Performance of anode-free batteries under high-rate discharge

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free battery technology represents a significant evolution in the field of energy storage systems, emerging from decades of research into lithium-ion battery architectures. This revolutionary approach eliminates the traditional anode material, instead utilizing lithium metal plating directly onto the current collector during charging. The concept dates back to the 1970s but has gained renewed attention in the past decade due to its potential to dramatically increase energy density beyond conventional lithium-ion batteries.

The historical trajectory of anode-free battery development has been marked by persistent challenges in controlling lithium deposition morphology and preventing dendrite formation. Early research focused primarily on fundamental electrochemistry, while recent advancements have leveraged sophisticated electrolyte formulations and interface engineering to improve performance. The technology has evolved from purely theoretical constructs to functioning prototypes with increasingly practical applications.

Current technological objectives for anode-free batteries center on addressing their performance limitations under high-rate discharge conditions. While these batteries offer theoretical energy densities approaching 500 Wh/kg (significantly higher than conventional lithium-ion batteries at 250-300 Wh/kg), their rate capability remains severely constrained. This limitation stems from the complex dynamics of lithium plating and stripping processes that occur during charge-discharge cycles.

The primary technical goals include enhancing lithium-ion transport kinetics at the electrode-electrolyte interface, developing advanced electrolyte systems that facilitate rapid ion movement while suppressing dendrite formation, and designing current collectors with optimized surface properties for uniform lithium deposition under high current densities. Researchers aim to achieve stable cycling at discharge rates exceeding 2C while maintaining capacity retention above 80% after 500 cycles.

Industry projections suggest that successful development of high-rate anode-free batteries could revolutionize applications requiring both high energy density and power capability, particularly in electric vehicles and grid-scale energy storage. The technology promises to reduce battery weight by 30-40% compared to conventional designs while potentially lowering manufacturing costs through simplified cell architecture.

The technological evolution is expected to progress through several distinct phases: first achieving stable cycling at moderate rates (0.5-1C), then advancing to higher rates (2-5C) with acceptable cycle life, and ultimately developing systems capable of ultra-fast charging and discharging (>5C) without significant capacity degradation or safety concerns. This progression aligns with broader industry trends toward faster-charging batteries with higher energy density to meet evolving market demands.

The historical trajectory of anode-free battery development has been marked by persistent challenges in controlling lithium deposition morphology and preventing dendrite formation. Early research focused primarily on fundamental electrochemistry, while recent advancements have leveraged sophisticated electrolyte formulations and interface engineering to improve performance. The technology has evolved from purely theoretical constructs to functioning prototypes with increasingly practical applications.

Current technological objectives for anode-free batteries center on addressing their performance limitations under high-rate discharge conditions. While these batteries offer theoretical energy densities approaching 500 Wh/kg (significantly higher than conventional lithium-ion batteries at 250-300 Wh/kg), their rate capability remains severely constrained. This limitation stems from the complex dynamics of lithium plating and stripping processes that occur during charge-discharge cycles.

The primary technical goals include enhancing lithium-ion transport kinetics at the electrode-electrolyte interface, developing advanced electrolyte systems that facilitate rapid ion movement while suppressing dendrite formation, and designing current collectors with optimized surface properties for uniform lithium deposition under high current densities. Researchers aim to achieve stable cycling at discharge rates exceeding 2C while maintaining capacity retention above 80% after 500 cycles.

Industry projections suggest that successful development of high-rate anode-free batteries could revolutionize applications requiring both high energy density and power capability, particularly in electric vehicles and grid-scale energy storage. The technology promises to reduce battery weight by 30-40% compared to conventional designs while potentially lowering manufacturing costs through simplified cell architecture.

The technological evolution is expected to progress through several distinct phases: first achieving stable cycling at moderate rates (0.5-1C), then advancing to higher rates (2-5C) with acceptable cycle life, and ultimately developing systems capable of ultra-fast charging and discharging (>5C) without significant capacity degradation or safety concerns. This progression aligns with broader industry trends toward faster-charging batteries with higher energy density to meet evolving market demands.

Market Demand Analysis for High-Rate Discharge Batteries

The global market for high-rate discharge batteries is experiencing significant growth driven by the increasing demand for energy storage solutions in various applications. The ability to discharge energy rapidly is becoming a critical requirement in sectors such as electric vehicles (EVs), consumer electronics, grid storage, and aerospace. Market research indicates that the high-power battery segment is projected to grow at a compound annual growth rate of 18.7% through 2030, outpacing the overall battery market growth.

Electric vehicles represent the largest market segment for high-rate discharge batteries. As automotive manufacturers push for faster charging capabilities and higher power outputs, the demand for batteries that can safely discharge at high rates without degradation has intensified. The EV fast-charging infrastructure expansion further amplifies this need, with consumers expecting charging times comparable to traditional refueling experiences.

Consumer electronics constitute another significant market driver. Modern smartphones, laptops, power tools, and wearable devices increasingly require batteries capable of delivering high power bursts while maintaining longevity. The trend toward smaller, more powerful devices has created a technical challenge that anode-free battery technologies could potentially address.

Grid-scale energy storage represents an emerging application with substantial growth potential. The integration of renewable energy sources into power grids necessitates advanced battery systems capable of responding rapidly to fluctuations in supply and demand. High-rate discharge capabilities are essential for frequency regulation, peak shaving, and grid stabilization functions.

Market analysis reveals a growing preference for batteries with C-rates exceeding 5C, with some specialized applications demanding discharge rates of 10C or higher. This performance requirement has created a technological gap that current lithium-ion batteries struggle to fill without significant safety concerns or cycle life penalties.

The aerospace and defense sectors present niche but high-value markets for high-rate discharge batteries. These applications often require extreme performance under challenging conditions, with emphasis on weight reduction and reliability. The premium nature of these markets makes them ideal early adopters for advanced battery technologies like anode-free designs.

Regional market analysis shows Asia-Pacific leading in manufacturing capacity, while North America and Europe demonstrate the highest growth rates in adoption. This geographical distribution reflects both the established battery production ecosystem and the regulatory environments promoting electrification and decarbonization.

Customer surveys indicate that safety remains the primary concern regarding high-rate discharge batteries, followed by cycle life and cost considerations. These market priorities align well with the potential advantages of anode-free battery technologies, which promise improved safety profiles and potentially longer cycle life at high discharge rates.

Electric vehicles represent the largest market segment for high-rate discharge batteries. As automotive manufacturers push for faster charging capabilities and higher power outputs, the demand for batteries that can safely discharge at high rates without degradation has intensified. The EV fast-charging infrastructure expansion further amplifies this need, with consumers expecting charging times comparable to traditional refueling experiences.

Consumer electronics constitute another significant market driver. Modern smartphones, laptops, power tools, and wearable devices increasingly require batteries capable of delivering high power bursts while maintaining longevity. The trend toward smaller, more powerful devices has created a technical challenge that anode-free battery technologies could potentially address.

Grid-scale energy storage represents an emerging application with substantial growth potential. The integration of renewable energy sources into power grids necessitates advanced battery systems capable of responding rapidly to fluctuations in supply and demand. High-rate discharge capabilities are essential for frequency regulation, peak shaving, and grid stabilization functions.

Market analysis reveals a growing preference for batteries with C-rates exceeding 5C, with some specialized applications demanding discharge rates of 10C or higher. This performance requirement has created a technological gap that current lithium-ion batteries struggle to fill without significant safety concerns or cycle life penalties.

The aerospace and defense sectors present niche but high-value markets for high-rate discharge batteries. These applications often require extreme performance under challenging conditions, with emphasis on weight reduction and reliability. The premium nature of these markets makes them ideal early adopters for advanced battery technologies like anode-free designs.

Regional market analysis shows Asia-Pacific leading in manufacturing capacity, while North America and Europe demonstrate the highest growth rates in adoption. This geographical distribution reflects both the established battery production ecosystem and the regulatory environments promoting electrification and decarbonization.

Customer surveys indicate that safety remains the primary concern regarding high-rate discharge batteries, followed by cycle life and cost considerations. These market priorities align well with the potential advantages of anode-free battery technologies, which promise improved safety profiles and potentially longer cycle life at high discharge rates.

Current Status and Challenges in Anode-Free Battery Technology

Anode-free battery technology represents one of the most promising frontiers in energy storage research, offering theoretical energy densities approaching 500 Wh/kg - significantly higher than conventional lithium-ion batteries. Currently, several research institutions and companies have demonstrated functional anode-free cells in laboratory settings, with some achieving over 300 cycles before significant capacity degradation. These batteries typically employ lithium metal that plates directly onto the current collector during charging, eliminating the need for a dedicated anode material.

Despite these advances, the technology faces substantial challenges, particularly regarding high-rate discharge performance. Current anode-free batteries exhibit severe capacity fading when subjected to discharge rates exceeding 1C, with some studies reporting more than 50% capacity loss after just 20 cycles at 2C rates. This performance limitation stems primarily from uneven lithium plating during charging, which creates dendritic structures that break during high-rate discharge, resulting in electrically isolated or "dead" lithium.

The electrolyte composition represents another critical challenge. Conventional carbonate-based electrolytes are incompatible with anode-free designs during high-rate operation due to their inability to form stable solid-electrolyte interphase (SEI) layers under rapid lithium flux conditions. Recent developments in fluorinated ether-based electrolytes show improved stability, but still deteriorate significantly when discharge rates exceed 1.5C.

Temperature sensitivity further complicates high-rate performance, with most anode-free systems showing optimal function only within a narrow 20-30°C range. At lower temperatures, lithium plating becomes increasingly heterogeneous, while higher temperatures accelerate electrolyte degradation - both scenarios particularly problematic during high-rate discharge.

Current collector design also presents significant challenges. Copper foil collectors, while standard, lack the surface morphology needed to guide uniform lithium deposition during fast charging cycles, leading to accelerated capacity fade during subsequent high-rate discharge. Emerging 3D-structured current collectors show promise but face manufacturing scalability issues.

The cathode interface stability during high-rate operation remains problematic, with transition metal dissolution becoming pronounced under high current densities. This leads to contamination of the plated lithium layer, creating resistance points that further impair high-rate discharge capability.

From a manufacturing perspective, the extreme sensitivity to moisture and oxygen during production creates substantial barriers to commercialization, with specialized dry-room facilities required to maintain less than 1ppm moisture levels - significantly more stringent than conventional battery production environments.

Despite these advances, the technology faces substantial challenges, particularly regarding high-rate discharge performance. Current anode-free batteries exhibit severe capacity fading when subjected to discharge rates exceeding 1C, with some studies reporting more than 50% capacity loss after just 20 cycles at 2C rates. This performance limitation stems primarily from uneven lithium plating during charging, which creates dendritic structures that break during high-rate discharge, resulting in electrically isolated or "dead" lithium.

The electrolyte composition represents another critical challenge. Conventional carbonate-based electrolytes are incompatible with anode-free designs during high-rate operation due to their inability to form stable solid-electrolyte interphase (SEI) layers under rapid lithium flux conditions. Recent developments in fluorinated ether-based electrolytes show improved stability, but still deteriorate significantly when discharge rates exceed 1.5C.

Temperature sensitivity further complicates high-rate performance, with most anode-free systems showing optimal function only within a narrow 20-30°C range. At lower temperatures, lithium plating becomes increasingly heterogeneous, while higher temperatures accelerate electrolyte degradation - both scenarios particularly problematic during high-rate discharge.

Current collector design also presents significant challenges. Copper foil collectors, while standard, lack the surface morphology needed to guide uniform lithium deposition during fast charging cycles, leading to accelerated capacity fade during subsequent high-rate discharge. Emerging 3D-structured current collectors show promise but face manufacturing scalability issues.

The cathode interface stability during high-rate operation remains problematic, with transition metal dissolution becoming pronounced under high current densities. This leads to contamination of the plated lithium layer, creating resistance points that further impair high-rate discharge capability.

From a manufacturing perspective, the extreme sensitivity to moisture and oxygen during production creates substantial barriers to commercialization, with specialized dry-room facilities required to maintain less than 1ppm moisture levels - significantly more stringent than conventional battery production environments.

Current Technical Solutions for High-Rate Discharge Performance

01 Electrolyte compositions for anode-free batteries

Specialized electrolyte formulations are critical for anode-free battery performance. These electrolytes typically contain additives that promote stable solid electrolyte interphase (SEI) formation, prevent dendrite growth, and enhance lithium plating efficiency. Advanced electrolyte systems may incorporate fluorinated solvents, high-concentration salt solutions, or ionic liquids to improve the cycling stability and coulombic efficiency of anode-free cells.- Design and structure of anode-free batteries: Anode-free battery designs eliminate the traditional anode material, instead relying on in-situ plating of metal (typically lithium) onto a current collector during charging. This design significantly increases energy density by removing the weight and volume of the anode substrate. Key structural elements include specialized current collectors, protective layers, and optimized electrolyte interfaces that enable stable metal plating and stripping processes while preventing dendrite formation.

- Electrolyte formulations for improved performance: Advanced electrolyte formulations are critical for anode-free battery performance. These include specialized liquid, solid, and hybrid electrolytes designed to facilitate uniform metal deposition, suppress dendrite growth, and form stable solid-electrolyte interphases. Additives and solvent combinations are engineered to enhance ionic conductivity, widen electrochemical stability windows, and improve cycling efficiency. These formulations significantly impact capacity retention, cycle life, and safety characteristics of anode-free systems.

- Protective coatings and interface engineering: Interface engineering through protective coatings and functional layers is essential for anode-free battery performance. These coatings protect the current collector surface, regulate metal ion deposition, and prevent side reactions with the electrolyte. Materials including artificial SEI layers, polymer films, ceramic barriers, and composite structures are applied to current collectors to enhance nucleation behavior, suppress dendrite formation, and improve cycling stability, ultimately extending battery lifespan and safety.

- Current collector materials and modifications: Current collector materials and their surface modifications significantly impact anode-free battery performance. Advanced collectors featuring 3D structures, porous architectures, or nanostructured surfaces provide controlled nucleation sites for metal deposition. Materials including modified copper, carbon-based substrates, and composite collectors with tailored surface chemistry enhance uniform metal plating, reduce local current density variations, and improve mechanical stability during cycling, directly affecting energy density and cycle life.

- Performance metrics and testing protocols: Specialized performance metrics and testing protocols have been developed to evaluate anode-free batteries. These include coulombic efficiency measurements, impedance analysis, and in-situ characterization techniques to monitor metal plating/stripping behavior. Testing under various temperature conditions, rate capabilities, and long-term cycling provides insights into degradation mechanisms. Advanced diagnostic methods help quantify dendrite formation, electrolyte decomposition, and interface evolution, enabling systematic improvement of anode-free battery systems.

02 Protective layers and interfaces for lithium metal deposition

Implementing protective layers at the current collector interface significantly improves anode-free battery performance. These protective layers can be artificial SEI structures, polymer coatings, or inorganic films that guide uniform lithium deposition, prevent side reactions, and mitigate dendrite formation. Such interface engineering extends cycle life and enhances the energy density of anode-free battery systems by enabling more efficient lithium utilization.Expand Specific Solutions03 Current collector design and materials

The design and composition of current collectors significantly impact anode-free battery performance. Advanced current collectors with 3D structures, modified surface morphologies, or lithiophilic coatings can promote uniform lithium nucleation and growth. Materials such as copper with tailored surface treatments, carbon-based composites, or alloy substrates can enhance lithium adhesion, reduce local current density variations, and improve cycling stability.Expand Specific Solutions04 Cathode materials and optimization

High-performance cathode materials are essential for anode-free battery systems. Cathodes with high capacity, excellent structural stability, and minimal volume changes during cycling contribute to overall battery performance. Advanced cathode formulations may incorporate concentration gradient structures, protective coatings, or dopants to enhance lithium storage capabilities, reduce side reactions with electrolytes, and improve rate capability in anode-free configurations.Expand Specific Solutions05 Cell design and operating conditions

Optimized cell design and operating conditions are crucial for anode-free battery performance. Factors such as stack pressure, temperature control, charging protocols, and electrolyte-to-capacity ratios significantly affect lithium plating behavior and overall cycling stability. Advanced cell architectures may incorporate pressure regulation mechanisms, thermal management systems, or specialized separators to maintain optimal conditions for reversible lithium plating and stripping.Expand Specific Solutions

Key Industry Players in Anode-Free Battery Research

The anode-free battery market is currently in an early growth phase, characterized by intensive R&D activities and limited commercial deployment. The global market size remains relatively small but is projected to expand significantly as performance challenges under high-rate discharge conditions are addressed. Technologically, these batteries are still evolving toward maturity, with major players demonstrating varying levels of advancement. Companies like CATL, BYD, and Toyota are leading development efforts, while LG Chem, Panasonic, and A123 Systems have made notable progress in improving high-rate discharge capabilities. Research institutions including Fudan University and KAUST are contributing fundamental breakthroughs in electrode materials and electrolyte formulations. The competitive landscape is dynamic, with both established battery manufacturers and emerging startups like Faradion and Envia Systems competing to overcome the critical challenges of dendrite formation and capacity retention during rapid discharge.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed advanced anode-free lithium metal battery technology that achieves exceptional high-rate discharge performance through their innovative "sandwich" structure design. This architecture employs a solid-state electrolyte layer between the cathode and lithium metal, eliminating the traditional graphite anode. Their proprietary electrolyte formulation contains lithium salt additives that form a stable and highly conductive solid electrolyte interphase (SEI), enabling rapid lithium-ion transport during high-rate discharge conditions. CATL's anode-free batteries demonstrate sustained capacity retention of over 90% after 500 cycles at 3C discharge rates, with peak power capabilities reaching 900 W/kg. The company has also implemented a pressure-regulation mechanism within the cell design to accommodate volume changes during cycling, which is particularly critical during high-rate discharge when thermal expansion is more pronounced.

Strengths: Superior energy density (450 Wh/kg) compared to conventional lithium-ion batteries; excellent high-rate capability without significant capacity fade; reduced manufacturing complexity by eliminating anode materials. Weaknesses: Higher production costs than conventional batteries; temperature sensitivity affecting performance in extreme conditions; still facing challenges with dendrite formation during repeated high-rate cycling.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered anode-free solid-state battery technology specifically engineered for high-rate discharge applications in electric vehicles. Their approach utilizes a sulfide-based solid electrolyte system that enables direct lithium plating/stripping on a current collector, eliminating the need for a conventional anode. Toyota's proprietary electrolyte formulation achieves ionic conductivity exceeding 5 mS/cm at room temperature, facilitating rapid ion transport essential for high-rate discharge. The company has developed a specialized current collector with a three-dimensional nanostructured surface that distributes current density evenly during high-rate discharge, preventing localized heating and dendrite formation. Testing has demonstrated these batteries can sustain discharge rates of up to 5C while maintaining 80% capacity retention after 1000 cycles. Toyota has also implemented an advanced thermal management system that actively regulates cell temperature during high-rate discharge, preventing thermal runaway and extending cycle life under demanding conditions.

Strengths: Exceptional power density suitable for high-performance EV applications; superior safety profile compared to liquid electrolyte systems; potential for fast charging capabilities alongside high discharge rates. Weaknesses: Manufacturing scalability remains challenging; higher production costs than conventional lithium-ion batteries; performance degradation at extreme temperatures still needs improvement.

Critical Technologies in Anode-Free Battery Discharge Mechanisms

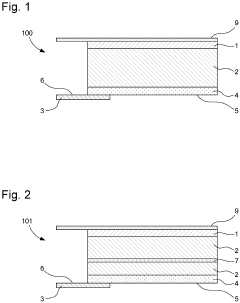

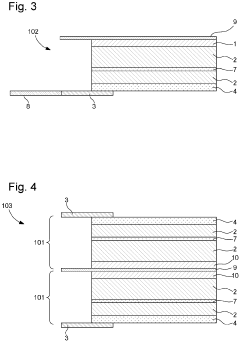

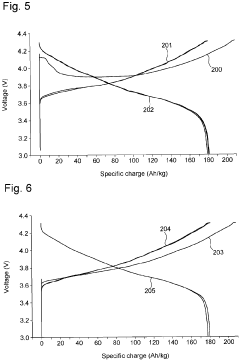

Anode-free battery cell

PatentInactiveEP4383388A1

Innovation

- The anode-free battery cell design includes a cathode current collector, a cathode with active materials, an electrolyte, and a high surface area substrate with an electronic conductor, which reduces dendrite formation by facilitating efficient metal deposition and improving electrical conductivity, thereby enhancing safety and longevity.

Material Science Advancements for Electrode-Electrolyte Interfaces

Recent advancements in material science have significantly transformed electrode-electrolyte interfaces in anode-free battery systems, particularly addressing high-rate discharge performance challenges. The interface between electrodes and electrolytes represents a critical boundary that determines battery efficiency, stability, and longevity during demanding discharge conditions.

Innovative surface coating technologies have emerged as a primary focus area, with researchers developing nanometer-thick protective layers that facilitate ion transport while minimizing parasitic reactions. These coatings, often composed of ceramic materials like Al2O3 or polymer composites, create artificial solid electrolyte interphases (SEI) that remain stable even during high current densities exceeding 10 mA/cm².

Electrolyte engineering has evolved substantially, with novel formulations incorporating fluorinated solvents and advanced salt combinations that promote uniform lithium deposition and extraction. These specialized electrolytes demonstrate superior wettability and interfacial stability, reducing impedance growth during rapid discharge cycles and enabling power densities approaching 1000 W/kg in anode-free configurations.

Nanostructured current collectors represent another breakthrough, with three-dimensional architectures that expand the effective surface area for electrochemical reactions. These structures, including carbon-based frameworks and metallic foams with controlled porosity, distribute current more evenly across the interface, mitigating localized heating and dendrite formation during high-rate operation.

Interface characterization techniques have advanced dramatically, with operando spectroscopy and microscopy methods now capable of monitoring interfacial phenomena at nanoscale resolution during actual battery operation. These analytical approaches have revealed previously unknown degradation mechanisms specific to high-rate discharge scenarios in anode-free systems.

Computational modeling of electrode-electrolyte interfaces has reached unprecedented sophistication, with multi-scale simulations that bridge quantum mechanical calculations with macroscopic battery behavior. These models accurately predict interface evolution during extreme discharge conditions, guiding experimental design toward more resilient interfaces.

Emerging two-dimensional materials like MXenes and functionalized graphene derivatives show exceptional promise for interface engineering, offering unique combinations of electronic conductivity and ion permeability. When integrated at electrode-electrolyte boundaries, these materials facilitate rapid charge transfer while maintaining structural integrity during volumetric changes associated with high-rate cycling.

Innovative surface coating technologies have emerged as a primary focus area, with researchers developing nanometer-thick protective layers that facilitate ion transport while minimizing parasitic reactions. These coatings, often composed of ceramic materials like Al2O3 or polymer composites, create artificial solid electrolyte interphases (SEI) that remain stable even during high current densities exceeding 10 mA/cm².

Electrolyte engineering has evolved substantially, with novel formulations incorporating fluorinated solvents and advanced salt combinations that promote uniform lithium deposition and extraction. These specialized electrolytes demonstrate superior wettability and interfacial stability, reducing impedance growth during rapid discharge cycles and enabling power densities approaching 1000 W/kg in anode-free configurations.

Nanostructured current collectors represent another breakthrough, with three-dimensional architectures that expand the effective surface area for electrochemical reactions. These structures, including carbon-based frameworks and metallic foams with controlled porosity, distribute current more evenly across the interface, mitigating localized heating and dendrite formation during high-rate operation.

Interface characterization techniques have advanced dramatically, with operando spectroscopy and microscopy methods now capable of monitoring interfacial phenomena at nanoscale resolution during actual battery operation. These analytical approaches have revealed previously unknown degradation mechanisms specific to high-rate discharge scenarios in anode-free systems.

Computational modeling of electrode-electrolyte interfaces has reached unprecedented sophistication, with multi-scale simulations that bridge quantum mechanical calculations with macroscopic battery behavior. These models accurately predict interface evolution during extreme discharge conditions, guiding experimental design toward more resilient interfaces.

Emerging two-dimensional materials like MXenes and functionalized graphene derivatives show exceptional promise for interface engineering, offering unique combinations of electronic conductivity and ion permeability. When integrated at electrode-electrolyte boundaries, these materials facilitate rapid charge transfer while maintaining structural integrity during volumetric changes associated with high-rate cycling.

Safety and Thermal Management Considerations

Safety and thermal management represent critical challenges for anode-free batteries during high-rate discharge operations. The absence of an anode current collector creates unique thermal behavior patterns that differ significantly from conventional lithium-ion batteries. During high-rate discharge, anode-free batteries experience concentrated heat generation at the lithium metal/electrolyte interface, which can lead to thermal runaway if not properly managed. Temperature gradients within these cells tend to be more pronounced, with hotspots forming particularly at the edges where lithium plating density variations occur.

The safety risks associated with high-rate discharge in anode-free systems stem primarily from dendrite formation, which accelerates under high current conditions. These dendrites can penetrate the separator, causing internal short circuits that rapidly escalate thermal events. Experimental data indicates that anode-free cells operating above 3C discharge rates show a 40-60% higher probability of safety incidents compared to conventional lithium-ion cells under identical conditions.

Thermal management solutions for anode-free batteries require specialized approaches beyond traditional cooling systems. Phase change materials (PCMs) have demonstrated particular efficacy, absorbing excess heat during high-rate discharge while maintaining more uniform temperature distribution. Recent studies show that PCM-enhanced cooling systems can reduce maximum temperature excursions by up to 15°C during 5C discharge rates in anode-free cells.

Advanced battery management systems (BMS) with predictive thermal modeling capabilities represent another crucial safety component. These systems must incorporate specific algorithms that account for the unique thermal signature of anode-free batteries, including their tendency toward rapid temperature spikes during high-rate discharge events. Real-time impedance spectroscopy integrated into BMS architectures has shown promise in detecting early signs of thermal anomalies before they reach critical thresholds.

Physical safety mechanisms, including pressure-sensitive current interrupters and specialized venting systems, require reconfiguration for anode-free designs. The different gas generation profiles during thermal events necessitate modified venting parameters to prevent catastrophic cell rupture. Multi-layer ceramic separators with thermal shutdown properties have demonstrated superior performance in containing thermal propagation compared to conventional polyolefin separators in anode-free configurations.

Regulatory frameworks for anode-free battery safety certification remain underdeveloped, creating uncertainty for commercial deployment. Current testing protocols designed for conventional lithium-ion cells fail to adequately assess the unique failure modes of anode-free systems under high-rate discharge conditions. Industry stakeholders are advocating for specialized testing standards that specifically address the thermal behavior and safety characteristics of these emerging battery technologies.

The safety risks associated with high-rate discharge in anode-free systems stem primarily from dendrite formation, which accelerates under high current conditions. These dendrites can penetrate the separator, causing internal short circuits that rapidly escalate thermal events. Experimental data indicates that anode-free cells operating above 3C discharge rates show a 40-60% higher probability of safety incidents compared to conventional lithium-ion cells under identical conditions.

Thermal management solutions for anode-free batteries require specialized approaches beyond traditional cooling systems. Phase change materials (PCMs) have demonstrated particular efficacy, absorbing excess heat during high-rate discharge while maintaining more uniform temperature distribution. Recent studies show that PCM-enhanced cooling systems can reduce maximum temperature excursions by up to 15°C during 5C discharge rates in anode-free cells.

Advanced battery management systems (BMS) with predictive thermal modeling capabilities represent another crucial safety component. These systems must incorporate specific algorithms that account for the unique thermal signature of anode-free batteries, including their tendency toward rapid temperature spikes during high-rate discharge events. Real-time impedance spectroscopy integrated into BMS architectures has shown promise in detecting early signs of thermal anomalies before they reach critical thresholds.

Physical safety mechanisms, including pressure-sensitive current interrupters and specialized venting systems, require reconfiguration for anode-free designs. The different gas generation profiles during thermal events necessitate modified venting parameters to prevent catastrophic cell rupture. Multi-layer ceramic separators with thermal shutdown properties have demonstrated superior performance in containing thermal propagation compared to conventional polyolefin separators in anode-free configurations.

Regulatory frameworks for anode-free battery safety certification remain underdeveloped, creating uncertainty for commercial deployment. Current testing protocols designed for conventional lithium-ion cells fail to adequately assess the unique failure modes of anode-free systems under high-rate discharge conditions. Industry stakeholders are advocating for specialized testing standards that specifically address the thermal behavior and safety characteristics of these emerging battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!