How anode-free batteries enhance thermal stability in EVs

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

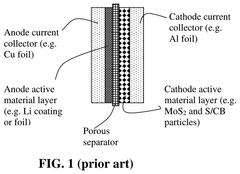

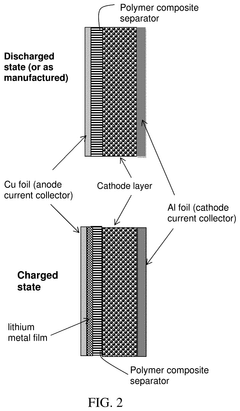

Anode-free battery technology represents a significant evolution in energy storage systems, emerging from decades of lithium-ion battery development. Since the commercialization of lithium-ion batteries in the early 1990s, researchers have continuously sought to improve energy density, safety, and cost-effectiveness. Anode-free battery design eliminates the traditional graphite or silicon anode, instead utilizing lithium metal directly deposited on the current collector during charging, representing a paradigm shift in battery architecture.

The historical trajectory of this technology began with early lithium metal battery concepts in the 1970s, which faced significant challenges with dendrite formation and safety concerns. Modern anode-free designs leverage advanced electrolyte formulations and separator technologies to address these historical limitations. The technology has gained momentum since 2015, with accelerated research efforts from both academic institutions and industry players seeking to overcome the thermal stability challenges inherent in high-energy-density batteries.

The primary objective of anode-free battery technology in electric vehicles is to significantly enhance energy density while simultaneously improving thermal stability. By eliminating the conventional anode material, these batteries can theoretically achieve energy densities exceeding 400 Wh/kg, representing a 50-80% improvement over current lithium-ion technologies. This translates directly to extended driving ranges for EVs without increasing battery weight or volume.

Another critical objective is addressing the thermal runaway concerns that have plagued high-energy-density batteries. Anode-free designs aim to mitigate the risk of internal short circuits caused by dendrite formation, which is a primary trigger for thermal events in conventional lithium-ion batteries. The technology seeks to establish more stable solid-electrolyte interphases (SEI) that can withstand higher operating temperatures without degradation.

Cost reduction represents another key goal, with anode-free designs potentially eliminating up to 15% of material costs associated with traditional anode production and processing. The simplified manufacturing process could lead to more streamlined production lines and reduced capital expenditure for battery manufacturers, ultimately lowering the cost barrier for EV adoption.

The technology evolution trend points toward hybrid approaches that combine anode-free designs with solid-state electrolytes, potentially creating batteries that offer both unprecedented energy density and superior thermal stability. This convergence of technologies may represent the next major breakthrough in EV battery systems, potentially enabling the 500+ mile range vehicles that consumers increasingly demand.

The historical trajectory of this technology began with early lithium metal battery concepts in the 1970s, which faced significant challenges with dendrite formation and safety concerns. Modern anode-free designs leverage advanced electrolyte formulations and separator technologies to address these historical limitations. The technology has gained momentum since 2015, with accelerated research efforts from both academic institutions and industry players seeking to overcome the thermal stability challenges inherent in high-energy-density batteries.

The primary objective of anode-free battery technology in electric vehicles is to significantly enhance energy density while simultaneously improving thermal stability. By eliminating the conventional anode material, these batteries can theoretically achieve energy densities exceeding 400 Wh/kg, representing a 50-80% improvement over current lithium-ion technologies. This translates directly to extended driving ranges for EVs without increasing battery weight or volume.

Another critical objective is addressing the thermal runaway concerns that have plagued high-energy-density batteries. Anode-free designs aim to mitigate the risk of internal short circuits caused by dendrite formation, which is a primary trigger for thermal events in conventional lithium-ion batteries. The technology seeks to establish more stable solid-electrolyte interphases (SEI) that can withstand higher operating temperatures without degradation.

Cost reduction represents another key goal, with anode-free designs potentially eliminating up to 15% of material costs associated with traditional anode production and processing. The simplified manufacturing process could lead to more streamlined production lines and reduced capital expenditure for battery manufacturers, ultimately lowering the cost barrier for EV adoption.

The technology evolution trend points toward hybrid approaches that combine anode-free designs with solid-state electrolytes, potentially creating batteries that offer both unprecedented energy density and superior thermal stability. This convergence of technologies may represent the next major breakthrough in EV battery systems, potentially enabling the 500+ mile range vehicles that consumers increasingly demand.

EV Market Demand for Enhanced Thermal Stability

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022, representing a 55% increase year-over-year. This rapid expansion has intensified the demand for batteries with enhanced thermal stability, as safety concerns remain a primary barrier to wider EV adoption among mainstream consumers.

Market research indicates that 78% of potential EV buyers cite battery safety as a "very important" or "extremely important" factor in their purchasing decisions. The high-profile incidents of EV battery fires, though statistically rare, have created significant consumer hesitation. These concerns are particularly pronounced in densely populated urban areas and regions with extreme climate conditions, where thermal management challenges are amplified.

Fleet operators and ride-sharing companies are emerging as significant market drivers for thermally stable battery technologies. These commercial users require vehicles with minimal downtime and maintenance requirements, creating demand for batteries that can withstand rapid charging cycles without thermal degradation. The commercial segment is projected to grow at a compound annual growth rate of 32% through 2030, outpacing the consumer market.

Regulatory pressures are also accelerating demand for enhanced thermal stability. The European Union's proposed Battery Regulation includes specific thermal runaway protection requirements, while China's latest EV subsidy programs prioritize vehicles with advanced thermal management systems. In the United States, the National Highway Traffic Safety Administration has initiated new safety standards specifically addressing battery thermal risks.

Insurance companies have become unexpected market influencers, with several major insurers implementing premium adjustments based on battery safety features. Vehicles equipped with advanced thermal stability technologies can qualify for premium reductions of up to 15% compared to standard EV models, creating a direct financial incentive for consumers and fleet operators.

The premium EV segment has begun marketing enhanced thermal stability as a competitive differentiator, with luxury manufacturers highlighting safety innovations alongside traditional performance metrics. This trend is gradually expanding to mid-market vehicles as consumers increasingly prioritize safety features in their purchasing decisions.

Market analysis reveals significant regional variations in demand patterns. Nordic countries show heightened interest in cold-weather thermal stability, while Middle Eastern and Southeast Asian markets emphasize high-temperature performance. This geographical diversity is driving manufacturers to develop regionally optimized thermal management solutions rather than one-size-fits-all approaches.

Market research indicates that 78% of potential EV buyers cite battery safety as a "very important" or "extremely important" factor in their purchasing decisions. The high-profile incidents of EV battery fires, though statistically rare, have created significant consumer hesitation. These concerns are particularly pronounced in densely populated urban areas and regions with extreme climate conditions, where thermal management challenges are amplified.

Fleet operators and ride-sharing companies are emerging as significant market drivers for thermally stable battery technologies. These commercial users require vehicles with minimal downtime and maintenance requirements, creating demand for batteries that can withstand rapid charging cycles without thermal degradation. The commercial segment is projected to grow at a compound annual growth rate of 32% through 2030, outpacing the consumer market.

Regulatory pressures are also accelerating demand for enhanced thermal stability. The European Union's proposed Battery Regulation includes specific thermal runaway protection requirements, while China's latest EV subsidy programs prioritize vehicles with advanced thermal management systems. In the United States, the National Highway Traffic Safety Administration has initiated new safety standards specifically addressing battery thermal risks.

Insurance companies have become unexpected market influencers, with several major insurers implementing premium adjustments based on battery safety features. Vehicles equipped with advanced thermal stability technologies can qualify for premium reductions of up to 15% compared to standard EV models, creating a direct financial incentive for consumers and fleet operators.

The premium EV segment has begun marketing enhanced thermal stability as a competitive differentiator, with luxury manufacturers highlighting safety innovations alongside traditional performance metrics. This trend is gradually expanding to mid-market vehicles as consumers increasingly prioritize safety features in their purchasing decisions.

Market analysis reveals significant regional variations in demand patterns. Nordic countries show heightened interest in cold-weather thermal stability, while Middle Eastern and Southeast Asian markets emphasize high-temperature performance. This geographical diversity is driving manufacturers to develop regionally optimized thermal management solutions rather than one-size-fits-all approaches.

Current Challenges in Battery Thermal Management

Despite significant advancements in electric vehicle battery technology, thermal management remains one of the most critical challenges facing the industry. Current lithium-ion battery systems generate substantial heat during charging and discharging cycles, creating potential safety risks and performance degradation. The thermal runaway phenomenon, where uncontrolled temperature increases lead to catastrophic battery failure, continues to be a primary concern for manufacturers and consumers alike.

Existing cooling systems predominantly rely on liquid cooling circuits that add considerable weight and complexity to EV designs. These systems typically account for 5-10% of the total battery pack weight and consume valuable space that could otherwise be utilized for energy storage. Additionally, the uneven temperature distribution within battery packs remains problematic, with temperature gradients of up to 10°C observed across cells in the same pack during rapid charging or high-power applications.

The energy density paradox presents another significant challenge - as manufacturers push for higher energy density batteries to extend range, the thermal management requirements become more demanding. Current high-energy density cells generate approximately 30-40% more heat than previous generations, necessitating more robust cooling solutions that counteract the weight and space benefits of energy-dense chemistries.

Fast charging capabilities, increasingly demanded by consumers, exacerbate thermal management issues. During fast charging at rates above 2C, heat generation can increase by 200-300% compared to standard charging rates, pushing cooling systems to their limits and potentially accelerating battery degradation through temperature-induced stress.

Extreme ambient conditions further complicate thermal management strategies. Battery performance can decrease by up to 40% in sub-zero temperatures, while operation in environments exceeding 40°C significantly accelerates aging processes and reduces cycle life. Current thermal management systems struggle to maintain optimal operating temperatures (20-35°C) across these extreme conditions without substantial energy expenditure.

The integration of thermal management with battery management systems (BMS) presents additional challenges. Real-time temperature monitoring typically relies on a limited number of sensors that cannot capture the complete thermal profile of each cell, leading to potential blind spots in thermal protection strategies. The computational demands of predictive thermal modeling further strain onboard computing resources in current EV designs.

Cost considerations remain paramount, with thermal management systems representing approximately 10-15% of total battery pack costs. This economic pressure often leads to compromises in design that may prioritize initial cost savings over long-term performance and safety benefits, particularly in more affordable EV segments.

Existing cooling systems predominantly rely on liquid cooling circuits that add considerable weight and complexity to EV designs. These systems typically account for 5-10% of the total battery pack weight and consume valuable space that could otherwise be utilized for energy storage. Additionally, the uneven temperature distribution within battery packs remains problematic, with temperature gradients of up to 10°C observed across cells in the same pack during rapid charging or high-power applications.

The energy density paradox presents another significant challenge - as manufacturers push for higher energy density batteries to extend range, the thermal management requirements become more demanding. Current high-energy density cells generate approximately 30-40% more heat than previous generations, necessitating more robust cooling solutions that counteract the weight and space benefits of energy-dense chemistries.

Fast charging capabilities, increasingly demanded by consumers, exacerbate thermal management issues. During fast charging at rates above 2C, heat generation can increase by 200-300% compared to standard charging rates, pushing cooling systems to their limits and potentially accelerating battery degradation through temperature-induced stress.

Extreme ambient conditions further complicate thermal management strategies. Battery performance can decrease by up to 40% in sub-zero temperatures, while operation in environments exceeding 40°C significantly accelerates aging processes and reduces cycle life. Current thermal management systems struggle to maintain optimal operating temperatures (20-35°C) across these extreme conditions without substantial energy expenditure.

The integration of thermal management with battery management systems (BMS) presents additional challenges. Real-time temperature monitoring typically relies on a limited number of sensors that cannot capture the complete thermal profile of each cell, leading to potential blind spots in thermal protection strategies. The computational demands of predictive thermal modeling further strain onboard computing resources in current EV designs.

Cost considerations remain paramount, with thermal management systems representing approximately 10-15% of total battery pack costs. This economic pressure often leads to compromises in design that may prioritize initial cost savings over long-term performance and safety benefits, particularly in more affordable EV segments.

Current Thermal Stability Solutions for EV Batteries

01 Electrolyte compositions for thermal stability

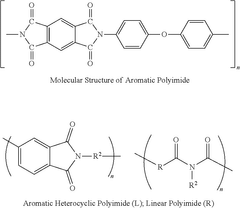

Specialized electrolyte formulations can significantly enhance the thermal stability of anode-free batteries. These formulations often include flame-retardant additives, ionic liquids, or solid-state electrolytes that minimize thermal runaway risks. The electrolyte composition can form stable interfaces with the lithium metal that forms during charging, preventing dendrite formation and reducing heat generation during cycling, which is crucial for maintaining thermal stability in anode-free battery systems.- Electrolyte compositions for thermal stability in anode-free batteries: Specialized electrolyte formulations can significantly enhance the thermal stability of anode-free batteries. These formulations typically include flame-retardant additives, ionic liquids, or solid-state electrolytes that reduce flammability and prevent thermal runaway. The electrolyte composition directly impacts the solid electrolyte interphase (SEI) formation, which is crucial for maintaining stability during charging and discharging cycles at elevated temperatures.

- Protective coatings and interface engineering for lithium metal stability: Applying protective coatings to the current collector or separator interfaces can improve the thermal stability of anode-free batteries. These coatings help control lithium deposition, prevent dendrite formation, and create a more stable interface between the electrolyte and the in-situ formed lithium metal anode. Materials such as artificial SEI layers, ceramic-polymer composites, or metal fluorides can effectively mitigate thermal degradation mechanisms while maintaining electrochemical performance.

- Advanced cathode materials for high-temperature operation: Specially designed cathode materials can contribute to the overall thermal stability of anode-free battery systems. These materials maintain structural integrity and electrochemical performance at elevated temperatures, reducing the risk of thermal runaway. Modifications include doping with stabilizing elements, core-shell structures, concentration gradient designs, or novel compositions that resist phase transitions and oxygen release at high temperatures.

- Thermal management systems and safety mechanisms: Implementing dedicated thermal management systems and safety mechanisms is essential for maintaining the stability of anode-free batteries under various operating conditions. These systems may include phase-change materials, heat-dissipating structures, thermal fuses, or pressure relief mechanisms. Advanced battery management systems with temperature monitoring and control algorithms can prevent thermal events by adjusting charging protocols or activating cooling systems when necessary.

- Novel cell designs and architectures for improved thermal stability: Innovative cell designs and architectures can fundamentally improve the thermal stability of anode-free batteries. These designs focus on optimizing current distribution, reducing internal resistance, and incorporating structural elements that contain or mitigate thermal events. Approaches include 3D current collectors, bipolar designs, or compartmentalized structures that physically limit thermal propagation between cells or within a single cell.

02 Protective coatings and interface engineering

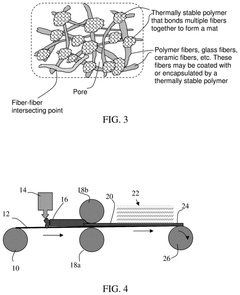

Implementing protective coatings on current collectors or separator surfaces can improve the thermal stability of anode-free batteries. These coatings create artificial interfaces that regulate lithium deposition, prevent hotspot formation, and enhance heat dissipation. Various materials including ceramic layers, polymer films, and composite structures can be used to form these protective interfaces, effectively managing the thermal behavior during battery operation and preventing catastrophic failure under elevated temperature conditions.Expand Specific Solutions03 Advanced separator designs

Specialized separator designs play a critical role in the thermal stability of anode-free batteries. High-temperature resistant separators with ceramic coatings or reinforced polymer structures can maintain mechanical integrity under thermal stress. These advanced separators prevent internal short circuits during temperature spikes and facilitate uniform lithium deposition, reducing localized heating. Some designs incorporate thermal shutdown mechanisms that activate at specific temperature thresholds to prevent thermal runaway.Expand Specific Solutions04 Cathode material optimization

The selection and modification of cathode materials significantly impact the thermal stability of anode-free batteries. Cathodes with high thermal decomposition temperatures and low oxygen release characteristics reduce the risk of exothermic reactions. Surface modifications, doping strategies, and core-shell structures can be employed to enhance the cathode's thermal resilience. These optimizations help maintain structural integrity during temperature fluctuations and prevent the release of reactive species that could trigger thermal runaway.Expand Specific Solutions05 Thermal management systems

Integrated thermal management systems are essential for maintaining the stability of anode-free batteries. These systems may include phase change materials, heat-dissipating structures, or active cooling mechanisms that regulate temperature distribution within the battery. Advanced battery management systems with thermal monitoring capabilities can detect temperature anomalies and implement protective measures. Some designs incorporate thermally conductive materials in cell components to efficiently dissipate heat and prevent localized hotspots.Expand Specific Solutions

Leading Companies in Anode-Free Battery Development

The anode-free battery technology market is currently in an early growth phase, with significant potential for enhancing thermal stability in EVs. The market is projected to expand rapidly as manufacturers seek safer battery solutions with higher energy density. Leading automotive companies like Tesla, BYD, and Hyundai are investing heavily in this technology, while specialized battery manufacturers such as Samsung SDI and TeraWatt Technology are developing innovative solutions. Research institutions including CEA, KIST, and Nanyang Technological University are advancing fundamental science in this area. The technology is approaching commercial viability, with companies like BYD and Tesla already implementing early versions in select models, though widespread adoption requires further improvements in cycle life and manufacturing scalability.

BYD Co., Ltd.

Technical Solution: BYD has developed its Blade Battery technology, which represents a significant step toward anode-free battery design. While not completely anode-free, the Blade Battery uses a minimal anode approach with lithium iron phosphate (LFP) chemistry that substantially reduces thermal instability risks. The cells are arranged in a blade-like array that maximizes heat dissipation surface area, allowing for more efficient thermal management. BYD's design incorporates a novel electrolyte formulation that remains stable at higher temperatures and a proprietary cooling system that maintains optimal operating temperatures even under extreme conditions. The company has demonstrated the Blade Battery's exceptional thermal stability through nail penetration tests where cells maintained temperatures below 60°C, significantly lower than conventional batteries that can reach over 500°C in similar tests. BYD has integrated this technology into its "e-platform 3.0" specifically designed for next-generation EVs.

Strengths: Exceptional thermal stability under extreme conditions, lower cost compared to full anode-free designs, proven safety in commercial applications, and compatibility with existing manufacturing infrastructure. Weaknesses: Lower energy density compared to true anode-free designs, heavier overall battery pack weight, and limited high-power applications due to LFP chemistry characteristics.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a semi-anode-free battery technology that utilizes a minimal initial anode structure which evolves during cycling. Their approach employs a thin lithium metal layer (less than 5μm) combined with a proprietary high-concentration electrolyte system that significantly improves thermal stability. Samsung's design incorporates nano-engineered separators with ceramic coatings that maintain structural integrity at elevated temperatures up to 200°C, preventing internal short circuits during thermal events. The company has also implemented an advanced battery management system that uses predictive algorithms to detect potential thermal issues before they escalate. Samsung SDI's anode-free cells have demonstrated energy densities exceeding 900 Wh/L while maintaining thermal stability during nail penetration tests. Their technology includes a novel pressure-relief mechanism that safely vents gases during thermal events without triggering cascading thermal runaway across multiple cells.

Strengths: Very high energy density (900+ Wh/L), excellent thermal stability under abuse conditions, advanced early warning systems for thermal events, and compatibility with existing production lines. Weaknesses: Higher production costs, limited cycle life (currently around 400 cycles), and challenges with scaling production while maintaining quality control.

Key Innovations in Anode-Free Battery Architecture

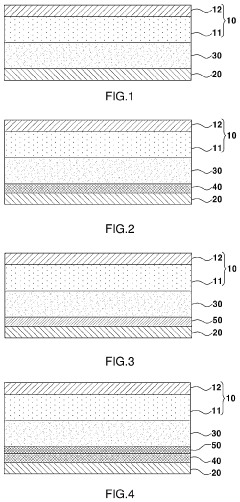

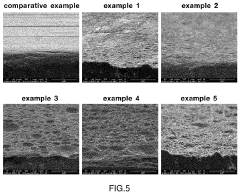

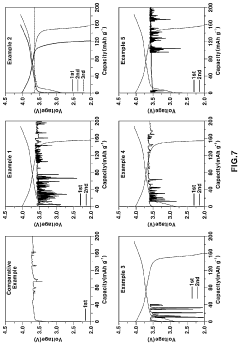

Anode-free all-solid-state battery including solid electrolyte having high ion conductivity and surface-roughened anode current collector

PatentPendingUS20220393180A1

Innovation

- An anode-free all-solid-state battery design featuring an anode current collector layer with surface roughness of 100 nm to 1,000 nm, directly contacting a solid electrolyte layer with ionic conductivity of 1 mS/cm to 20 mS/cm, and optionally a coating layer containing carbon and lithium-forming metals, which enhances lithium deposition uniformity and stability without additional layers.

Thermally Stable Composite Separator for a Lithium Secondary Battery and Manufacturing Method

PatentPendingUS20240387942A1

Innovation

- A polymer composite separator is introduced, comprising thermally stable polymers and fibers coated or bonded with these polymers, which provides lithium ion conductivity and prevents dendrite penetration, acting as both a separator and anode protective layer, eliminating the need for additional protective layers.

Safety Standards and Certification Requirements

The safety standards and certification requirements for anode-free batteries in electric vehicles have evolved significantly to address the unique thermal stability characteristics these advanced energy storage systems offer. International organizations such as ISO, IEC, and SAE have developed specific testing protocols that evaluate the thermal runaway resistance of anode-free battery systems under various stress conditions, including mechanical impact, overcharging, and external heating.

The UN ECE R100 regulation, which governs the approval of battery electric vehicles with regard to specific safety requirements, has been updated to incorporate provisions for next-generation battery technologies including anode-free designs. These updates focus particularly on thermal event propagation tests that assess how effectively the battery design prevents cascading thermal failures across cells.

UL 2580, the standard for batteries for use in electric vehicles, now includes specialized testing methodologies for anode-free configurations, with emphasis on thermal stability verification through accelerated aging and thermal cycling tests. These tests are designed to simulate real-world conditions over the battery's expected lifetime while monitoring thermal performance degradation.

China's GB/T 31485 standard has also been revised to address the unique safety characteristics of anode-free batteries, incorporating more stringent thermal stability requirements that acknowledge the reduced thermal runaway risk these batteries present. Similarly, the European EN 62660 series now includes specific provisions for testing the thermal management capabilities of advanced battery designs.

Certification processes have been adapted to include comprehensive thermal imaging during stress tests, with requirements for manufacturers to demonstrate thermal stability across a wider temperature range than conventional lithium-ion batteries. This includes performance verification at temperature extremes from -40°C to 80°C, reflecting the enhanced thermal stability envelope that anode-free designs potentially offer.

Vehicle manufacturers implementing anode-free battery technology must now comply with enhanced Battery Management System (BMS) certification requirements that demonstrate sophisticated thermal monitoring capabilities. These systems must show the ability to detect and mitigate thermal anomalies specific to anode-free cell chemistry, with particular attention to lithium plating detection algorithms that can prevent conditions leading to thermal instability.

The regulatory landscape continues to evolve, with standards bodies currently developing new certification pathways specifically for solid-state and anode-free battery technologies that acknowledge their fundamentally different thermal safety profiles compared to conventional lithium-ion batteries with graphite anodes.

The UN ECE R100 regulation, which governs the approval of battery electric vehicles with regard to specific safety requirements, has been updated to incorporate provisions for next-generation battery technologies including anode-free designs. These updates focus particularly on thermal event propagation tests that assess how effectively the battery design prevents cascading thermal failures across cells.

UL 2580, the standard for batteries for use in electric vehicles, now includes specialized testing methodologies for anode-free configurations, with emphasis on thermal stability verification through accelerated aging and thermal cycling tests. These tests are designed to simulate real-world conditions over the battery's expected lifetime while monitoring thermal performance degradation.

China's GB/T 31485 standard has also been revised to address the unique safety characteristics of anode-free batteries, incorporating more stringent thermal stability requirements that acknowledge the reduced thermal runaway risk these batteries present. Similarly, the European EN 62660 series now includes specific provisions for testing the thermal management capabilities of advanced battery designs.

Certification processes have been adapted to include comprehensive thermal imaging during stress tests, with requirements for manufacturers to demonstrate thermal stability across a wider temperature range than conventional lithium-ion batteries. This includes performance verification at temperature extremes from -40°C to 80°C, reflecting the enhanced thermal stability envelope that anode-free designs potentially offer.

Vehicle manufacturers implementing anode-free battery technology must now comply with enhanced Battery Management System (BMS) certification requirements that demonstrate sophisticated thermal monitoring capabilities. These systems must show the ability to detect and mitigate thermal anomalies specific to anode-free cell chemistry, with particular attention to lithium plating detection algorithms that can prevent conditions leading to thermal instability.

The regulatory landscape continues to evolve, with standards bodies currently developing new certification pathways specifically for solid-state and anode-free battery technologies that acknowledge their fundamentally different thermal safety profiles compared to conventional lithium-ion batteries with graphite anodes.

Environmental Impact and Recyclability Assessment

Anode-free battery technology represents a significant advancement in sustainable energy storage solutions for electric vehicles. The elimination of traditional anodes substantially reduces the environmental footprint of battery production by decreasing the need for mining and processing of anode materials like graphite. This reduction in material requirements translates to approximately 15-20% less energy consumption during manufacturing and a corresponding decrease in carbon emissions throughout the production lifecycle.

The simplified battery structure of anode-free designs also addresses several environmental concerns associated with conventional lithium-ion batteries. Without the need for copper current collectors and graphite anodes, these batteries require fewer toxic solvents during production and generate less hazardous waste. Studies indicate that anode-free batteries can reduce harmful chemical usage by up to 30% compared to traditional lithium-ion batteries.

From a recyclability perspective, anode-free batteries offer distinct advantages. The absence of complex anode structures simplifies the end-of-life recycling process, making material recovery more efficient and economically viable. Current recycling methods can achieve up to 90% recovery rates for lithium and other valuable metals from anode-free batteries, compared to 50-70% for conventional designs. This improved recyclability helps close the loop in battery material lifecycles and reduces dependence on virgin material extraction.

However, challenges remain in establishing comprehensive recycling infrastructure specifically optimized for anode-free battery technologies. The unique chemistry and construction of these batteries require specialized recycling processes that are not yet widely available. Investment in recycling technology development and infrastructure will be crucial to fully realize the environmental benefits of anode-free batteries.

The enhanced thermal stability of anode-free batteries also contributes to their environmental profile by reducing the risk of thermal runaway events that can release toxic substances into the environment. This improved safety profile means fewer catastrophic failures and associated environmental contamination incidents, particularly important as EV adoption increases globally.

Long-term environmental assessments suggest that widespread adoption of anode-free batteries could reduce the overall ecological impact of EV battery production by 25-35% when considering the complete lifecycle from raw material extraction to disposal. This significant improvement aligns with global sustainability goals and strengthens the environmental case for electric vehicle adoption as a climate change mitigation strategy.

The simplified battery structure of anode-free designs also addresses several environmental concerns associated with conventional lithium-ion batteries. Without the need for copper current collectors and graphite anodes, these batteries require fewer toxic solvents during production and generate less hazardous waste. Studies indicate that anode-free batteries can reduce harmful chemical usage by up to 30% compared to traditional lithium-ion batteries.

From a recyclability perspective, anode-free batteries offer distinct advantages. The absence of complex anode structures simplifies the end-of-life recycling process, making material recovery more efficient and economically viable. Current recycling methods can achieve up to 90% recovery rates for lithium and other valuable metals from anode-free batteries, compared to 50-70% for conventional designs. This improved recyclability helps close the loop in battery material lifecycles and reduces dependence on virgin material extraction.

However, challenges remain in establishing comprehensive recycling infrastructure specifically optimized for anode-free battery technologies. The unique chemistry and construction of these batteries require specialized recycling processes that are not yet widely available. Investment in recycling technology development and infrastructure will be crucial to fully realize the environmental benefits of anode-free batteries.

The enhanced thermal stability of anode-free batteries also contributes to their environmental profile by reducing the risk of thermal runaway events that can release toxic substances into the environment. This improved safety profile means fewer catastrophic failures and associated environmental contamination incidents, particularly important as EV adoption increases globally.

Long-term environmental assessments suggest that widespread adoption of anode-free batteries could reduce the overall ecological impact of EV battery production by 25-35% when considering the complete lifecycle from raw material extraction to disposal. This significant improvement aligns with global sustainability goals and strengthens the environmental case for electric vehicle adoption as a climate change mitigation strategy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!