Why anode-free batteries are crucial for electric aviation

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Battery technology has undergone significant evolution since the commercialization of lithium-ion batteries in the early 1990s. Traditional lithium-ion batteries consist of a graphite anode, a cathode (typically lithium metal oxide), and an electrolyte. However, the energy density limitations of conventional designs have prompted researchers to explore more advanced configurations, with anode-free batteries emerging as a promising frontier in energy storage innovation.

Anode-free battery technology represents a paradigm shift in battery architecture by eliminating the traditional graphite anode, instead utilizing lithium metal directly deposited on the current collector during charging. This fundamental redesign addresses the critical challenge of energy density - a paramount concern for electric aviation applications where weight-to-energy ratio directly impacts flight range and payload capacity.

The aviation industry's transition toward electrification faces unique constraints compared to ground transportation. Aircraft require energy storage systems with exceptional gravimetric energy density (Wh/kg) to achieve practical flight ranges while maintaining sufficient payload capacity. Conventional lithium-ion batteries, with energy densities typically below 300 Wh/kg, fall short of the estimated 400-500 Wh/kg threshold needed for commercially viable electric regional aircraft.

Anode-free battery technology offers theoretical energy densities exceeding 500 Wh/kg by eliminating the redundant host material in traditional anodes. This represents a potential doubling of energy capacity compared to conventional lithium-ion designs, making electric aviation technically feasible for short and medium-range flights.

The development trajectory of anode-free batteries has accelerated in recent years, driven by both academic research and industrial R&D investments. Early proof-of-concept designs demonstrated the fundamental viability but suffered from rapid capacity fade and safety concerns related to dendrite formation. Recent advancements in electrolyte formulations and separator technologies have significantly improved cycle life and safety profiles.

The primary technical objective for anode-free battery development in aviation applications centers on achieving the optimal balance between energy density, cycle life, and safety. Specific targets include reaching stable energy densities above 450 Wh/kg with cycle life exceeding 1,000 cycles while maintaining stringent aviation safety standards regarding thermal runaway and structural integrity under various flight conditions.

Secondary objectives include developing manufacturing processes compatible with existing production infrastructure, ensuring cost competitiveness with conventional lithium-ion technologies, and addressing unique aviation requirements such as rapid charging capabilities for turnaround operations and performance stability across wide temperature and pressure ranges encountered during flight operations.

Anode-free battery technology represents a paradigm shift in battery architecture by eliminating the traditional graphite anode, instead utilizing lithium metal directly deposited on the current collector during charging. This fundamental redesign addresses the critical challenge of energy density - a paramount concern for electric aviation applications where weight-to-energy ratio directly impacts flight range and payload capacity.

The aviation industry's transition toward electrification faces unique constraints compared to ground transportation. Aircraft require energy storage systems with exceptional gravimetric energy density (Wh/kg) to achieve practical flight ranges while maintaining sufficient payload capacity. Conventional lithium-ion batteries, with energy densities typically below 300 Wh/kg, fall short of the estimated 400-500 Wh/kg threshold needed for commercially viable electric regional aircraft.

Anode-free battery technology offers theoretical energy densities exceeding 500 Wh/kg by eliminating the redundant host material in traditional anodes. This represents a potential doubling of energy capacity compared to conventional lithium-ion designs, making electric aviation technically feasible for short and medium-range flights.

The development trajectory of anode-free batteries has accelerated in recent years, driven by both academic research and industrial R&D investments. Early proof-of-concept designs demonstrated the fundamental viability but suffered from rapid capacity fade and safety concerns related to dendrite formation. Recent advancements in electrolyte formulations and separator technologies have significantly improved cycle life and safety profiles.

The primary technical objective for anode-free battery development in aviation applications centers on achieving the optimal balance between energy density, cycle life, and safety. Specific targets include reaching stable energy densities above 450 Wh/kg with cycle life exceeding 1,000 cycles while maintaining stringent aviation safety standards regarding thermal runaway and structural integrity under various flight conditions.

Secondary objectives include developing manufacturing processes compatible with existing production infrastructure, ensuring cost competitiveness with conventional lithium-ion technologies, and addressing unique aviation requirements such as rapid charging capabilities for turnaround operations and performance stability across wide temperature and pressure ranges encountered during flight operations.

Electric Aviation Market Demand Analysis

The electric aviation market is experiencing unprecedented growth, driven by increasing environmental concerns and the push for sustainable transportation solutions. Current projections indicate the global electric aircraft market will reach approximately $27.7 billion by 2030, with a compound annual growth rate exceeding 14% from 2023 to 2030. This remarkable growth trajectory reflects the aviation industry's urgent need to reduce carbon emissions, which currently account for about 2.5% of global CO2 emissions and are projected to triple by 2050 without intervention.

Battery technology stands as the critical bottleneck in electric aviation development. Conventional lithium-ion batteries offer energy densities of 250-300 Wh/kg, significantly below the 500-800 Wh/kg threshold required for commercially viable electric aircraft. This energy density gap represents the primary technical barrier limiting flight range and payload capacity of electric aircraft.

Market segmentation reveals distinct demand patterns across different aviation sectors. Urban air mobility (UAM) represents the fastest-growing segment, with projected market value of $9 billion by 2030 and over 430,000 autonomous aerial vehicles expected to be transporting passengers and cargo by 2040. Regional electric aircraft for short-haul flights (under 500 miles) constitute another significant market segment, with major airlines increasingly investing in electric fleet development to meet sustainability targets.

Consumer and regulatory pressures are intensifying market demand. Surveys indicate 68% of air travelers are willing to pay premium prices for environmentally friendly flight options. Meanwhile, regulatory frameworks like the European Union's "Fit for 55" package aim to reduce aviation emissions by 55% by 2030, creating strong policy incentives for electric aviation adoption.

Battery performance requirements vary significantly across market segments. Urban air taxis require batteries optimized for frequent charge-discharge cycles and rapid charging capabilities, while regional aircraft prioritize maximum energy density and operational longevity. This diversity of requirements is driving specialized battery development pathways.

Economic analyses demonstrate that despite higher initial capital costs, electric aircraft offer potential operational cost savings of 40-60% compared to conventional aircraft through reduced fuel and maintenance expenses. The total cost of ownership advantage becomes particularly compelling as battery technology advances and production scales.

Market adoption faces several barriers beyond battery technology, including charging infrastructure limitations, regulatory certification challenges, and public perception concerns regarding safety. However, significant investments in charging networks and progressive regulatory frameworks in regions like Scandinavia, parts of North America, and East Asia are creating favorable market entry points for early electric aviation deployment.

Battery technology stands as the critical bottleneck in electric aviation development. Conventional lithium-ion batteries offer energy densities of 250-300 Wh/kg, significantly below the 500-800 Wh/kg threshold required for commercially viable electric aircraft. This energy density gap represents the primary technical barrier limiting flight range and payload capacity of electric aircraft.

Market segmentation reveals distinct demand patterns across different aviation sectors. Urban air mobility (UAM) represents the fastest-growing segment, with projected market value of $9 billion by 2030 and over 430,000 autonomous aerial vehicles expected to be transporting passengers and cargo by 2040. Regional electric aircraft for short-haul flights (under 500 miles) constitute another significant market segment, with major airlines increasingly investing in electric fleet development to meet sustainability targets.

Consumer and regulatory pressures are intensifying market demand. Surveys indicate 68% of air travelers are willing to pay premium prices for environmentally friendly flight options. Meanwhile, regulatory frameworks like the European Union's "Fit for 55" package aim to reduce aviation emissions by 55% by 2030, creating strong policy incentives for electric aviation adoption.

Battery performance requirements vary significantly across market segments. Urban air taxis require batteries optimized for frequent charge-discharge cycles and rapid charging capabilities, while regional aircraft prioritize maximum energy density and operational longevity. This diversity of requirements is driving specialized battery development pathways.

Economic analyses demonstrate that despite higher initial capital costs, electric aircraft offer potential operational cost savings of 40-60% compared to conventional aircraft through reduced fuel and maintenance expenses. The total cost of ownership advantage becomes particularly compelling as battery technology advances and production scales.

Market adoption faces several barriers beyond battery technology, including charging infrastructure limitations, regulatory certification challenges, and public perception concerns regarding safety. However, significant investments in charging networks and progressive regulatory frameworks in regions like Scandinavia, parts of North America, and East Asia are creating favorable market entry points for early electric aviation deployment.

Current State and Challenges of Anode-Free Batteries

Anode-free battery technology represents one of the most promising frontiers in energy storage development, particularly for electric aviation applications. Currently, these batteries have achieved energy densities ranging from 300-400 Wh/kg in laboratory settings, significantly surpassing conventional lithium-ion batteries that typically deliver 150-250 Wh/kg. This advancement positions them as potential enablers for electric aircraft that require high energy density power sources to achieve practical flight ranges.

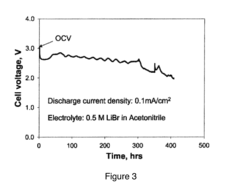

Despite these promising developments, anode-free batteries face substantial technical challenges that limit their commercial viability. The most critical issue is their limited cycle life, with most prototypes achieving only 50-100 charge-discharge cycles before significant capacity degradation occurs. This falls dramatically short of the 1,000+ cycles required for aviation applications where safety and reliability are paramount.

Dendrite formation represents another major technical obstacle. During charging processes, lithium metal tends to deposit unevenly on the current collector, forming needle-like structures that can penetrate the separator and cause catastrophic short circuits. This safety concern is particularly problematic for aviation applications where thermal runaway events could have severe consequences.

The electrolyte stability in anode-free systems presents additional challenges. Current electrolyte formulations struggle to maintain stable solid-electrolyte interphase (SEI) layers, leading to continuous electrolyte decomposition and rapid capacity fading. Research teams at institutions including Stanford University and the Chinese Academy of Sciences are exploring novel electrolyte compositions, but a definitive solution remains elusive.

Manufacturing scalability constitutes a significant constraint on commercialization efforts. Current production methods for anode-free batteries involve complex processes that are difficult to scale while maintaining quality and consistency. The precision required for uniform lithium deposition and electrolyte distribution presents formidable engineering challenges for mass production.

Geographically, research leadership in anode-free battery technology is concentrated in North America, East Asia, and Europe. The United States maintains strong positions through companies like QuantumScape and research at national laboratories, while China has rapidly expanded its research capabilities through entities like CATL and Gotion High-Tech. European efforts are primarily centered around consortiums involving automotive manufacturers and research institutions.

Temperature sensitivity further complicates the application of anode-free batteries in aviation contexts. These systems typically show optimal performance within narrow temperature ranges, whereas aircraft operate across extreme temperature variations. Addressing this limitation requires sophisticated thermal management systems that add weight and complexity, potentially offsetting the energy density advantages.

Despite these promising developments, anode-free batteries face substantial technical challenges that limit their commercial viability. The most critical issue is their limited cycle life, with most prototypes achieving only 50-100 charge-discharge cycles before significant capacity degradation occurs. This falls dramatically short of the 1,000+ cycles required for aviation applications where safety and reliability are paramount.

Dendrite formation represents another major technical obstacle. During charging processes, lithium metal tends to deposit unevenly on the current collector, forming needle-like structures that can penetrate the separator and cause catastrophic short circuits. This safety concern is particularly problematic for aviation applications where thermal runaway events could have severe consequences.

The electrolyte stability in anode-free systems presents additional challenges. Current electrolyte formulations struggle to maintain stable solid-electrolyte interphase (SEI) layers, leading to continuous electrolyte decomposition and rapid capacity fading. Research teams at institutions including Stanford University and the Chinese Academy of Sciences are exploring novel electrolyte compositions, but a definitive solution remains elusive.

Manufacturing scalability constitutes a significant constraint on commercialization efforts. Current production methods for anode-free batteries involve complex processes that are difficult to scale while maintaining quality and consistency. The precision required for uniform lithium deposition and electrolyte distribution presents formidable engineering challenges for mass production.

Geographically, research leadership in anode-free battery technology is concentrated in North America, East Asia, and Europe. The United States maintains strong positions through companies like QuantumScape and research at national laboratories, while China has rapidly expanded its research capabilities through entities like CATL and Gotion High-Tech. European efforts are primarily centered around consortiums involving automotive manufacturers and research institutions.

Temperature sensitivity further complicates the application of anode-free batteries in aviation contexts. These systems typically show optimal performance within narrow temperature ranges, whereas aircraft operate across extreme temperature variations. Addressing this limitation requires sophisticated thermal management systems that add weight and complexity, potentially offsetting the energy density advantages.

Current Anode-Free Battery Solutions for Aviation

01 Anode-free battery design and structure

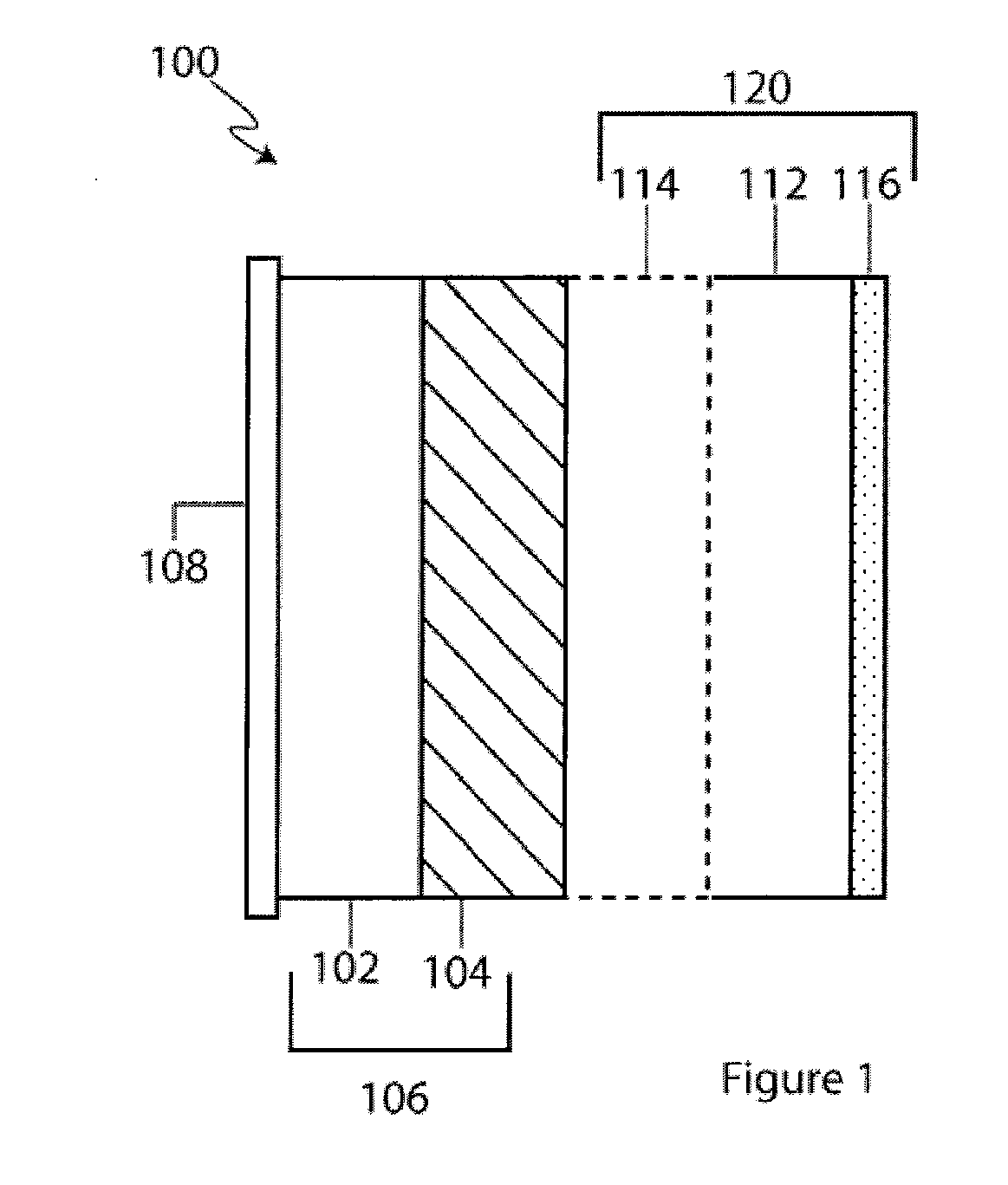

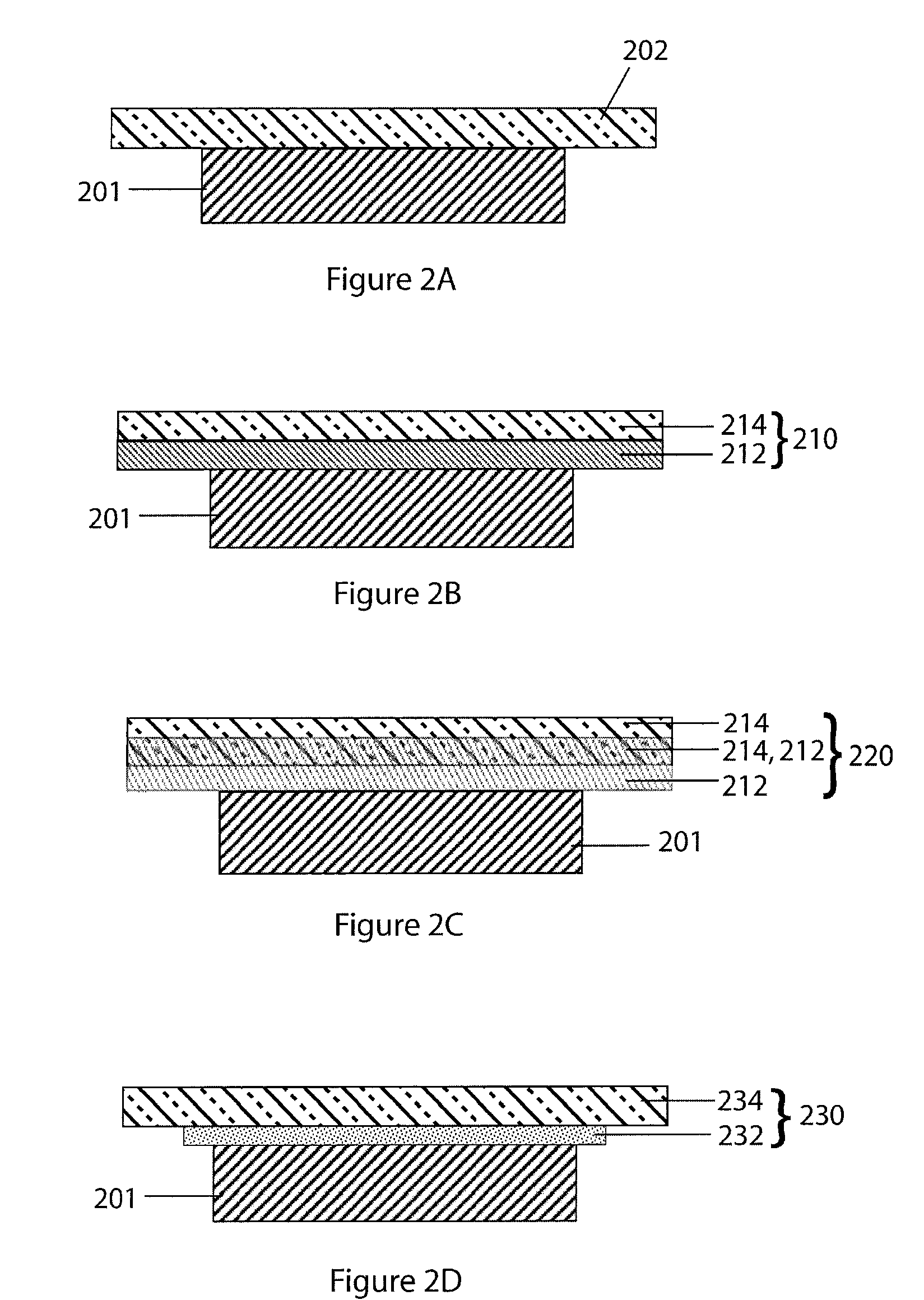

Anode-free batteries eliminate the traditional anode material during manufacturing, instead relying on in-situ formation of the anode during the first charge cycle when lithium ions plate onto the current collector. This design significantly increases energy density by reducing inactive components and simplifying battery construction. The structure typically includes a lithium-free negative electrode, a separator, and a lithium-containing cathode, with the anode forming during operation.- Design and structure of anode-free batteries: Anode-free batteries are designed without a pre-deposited anode, instead relying on in-situ formation of the anode during the first charge cycle. This design significantly increases energy density by eliminating the weight and volume of the traditional anode. The structure typically includes a current collector where lithium or other active materials deposit during charging. This approach reduces the overall weight and size of the battery while potentially increasing energy density by 30-50% compared to conventional lithium-ion batteries.

- Electrolyte compositions for anode-free batteries: Specialized electrolyte formulations are crucial for anode-free battery performance, as they must facilitate uniform metal deposition and prevent dendrite formation. These electrolytes often contain additives that create stable solid electrolyte interphase (SEI) layers and improve cycling efficiency. Formulations may include fluorinated solvents, high-concentration salt systems, or ionic liquids that enhance the stability of the metal-electrolyte interface. The electrolyte composition directly impacts coulombic efficiency, cycle life, and safety of anode-free battery systems.

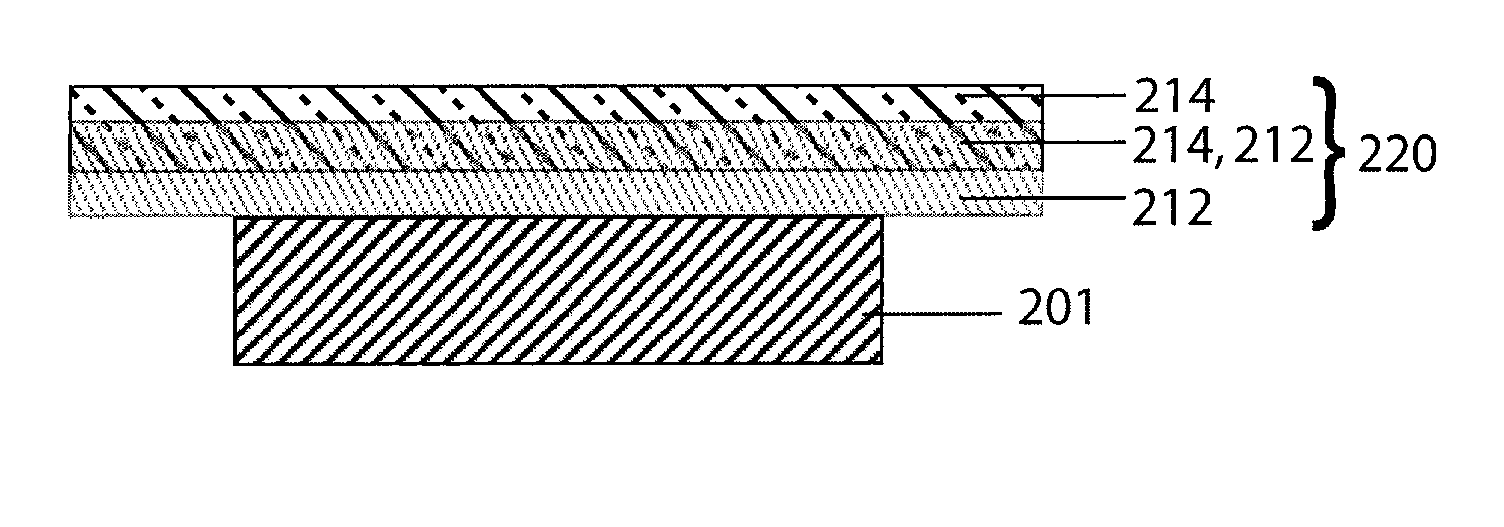

- Protective layers and interfaces for anode-free batteries: Protective layers and interface engineering are essential in anode-free battery technology to prevent dendrite formation and improve cycling stability. These protective layers can be applied to the current collector or formed in-situ during battery operation. Materials such as artificial SEI layers, polymer coatings, or ceramic-based protective films help control metal deposition morphology and prevent side reactions. Advanced interface designs can significantly extend battery life by maintaining uniform metal plating/stripping and reducing parasitic reactions that consume active materials.

- Cathode materials for high-energy anode-free systems: Cathode materials for anode-free batteries require specific properties to complement the anode-free design and maximize energy density. High-capacity cathode materials such as nickel-rich layered oxides, lithium-rich materials, or conversion-type cathodes are often employed. These materials must maintain structural stability during deep cycling and operate at appropriate voltage windows compatible with the electrolyte system. The cathode composition and structure significantly influence the overall performance, energy density, and cycle life of anode-free battery systems.

- Manufacturing methods and commercial applications: Manufacturing processes for anode-free batteries require specialized techniques to ensure quality and performance. These include precise control of current collector surface properties, electrolyte filling procedures, and initial formation protocols. The absence of a pre-deposited anode simplifies some manufacturing steps while introducing new challenges in cell balancing and quality control. Anode-free batteries show promising applications in portable electronics, electric vehicles, and grid storage due to their potential for higher energy density, though commercial adoption faces challenges related to cycle life and production scaling.

02 Electrolyte formulations for anode-free batteries

Specialized electrolyte formulations are critical for anode-free battery performance, addressing challenges like dendrite formation and low Coulombic efficiency. These formulations often include additives that create stable solid electrolyte interphases (SEI) on the current collector surface. Advanced electrolytes may incorporate fluorinated compounds, high-concentration salt systems, or ionic liquids to improve lithium plating/stripping efficiency and extend cycle life while maintaining the benefits of the anode-free design.Expand Specific Solutions03 Current collector modifications for anode-free batteries

Engineered current collectors are essential for effective anode-free battery operation, as they serve as the substrate for lithium plating. Modifications include surface treatments to improve lithium nucleation, specialized coatings to enhance adhesion, and three-dimensional structures to accommodate volume changes during cycling. These modifications help achieve uniform lithium deposition, prevent dendrite formation, and improve the overall electrochemical performance and safety of anode-free batteries.Expand Specific Solutions04 Protective layers and interfaces for anode-free systems

Protective layers and interface engineering are employed in anode-free batteries to stabilize the lithium-electrolyte interface and prevent side reactions. These include artificial SEI layers applied to current collectors before cell assembly, polymer or ceramic coatings that regulate ion transport, and gradient interfaces that manage mechanical stress during cycling. Such protective strategies significantly improve cycling stability, Coulombic efficiency, and prevent capacity fade in anode-free battery systems.Expand Specific Solutions05 Manufacturing methods for anode-free batteries

Specialized manufacturing techniques have been developed for anode-free batteries to address their unique requirements. These include dry-room or controlled-atmosphere assembly processes to prevent moisture contamination, precision electrolyte filling methods to ensure proper wetting of components, and specialized formation protocols that carefully control the initial lithium plating process. Advanced quality control measures and testing protocols are also implemented to ensure consistent performance and safety of these high-energy-density systems.Expand Specific Solutions

Key Industry Players in Electric Aviation Battery Development

Anode-free batteries represent a critical technological advancement for electric aviation, currently in an early development stage with significant growth potential. The market is expanding rapidly due to increasing demand for sustainable aviation solutions, with projections suggesting substantial growth as the technology matures. From a technical maturity perspective, research institutions like MIT, Nanyang Technological University, and companies including Sila Nanotechnologies, PolyPlus Battery, and Wildcat Discovery Technologies are leading development efforts. These organizations are addressing key challenges of energy density, safety, and cycle life that are essential for aviation applications. The competitive landscape features both established battery manufacturers and specialized startups working to overcome the weight and range limitations that currently constrain electric aircraft development.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have developed an innovative anode-free battery architecture specifically addressing the unique requirements of electric aviation. Their approach utilizes a dual-phase electrolyte system that combines the benefits of solid and liquid electrolytes to enable stable lithium plating during charging cycles. This hybrid design achieves energy densities exceeding 400 Wh/kg while maintaining the power delivery capabilities necessary for aircraft operations. MIT's technology incorporates advanced separator materials with precisely engineered porosity and tortuosity to control lithium ion transport pathways, significantly reducing dendrite formation risk. Their research has demonstrated that controlling the lithium nucleation process through specialized current collector surface treatments can extend cycle life beyond 300 cycles while maintaining 80% capacity - a critical threshold for aviation applications. The team has also developed computational models that predict battery performance under various flight conditions, including rapid altitude and temperature changes typical in aviation environments.

Strengths: Hybrid electrolyte system provides both high energy density and improved safety characteristics compared to conventional lithium-metal designs. Advanced computational modeling enables performance prediction under various flight conditions, accelerating certification processes. Weaknesses: Complex manufacturing processes for the dual-phase electrolyte system may present scaling challenges. Technology remains primarily in research phase with limited large-format cell demonstrations.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has developed a proprietary anode-free lithium battery technology specifically engineered for the demanding requirements of electric aviation. Their approach utilizes a protected lithium electrode (PLE) architecture where lithium ions plate directly onto a specialized current collector during charging, eliminating the need for a pre-formed anode. This design achieves energy densities approaching 450 Wh/kg - nearly double that of conventional lithium-ion batteries. The company's patented water-stable lithium-metal technology incorporates a solid electrolyte interface that prevents unwanted reactions between lithium and the electrolyte, addressing a key degradation mechanism. PolyPlus has focused on scalable manufacturing processes, developing roll-to-roll production techniques for their specialized membranes and electrode structures. Their aviation-specific designs incorporate redundant safety features including thermal runaway prevention systems and cell-level monitoring capabilities.

Strengths: Exceptional energy density (up to 450 Wh/kg) provides significantly extended flight range compared to conventional batteries. Proprietary protected lithium electrode technology offers improved safety characteristics critical for aviation applications. Weaknesses: Higher production costs compared to traditional lithium-ion batteries may limit initial commercial adoption. Technology is relatively new to market with limited real-world operational history in aviation environments.

Critical Patents and Research in Anode-Free Battery Technology

Battery and electrolytes therefor

PatentPendingCA3219323A1

Innovation

- Incorporating a conductive spacer to increase internal pressure within the battery cell, combined with a hybrid electrolyte comprising diglyme and lithium nitrate, which forms a robust solvation structure and inorganic-rich solid-electrolyte interphase, enhancing Li deposition homogeneity and cycle stability.

Li/air non-aqueous batteries

PatentActiveUS20070117007A1

Innovation

- A non-aqueous lithium/air battery cell with a protected alkali metal anode and a non-aqueous electrolyte, where the anode is decoupled from the cathode environment by a protective membrane architecture that prevents direct contact with moisture and air, allowing the use of cathode performance-enhancing solvents that are incompatible with lithium.

Safety and Certification Requirements for Aviation Batteries

Aviation battery systems face uniquely stringent safety and certification requirements compared to ground-based applications. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive regulatory frameworks that any battery technology, including anode-free designs, must satisfy before implementation in aircraft. These regulations focus primarily on preventing catastrophic failures that could compromise flight safety.

The certification process for aviation batteries requires demonstrating resistance to thermal runaway under various operational conditions. Current standards mandate that battery systems contain any potential fire or explosion without affecting critical flight systems or structures. For anode-free lithium metal batteries, this presents significant challenges due to their higher energy density and the reactive nature of lithium metal.

RTCA DO-311A and DO-160 standards specifically outline environmental testing requirements for rechargeable lithium batteries in aviation applications. These include vibration testing, altitude simulation, temperature cycling, and electromagnetic compatibility. Anode-free batteries must demonstrate compliance with these standards while maintaining their performance advantages.

Safety redundancy represents another critical certification requirement. Aviation battery systems must incorporate multiple layers of protection, including battery management systems (BMS) with sophisticated monitoring capabilities. These systems must detect and mitigate potential failure modes specific to anode-free designs, such as dendrite formation or electrolyte degradation, which differ from conventional lithium-ion failure mechanisms.

The certification pathway for novel battery technologies like anode-free systems typically involves a phased approach. Initial certifications may be granted for non-critical applications before progressing to propulsion systems. This graduated implementation allows for real-world safety data collection while minimizing risk. Several electric aircraft developers are currently working with regulatory authorities to establish certification pathways specifically for high-energy-density battery technologies.

Material qualification represents a particular challenge for anode-free batteries in aviation. The absence of a pre-deposited anode requires extensive testing to ensure consistent lithium plating behavior throughout the battery's operational life. Certification bodies require accelerated life testing that simulates years of operational cycles under various environmental conditions to validate long-term safety and performance.

The certification process for aviation batteries requires demonstrating resistance to thermal runaway under various operational conditions. Current standards mandate that battery systems contain any potential fire or explosion without affecting critical flight systems or structures. For anode-free lithium metal batteries, this presents significant challenges due to their higher energy density and the reactive nature of lithium metal.

RTCA DO-311A and DO-160 standards specifically outline environmental testing requirements for rechargeable lithium batteries in aviation applications. These include vibration testing, altitude simulation, temperature cycling, and electromagnetic compatibility. Anode-free batteries must demonstrate compliance with these standards while maintaining their performance advantages.

Safety redundancy represents another critical certification requirement. Aviation battery systems must incorporate multiple layers of protection, including battery management systems (BMS) with sophisticated monitoring capabilities. These systems must detect and mitigate potential failure modes specific to anode-free designs, such as dendrite formation or electrolyte degradation, which differ from conventional lithium-ion failure mechanisms.

The certification pathway for novel battery technologies like anode-free systems typically involves a phased approach. Initial certifications may be granted for non-critical applications before progressing to propulsion systems. This graduated implementation allows for real-world safety data collection while minimizing risk. Several electric aircraft developers are currently working with regulatory authorities to establish certification pathways specifically for high-energy-density battery technologies.

Material qualification represents a particular challenge for anode-free batteries in aviation. The absence of a pre-deposited anode requires extensive testing to ensure consistent lithium plating behavior throughout the battery's operational life. Certification bodies require accelerated life testing that simulates years of operational cycles under various environmental conditions to validate long-term safety and performance.

Environmental Impact and Sustainability Considerations

The aviation industry's environmental footprint has become increasingly scrutinized as global efforts to combat climate change intensify. Anode-free battery technology represents a significant advancement in sustainable aviation by addressing several critical environmental concerns. These batteries offer substantially higher energy density compared to conventional lithium-ion batteries, enabling electric aircraft to achieve longer ranges while maintaining lower overall weight. This efficiency translates directly into reduced energy consumption per passenger mile, a key metric for sustainable transportation systems.

Manufacturing processes for anode-free batteries potentially require fewer raw materials and energy inputs compared to traditional battery technologies. The elimination of the anode component reduces the need for mining and processing certain materials, particularly graphite, which often involves environmentally damaging extraction methods and significant energy consumption. This streamlined material requirement contributes to a smaller carbon footprint across the battery lifecycle, from production through operation to eventual recycling or disposal.

The environmental benefits extend beyond manufacturing considerations. Electric aviation powered by anode-free batteries produces zero direct emissions during operation, eliminating the release of carbon dioxide, nitrogen oxides, and particulate matter that contribute to both climate change and local air pollution. When charged using renewable energy sources, these aircraft can approach true carbon neutrality, representing a transformative shift from conventional aviation's heavy dependence on fossil fuels.

Sustainability considerations must also account for end-of-life management. Anode-free battery designs potentially offer advantages in recyclability due to their simplified structure and reduced material complexity. This characteristic aligns with circular economy principles, where materials are recovered and reused rather than discarded, further reducing environmental impact and resource depletion associated with battery production.

The reduced weight of anode-free batteries creates cascading environmental benefits throughout aircraft design and operation. Lighter batteries enable more efficient aircraft structures, requiring less energy for takeoff, cruise, and landing operations. This weight reduction can trigger a positive feedback loop where lighter batteries lead to lighter aircraft structures, which in turn require less energy to operate, further reducing environmental impact across the entire aviation ecosystem.

Water consumption and pollution risks are also potentially mitigated with anode-free battery technology. Traditional battery manufacturing processes often require significant water resources and create wastewater containing heavy metals and other contaminants. The simplified chemistry and structure of anode-free designs may reduce these environmental hazards, contributing to more sustainable manufacturing practices in the aviation supply chain.

Manufacturing processes for anode-free batteries potentially require fewer raw materials and energy inputs compared to traditional battery technologies. The elimination of the anode component reduces the need for mining and processing certain materials, particularly graphite, which often involves environmentally damaging extraction methods and significant energy consumption. This streamlined material requirement contributes to a smaller carbon footprint across the battery lifecycle, from production through operation to eventual recycling or disposal.

The environmental benefits extend beyond manufacturing considerations. Electric aviation powered by anode-free batteries produces zero direct emissions during operation, eliminating the release of carbon dioxide, nitrogen oxides, and particulate matter that contribute to both climate change and local air pollution. When charged using renewable energy sources, these aircraft can approach true carbon neutrality, representing a transformative shift from conventional aviation's heavy dependence on fossil fuels.

Sustainability considerations must also account for end-of-life management. Anode-free battery designs potentially offer advantages in recyclability due to their simplified structure and reduced material complexity. This characteristic aligns with circular economy principles, where materials are recovered and reused rather than discarded, further reducing environmental impact and resource depletion associated with battery production.

The reduced weight of anode-free batteries creates cascading environmental benefits throughout aircraft design and operation. Lighter batteries enable more efficient aircraft structures, requiring less energy for takeoff, cruise, and landing operations. This weight reduction can trigger a positive feedback loop where lighter batteries lead to lighter aircraft structures, which in turn require less energy to operate, further reducing environmental impact across the entire aviation ecosystem.

Water consumption and pollution risks are also potentially mitigated with anode-free battery technology. Traditional battery manufacturing processes often require significant water resources and create wastewater containing heavy metals and other contaminants. The simplified chemistry and structure of anode-free designs may reduce these environmental hazards, contributing to more sustainable manufacturing practices in the aviation supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!