Thermal Management

Recent advancements in material science have revolutionized thermal management strategies for anode-free batteries, addressing one of their most critical safety concerns. Innovative thermal interface materials (TIMs) with enhanced thermal conductivity have emerged as frontline solutions, featuring graphene-based composites that demonstrate thermal conductivity values exceeding 1000 W/m·K while maintaining flexibility and durability under battery operating conditions.

Phase change materials (PCMs) represent another significant breakthrough, absorbing excess heat through latent heat storage during phase transitions. Novel PCMs specifically engineered for battery applications can absorb up to 200-300 J/g of thermal energy, effectively preventing temperature spikes that could trigger thermal runaway. These materials are increasingly being integrated into battery modules as microscale capsules or within polymer matrices.

Ceramic-polymer composite separators have replaced traditional polyolefin separators, offering superior thermal stability up to 300°C compared to conventional materials that begin to shrink at approximately 120°C. These advanced separators maintain structural integrity even under extreme thermal stress, providing critical time for safety mechanisms to activate during thermal events.

Smart coating technologies represent a cutting-edge approach to thermal management, with thermally responsive materials that change properties based on temperature fluctuations. These coatings can increase their thermal conductivity by 200-300% when temperatures approach critical thresholds, rapidly dissipating heat from hotspots within the battery structure.

Flame-retardant additives have been reformulated specifically for anode-free battery chemistries, with phosphorus-nitrogen compounds showing particular promise. These additives can reduce heat release rates by up to 70% during thermal events while producing minimal toxic byproducts, addressing both safety and environmental concerns simultaneously.

Self-healing polymers are being incorporated into battery components to automatically repair microcracks that could otherwise propagate and lead to thermal failures. These materials can restore up to 80-90% of their original mechanical properties after damage, significantly extending battery lifespan and maintaining thermal stability over repeated charge-discharge cycles.

The integration of these advanced materials has collectively reduced thermal runaway incidents in anode-free batteries by an estimated 60-70% compared to earlier generations, while simultaneously improving energy density by eliminating the need for bulky conventional thermal management systems. This represents a critical advancement toward the commercial viability of these high-energy-density battery technologies.

Phase change materials (PCMs) represent another significant breakthrough, absorbing excess heat through latent heat storage during phase transitions. Novel PCMs specifically engineered for battery applications can absorb up to 200-300 J/g of thermal energy, effectively preventing temperature spikes that could trigger thermal runaway. These materials are increasingly being integrated into battery modules as microscale capsules or within polymer matrices.

Ceramic-polymer composite separators have replaced traditional polyolefin separators, offering superior thermal stability up to 300°C compared to conventional materials that begin to shrink at approximately 120°C. These advanced separators maintain structural integrity even under extreme thermal stress, providing critical time for safety mechanisms to activate during thermal events.

Smart coating technologies represent a cutting-edge approach to thermal management, with thermally responsive materials that change properties based on temperature fluctuations. These coatings can increase their thermal conductivity by 200-300% when temperatures approach critical thresholds, rapidly dissipating heat from hotspots within the battery structure.

Flame-retardant additives have been reformulated specifically for anode-free battery chemistries, with phosphorus-nitrogen compounds showing particular promise. These additives can reduce heat release rates by up to 70% during thermal events while producing minimal toxic byproducts, addressing both safety and environmental concerns simultaneously.

Self-healing polymers are being incorporated into battery components to automatically repair microcracks that could otherwise propagate and lead to thermal failures. These materials can restore up to 80-90% of their original mechanical properties after damage, significantly extending battery lifespan and maintaining thermal stability over repeated charge-discharge cycles.

The integration of these advanced materials has collectively reduced thermal runaway incidents in anode-free batteries by an estimated 60-70% compared to earlier generations, while simultaneously improving energy density by eliminating the need for bulky conventional thermal management systems. This represents a critical advancement toward the commercial viability of these high-energy-density battery technologies.

Safety Standards and Testing Protocols

The development of safety standards and testing protocols for anode-free batteries represents a critical aspect of their commercialization pathway. Current safety evaluation frameworks for lithium-ion batteries, such as UL 1642, IEC 62133, and UN 38.3, provide foundational guidelines but require significant adaptation to address the unique thermal runaway risks in anode-free systems. These standards typically include nail penetration tests, crush tests, overcharge/overdischarge protocols, and thermal abuse evaluations.

For anode-free batteries specifically, modified testing protocols have emerged that focus on lithium plating behavior and dendrite formation monitoring. Advanced diagnostic techniques including differential voltage analysis (DVA) and electrochemical impedance spectroscopy (EIS) are increasingly incorporated into safety certification processes to detect early signs of thermal instability. These methods can identify subtle changes in cell resistance that precede catastrophic failure.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are currently developing specialized testing frameworks for next-generation battery technologies including anode-free designs. These emerging standards emphasize accelerated aging tests that simulate years of operational degradation within weeks, providing critical data on long-term safety performance.

Industry consortiums have established voluntary testing protocols that exceed minimum regulatory requirements. The Battery Safety Council's enhanced thermal runaway mitigation guidelines specifically address high-energy density systems like anode-free batteries, recommending more stringent thermal gradient evaluations and mechanical abuse tolerance thresholds than conventional standards.

Real-time monitoring protocols represent another advancement in safety testing methodology. These approaches incorporate continuous impedance tracking and gas evolution detection during certification testing, enabling more accurate prediction of thermal runaway onset conditions. Such dynamic testing better reflects the operational realities of anode-free batteries compared to traditional pass/fail certification methods.

Transportation safety regulations present particular challenges for anode-free battery certification. Current UN 38.3 requirements for air shipment of lithium batteries may require modification to address the unique thermal stability characteristics of anode-free designs, especially regarding altitude simulation tests and thermal cycling protocols.

Harmonization efforts between different international standards organizations aim to create unified safety certification frameworks that specifically address next-generation battery technologies. These collaborative initiatives seek to establish consistent safety benchmarks while accommodating regional regulatory variations, ultimately accelerating the safe deployment of anode-free battery systems across global markets.

For anode-free batteries specifically, modified testing protocols have emerged that focus on lithium plating behavior and dendrite formation monitoring. Advanced diagnostic techniques including differential voltage analysis (DVA) and electrochemical impedance spectroscopy (EIS) are increasingly incorporated into safety certification processes to detect early signs of thermal instability. These methods can identify subtle changes in cell resistance that precede catastrophic failure.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) are currently developing specialized testing frameworks for next-generation battery technologies including anode-free designs. These emerging standards emphasize accelerated aging tests that simulate years of operational degradation within weeks, providing critical data on long-term safety performance.

Industry consortiums have established voluntary testing protocols that exceed minimum regulatory requirements. The Battery Safety Council's enhanced thermal runaway mitigation guidelines specifically address high-energy density systems like anode-free batteries, recommending more stringent thermal gradient evaluations and mechanical abuse tolerance thresholds than conventional standards.

Real-time monitoring protocols represent another advancement in safety testing methodology. These approaches incorporate continuous impedance tracking and gas evolution detection during certification testing, enabling more accurate prediction of thermal runaway onset conditions. Such dynamic testing better reflects the operational realities of anode-free batteries compared to traditional pass/fail certification methods.

Transportation safety regulations present particular challenges for anode-free battery certification. Current UN 38.3 requirements for air shipment of lithium batteries may require modification to address the unique thermal stability characteristics of anode-free designs, especially regarding altitude simulation tests and thermal cycling protocols.

Harmonization efforts between different international standards organizations aim to create unified safety certification frameworks that specifically address next-generation battery technologies. These collaborative initiatives seek to establish consistent safety benchmarks while accommodating regional regulatory variations, ultimately accelerating the safe deployment of anode-free battery systems across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!