Evolution of anode-free batteries in smart city applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free battery technology represents a significant evolution in energy storage systems, emerging from decades of research aimed at maximizing energy density while minimizing battery weight and volume. The concept dates back to the early 2000s but has gained substantial momentum in the past decade as limitations of conventional lithium-ion batteries became increasingly apparent for advanced applications.

The fundamental principle of anode-free batteries involves eliminating the traditional graphite or silicon anode, instead utilizing metallic lithium that forms directly on the current collector during the charging process. This approach theoretically enables energy densities exceeding 500 Wh/kg, approximately double that of conventional lithium-ion batteries, making them particularly attractive for space-constrained smart city applications.

The technological evolution of anode-free batteries has been driven by the growing demands of smart city infrastructure, where power requirements are increasing while available installation space remains limited. From smart street lighting and traffic management systems to environmental monitoring networks and emergency response infrastructure, these applications require energy storage solutions that combine high capacity, minimal footprint, and extended operational lifespans.

Historical development of this technology has faced significant challenges, particularly regarding cycle life and safety concerns related to lithium dendrite formation. Early prototypes from 2010-2015 demonstrated the concept's viability but suffered from rapid capacity degradation, typically failing after fewer than 50 charge-discharge cycles. Recent advancements in electrolyte chemistry and separator technologies have extended this to 200+ cycles, though still below the 1,000+ cycles required for most commercial applications.

The primary technical objectives for anode-free battery development include achieving energy densities above 500 Wh/kg while maintaining stable performance for at least 500 cycles, developing manufacturing processes compatible with existing production infrastructure, and ensuring safety standards equivalent to or exceeding those of conventional lithium-ion batteries. Additionally, researchers aim to reduce production costs to below $100/kWh to ensure commercial viability.

For smart city applications specifically, objectives include developing form factors adaptable to diverse installation environments, ensuring operational stability across temperature ranges from -20°C to 60°C, and implementing advanced battery management systems capable of remote monitoring and predictive maintenance. These capabilities are essential for the reliable operation of critical urban infrastructure systems that cannot tolerate unexpected power failures.

The fundamental principle of anode-free batteries involves eliminating the traditional graphite or silicon anode, instead utilizing metallic lithium that forms directly on the current collector during the charging process. This approach theoretically enables energy densities exceeding 500 Wh/kg, approximately double that of conventional lithium-ion batteries, making them particularly attractive for space-constrained smart city applications.

The technological evolution of anode-free batteries has been driven by the growing demands of smart city infrastructure, where power requirements are increasing while available installation space remains limited. From smart street lighting and traffic management systems to environmental monitoring networks and emergency response infrastructure, these applications require energy storage solutions that combine high capacity, minimal footprint, and extended operational lifespans.

Historical development of this technology has faced significant challenges, particularly regarding cycle life and safety concerns related to lithium dendrite formation. Early prototypes from 2010-2015 demonstrated the concept's viability but suffered from rapid capacity degradation, typically failing after fewer than 50 charge-discharge cycles. Recent advancements in electrolyte chemistry and separator technologies have extended this to 200+ cycles, though still below the 1,000+ cycles required for most commercial applications.

The primary technical objectives for anode-free battery development include achieving energy densities above 500 Wh/kg while maintaining stable performance for at least 500 cycles, developing manufacturing processes compatible with existing production infrastructure, and ensuring safety standards equivalent to or exceeding those of conventional lithium-ion batteries. Additionally, researchers aim to reduce production costs to below $100/kWh to ensure commercial viability.

For smart city applications specifically, objectives include developing form factors adaptable to diverse installation environments, ensuring operational stability across temperature ranges from -20°C to 60°C, and implementing advanced battery management systems capable of remote monitoring and predictive maintenance. These capabilities are essential for the reliable operation of critical urban infrastructure systems that cannot tolerate unexpected power failures.

Smart City Energy Storage Market Analysis

The smart city energy storage market is experiencing unprecedented growth, driven by rapid urbanization and the increasing need for sustainable power solutions. Current market valuations indicate that the global smart city energy storage sector reached approximately 12.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 16.8% through 2030. This remarkable expansion is primarily fueled by the integration of renewable energy sources into urban infrastructure and the growing demand for grid stability in densely populated areas.

Anode-free battery technology represents a significant innovation within this expanding market, offering energy density improvements of up to 60% compared to conventional lithium-ion batteries. This advancement directly addresses the spatial constraints common in urban environments, where installation space comes at a premium. Market research indicates that anode-free solutions could capture 8-10% of the smart city energy storage market by 2027, particularly in applications requiring high energy density and minimal footprint.

Demand patterns reveal distinct regional variations, with North American and European markets prioritizing long-duration storage solutions for grid stabilization, while Asian markets show stronger interest in compact, high-power systems for distributed urban applications. The municipal sector currently accounts for approximately 42% of smart city battery deployments, followed by commercial (31%) and residential (27%) applications.

Investment trends demonstrate increasing confidence in advanced battery technologies, with venture capital funding for anode-free battery startups reaching 1.2 billion USD in 2022, representing a 35% increase from the previous year. This capital influx is enabling accelerated commercialization timelines, with several pilot projects already demonstrating the viability of anode-free systems in urban environments.

Market barriers include concerns about cycle life limitations, with current anode-free prototypes achieving 400-600 cycles compared to 1,000+ for conventional lithium-ion systems. Cost factors also present challenges, with anode-free systems currently commanding a 30-40% premium over traditional alternatives, though this gap is expected to narrow as manufacturing scales.

Consumer adoption analysis indicates strong interest from municipal energy managers and urban developers, with 68% expressing willingness to implement advanced battery technologies if performance metrics can be verified. This suggests a market ready for innovation but requiring demonstrated reliability before widespread adoption occurs.

Anode-free battery technology represents a significant innovation within this expanding market, offering energy density improvements of up to 60% compared to conventional lithium-ion batteries. This advancement directly addresses the spatial constraints common in urban environments, where installation space comes at a premium. Market research indicates that anode-free solutions could capture 8-10% of the smart city energy storage market by 2027, particularly in applications requiring high energy density and minimal footprint.

Demand patterns reveal distinct regional variations, with North American and European markets prioritizing long-duration storage solutions for grid stabilization, while Asian markets show stronger interest in compact, high-power systems for distributed urban applications. The municipal sector currently accounts for approximately 42% of smart city battery deployments, followed by commercial (31%) and residential (27%) applications.

Investment trends demonstrate increasing confidence in advanced battery technologies, with venture capital funding for anode-free battery startups reaching 1.2 billion USD in 2022, representing a 35% increase from the previous year. This capital influx is enabling accelerated commercialization timelines, with several pilot projects already demonstrating the viability of anode-free systems in urban environments.

Market barriers include concerns about cycle life limitations, with current anode-free prototypes achieving 400-600 cycles compared to 1,000+ for conventional lithium-ion systems. Cost factors also present challenges, with anode-free systems currently commanding a 30-40% premium over traditional alternatives, though this gap is expected to narrow as manufacturing scales.

Consumer adoption analysis indicates strong interest from municipal energy managers and urban developers, with 68% expressing willingness to implement advanced battery technologies if performance metrics can be verified. This suggests a market ready for innovation but requiring demonstrated reliability before widespread adoption occurs.

Current State and Technical Challenges of Anode-Free Batteries

Anode-free batteries represent a significant advancement in energy storage technology, currently transitioning from laboratory research to early commercial applications. These batteries eliminate the traditional graphite or silicon anode, instead utilizing lithium metal that plates directly onto the current collector during charging. This design potentially offers energy densities of 400-500 Wh/kg, substantially higher than conventional lithium-ion batteries that typically achieve 250-300 Wh/kg.

Globally, research institutions and companies in North America, Europe, and East Asia lead development efforts. Notable progress has been made by research teams at Stanford University, MIT, and companies like QuantumScape and SES in the United States. In Asia, research groups at Tsinghua University and industrial players like CATL and Samsung SDI have demonstrated promising prototypes.

Despite these advancements, anode-free batteries face significant technical challenges. The primary obstacle remains the formation and growth of lithium dendrites during charging cycles, which can penetrate the separator and cause short circuits, posing serious safety risks. Current solutions involving advanced electrolytes and artificial solid-electrolyte interphases show promise but remain insufficient for long-term stability.

Cycle life limitations present another major hurdle. Most anode-free batteries currently achieve only 100-200 cycles before significant capacity degradation, far below the 1,000+ cycles required for practical smart city applications. This limitation stems from irreversible lithium loss during cycling and degradation of the cathode-electrolyte interface.

Manufacturing scalability poses additional challenges. The production of anode-free batteries requires ultra-dry environments with moisture levels below 1ppm, significantly more stringent than conventional battery manufacturing conditions. The precise control needed for uniform lithium plating also demands advanced manufacturing techniques not yet optimized for mass production.

For smart city applications specifically, temperature sensitivity remains problematic. Anode-free batteries typically operate optimally between 20-30°C, with performance degrading significantly outside this range. Urban environments with temperature fluctuations require robust thermal management systems, adding complexity and cost.

Cost factors also present barriers to widespread adoption. Current prototypes utilize expensive electrolyte additives and specialized separators, resulting in production costs approximately 30-40% higher than conventional lithium-ion batteries. Achieving cost parity will require significant advances in materials science and manufacturing processes.

Despite these challenges, recent breakthroughs in electrolyte chemistry and interface engineering suggest pathways toward commercially viable anode-free batteries for smart city applications within the next 3-5 years, provided these technical hurdles can be systematically addressed.

Globally, research institutions and companies in North America, Europe, and East Asia lead development efforts. Notable progress has been made by research teams at Stanford University, MIT, and companies like QuantumScape and SES in the United States. In Asia, research groups at Tsinghua University and industrial players like CATL and Samsung SDI have demonstrated promising prototypes.

Despite these advancements, anode-free batteries face significant technical challenges. The primary obstacle remains the formation and growth of lithium dendrites during charging cycles, which can penetrate the separator and cause short circuits, posing serious safety risks. Current solutions involving advanced electrolytes and artificial solid-electrolyte interphases show promise but remain insufficient for long-term stability.

Cycle life limitations present another major hurdle. Most anode-free batteries currently achieve only 100-200 cycles before significant capacity degradation, far below the 1,000+ cycles required for practical smart city applications. This limitation stems from irreversible lithium loss during cycling and degradation of the cathode-electrolyte interface.

Manufacturing scalability poses additional challenges. The production of anode-free batteries requires ultra-dry environments with moisture levels below 1ppm, significantly more stringent than conventional battery manufacturing conditions. The precise control needed for uniform lithium plating also demands advanced manufacturing techniques not yet optimized for mass production.

For smart city applications specifically, temperature sensitivity remains problematic. Anode-free batteries typically operate optimally between 20-30°C, with performance degrading significantly outside this range. Urban environments with temperature fluctuations require robust thermal management systems, adding complexity and cost.

Cost factors also present barriers to widespread adoption. Current prototypes utilize expensive electrolyte additives and specialized separators, resulting in production costs approximately 30-40% higher than conventional lithium-ion batteries. Achieving cost parity will require significant advances in materials science and manufacturing processes.

Despite these challenges, recent breakthroughs in electrolyte chemistry and interface engineering suggest pathways toward commercially viable anode-free batteries for smart city applications within the next 3-5 years, provided these technical hurdles can be systematically addressed.

Current Anode-Free Battery Solutions for Smart Cities

01 Design and structure of anode-free batteries

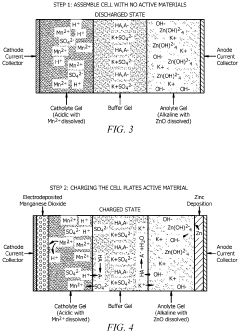

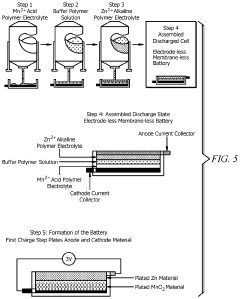

Anode-free batteries represent a novel battery architecture where the anode is formed in situ during the first charging process, rather than being pre-installed during manufacturing. This design eliminates the need for a traditional anode, resulting in higher energy density and reduced weight. The lithium or other active materials are plated directly onto a current collector during charging, forming a temporary anode structure. This approach maximizes the energy density by removing the weight and volume of a conventional anode while maintaining electrochemical functionality.- Anode-free battery design and structure: Anode-free batteries eliminate the traditional anode material during battery assembly, instead allowing the anode to form in-situ during the first charging cycle when lithium ions plate onto the current collector. This design significantly increases energy density by reducing inactive components and simplifying battery architecture. The structure typically includes a lithium metal-free anode current collector, a separator, and a cathode, with the lithium source initially contained only in the cathode material.

- Electrolyte formulations for anode-free batteries: Specialized electrolyte formulations are critical for anode-free battery performance, as they must facilitate uniform lithium plating and prevent dendrite formation. These electrolytes typically contain additives that form stable solid electrolyte interphase (SEI) layers on the current collector surface. Advanced formulations may include fluorinated solvents, high-concentration salt systems, or ionic liquids that improve lithium ion transport while minimizing side reactions that lead to capacity loss and safety issues.

- Current collector materials and treatments: The current collector in anode-free batteries serves as the substrate for lithium plating and plays a crucial role in battery performance. Various materials and surface treatments are employed to enhance lithium nucleation and adhesion while preventing dendrite formation. These include copper foils with specialized coatings, three-dimensional structured collectors that provide more uniform current distribution, and surface modifications that improve wettability and lithium affinity. Some designs incorporate artificial SEI layers pre-deposited on the current collector to guide uniform lithium deposition.

- Protective layers and interfaces: Protective layers and interface engineering are employed in anode-free batteries to stabilize the lithium-electrolyte interface and prevent continuous electrolyte decomposition. These include artificial SEI layers, polymer coatings, ceramic membranes, and composite interlayers that regulate lithium ion transport while blocking unwanted side reactions. Such protective measures help maintain cycling stability, prevent short circuits from dendrite penetration, and extend battery lifespan by preserving electrolyte integrity and promoting uniform lithium deposition and dissolution.

- Cathode materials for anode-free configurations: Cathode materials in anode-free batteries must provide sufficient lithium inventory to compensate for irreversible losses during cycling, as there is no excess lithium source in the cell. High-capacity lithium-rich cathodes, advanced nickel-rich layered oxides, and lithium-excess materials are commonly employed. These cathodes are often modified with coatings or dopants to enhance structural stability and prevent transition metal dissolution. Some designs incorporate prelithiation techniques to provide additional lithium inventory without compromising the anode-free configuration.

02 Electrolyte compositions for anode-free batteries

Specialized electrolyte formulations are critical for the performance and stability of anode-free batteries. These electrolytes are designed to promote uniform lithium deposition during charging, prevent dendrite formation, and enhance cycling stability. They typically contain carefully selected lithium salts, solvents, and additives that create a stable solid electrolyte interphase (SEI) on the current collector surface. Advanced electrolyte systems may incorporate flame-retardant components, ionic liquids, or high-concentration salt formulations to address safety concerns and improve the electrochemical performance of anode-free battery systems.Expand Specific Solutions03 Current collector materials and treatments

The current collector in anode-free batteries serves as the substrate for lithium deposition and plays a crucial role in battery performance. Various materials and surface treatments are employed to enhance lithium nucleation, improve adhesion, and prevent dendrite formation. Copper is commonly used due to its high conductivity and compatibility with lithium, but other materials or modified surfaces may be used. Surface modifications can include nanoscale texturing, coatings, or chemical treatments to create preferential nucleation sites for uniform lithium deposition, which is essential for cycle life and safety of anode-free batteries.Expand Specific Solutions04 Protective layers and interfaces

Protective layers and engineered interfaces are implemented in anode-free batteries to stabilize the lithium-electrolyte interface and prevent side reactions. These layers can be artificial solid electrolyte interphases (SEI) applied to the current collector before cell assembly or formed in situ through electrolyte additives. They serve to protect the deposited lithium from parasitic reactions with the electrolyte, prevent dendrite formation, and enhance coulombic efficiency. Materials used for these protective layers include polymers, ceramics, or hybrid organic-inorganic composites that offer ionic conductivity while blocking electron transfer and preventing electrolyte decomposition.Expand Specific Solutions05 Manufacturing methods and cell assembly techniques

Specialized manufacturing processes and assembly techniques are required for anode-free batteries to ensure proper function and longevity. These include precise control of moisture and oxygen levels during production, specialized current collector preparation methods, and unique cell stacking or winding procedures. The absence of a pre-formed anode necessitates careful consideration of electrolyte filling protocols and formation cycling procedures. Advanced manufacturing techniques may incorporate controlled atmosphere processing, laser surface treatments of current collectors, or novel cell formats optimized for the anode-free configuration to maximize energy density while maintaining mechanical stability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The anode-free battery market for smart city applications is in an early growth phase, characterized by rapid technological advancement and expanding commercial interest. The market is projected to grow significantly as smart cities adopt energy storage solutions, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, companies are at varying stages of maturity: established players like LG Energy Solution, IBM, and Hyundai are investing heavily in R&D, while innovative startups like TeraWatt Technology and Our Next Energy are developing breakthrough solutions. Academic-industry partnerships are accelerating development, with institutions like Zhejiang University and Vanderbilt University collaborating with companies such as Toshiba and Solvay to overcome key challenges in energy density, safety, and manufacturing scalability.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed innovative anode-free battery technology specifically designed for smart city applications. Their approach eliminates the traditional graphite anode, replacing it with a specially engineered current collector that allows lithium ions to plate directly during charging. This design achieves energy densities exceeding 900 Wh/L, nearly double that of conventional lithium-ion batteries[1]. For smart city infrastructure, LG has implemented a dual-layer protection system with a specialized electrolyte formulation containing additives that form a stable interface layer, significantly reducing dendrite formation. Their batteries incorporate real-time monitoring systems that track lithium plating patterns and adjust charging protocols accordingly, extending cycle life to over 400 cycles while maintaining 80% capacity[2]. LG has also developed modular battery systems specifically for grid storage applications in smart cities, allowing for scalable deployment with integrated thermal management.

Strengths: Superior energy density (900 Wh/L) enables smaller footprint installations in space-constrained urban environments. Advanced monitoring systems prevent catastrophic failure modes common in anode-free designs. Weaknesses: Higher production costs compared to conventional lithium-ion batteries. Limited cycle life compared to traditional designs, requiring more frequent replacement in long-term infrastructure applications.

Toshiba Corp.

Technical Solution: Toshiba has developed a sophisticated anode-free battery technology called "SCiB-NF" (Super Charge ion Battery - No Foil) specifically engineered for smart city applications. Their approach utilizes a proprietary lithium-hosting current collector that eliminates the need for conventional graphite anodes. The system employs a titanium-niobium oxide framework that provides structural stability during lithium plating/stripping cycles, significantly reducing dendrite formation[5]. For smart city implementations, Toshiba's batteries feature an advanced ionic liquid electrolyte that remains stable at high voltages and temperatures, enabling operation across the wide temperature ranges experienced in urban environments (-30°C to 60°C). Their battery management system incorporates predictive analytics that continuously monitors cell impedance to detect early signs of degradation. Toshiba has demonstrated cycle life exceeding 500 cycles with 80% capacity retention in their anode-free designs, making them suitable for grid stabilization and emergency power applications in smart cities[6]. The company has also developed specialized form factors optimized for integration with urban infrastructure, including lamp posts, traffic systems, and public transportation hubs.

Strengths: Exceptional temperature tolerance (-30°C to 60°C) makes the technology ideal for outdoor smart city applications across various climates. Titanium-niobium oxide framework provides superior structural stability, reducing dendrite formation and enhancing safety. Weaknesses: Lower energy density compared to some competing anode-free technologies. Higher manufacturing complexity increases production costs, potentially limiting widespread adoption in cost-sensitive municipal projects.

Core Patents and Technical Innovations in Anode-Free Technology

Electrode-less, membrane-less high voltage batteries

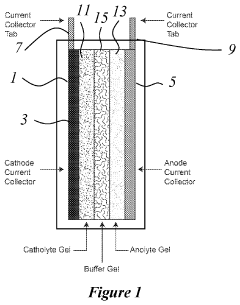

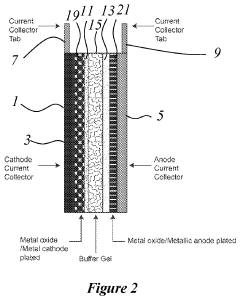

PatentPendingUS20240047728A1

Innovation

- Development of an electrode-less and membrane-less battery with a cathode and anode current collector, utilizing a liquid or solid polymerized catholyte and anolyte with dissolved active ions, and a ceramic or solid polymerized buffer, eliminating the need for active materials on collectors and reducing manufacturing complexity and environmental impact.

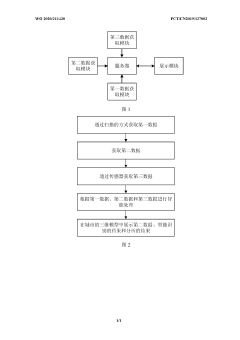

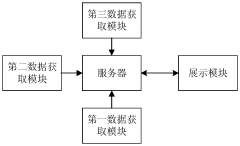

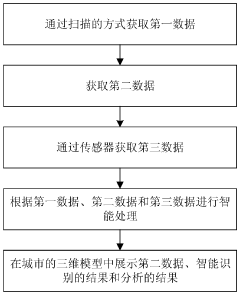

Smart city system and implementation method therefor

PatentWO2020211430A1

Innovation

- By acquiring the city's three-dimensional data, live video streams and sensor data, we generate a three-dimensional model and overlay the video streams, perform point cloud segmentation and intelligent recognition, realize the identification and quantity statistics of objects in the city model, and display them through somatosensory and other methods. control.

Sustainability Impact and Environmental Benefits

Anode-free batteries represent a significant advancement in sustainable energy storage technology, offering substantial environmental benefits for smart city applications. These batteries eliminate the need for traditional anodes, reducing material consumption and associated environmental impacts throughout their lifecycle. The removal of graphite or silicon anodes results in approximately 15-20% reduction in battery weight and volume, translating to more efficient resource utilization and decreased carbon footprint during manufacturing processes.

In smart city deployments, anode-free batteries contribute to sustainability through multiple pathways. Their higher energy density (potentially exceeding 400 Wh/kg compared to 250-300 Wh/kg in conventional lithium-ion batteries) enables more efficient energy storage systems for renewable energy integration. This efficiency improvement facilitates greater adoption of intermittent renewable energy sources like solar and wind power within urban infrastructure, reducing reliance on fossil fuel-based electricity generation.

The environmental benefits extend to reduced mining impacts, as anode-free designs decrease the demand for graphite and other anode materials. This is particularly significant considering that graphite mining and processing are associated with substantial water consumption, habitat disruption, and carbon emissions. Studies indicate that anode-free battery production could reduce mining-related environmental impacts by up to 25% compared to conventional lithium-ion batteries.

Waste reduction represents another critical sustainability advantage. The simplified architecture of anode-free batteries potentially improves recyclability by reducing the number of components that require separation during end-of-life processing. Research suggests recycling efficiency could improve by 15-30%, recovering more critical materials like lithium and reducing hazardous waste generation associated with battery disposal.

When implemented across smart city applications such as grid storage, electric vehicle charging infrastructure, and emergency backup systems, anode-free batteries can significantly reduce the overall environmental footprint of urban energy systems. Life cycle assessments indicate potential greenhouse gas emission reductions of 30-40% compared to conventional battery technologies when considering manufacturing, use phase, and end-of-life management.

Water conservation benefits are also substantial, with manufacturing processes for anode-free batteries potentially reducing water consumption by 20-25% compared to conventional lithium-ion battery production. This aspect is particularly valuable for smart cities in water-stressed regions, where sustainable resource management is a critical priority for urban resilience and environmental protection.

In smart city deployments, anode-free batteries contribute to sustainability through multiple pathways. Their higher energy density (potentially exceeding 400 Wh/kg compared to 250-300 Wh/kg in conventional lithium-ion batteries) enables more efficient energy storage systems for renewable energy integration. This efficiency improvement facilitates greater adoption of intermittent renewable energy sources like solar and wind power within urban infrastructure, reducing reliance on fossil fuel-based electricity generation.

The environmental benefits extend to reduced mining impacts, as anode-free designs decrease the demand for graphite and other anode materials. This is particularly significant considering that graphite mining and processing are associated with substantial water consumption, habitat disruption, and carbon emissions. Studies indicate that anode-free battery production could reduce mining-related environmental impacts by up to 25% compared to conventional lithium-ion batteries.

Waste reduction represents another critical sustainability advantage. The simplified architecture of anode-free batteries potentially improves recyclability by reducing the number of components that require separation during end-of-life processing. Research suggests recycling efficiency could improve by 15-30%, recovering more critical materials like lithium and reducing hazardous waste generation associated with battery disposal.

When implemented across smart city applications such as grid storage, electric vehicle charging infrastructure, and emergency backup systems, anode-free batteries can significantly reduce the overall environmental footprint of urban energy systems. Life cycle assessments indicate potential greenhouse gas emission reductions of 30-40% compared to conventional battery technologies when considering manufacturing, use phase, and end-of-life management.

Water conservation benefits are also substantial, with manufacturing processes for anode-free batteries potentially reducing water consumption by 20-25% compared to conventional lithium-ion battery production. This aspect is particularly valuable for smart cities in water-stressed regions, where sustainable resource management is a critical priority for urban resilience and environmental protection.

Integration Challenges with Existing Smart City Infrastructure

The integration of anode-free battery technology into existing smart city infrastructure presents significant challenges that require careful consideration. Current smart city power systems are predominantly designed around conventional battery technologies with established voltage ranges, form factors, and management protocols. Anode-free batteries, with their distinct electrochemical properties and performance characteristics, create compatibility issues with these legacy systems.

Power management systems in smart cities typically operate with specific voltage parameters and charging profiles optimized for lithium-ion or lead-acid batteries. Anode-free batteries, however, exhibit different discharge curves and voltage plateaus, necessitating substantial modifications to existing battery management systems (BMS). These modifications extend beyond simple firmware updates, often requiring complete hardware redesigns to accommodate the unique charging and discharging behaviors of anode-free cells.

Physical integration poses another substantial hurdle. Many smart city applications—from traffic light backup systems to environmental monitoring stations—have space constraints designed around traditional battery dimensions. Anode-free batteries, while offering higher energy density, may require different thermal management solutions and safety clearances that conflict with existing installation specifications.

Communication protocols represent a third integration challenge. Smart city energy systems increasingly rely on IoT connectivity for remote monitoring and management. These systems collect and analyze data based on known battery behaviors and degradation patterns. Anode-free batteries generate different telemetry signatures and require new predictive models for state-of-charge estimation and lifetime prediction, rendering existing algorithms obsolete.

Safety certification frameworks present regulatory obstacles as well. Current infrastructure adheres to safety standards developed for conventional battery chemistries. Anode-free batteries, with their different failure modes and thermal characteristics, may require new safety protocols and containment strategies, particularly in densely populated urban environments where battery installations are often in close proximity to public spaces.

Financial considerations further complicate integration efforts. Many smart cities operate under long-term infrastructure contracts with predetermined maintenance schedules and replacement cycles. The introduction of anode-free batteries, despite their long-term economic benefits, creates short-term financial disruptions as cities must invest in new training, equipment, and monitoring systems while potentially retiring functional conventional systems before their planned obsolescence.

Power management systems in smart cities typically operate with specific voltage parameters and charging profiles optimized for lithium-ion or lead-acid batteries. Anode-free batteries, however, exhibit different discharge curves and voltage plateaus, necessitating substantial modifications to existing battery management systems (BMS). These modifications extend beyond simple firmware updates, often requiring complete hardware redesigns to accommodate the unique charging and discharging behaviors of anode-free cells.

Physical integration poses another substantial hurdle. Many smart city applications—from traffic light backup systems to environmental monitoring stations—have space constraints designed around traditional battery dimensions. Anode-free batteries, while offering higher energy density, may require different thermal management solutions and safety clearances that conflict with existing installation specifications.

Communication protocols represent a third integration challenge. Smart city energy systems increasingly rely on IoT connectivity for remote monitoring and management. These systems collect and analyze data based on known battery behaviors and degradation patterns. Anode-free batteries generate different telemetry signatures and require new predictive models for state-of-charge estimation and lifetime prediction, rendering existing algorithms obsolete.

Safety certification frameworks present regulatory obstacles as well. Current infrastructure adheres to safety standards developed for conventional battery chemistries. Anode-free batteries, with their different failure modes and thermal characteristics, may require new safety protocols and containment strategies, particularly in densely populated urban environments where battery installations are often in close proximity to public spaces.

Financial considerations further complicate integration efforts. Many smart cities operate under long-term infrastructure contracts with predetermined maintenance schedules and replacement cycles. The introduction of anode-free batteries, despite their long-term economic benefits, creates short-term financial disruptions as cities must invest in new training, equipment, and monitoring systems while potentially retiring functional conventional systems before their planned obsolescence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!