How coatings affect the cycle life of anode-free batteries

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Technology Background and Objectives

Coating technologies have emerged as a critical factor in addressing the challenges faced by anode-free batteries, representing one of the most promising next-generation energy storage solutions. The evolution of coating technologies for battery applications traces back to the early 2000s, when researchers began exploring protective layers to enhance electrode stability. Over the past decade, significant advancements have been made in developing specialized coatings specifically designed for lithium metal and anode-free battery systems.

The technological trajectory has shifted from simple passive protection layers to multifunctional coatings that actively participate in the electrochemical processes. Early coating materials primarily focused on physical barriers against electrolyte decomposition, while contemporary approaches incorporate ion-conductive properties, mechanical flexibility, and self-healing capabilities to accommodate the dynamic nature of battery operation.

Recent developments have demonstrated particular interest in artificial solid electrolyte interphase (SEI) coatings, polymer-based protective layers, and ceramic/inorganic films that can effectively regulate lithium deposition behavior. The convergence of nanotechnology with coating science has further expanded the toolkit available to battery engineers, enabling precise control over interface properties at the nanoscale.

The primary technical objective in this domain is to develop coating technologies that can significantly extend the cycle life of anode-free batteries from the current industry standard of 200-300 cycles to over 1,000 cycles, making them commercially viable alternatives to conventional lithium-ion batteries. This requires coatings that can simultaneously address multiple failure mechanisms, including dendrite formation, electrolyte decomposition, and irreversible lithium consumption.

Secondary objectives include enhancing the coating's ability to maintain performance under extreme temperature conditions (-20°C to 60°C), improving fast-charging capabilities without compromising cycle life, and developing scalable manufacturing processes that can be integrated into existing battery production lines without significant cost increases.

The technical evolution trend points toward multi-layer composite coatings that combine the advantages of different materials, such as the mechanical strength of ceramics with the flexibility of polymers. Additionally, there is growing interest in stimuli-responsive coatings that can adapt their properties based on the battery's operating conditions, providing dynamic protection throughout the battery's lifetime.

Achieving these objectives would represent a paradigm shift in energy storage technology, potentially enabling electric vehicles with significantly higher range, consumer electronics with multi-day battery life, and grid storage solutions with unprecedented cycle life and safety characteristics.

The technological trajectory has shifted from simple passive protection layers to multifunctional coatings that actively participate in the electrochemical processes. Early coating materials primarily focused on physical barriers against electrolyte decomposition, while contemporary approaches incorporate ion-conductive properties, mechanical flexibility, and self-healing capabilities to accommodate the dynamic nature of battery operation.

Recent developments have demonstrated particular interest in artificial solid electrolyte interphase (SEI) coatings, polymer-based protective layers, and ceramic/inorganic films that can effectively regulate lithium deposition behavior. The convergence of nanotechnology with coating science has further expanded the toolkit available to battery engineers, enabling precise control over interface properties at the nanoscale.

The primary technical objective in this domain is to develop coating technologies that can significantly extend the cycle life of anode-free batteries from the current industry standard of 200-300 cycles to over 1,000 cycles, making them commercially viable alternatives to conventional lithium-ion batteries. This requires coatings that can simultaneously address multiple failure mechanisms, including dendrite formation, electrolyte decomposition, and irreversible lithium consumption.

Secondary objectives include enhancing the coating's ability to maintain performance under extreme temperature conditions (-20°C to 60°C), improving fast-charging capabilities without compromising cycle life, and developing scalable manufacturing processes that can be integrated into existing battery production lines without significant cost increases.

The technical evolution trend points toward multi-layer composite coatings that combine the advantages of different materials, such as the mechanical strength of ceramics with the flexibility of polymers. Additionally, there is growing interest in stimuli-responsive coatings that can adapt their properties based on the battery's operating conditions, providing dynamic protection throughout the battery's lifetime.

Achieving these objectives would represent a paradigm shift in energy storage technology, potentially enabling electric vehicles with significantly higher range, consumer electronics with multi-day battery life, and grid storage solutions with unprecedented cycle life and safety characteristics.

Market Analysis for Anode-Free Battery Solutions

The anode-free battery market is experiencing significant growth driven by the increasing demand for high-energy-density energy storage solutions across multiple sectors. Current market projections indicate that the global anode-free battery market could reach substantial valuation by 2030, with a compound annual growth rate exceeding traditional lithium-ion technologies. This accelerated growth is primarily fueled by the automotive industry's shift toward electric vehicles, where battery energy density directly impacts driving range and consumer adoption.

Market segmentation reveals that electric vehicles represent the largest application segment for anode-free batteries, followed by consumer electronics and grid-scale energy storage systems. The automotive sector's demand is particularly strong in regions with aggressive electrification targets, including Europe, China, and North America, where regulatory frameworks increasingly favor zero-emission vehicles.

Consumer demand patterns indicate a clear preference for batteries offering higher energy density without compromising safety or longevity. This market pull has intensified research into protective coating technologies that can mitigate the degradation mechanisms inherent to anode-free designs, particularly those addressing lithium dendrite formation and electrolyte decomposition.

Investment trends in the anode-free battery space have shown remarkable growth, with venture capital funding increasing by double digits annually over the past three years. Strategic partnerships between coating technology developers and battery manufacturers have become increasingly common, reflecting the industry's recognition that advanced coating solutions represent a critical enabler for commercial viability.

Market barriers include cost considerations, with current anode-free battery designs and their specialized coatings commanding premium prices compared to conventional lithium-ion cells. Manufacturing scalability presents another significant challenge, as precision coating processes often require specialized equipment and tightly controlled production environments that limit mass production capabilities.

Customer adoption analysis reveals that early markets are likely to emerge in premium electric vehicles and high-end consumer electronics, where the performance advantages can justify higher costs. As coating technologies mature and manufacturing processes improve, broader market penetration is expected to follow, particularly as energy density improvements translate to tangible consumer benefits like extended device runtime or vehicle range.

Regional market dynamics show Asia-Pacific leading in manufacturing capacity development, while North American and European markets demonstrate stronger research output in novel coating technologies. This geographic distribution suggests that successful commercialization will likely require international collaboration across the value chain.

Market segmentation reveals that electric vehicles represent the largest application segment for anode-free batteries, followed by consumer electronics and grid-scale energy storage systems. The automotive sector's demand is particularly strong in regions with aggressive electrification targets, including Europe, China, and North America, where regulatory frameworks increasingly favor zero-emission vehicles.

Consumer demand patterns indicate a clear preference for batteries offering higher energy density without compromising safety or longevity. This market pull has intensified research into protective coating technologies that can mitigate the degradation mechanisms inherent to anode-free designs, particularly those addressing lithium dendrite formation and electrolyte decomposition.

Investment trends in the anode-free battery space have shown remarkable growth, with venture capital funding increasing by double digits annually over the past three years. Strategic partnerships between coating technology developers and battery manufacturers have become increasingly common, reflecting the industry's recognition that advanced coating solutions represent a critical enabler for commercial viability.

Market barriers include cost considerations, with current anode-free battery designs and their specialized coatings commanding premium prices compared to conventional lithium-ion cells. Manufacturing scalability presents another significant challenge, as precision coating processes often require specialized equipment and tightly controlled production environments that limit mass production capabilities.

Customer adoption analysis reveals that early markets are likely to emerge in premium electric vehicles and high-end consumer electronics, where the performance advantages can justify higher costs. As coating technologies mature and manufacturing processes improve, broader market penetration is expected to follow, particularly as energy density improvements translate to tangible consumer benefits like extended device runtime or vehicle range.

Regional market dynamics show Asia-Pacific leading in manufacturing capacity development, while North American and European markets demonstrate stronger research output in novel coating technologies. This geographic distribution suggests that successful commercialization will likely require international collaboration across the value chain.

Current Coating Challenges in Anode-Free Systems

Despite significant advancements in anode-free battery technology, coating development remains a critical challenge that directly impacts cycle life performance. Current coating solutions face several persistent issues that limit their effectiveness in protecting lithium metal interfaces and stabilizing electrolyte interactions.

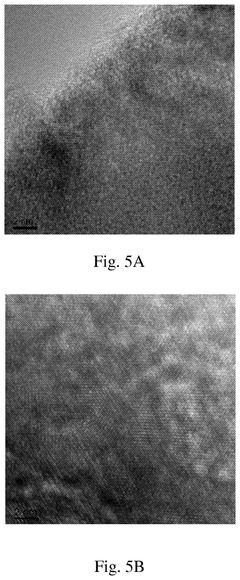

The most prominent challenge is achieving uniform and defect-free coating deposition on current collectors. Conventional coating methods often result in microscopic pinholes, cracks, and thickness variations that create preferential nucleation sites for lithium deposition. These imperfections lead to uneven lithium plating during charging cycles, accelerating dendrite formation and ultimately causing premature battery failure.

Coating adhesion presents another significant hurdle, particularly during repeated volume expansion and contraction cycles. Many existing coatings demonstrate excellent initial performance but deteriorate rapidly as mechanical stresses cause delamination from the current collector surface. This separation creates dead zones where lithium becomes electrochemically inactive, progressively reducing capacity and cycle life.

Chemical stability of coating materials in highly reactive electrolyte environments poses a substantial challenge. Most coating formulations experience gradual degradation through side reactions with electrolyte components, especially at high voltages or elevated temperatures. This degradation compromises the protective function of the coating and accelerates the formation of unstable solid electrolyte interphase (SEI) layers.

Ion transport properties represent a critical trade-off in coating design. While thicker, more robust coatings provide enhanced protection against side reactions, they simultaneously increase internal resistance and impede lithium-ion diffusion. Conversely, thinner coatings with superior ion conductivity often lack sufficient mechanical strength and chemical stability to maintain long-term protection.

Manufacturing scalability remains problematic for many advanced coating technologies. Laboratory-scale processes that produce excellent results often face significant challenges in translation to industrial production environments. Issues include process complexity, equipment compatibility, production speed limitations, and cost-effectiveness barriers that hinder commercial implementation.

Electrolyte compatibility presents another dimension of difficulty, as coating materials must function effectively with next-generation electrolyte formulations. Many promising coating materials demonstrate excellent performance with conventional liquid electrolytes but fail to maintain protection when paired with high-concentration electrolytes or solid-state electrolyte systems being developed for advanced anode-free configurations.

The most prominent challenge is achieving uniform and defect-free coating deposition on current collectors. Conventional coating methods often result in microscopic pinholes, cracks, and thickness variations that create preferential nucleation sites for lithium deposition. These imperfections lead to uneven lithium plating during charging cycles, accelerating dendrite formation and ultimately causing premature battery failure.

Coating adhesion presents another significant hurdle, particularly during repeated volume expansion and contraction cycles. Many existing coatings demonstrate excellent initial performance but deteriorate rapidly as mechanical stresses cause delamination from the current collector surface. This separation creates dead zones where lithium becomes electrochemically inactive, progressively reducing capacity and cycle life.

Chemical stability of coating materials in highly reactive electrolyte environments poses a substantial challenge. Most coating formulations experience gradual degradation through side reactions with electrolyte components, especially at high voltages or elevated temperatures. This degradation compromises the protective function of the coating and accelerates the formation of unstable solid electrolyte interphase (SEI) layers.

Ion transport properties represent a critical trade-off in coating design. While thicker, more robust coatings provide enhanced protection against side reactions, they simultaneously increase internal resistance and impede lithium-ion diffusion. Conversely, thinner coatings with superior ion conductivity often lack sufficient mechanical strength and chemical stability to maintain long-term protection.

Manufacturing scalability remains problematic for many advanced coating technologies. Laboratory-scale processes that produce excellent results often face significant challenges in translation to industrial production environments. Issues include process complexity, equipment compatibility, production speed limitations, and cost-effectiveness barriers that hinder commercial implementation.

Electrolyte compatibility presents another dimension of difficulty, as coating materials must function effectively with next-generation electrolyte formulations. Many promising coating materials demonstrate excellent performance with conventional liquid electrolytes but fail to maintain protection when paired with high-concentration electrolytes or solid-state electrolyte systems being developed for advanced anode-free configurations.

Current Coating Solutions for Cycle Life Extension

01 Protective coatings for lithium metal anodes

Protective coatings applied to lithium metal anodes in anode-free battery configurations can significantly improve cycle life by preventing dendrite formation and reducing side reactions with the electrolyte. These coatings include artificial solid electrolyte interphase (SEI) layers, polymer films, and ceramic materials that act as physical barriers while maintaining efficient lithium ion transport. The protective layers help stabilize the lithium-electrolyte interface during repeated cycling, leading to enhanced battery longevity.- Protective coatings for lithium metal anodes: Protective coatings applied to lithium metal anodes in anode-free battery configurations can significantly improve cycle life by preventing dendrite formation and reducing side reactions with the electrolyte. These coatings include artificial solid electrolyte interphases (SEI), polymer layers, and ceramic materials that act as physical barriers while maintaining efficient lithium ion transport. The protective layers help stabilize the lithium-electrolyte interface during repeated cycling, leading to enhanced battery longevity and performance.

- Advanced electrolyte formulations: Specialized electrolyte formulations play a crucial role in extending the cycle life of anode-free batteries by forming stable interfaces with the in-situ formed lithium metal anode. These formulations often include additives that promote uniform lithium deposition, fluorinated solvents that resist oxidation, and salt combinations that enhance ionic conductivity while minimizing parasitic reactions. The electrolyte composition directly impacts lithium plating/stripping efficiency, which is critical for maintaining capacity over numerous cycles in anode-free battery systems.

- Current collector surface modifications: Modifying the surface of current collectors in anode-free batteries creates preferential nucleation sites for lithium deposition, leading to more uniform plating and improved cycle life. These modifications include creating nanostructured surfaces, applying lithiophilic coatings, or introducing functional groups that guide lithium deposition behavior. By controlling the initial stages of lithium nucleation and growth, these engineered surfaces help prevent dendrite formation and maintain electrode integrity through multiple charge-discharge cycles.

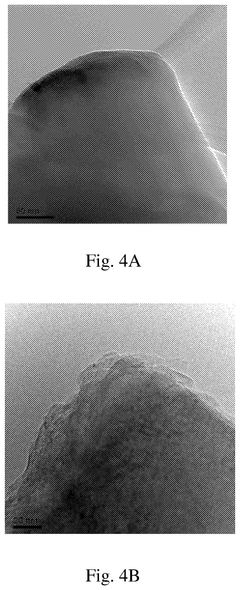

- Host materials for lithium deposition: Incorporating host materials such as 3D carbon frameworks, metal foams, or porous structures provides dedicated spaces for lithium deposition in anode-free batteries, significantly improving cycle life. These host structures accommodate volume changes during cycling, guide uniform lithium deposition, and maintain electronic pathways throughout the electrode. The physical confinement offered by these host materials prevents dendrite formation and electrode pulverization, resulting in more stable cycling performance and extended battery lifespan.

- Pressure regulation and cell design: Optimized cell design and pressure regulation systems enhance the cycle life of anode-free batteries by maintaining physical constraints on the electrodes during operation. Controlled stack pressure helps suppress dendrite growth and promotes uniform lithium deposition. Advanced cell architectures incorporate features like pressure-regulating components, specialized separators, and mechanical constraints that work together to preserve electrode integrity throughout cycling. These design considerations are particularly important for anode-free configurations where managing lithium morphology is critical for long-term performance.

02 Advanced electrolyte formulations

Specialized electrolyte formulations play a crucial role in extending the cycle life of anode-free batteries by promoting uniform lithium deposition and reducing parasitic reactions. These formulations may include fluorinated solvents, high-concentration electrolytes, and additives that form stable interfaces with lithium metal. The optimized electrolyte chemistry helps control lithium plating/stripping efficiency, minimizes electrolyte decomposition, and prevents capacity fade during cycling, resulting in batteries with significantly improved lifespan.Expand Specific Solutions03 Host materials for lithium deposition

Engineered host materials designed to accommodate lithium deposition in anode-free batteries can substantially improve cycle life by providing structured frameworks for controlled lithium plating. These host materials include 3D conductive frameworks, porous carbon structures, and metal-based scaffolds that guide lithium deposition, prevent dendrite formation, and maintain electrode integrity during cycling. By facilitating uniform lithium distribution and reducing volume changes, these host structures enable more stable cycling performance.Expand Specific Solutions04 Current collector modifications

Modified current collectors in anode-free batteries can significantly enhance cycle life by improving lithium nucleation and adhesion properties. These modifications include surface texturing, chemical treatments, and composite structures that create favorable interfaces for lithium deposition. The engineered current collectors help achieve more uniform lithium plating, better mechanical stability, and reduced dead lithium formation during cycling, leading to batteries with extended operational lifespans.Expand Specific Solutions05 Battery management strategies

Advanced battery management strategies specifically designed for anode-free batteries can extend cycle life by optimizing charging protocols, temperature control, and pressure application. These approaches include tailored charging algorithms that prevent lithium dendrite formation, pressure-modulation systems that maintain physical contact between components, and thermal management techniques that ensure optimal operating conditions. By controlling the operational parameters, these management strategies minimize degradation mechanisms and maximize the reversibility of lithium plating/stripping processes.Expand Specific Solutions

Leading Companies in Battery Coating Development

The anode-free battery coating technology market is currently in an early growth phase, with significant R&D investment but limited commercial deployment. Market size is projected to expand rapidly as electric vehicle adoption accelerates, potentially reaching several billion dollars by 2030. Technologically, coatings that protect lithium metal interfaces remain at mid-maturity, with leading companies developing proprietary solutions. Key players include established battery manufacturers (CATL, LG Energy Solution, Samsung SDI) investing heavily in protective coating technologies, while specialized coating innovators like Forge Nano and NanoGraf are advancing atomic layer deposition techniques. Research-focused entities (Northwestern University, Argonne) are pioneering fundamental coating science, while companies like Factorial and Enevate are integrating coating technologies with novel battery architectures to extend cycle life and improve safety profiles.

Forge Nano, Inc.

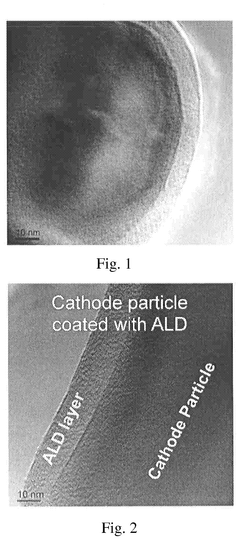

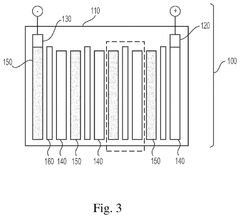

Technical Solution: Forge Nano has developed Atomic Layer Deposition (ALD) coating technology specifically for anode-free batteries. Their proprietary process applies ultra-thin, uniform protective coatings at the atomic scale to lithium metal and solid electrolyte interfaces. The ALD technology creates conformal nanoscale coatings that protect the lithium metal surface from parasitic reactions with the electrolyte, preventing dendrite formation and electrolyte decomposition. Their process enables precise thickness control (down to angstrom level) and can be applied to various substrate geometries. Forge Nano's coatings have demonstrated the ability to extend cycle life by up to 3x in anode-free configurations by maintaining a stable solid electrolyte interphase (SEI) and preventing continuous lithium consumption during cycling.

Strengths: Precise atomic-level control over coating thickness and composition; scalable manufacturing process compatible with existing battery production lines; demonstrated significant cycle life improvements. Weaknesses: May add additional processing costs; requires specialized equipment for implementation; optimal coating formulations may vary based on specific electrolyte chemistries.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a multi-functional protective coating strategy for anode-free lithium metal batteries. Their approach utilizes a dual-layer coating system: an inner artificial SEI layer composed of lithium-conductive materials (such as Li3PO4 or LiF-rich compounds) directly on the current collector, and an outer elastic polymer-based layer that accommodates volume changes during cycling. This coating architecture helps regulate lithium deposition behavior, promoting smooth and dendrite-free plating. Samsung's research shows that their coated current collectors enable more uniform lithium nucleation and growth, significantly reducing dead lithium formation. Their proprietary coating formulations incorporate additives that scavenge trace moisture and impurities, further enhancing cycle stability. Testing has demonstrated over 400 cycles with capacity retention above 80% in pouch cell formats.

Strengths: Comprehensive approach addressing multiple failure mechanisms; backed by Samsung's extensive manufacturing expertise; demonstrated performance in practical cell formats. Weaknesses: Complex multi-layer coating process may increase production complexity; some formulations may be sensitive to environmental conditions during application.

Key Innovations in Interface Engineering

Nano-engineered coatings for anode active materials, cathode active materials, and solid-state electrolytes and methods of making batteries containing nano-engineered coatings

PatentPendingUS20240429437A1

Innovation

- Applying a nano-engineered coating on anode, cathode, or solid-state electrolyte materials using techniques like atomic layer deposition, molecular layer deposition, or chemical vapor deposition, which are mechanically stable, thin, continuous, and non-porous, to inhibit undesirable chemical pathways and side reactions, thereby altering the behavior of the SEI layer and reducing contact and concentration polarization resistances.

Nano-engineered coatings for anode active materials, cathode active materials, and solid-state electrolytes and methods of making batteries containing nano-engineered coatings

PatentPendingUS20240429437A1

Innovation

- Applying a nano-engineered coating on anode, cathode, or solid-state electrolyte materials using techniques like atomic layer deposition, molecular layer deposition, or chemical vapor deposition, which are mechanically stable, thin, continuous, and non-porous, to inhibit undesirable chemical pathways and side reactions, thereby altering the behavior of the SEI layer and reducing contact and concentration polarization resistances.

Environmental Impact of Coating Materials

The environmental footprint of coating materials used in anode-free batteries represents a critical consideration in the overall sustainability assessment of this emerging energy storage technology. Traditional battery manufacturing processes often involve environmentally harmful substances that pose significant ecological risks throughout their lifecycle. Coating materials, while constituting a relatively small portion of battery mass, can have disproportionate environmental impacts due to their chemical composition and production methods.

Most contemporary coating materials for anode-free batteries utilize fluorinated compounds, metal oxides, and specialized polymers that require energy-intensive manufacturing processes. The extraction of rare elements used in certain high-performance coatings, such as lanthanum, cerium, and other lanthanides, involves substantial land disruption, water usage, and potential toxic runoff. Life cycle assessments indicate that the environmental burden of these materials can offset some of the sustainability advantages that anode-free batteries otherwise offer.

Water-based coating solutions have emerged as more environmentally benign alternatives to solvent-based systems, reducing volatile organic compound (VOC) emissions by up to 95%. However, these aqueous systems often deliver inferior performance in terms of uniformity and adhesion, presenting a classic sustainability-performance tradeoff that researchers continue to address through innovative formulations.

The end-of-life management of coating materials presents additional environmental challenges. Many specialized coatings are difficult to separate during recycling processes, potentially contaminating recovered materials or requiring additional energy-intensive separation steps. This complicates the circular economy potential of anode-free batteries and may contribute to electronic waste issues if not properly addressed through design-for-recycling approaches.

Recent advancements in bio-derived coating materials show promise for reducing environmental impact. Cellulose-based coatings and lignin derivatives have demonstrated competitive performance while offering biodegradability advantages. These materials can reduce carbon footprint by up to 40% compared to petroleum-based alternatives, though scale-up challenges remain significant barriers to widespread adoption.

Regulatory frameworks increasingly recognize the environmental implications of battery components, with the European Union's Battery Directive and similar legislation in Asia and North America beginning to address coating materials specifically. Manufacturers are responding by developing environmentally certified coating solutions that maintain performance while reducing ecological burden, creating a new competitive dimension in the battery market focused on sustainability credentials.

Most contemporary coating materials for anode-free batteries utilize fluorinated compounds, metal oxides, and specialized polymers that require energy-intensive manufacturing processes. The extraction of rare elements used in certain high-performance coatings, such as lanthanum, cerium, and other lanthanides, involves substantial land disruption, water usage, and potential toxic runoff. Life cycle assessments indicate that the environmental burden of these materials can offset some of the sustainability advantages that anode-free batteries otherwise offer.

Water-based coating solutions have emerged as more environmentally benign alternatives to solvent-based systems, reducing volatile organic compound (VOC) emissions by up to 95%. However, these aqueous systems often deliver inferior performance in terms of uniformity and adhesion, presenting a classic sustainability-performance tradeoff that researchers continue to address through innovative formulations.

The end-of-life management of coating materials presents additional environmental challenges. Many specialized coatings are difficult to separate during recycling processes, potentially contaminating recovered materials or requiring additional energy-intensive separation steps. This complicates the circular economy potential of anode-free batteries and may contribute to electronic waste issues if not properly addressed through design-for-recycling approaches.

Recent advancements in bio-derived coating materials show promise for reducing environmental impact. Cellulose-based coatings and lignin derivatives have demonstrated competitive performance while offering biodegradability advantages. These materials can reduce carbon footprint by up to 40% compared to petroleum-based alternatives, though scale-up challenges remain significant barriers to widespread adoption.

Regulatory frameworks increasingly recognize the environmental implications of battery components, with the European Union's Battery Directive and similar legislation in Asia and North America beginning to address coating materials specifically. Manufacturers are responding by developing environmentally certified coating solutions that maintain performance while reducing ecological burden, creating a new competitive dimension in the battery market focused on sustainability credentials.

Scalability and Manufacturing Considerations

The scalability of coating technologies represents a critical factor in the commercial viability of anode-free batteries. Current laboratory-scale coating processes demonstrate promising results for extending cycle life, but transitioning these methods to mass production presents significant challenges. The precision required for uniform nanometer-thick protective layers demands sophisticated equipment and stringent quality control measures that may not be readily available in existing battery manufacturing facilities.

Manufacturing considerations must address the integration of coating processes into established battery production lines. Wet chemical deposition methods offer relatively straightforward scalability but may introduce additional drying steps that extend production time and energy consumption. Physical vapor deposition techniques provide excellent coating uniformity but require substantial capital investment in vacuum equipment and may create production bottlenecks due to batch processing limitations.

Cost implications of coating technologies vary significantly based on materials and methods. Noble metal-based coatings (e.g., gold, platinum) demonstrate excellent protective properties but remain prohibitively expensive for mass-market applications. Alternative materials such as carbon-based coatings or metal oxides offer more economical options but may require more complex deposition processes to achieve comparable performance benefits.

Environmental considerations and regulatory compliance also impact manufacturing scalability. Certain coating materials or processes may involve toxic precursors or solvents that require specialized handling and waste management systems. Manufacturers must balance performance benefits against potential environmental liabilities and regulatory hurdles when selecting coating technologies for large-scale implementation.

Quality control represents another critical manufacturing challenge. The effectiveness of protective coatings in extending battery cycle life depends on consistent thickness, uniform coverage, and absence of defects. Developing inline inspection methods capable of detecting nanoscale imperfections at production speeds remains technically challenging but essential for ensuring consistent battery performance.

Supply chain resilience must be evaluated when selecting coating materials for large-scale production. Some high-performance coating materials may rely on limited raw material sources or specialized processing techniques with few suppliers. Manufacturers must consider material availability, price volatility, and geopolitical factors that could disrupt supply chains for critical coating components.

Manufacturing considerations must address the integration of coating processes into established battery production lines. Wet chemical deposition methods offer relatively straightforward scalability but may introduce additional drying steps that extend production time and energy consumption. Physical vapor deposition techniques provide excellent coating uniformity but require substantial capital investment in vacuum equipment and may create production bottlenecks due to batch processing limitations.

Cost implications of coating technologies vary significantly based on materials and methods. Noble metal-based coatings (e.g., gold, platinum) demonstrate excellent protective properties but remain prohibitively expensive for mass-market applications. Alternative materials such as carbon-based coatings or metal oxides offer more economical options but may require more complex deposition processes to achieve comparable performance benefits.

Environmental considerations and regulatory compliance also impact manufacturing scalability. Certain coating materials or processes may involve toxic precursors or solvents that require specialized handling and waste management systems. Manufacturers must balance performance benefits against potential environmental liabilities and regulatory hurdles when selecting coating technologies for large-scale implementation.

Quality control represents another critical manufacturing challenge. The effectiveness of protective coatings in extending battery cycle life depends on consistent thickness, uniform coverage, and absence of defects. Developing inline inspection methods capable of detecting nanoscale imperfections at production speeds remains technically challenging but essential for ensuring consistent battery performance.

Supply chain resilience must be evaluated when selecting coating materials for large-scale production. Some high-performance coating materials may rely on limited raw material sources or specialized processing techniques with few suppliers. Manufacturers must consider material availability, price volatility, and geopolitical factors that could disrupt supply chains for critical coating components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!