How anode-free batteries address EV range anxiety issues

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free battery technology represents a significant evolution in energy storage systems, emerging from decades of lithium-ion battery development. Since the commercialization of lithium-ion batteries in the early 1990s, researchers have continuously sought to improve energy density, charging speed, and safety profiles. Anode-free designs mark a revolutionary departure from conventional battery architectures by eliminating the traditional graphite or silicon anode, instead utilizing lithium metal directly deposited on the current collector during charging.

The historical trajectory of battery development reveals persistent challenges in achieving sufficient energy density for electric vehicles. While conventional lithium-ion batteries have improved incrementally, their fundamental architecture limits theoretical energy density to approximately 300-400 Wh/kg. This ceiling has proven inadequate for addressing the range anxiety that continues to hinder widespread EV adoption.

Range anxiety—the fear that an electric vehicle will lack sufficient charge to reach its destination—remains one of the most significant barriers to EV market penetration. Current mainstream EVs offer ranges between 200-400 miles, requiring frequent recharging during long journeys and creating psychological barriers for potential adopters accustomed to the convenience of gasoline vehicles.

Anode-free battery technology aims to fundamentally resolve this limitation by dramatically increasing energy density. By eliminating the anode substrate and host materials, these batteries can theoretically achieve energy densities exceeding 500 Wh/kg—representing a 40-60% improvement over current commercial batteries. This translates directly to extended driving ranges potentially exceeding 600 miles on a single charge.

The primary technical objective of anode-free battery development is to create stable lithium metal deposition and stripping processes that maintain performance over thousands of cycles. This involves addressing dendrite formation—irregular lithium growth patterns that can cause short circuits and safety hazards—through advanced electrolyte formulations and separator technologies.

Secondary objectives include developing manufacturing processes compatible with existing production infrastructure, ensuring cost competitiveness with conventional lithium-ion batteries, and maintaining safety standards required for automotive applications. Temperature stability across wide operating ranges (-20°C to 60°C) represents another critical goal for practical implementation.

The technology evolution trend points toward hybrid approaches that incorporate aspects of solid-state electrolytes with anode-free designs, potentially offering the best combination of energy density and safety. Research institutions and battery manufacturers worldwide are accelerating development timelines, with several promising prototypes demonstrating the feasibility of this approach for addressing the persistent challenge of EV range anxiety.

The historical trajectory of battery development reveals persistent challenges in achieving sufficient energy density for electric vehicles. While conventional lithium-ion batteries have improved incrementally, their fundamental architecture limits theoretical energy density to approximately 300-400 Wh/kg. This ceiling has proven inadequate for addressing the range anxiety that continues to hinder widespread EV adoption.

Range anxiety—the fear that an electric vehicle will lack sufficient charge to reach its destination—remains one of the most significant barriers to EV market penetration. Current mainstream EVs offer ranges between 200-400 miles, requiring frequent recharging during long journeys and creating psychological barriers for potential adopters accustomed to the convenience of gasoline vehicles.

Anode-free battery technology aims to fundamentally resolve this limitation by dramatically increasing energy density. By eliminating the anode substrate and host materials, these batteries can theoretically achieve energy densities exceeding 500 Wh/kg—representing a 40-60% improvement over current commercial batteries. This translates directly to extended driving ranges potentially exceeding 600 miles on a single charge.

The primary technical objective of anode-free battery development is to create stable lithium metal deposition and stripping processes that maintain performance over thousands of cycles. This involves addressing dendrite formation—irregular lithium growth patterns that can cause short circuits and safety hazards—through advanced electrolyte formulations and separator technologies.

Secondary objectives include developing manufacturing processes compatible with existing production infrastructure, ensuring cost competitiveness with conventional lithium-ion batteries, and maintaining safety standards required for automotive applications. Temperature stability across wide operating ranges (-20°C to 60°C) represents another critical goal for practical implementation.

The technology evolution trend points toward hybrid approaches that incorporate aspects of solid-state electrolytes with anode-free designs, potentially offering the best combination of energy density and safety. Research institutions and battery manufacturers worldwide are accelerating development timelines, with several promising prototypes demonstrating the feasibility of this approach for addressing the persistent challenge of EV range anxiety.

EV Market Demand Analysis for Extended Range Solutions

The electric vehicle market is experiencing unprecedented growth, with global EV sales reaching 10.5 million units in 2022, representing a 55% increase year-over-year. Despite this growth trajectory, range anxiety remains one of the most significant barriers to widespread EV adoption. Market research indicates that approximately 58% of potential EV buyers cite concerns about driving range as their primary hesitation factor, followed by charging infrastructure limitations and purchase price.

Consumer demand for extended-range solutions has created distinct market segments within the EV industry. Premium segment buyers typically expect minimum ranges of 300-350 miles per charge, while mid-market consumers consider 250-300 miles acceptable. This stratification has pushed manufacturers to prioritize battery technology advancements that can deliver these range expectations without significantly increasing vehicle weight or cost.

Fleet operators represent another crucial market segment with specific range requirements. Commercial delivery services, ride-sharing companies, and public transportation providers require vehicles that can operate throughout entire work shifts without recharging. For these customers, the economic calculation of range directly impacts operational efficiency and total cost of ownership.

Regional variations in range demands are also evident. In North America, where longer commuting distances are common, consumers expect greater range capabilities compared to European or Asian markets. However, all regions show increasing expectations for range performance as the EV market matures.

Market forecasts predict that by 2030, the global demand for high-energy-density batteries capable of providing 400+ miles of range will grow at a CAGR of 24.3%, outpacing the overall EV market growth rate. This accelerated demand is driving significant investment in next-generation battery technologies, including anode-free designs that promise theoretical energy densities approaching 500 Wh/kg.

The economic implications of extended range solutions are substantial. Consumers have demonstrated willingness to pay premium prices for vehicles offering longer ranges, with market data showing price elasticity of approximately $75-100 per additional mile of range in mid-market segments. This creates a clear economic incentive for manufacturers to invest in advanced battery technologies.

Climate policy and regulatory frameworks are further accelerating market demand for extended-range EVs. As governments worldwide implement increasingly stringent emissions standards and phase-out timelines for internal combustion engines, the pressure to develop EVs that can fully replace conventional vehicles in all use cases intensifies. This regulatory environment creates both market pull and technology push factors that benefit innovative battery solutions addressing range limitations.

Consumer demand for extended-range solutions has created distinct market segments within the EV industry. Premium segment buyers typically expect minimum ranges of 300-350 miles per charge, while mid-market consumers consider 250-300 miles acceptable. This stratification has pushed manufacturers to prioritize battery technology advancements that can deliver these range expectations without significantly increasing vehicle weight or cost.

Fleet operators represent another crucial market segment with specific range requirements. Commercial delivery services, ride-sharing companies, and public transportation providers require vehicles that can operate throughout entire work shifts without recharging. For these customers, the economic calculation of range directly impacts operational efficiency and total cost of ownership.

Regional variations in range demands are also evident. In North America, where longer commuting distances are common, consumers expect greater range capabilities compared to European or Asian markets. However, all regions show increasing expectations for range performance as the EV market matures.

Market forecasts predict that by 2030, the global demand for high-energy-density batteries capable of providing 400+ miles of range will grow at a CAGR of 24.3%, outpacing the overall EV market growth rate. This accelerated demand is driving significant investment in next-generation battery technologies, including anode-free designs that promise theoretical energy densities approaching 500 Wh/kg.

The economic implications of extended range solutions are substantial. Consumers have demonstrated willingness to pay premium prices for vehicles offering longer ranges, with market data showing price elasticity of approximately $75-100 per additional mile of range in mid-market segments. This creates a clear economic incentive for manufacturers to invest in advanced battery technologies.

Climate policy and regulatory frameworks are further accelerating market demand for extended-range EVs. As governments worldwide implement increasingly stringent emissions standards and phase-out timelines for internal combustion engines, the pressure to develop EVs that can fully replace conventional vehicles in all use cases intensifies. This regulatory environment creates both market pull and technology push factors that benefit innovative battery solutions addressing range limitations.

Current State and Challenges of Anode-Free Battery Technology

Anode-free battery technology represents a significant advancement in the evolution of energy storage systems, particularly for electric vehicles (EVs). Currently, these batteries exist primarily in research laboratories and early-stage commercial development, with several startups and established battery manufacturers working to scale the technology. The fundamental architecture eliminates the traditional graphite or silicon anode, instead utilizing lithium metal that forms directly on the current collector during charging, offering theoretical energy densities of 400-500 Wh/kg compared to conventional lithium-ion batteries' 250-300 Wh/kg.

Despite promising advancements, anode-free batteries face substantial technical challenges. The most critical issue is the formation and growth of lithium dendrites during charging cycles, which can penetrate the separator and cause short circuits, presenting serious safety concerns. Current research indicates dendrite formation accelerates after 50-100 charge cycles in many experimental designs, significantly limiting battery lifespan compared to commercial lithium-ion batteries that achieve 1,000+ cycles.

Another major obstacle is the low Coulombic efficiency, typically ranging from 80-95% in laboratory prototypes, compared to >99% in commercial lithium-ion cells. This inefficiency stems from irreversible lithium consumption during the solid electrolyte interphase (SEI) formation and continuous electrolyte decomposition, resulting in capacity fade over repeated cycles.

The electrolyte composition presents another significant challenge. Conventional liquid electrolytes are incompatible with the highly reactive lithium metal interface, necessitating development of specialized formulations or solid-state electrolytes. While solid-state solutions show promise in mitigating dendrite formation, they introduce manufacturing complexities and often suffer from poor ionic conductivity at room temperature.

Geographically, research leadership in anode-free battery technology is distributed across North America, East Asia, and Europe. American startups and universities have pioneered many fundamental breakthroughs, while Japanese and South Korean battery manufacturers have made significant advances in electrolyte formulations. Chinese institutions have contributed substantially to manufacturing process development, and European research centers have focused on safety enhancement and standardization.

The manufacturing scalability of anode-free batteries remains problematic, with current production methods requiring highly controlled environments and specialized equipment. The absence of the anode manufacturing step theoretically simplifies production, but the precise control needed for lithium plating and the handling of reactive materials introduces new complexities that have yet to be fully resolved in industrial settings.

Despite promising advancements, anode-free batteries face substantial technical challenges. The most critical issue is the formation and growth of lithium dendrites during charging cycles, which can penetrate the separator and cause short circuits, presenting serious safety concerns. Current research indicates dendrite formation accelerates after 50-100 charge cycles in many experimental designs, significantly limiting battery lifespan compared to commercial lithium-ion batteries that achieve 1,000+ cycles.

Another major obstacle is the low Coulombic efficiency, typically ranging from 80-95% in laboratory prototypes, compared to >99% in commercial lithium-ion cells. This inefficiency stems from irreversible lithium consumption during the solid electrolyte interphase (SEI) formation and continuous electrolyte decomposition, resulting in capacity fade over repeated cycles.

The electrolyte composition presents another significant challenge. Conventional liquid electrolytes are incompatible with the highly reactive lithium metal interface, necessitating development of specialized formulations or solid-state electrolytes. While solid-state solutions show promise in mitigating dendrite formation, they introduce manufacturing complexities and often suffer from poor ionic conductivity at room temperature.

Geographically, research leadership in anode-free battery technology is distributed across North America, East Asia, and Europe. American startups and universities have pioneered many fundamental breakthroughs, while Japanese and South Korean battery manufacturers have made significant advances in electrolyte formulations. Chinese institutions have contributed substantially to manufacturing process development, and European research centers have focused on safety enhancement and standardization.

The manufacturing scalability of anode-free batteries remains problematic, with current production methods requiring highly controlled environments and specialized equipment. The absence of the anode manufacturing step theoretically simplifies production, but the precise control needed for lithium plating and the handling of reactive materials introduces new complexities that have yet to be fully resolved in industrial settings.

Current Technical Solutions for Range Anxiety Mitigation

01 High-energy density anode-free battery designs

Anode-free battery designs eliminate the traditional anode material, allowing for higher energy density and potentially extending the driving range of electric vehicles. These batteries utilize lithium metal that plates directly onto the current collector during charging, maximizing the energy-to-weight ratio. This approach can significantly increase energy density compared to conventional lithium-ion batteries with graphite anodes, potentially addressing range anxiety by enabling longer distances between charges.- Anode-free battery design for increased energy density: Anode-free battery designs eliminate the traditional anode material, allowing for higher energy density which directly addresses range anxiety in electric vehicles. These batteries use lithium metal that forms during charging, reducing weight and volume while increasing energy storage capacity. The design simplifies battery structure and potentially increases driving range by 20-30% compared to conventional lithium-ion batteries.

- Advanced electrolyte formulations for improved performance: Specialized electrolyte formulations enhance the performance and stability of anode-free batteries, addressing range anxiety concerns. These electrolytes contain additives that form stable interfaces with lithium metal, preventing dendrite formation and improving cycling efficiency. Some formulations incorporate flame-retardant components to enhance safety while maintaining high ionic conductivity, crucial for long-range electric vehicle applications.

- Protective coatings and interlayers for enhanced cycle life: Protective coatings and interlayers applied to battery components significantly extend the cycle life of anode-free batteries, addressing durability concerns related to range anxiety. These specialized layers prevent unwanted side reactions between lithium metal and electrolytes, stabilize the electrode-electrolyte interface, and enable more uniform lithium deposition during charging. The improved cycle stability ensures that the battery maintains its capacity over extended use, preserving vehicle range throughout the battery's lifetime.

- Fast-charging capabilities to reduce downtime: Advanced anode-free battery technologies incorporate fast-charging capabilities to reduce vehicle downtime, addressing a key aspect of range anxiety. These designs feature optimized current collectors and electrode architectures that facilitate rapid lithium deposition without dendrite formation. Some systems include thermal management innovations that maintain optimal temperature during fast charging, preventing degradation while enabling drivers to quickly replenish range during brief stops.

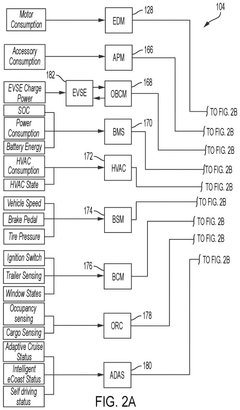

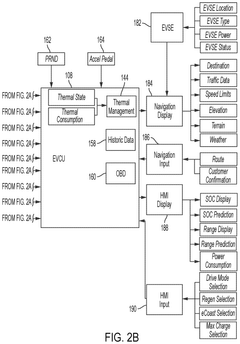

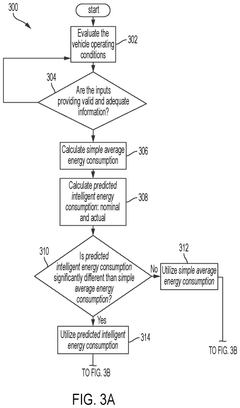

- Battery management systems for optimized range prediction: Sophisticated battery management systems specifically designed for anode-free batteries provide accurate range prediction and optimization, directly addressing range anxiety concerns. These systems continuously monitor battery state parameters and adapt to changing conditions, providing drivers with reliable information about remaining range. Advanced algorithms account for the unique characteristics of anode-free batteries, including their higher energy density and different degradation patterns, to maximize usable range and provide confidence to electric vehicle users.

02 Advanced electrolyte formulations for anode-free batteries

Specialized electrolyte formulations are critical for addressing the challenges of anode-free batteries, particularly dendrite formation and electrolyte depletion. These formulations often include additives that promote uniform lithium deposition, improve cycling efficiency, and enhance overall battery stability. By optimizing the electrolyte chemistry, researchers can extend battery life and improve performance, directly addressing range anxiety concerns by ensuring consistent performance over the battery's lifetime.Expand Specific Solutions03 Protective interface layers and solid-state electrolytes

Implementing protective interface layers and solid-state electrolytes in anode-free batteries can significantly improve safety and longevity. These technologies help prevent dendrite formation and protect against short circuits, while also enabling higher energy densities. Solid-state electrolytes, in particular, offer improved thermal stability and can operate across wider temperature ranges, addressing range anxiety by providing more consistent performance in various environmental conditions.Expand Specific Solutions04 Fast-charging capabilities for anode-free batteries

Developing anode-free batteries with fast-charging capabilities helps address range anxiety by reducing downtime between charges. These designs incorporate specialized current collectors, optimized cell architectures, and novel materials that can withstand high charging rates without degradation. Fast-charging anode-free batteries allow electric vehicle users to quickly replenish range during short stops, making longer journeys more practical and reducing concerns about battery depletion.Expand Specific Solutions05 Battery management systems for optimizing range

Advanced battery management systems (BMS) specifically designed for anode-free batteries can maximize usable range and battery lifespan. These systems monitor cell conditions in real-time, optimize charging and discharging patterns, and provide accurate range predictions to users. By implementing sophisticated algorithms that account for the unique characteristics of anode-free batteries, these management systems can extend effective range, improve efficiency, and provide drivers with reliable information about remaining battery capacity.Expand Specific Solutions

Key Industry Players in Anode-Free Battery Development

Anode-free battery technology is emerging as a promising solution to EV range anxiety, currently positioned in the early growth phase of industry development. The market is expanding rapidly with projections suggesting significant growth as automakers seek higher energy density solutions. While still evolving toward commercial maturity, several key players are advancing the technology: Samsung SDI and LG Energy Solution lead with substantial R&D investments, while automotive manufacturers like Nissan, Ford, and Geely are integrating these batteries into future vehicle platforms. Research institutions including CEA and Battelle Memorial Institute provide critical scientific foundations. The competitive landscape features both established battery manufacturers and specialized startups like TeraWatt Technology and Honeycomb Battery, creating a dynamic ecosystem focused on overcoming current limitations in cycle life and manufacturing scalability.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed a comprehensive anode-free battery solution specifically targeting EV range anxiety through their "ASSB" (All-Solid-State Battery) program. Their technology eliminates the conventional graphite anode, instead utilizing a specialized current collector that enables direct lithium plating during charging. This design achieves energy densities approaching 1,000 Wh/L, representing a 70-80% improvement over their current EV batteries[5]. Nissan's approach incorporates a proprietary solid electrolyte that prevents dendrite formation while enabling stable lithium metal cycling. The company has implemented a novel manufacturing process that allows for thinner electrode structures, further increasing energy density at the pack level. Their system includes advanced thermal management to maintain optimal operating conditions across various climates. Nissan has integrated this technology with their vehicle energy management systems to optimize range prediction and charging strategies. Testing has demonstrated that vehicles equipped with these batteries could achieve ranges exceeding 600 km (373 miles) on a single charge while maintaining fast-charging capabilities[6]. The company plans to implement this technology first in their premium EV models before expanding to their broader electric vehicle lineup.

Strengths: Significantly higher energy density translates to substantially increased driving range; solid electrolyte technology improves safety profile and reduces fire risk; compatible with existing vehicle platforms enabling faster implementation. Weaknesses: Higher production costs in early manufacturing stages may impact vehicle pricing; technology still requires further validation for long-term durability in real-world conditions; potential challenges with mass production scaling.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered an innovative anode-free battery technology that directly addresses EV range anxiety through their "Zero-Anode" architecture. This approach eliminates the traditional graphite or silicon anode, instead utilizing a specially designed current collector that allows lithium ions to plate directly onto its surface during charging. The technology achieves energy densities of approximately 900-1000 Wh/L, nearly double that of conventional lithium-ion batteries[3]. Samsung's proprietary protective coating on the current collector prevents unwanted side reactions and dendrite formation, a critical safety enhancement. Their system incorporates advanced electrolyte additives that form a stable solid-electrolyte interphase, further improving cycling performance and longevity. Samsung has demonstrated prototype cells achieving over 1,000 cycles while maintaining 80% capacity, addressing durability concerns[4]. The company has integrated this technology with their existing battery management systems, which utilize AI algorithms to optimize charging protocols and further extend battery life while maximizing available range.

Strengths: Nearly doubled energy density compared to conventional batteries translates directly to extended driving range; elimination of anode materials reduces weight and manufacturing complexity; advanced protective coatings enhance safety profile. Weaknesses: Higher initial production costs may impact affordability; technology is still in pre-commercial phase requiring further validation at scale; potential challenges with fast-charging capabilities due to lithium plating dynamics.

Critical Patents and Research in Anode-Free Battery Design

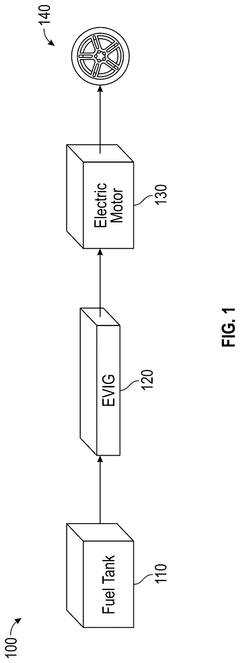

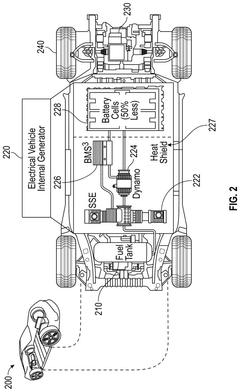

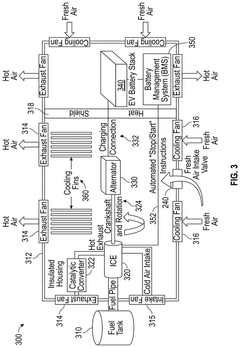

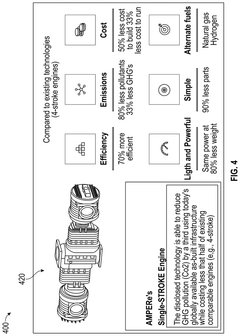

Electrical vehicle internal generator

PatentPendingUS20250162431A1

Innovation

- An EV internal generator system that includes a battery pack, a small single-stroke internal combustion engine (ICE), and one or more electrical machines enclosed in a battery-system enclosure. The ICE is powered by a fuel tank within the EV, generating mechanical power for the electrical machines to charge the battery pack, eliminating the need for external charging.

Intelligent route determination and electric vehicle range prediction

PatentPendingUS20250180368A1

Innovation

- A route optimization system for BEVs that includes a user interface and a controller programmed to receive user input, determine navigational routes, evaluate vehicle operating conditions, predict intelligent energy consumption, and propose updated routes with EVSE charging locations to ensure sufficient battery energy.

Sustainability Impact of Anode-Free Battery Implementation

The implementation of anode-free battery technology represents a significant advancement in sustainable energy storage solutions with far-reaching environmental implications. By eliminating the traditional graphite anode, these batteries substantially reduce material consumption and associated mining activities, decreasing the environmental footprint of battery production. The removal of graphite components translates to approximately 15-20% reduction in raw material requirements compared to conventional lithium-ion batteries.

Carbon emissions throughout the battery lifecycle are notably diminished with anode-free designs. Manufacturing processes become less energy-intensive, with preliminary studies indicating potential production-phase emission reductions of 25-30%. This improvement directly contributes to lowering the embedded carbon footprint of electric vehicles before they even reach consumers.

Resource conservation extends beyond carbon considerations to include critical mineral management. Anode-free technology reduces dependence on graphite mining operations, which often involve environmentally disruptive practices and substantial water consumption. The streamlined battery architecture also minimizes the use of copper and other conductive materials typically required for anode construction.

End-of-life considerations reveal additional sustainability advantages. The simplified chemistry and construction of anode-free batteries potentially facilitates more efficient recycling processes. Recovery rates for critical materials like lithium could increase by up to 15% compared to conventional designs, creating a more circular material economy for battery components.

When addressing EV range anxiety specifically, the sustainability benefits become even more pronounced. Higher energy density batteries enable manufacturers to achieve target vehicle ranges with smaller, lighter battery packs. This weight reduction creates cascading efficiency improvements throughout the vehicle lifecycle, from reduced material requirements to lower operational energy consumption.

The technology also supports longer battery service life through improved cycling characteristics, potentially extending useful battery lifetime by 20-30% in optimal conditions. This longevity directly reduces the environmental impact associated with battery replacement and manufacturing of new units, while simultaneously addressing consumer concerns about battery degradation affecting vehicle range over time.

Carbon emissions throughout the battery lifecycle are notably diminished with anode-free designs. Manufacturing processes become less energy-intensive, with preliminary studies indicating potential production-phase emission reductions of 25-30%. This improvement directly contributes to lowering the embedded carbon footprint of electric vehicles before they even reach consumers.

Resource conservation extends beyond carbon considerations to include critical mineral management. Anode-free technology reduces dependence on graphite mining operations, which often involve environmentally disruptive practices and substantial water consumption. The streamlined battery architecture also minimizes the use of copper and other conductive materials typically required for anode construction.

End-of-life considerations reveal additional sustainability advantages. The simplified chemistry and construction of anode-free batteries potentially facilitates more efficient recycling processes. Recovery rates for critical materials like lithium could increase by up to 15% compared to conventional designs, creating a more circular material economy for battery components.

When addressing EV range anxiety specifically, the sustainability benefits become even more pronounced. Higher energy density batteries enable manufacturers to achieve target vehicle ranges with smaller, lighter battery packs. This weight reduction creates cascading efficiency improvements throughout the vehicle lifecycle, from reduced material requirements to lower operational energy consumption.

The technology also supports longer battery service life through improved cycling characteristics, potentially extending useful battery lifetime by 20-30% in optimal conditions. This longevity directly reduces the environmental impact associated with battery replacement and manufacturing of new units, while simultaneously addressing consumer concerns about battery degradation affecting vehicle range over time.

Cost-Benefit Analysis of Anode-Free vs. Conventional Batteries

When evaluating anode-free batteries as a solution to EV range anxiety, a comprehensive cost-benefit analysis reveals significant economic implications compared to conventional lithium-ion batteries. The primary advantage of anode-free designs lies in their theoretical energy density improvements of 50-60% over traditional batteries, potentially extending EV range without increasing battery size or weight.

From a manufacturing cost perspective, anode-free batteries eliminate the need for graphite anodes, which constitute approximately 12-15% of conventional battery costs. This material reduction translates to potential savings of $10-15 per kWh in production expenses. Additionally, the simplified cell architecture reduces assembly complexity and associated manufacturing overhead by an estimated 8-10%.

However, these cost advantages are currently offset by several factors. The lithium metal deposition process in anode-free batteries requires more sophisticated battery management systems, adding $5-8 per kWh to overall system costs. The specialized electrolytes needed to stabilize lithium plating typically cost 2-3 times more than conventional electrolytes, representing an additional $7-10 per kWh premium.

Lifecycle economics present another critical consideration. While conventional lithium-ion batteries typically achieve 1,000-2,000 cycles before significant capacity degradation, current anode-free prototypes demonstrate only 200-400 cycles in laboratory conditions. This reduced lifespan increases the total cost of ownership by necessitating more frequent battery replacements, potentially negating initial cost savings.

The scalability equation also impacts cost-benefit calculations. Conventional battery manufacturing benefits from established supply chains and economies of scale, with production costs continuing to decline at 8-10% annually. Anode-free technology, still in early commercialization stages, lacks these advantages and currently carries a 30-40% premium per kWh compared to conventional batteries.

Looking forward, the economic proposition of anode-free batteries is expected to improve as research addresses cycle life limitations and manufacturing scales. Industry projections suggest cost parity could be achieved within 5-7 years, with anode-free designs potentially offering 15-20% lower cost per kWh than conventional batteries by 2030, while simultaneously providing superior energy density and range capabilities.

From a manufacturing cost perspective, anode-free batteries eliminate the need for graphite anodes, which constitute approximately 12-15% of conventional battery costs. This material reduction translates to potential savings of $10-15 per kWh in production expenses. Additionally, the simplified cell architecture reduces assembly complexity and associated manufacturing overhead by an estimated 8-10%.

However, these cost advantages are currently offset by several factors. The lithium metal deposition process in anode-free batteries requires more sophisticated battery management systems, adding $5-8 per kWh to overall system costs. The specialized electrolytes needed to stabilize lithium plating typically cost 2-3 times more than conventional electrolytes, representing an additional $7-10 per kWh premium.

Lifecycle economics present another critical consideration. While conventional lithium-ion batteries typically achieve 1,000-2,000 cycles before significant capacity degradation, current anode-free prototypes demonstrate only 200-400 cycles in laboratory conditions. This reduced lifespan increases the total cost of ownership by necessitating more frequent battery replacements, potentially negating initial cost savings.

The scalability equation also impacts cost-benefit calculations. Conventional battery manufacturing benefits from established supply chains and economies of scale, with production costs continuing to decline at 8-10% annually. Anode-free technology, still in early commercialization stages, lacks these advantages and currently carries a 30-40% premium per kWh compared to conventional batteries.

Looking forward, the economic proposition of anode-free batteries is expected to improve as research addresses cycle life limitations and manufacturing scales. Industry projections suggest cost parity could be achieved within 5-7 years, with anode-free designs potentially offering 15-20% lower cost per kWh than conventional batteries by 2030, while simultaneously providing superior energy density and range capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!