Integrating anode-free batteries with smart grid infrastructure

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

Anode-free battery technology represents a significant evolution in energy storage systems, emerging from decades of battery development that began with primary cells and evolved through various lithium-ion configurations. This revolutionary approach eliminates the traditional anode material, typically graphite, resulting in batteries with potentially higher energy density, reduced weight, and lower production costs compared to conventional lithium-ion batteries.

The historical trajectory of battery technology has consistently aimed at increasing energy density while reducing costs. Anode-free designs represent the latest milestone in this journey, with research dating back to the early 2010s but gaining substantial momentum only in the past five years as materials science and manufacturing techniques have advanced sufficiently to address earlier stability challenges.

The primary objective of anode-free battery development is to achieve energy densities exceeding 500 Wh/kg, nearly double that of current commercial lithium-ion batteries. This advancement would significantly impact electric vehicle range, portable electronics duration, and grid storage capacity. When specifically considering integration with smart grid infrastructure, the objectives expand to include rapid charge/discharge capabilities, extended cycle life under variable load conditions, and intelligent battery management systems that can communicate with grid control systems.

Current technological goals focus on overcoming the dendrite formation issues that have historically plagued lithium metal batteries, improving the solid-electrolyte interface stability, and developing manufacturing processes that can scale economically. Research indicates that successful anode-free batteries could reduce battery pack costs by 15-30% while increasing energy storage capacity by 20-40%.

The integration of anode-free batteries with smart grid infrastructure presents unique technical objectives, including the development of bidirectional charging protocols, enhanced safety mechanisms for grid-connected systems, and sophisticated thermal management systems capable of handling the higher energy densities involved. These batteries must also demonstrate resilience to the irregular charging patterns typical in renewable energy environments.

Looking forward, the technology roadmap aims to achieve commercial viability for grid applications by 2025-2027, with initial deployments focusing on stationary storage before expanding to mobile applications. The ultimate goal is to create a seamless interface between high-density energy storage and intelligent grid management systems, enabling more efficient renewable energy integration, enhanced grid stability, and reduced reliance on fossil fuel peaker plants.

The historical trajectory of battery technology has consistently aimed at increasing energy density while reducing costs. Anode-free designs represent the latest milestone in this journey, with research dating back to the early 2010s but gaining substantial momentum only in the past five years as materials science and manufacturing techniques have advanced sufficiently to address earlier stability challenges.

The primary objective of anode-free battery development is to achieve energy densities exceeding 500 Wh/kg, nearly double that of current commercial lithium-ion batteries. This advancement would significantly impact electric vehicle range, portable electronics duration, and grid storage capacity. When specifically considering integration with smart grid infrastructure, the objectives expand to include rapid charge/discharge capabilities, extended cycle life under variable load conditions, and intelligent battery management systems that can communicate with grid control systems.

Current technological goals focus on overcoming the dendrite formation issues that have historically plagued lithium metal batteries, improving the solid-electrolyte interface stability, and developing manufacturing processes that can scale economically. Research indicates that successful anode-free batteries could reduce battery pack costs by 15-30% while increasing energy storage capacity by 20-40%.

The integration of anode-free batteries with smart grid infrastructure presents unique technical objectives, including the development of bidirectional charging protocols, enhanced safety mechanisms for grid-connected systems, and sophisticated thermal management systems capable of handling the higher energy densities involved. These batteries must also demonstrate resilience to the irregular charging patterns typical in renewable energy environments.

Looking forward, the technology roadmap aims to achieve commercial viability for grid applications by 2025-2027, with initial deployments focusing on stationary storage before expanding to mobile applications. The ultimate goal is to create a seamless interface between high-density energy storage and intelligent grid management systems, enabling more efficient renewable energy integration, enhanced grid stability, and reduced reliance on fossil fuel peaker plants.

Smart Grid Integration Market Analysis

The smart grid integration market for anode-free battery technology is experiencing significant growth, driven by increasing demand for efficient energy storage solutions within modern electrical infrastructure. Current market valuations indicate that the global smart grid market reached approximately 43.1 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 17.9% through 2030. Within this broader market, energy storage integration represents one of the fastest-growing segments, with particular interest in next-generation battery technologies.

Anode-free batteries present a compelling value proposition for smart grid applications due to their higher energy density, reduced material costs, and potential for improved safety profiles. Market analysis reveals that utility companies and grid operators are increasingly investing in advanced battery technologies to address grid stabilization challenges, peak demand management, and integration of renewable energy sources.

Regional market distribution shows North America currently leading smart grid battery integration, accounting for roughly 35% of global market share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and South Korea making substantial investments in both anode-free battery research and smart grid modernization programs.

Consumer demand patterns indicate a growing preference for distributed energy resources (DERs) that can seamlessly integrate with smart grid infrastructure. This trend is creating market opportunities for anode-free battery manufacturers who can develop products with built-in grid communication capabilities and intelligent energy management systems.

Market segmentation analysis reveals three primary application sectors for anode-free batteries in smart grids: utility-scale energy storage (representing approximately 45% of potential market applications), commercial and industrial energy management (30%), and residential energy storage systems (25%). The utility-scale segment presents the largest immediate opportunity, particularly for grid-level frequency regulation and load balancing applications.

Competitive landscape assessment identifies several key market barriers including high initial implementation costs, technical integration challenges with existing grid infrastructure, and regulatory uncertainties regarding energy storage deployment. Despite these challenges, market forecasts predict that anode-free battery integration in smart grids could reach 7.8 billion USD by 2028, representing a specialized but rapidly expanding market segment.

Customer willingness-to-pay analysis indicates that grid operators are increasingly recognizing the total cost of ownership benefits that advanced battery technologies provide, particularly when factoring in longer cycle life, reduced maintenance requirements, and enhanced grid services capabilities that anode-free batteries potentially offer.

Anode-free batteries present a compelling value proposition for smart grid applications due to their higher energy density, reduced material costs, and potential for improved safety profiles. Market analysis reveals that utility companies and grid operators are increasingly investing in advanced battery technologies to address grid stabilization challenges, peak demand management, and integration of renewable energy sources.

Regional market distribution shows North America currently leading smart grid battery integration, accounting for roughly 35% of global market share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and South Korea making substantial investments in both anode-free battery research and smart grid modernization programs.

Consumer demand patterns indicate a growing preference for distributed energy resources (DERs) that can seamlessly integrate with smart grid infrastructure. This trend is creating market opportunities for anode-free battery manufacturers who can develop products with built-in grid communication capabilities and intelligent energy management systems.

Market segmentation analysis reveals three primary application sectors for anode-free batteries in smart grids: utility-scale energy storage (representing approximately 45% of potential market applications), commercial and industrial energy management (30%), and residential energy storage systems (25%). The utility-scale segment presents the largest immediate opportunity, particularly for grid-level frequency regulation and load balancing applications.

Competitive landscape assessment identifies several key market barriers including high initial implementation costs, technical integration challenges with existing grid infrastructure, and regulatory uncertainties regarding energy storage deployment. Despite these challenges, market forecasts predict that anode-free battery integration in smart grids could reach 7.8 billion USD by 2028, representing a specialized but rapidly expanding market segment.

Customer willingness-to-pay analysis indicates that grid operators are increasingly recognizing the total cost of ownership benefits that advanced battery technologies provide, particularly when factoring in longer cycle life, reduced maintenance requirements, and enhanced grid services capabilities that anode-free batteries potentially offer.

Technical Challenges in Anode-Free Battery Grid Implementation

The integration of anode-free batteries with smart grid infrastructure faces significant technical challenges that must be addressed before widespread implementation. One primary obstacle is the inherent instability of lithium metal electrodes in anode-free designs, which can lead to dendrite formation during charging cycles. These dendrites not only reduce battery efficiency but also create potential safety hazards that are unacceptable in grid-scale applications where reliability is paramount.

Voltage fluctuations present another critical challenge. Anode-free batteries typically exhibit wider voltage ranges compared to conventional lithium-ion batteries, requiring more sophisticated power electronics and control systems to manage these variations effectively within grid infrastructure. This complexity increases both implementation costs and potential points of failure in the system.

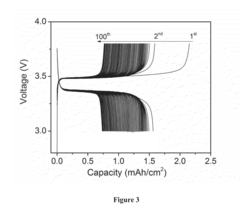

The cycle life limitations of current anode-free battery technologies pose significant barriers to grid integration. While conventional grid storage solutions are expected to operate reliably for 10-15 years, many anode-free designs currently demonstrate rapid capacity fade after several hundred cycles, making them economically unviable for long-term grid applications without substantial improvements.

Temperature sensitivity represents another major hurdle. Anode-free batteries often show pronounced performance degradation outside narrow temperature ranges, whereas grid storage systems must function reliably across diverse environmental conditions. This mismatch necessitates additional thermal management systems, further complicating integration efforts and increasing costs.

Scalability challenges are particularly pronounced when considering manufacturing processes. Current production methods for anode-free batteries are largely laboratory-focused, with significant barriers to economical mass production. The specialized handling requirements for lithium metal and air-sensitive components complicate manufacturing scale-up, creating bottlenecks in supply chains.

Grid compatibility issues extend to communication protocols and control systems. Existing grid management software and hardware are optimized for conventional battery chemistries with well-understood characteristics. Anode-free batteries require new algorithms for state-of-charge estimation and health monitoring, necessitating substantial updates to grid management systems.

Regulatory and safety certification presents additional challenges. The novel nature of anode-free technologies means that existing safety standards may not adequately address their unique characteristics, requiring new testing protocols and certification processes before utility companies will adopt these solutions at scale.

Voltage fluctuations present another critical challenge. Anode-free batteries typically exhibit wider voltage ranges compared to conventional lithium-ion batteries, requiring more sophisticated power electronics and control systems to manage these variations effectively within grid infrastructure. This complexity increases both implementation costs and potential points of failure in the system.

The cycle life limitations of current anode-free battery technologies pose significant barriers to grid integration. While conventional grid storage solutions are expected to operate reliably for 10-15 years, many anode-free designs currently demonstrate rapid capacity fade after several hundred cycles, making them economically unviable for long-term grid applications without substantial improvements.

Temperature sensitivity represents another major hurdle. Anode-free batteries often show pronounced performance degradation outside narrow temperature ranges, whereas grid storage systems must function reliably across diverse environmental conditions. This mismatch necessitates additional thermal management systems, further complicating integration efforts and increasing costs.

Scalability challenges are particularly pronounced when considering manufacturing processes. Current production methods for anode-free batteries are largely laboratory-focused, with significant barriers to economical mass production. The specialized handling requirements for lithium metal and air-sensitive components complicate manufacturing scale-up, creating bottlenecks in supply chains.

Grid compatibility issues extend to communication protocols and control systems. Existing grid management software and hardware are optimized for conventional battery chemistries with well-understood characteristics. Anode-free batteries require new algorithms for state-of-charge estimation and health monitoring, necessitating substantial updates to grid management systems.

Regulatory and safety certification presents additional challenges. The novel nature of anode-free technologies means that existing safety standards may not adequately address their unique characteristics, requiring new testing protocols and certification processes before utility companies will adopt these solutions at scale.

Current Integration Solutions for Advanced Batteries with Smart Grids

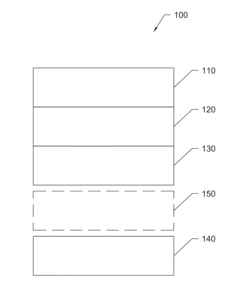

01 Anode-free battery design and structure

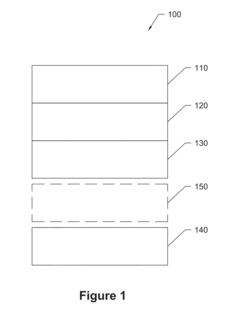

Anode-free batteries eliminate the traditional anode material during assembly, instead forming the anode in-situ during the first charging cycle when lithium ions plate onto the current collector. This design significantly increases energy density by reducing inactive components and simplifying battery architecture. The structure typically includes a lithium metal-free negative electrode, a separator, and a cathode, with the anode forming during operation through electrodeposition of lithium from the cathode.- Anode-free battery design and structure: Anode-free batteries eliminate the traditional anode material during battery assembly, instead forming the anode in-situ during the first charging cycle when lithium ions plate onto the current collector. This design significantly increases energy density by removing the weight and volume of the anode substrate. The structure typically includes a lithium-metal-free negative electrode, a separator, and a lithium-containing positive electrode, with the negative current collector serving as the plating surface for lithium ions during charging.

- Electrolyte formulations for anode-free batteries: Specialized electrolyte formulations are critical for anode-free battery performance, as they must facilitate uniform lithium plating and prevent dendrite formation. These electrolytes often contain additives that form stable solid electrolyte interphases (SEI) on the current collector surface. Advanced formulations may include fluorinated solvents, high-concentration salt systems, or ionic liquids that improve lithium ion transport while minimizing side reactions that lead to capacity loss and short-circuiting.

- Current collector materials and treatments: The current collector in anode-free batteries serves as the substrate for lithium plating and plays a crucial role in battery performance. Various materials and surface treatments are employed to enhance lithium nucleation and adhesion while preventing dendrite formation. These include copper foils with specialized coatings, three-dimensional structured current collectors with increased surface area, and surface modifications that improve wetting and lithium distribution during plating cycles.

- Protective layers and interfaces: Protective layers at the current collector-electrolyte interface are essential for anode-free battery longevity. These layers prevent continuous electrolyte decomposition and stabilize the lithium plating/stripping process. Approaches include artificial SEI layers applied before cell assembly, polymer or ceramic coatings that regulate ion transport, and composite interlayers that accommodate volume changes during cycling while maintaining mechanical integrity and preventing short circuits.

- Cathode materials for anode-free configurations: Cathode materials in anode-free batteries must contain sufficient lithium to supply both electrodes since no lithium is present in the anode initially. High-capacity lithium-rich cathode materials are preferred, including advanced lithium nickel manganese cobalt oxides (NMC), lithium-rich layered oxides, and high-voltage spinel structures. These materials are often modified to improve structural stability during deep cycling and to minimize transition metal dissolution that can contaminate the plating surface of the current collector.

02 Electrolyte compositions for anode-free batteries

Specialized electrolyte formulations are crucial for anode-free battery performance, addressing challenges like dendrite formation and low Coulombic efficiency. These electrolytes often contain additives that form stable solid electrolyte interphases (SEI) on the current collector surface, facilitating uniform lithium deposition. Formulations may include fluorinated solvents, lithium salts, and various organic and inorganic additives designed to enhance cycling stability and prevent side reactions during repeated lithium plating/stripping cycles.Expand Specific Solutions03 Current collector materials and treatments

The current collector in anode-free batteries serves as the substrate for lithium deposition and plays a critical role in battery performance. Various materials and surface treatments are employed to improve lithium nucleation and adhesion while preventing dendrite formation. These include copper foils with specialized coatings, surface texturing techniques, and composite current collectors incorporating carbon-based materials. Some designs feature three-dimensional structures to increase surface area and improve lithium deposition uniformity.Expand Specific Solutions04 Protection layers and interface engineering

Interface engineering is essential in anode-free batteries to control lithium deposition behavior and prevent side reactions. Protective layers applied to the current collector or separator can significantly improve cycling performance by promoting uniform lithium plating and reducing parasitic reactions. These layers may consist of polymers, ceramics, or composite materials that facilitate ion transport while blocking unwanted reactions. Some designs incorporate artificial SEI layers pre-deposited on the current collector before battery assembly.Expand Specific Solutions05 Manufacturing methods and scale-up techniques

Manufacturing anode-free batteries presents unique challenges compared to conventional lithium-ion batteries. Specialized production techniques focus on maintaining ultra-dry environments, precise electrolyte filling, and careful sealing to prevent moisture contamination. Advanced assembly methods include modified roll-to-roll processes, controlled pressure application during cell stacking, and specialized formation protocols to establish optimal initial lithium deposition patterns. Scale-up approaches address challenges in maintaining consistent quality across larger format cells while minimizing production costs.Expand Specific Solutions

Key Industry Players in Anode-Free Battery and Smart Grid Sectors

The anode-free battery integration with smart grid infrastructure market is currently in an early growth phase, characterized by significant R&D investment and emerging commercial applications. The global market size is projected to expand rapidly as grid storage demands increase, with estimates suggesting a compound annual growth rate exceeding 25% through 2030. From a technological maturity perspective, the landscape shows varied development stages across key players. Tesla and LG Energy Solution lead in commercial deployment, while State Grid Corp. of China and Samsung SDI are advancing large-scale integration solutions. Research institutions including Tsinghua University and University of Southern California are pioneering next-generation technologies, while specialized innovators like Enevate and Urban Electric Power focus on novel anode-free architectures. CATL (Ningde Amperex) has made significant strides in manufacturing scalability, positioning this technology at the cusp of broader market adoption.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology) has developed a comprehensive anode-free battery integration system for smart grid applications. Their technology employs a lithium metal battery architecture that eliminates traditional graphite anodes, achieving volumetric energy densities approaching 900 Wh/L. CATL's smart grid integration platform features their proprietary "Cloud Battery Management System" that enables real-time monitoring and optimization of thousands of battery cells simultaneously. The system incorporates advanced thermal management solutions that maintain optimal operating temperatures even under high-power grid balancing operations. CATL's grid integration technology includes frequency regulation capabilities that can respond to grid signals within milliseconds, providing essential grid stabilization services. Their solution also features a modular design that allows for scalable deployment from residential to utility-scale applications, with standardized interfaces for seamless integration with existing smart grid infrastructure. The technology incorporates artificial intelligence algorithms that predict grid demand patterns and optimize battery cycling accordingly.

Strengths: Industry-leading manufacturing scale that enables cost competitiveness; extensive experience with grid-scale deployments; advanced thermal management systems. Weaknesses: Relatively limited experience with lithium metal technology compared to conventional lithium-ion; potential supply chain constraints for certain critical materials; regulatory hurdles in some international markets.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed an extensive anode-free battery integration framework for their nationwide smart grid infrastructure. Their approach utilizes thin-film lithium metal battery technology with specialized protective coatings to prevent dendrite formation. The system incorporates a hierarchical control architecture that enables coordination between distributed battery assets across multiple grid levels, from transmission to distribution. State Grid's solution features advanced power electronics interfaces that provide grid-supporting functions including voltage regulation, reactive power compensation, and synthetic inertia. Their platform includes a comprehensive energy management system that optimizes battery operation based on grid conditions, renewable energy forecasts, and electricity market signals. The technology has been deployed in several pilot projects across China, demonstrating successful integration with their ultra-high voltage transmission network. State Grid's approach emphasizes standardization of communication protocols and grid interfaces to ensure interoperability across different battery technologies and grid assets.

Strengths: Unparalleled access to large-scale grid infrastructure for testing and deployment; strong government backing for technology development; comprehensive approach addressing multiple grid levels. Weaknesses: Technology may be optimized specifically for Chinese grid characteristics; potential international concerns regarding data security and system access; relatively limited commercial deployment outside domestic market.

Critical Patents and Research in Anode-Free Battery Grid Applications

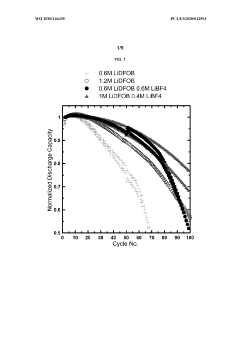

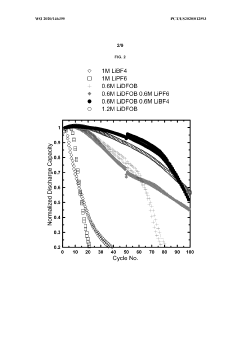

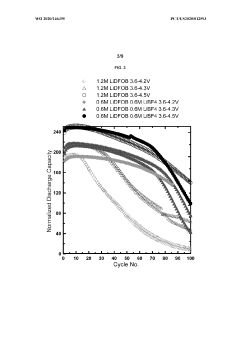

Electrolytes with lithium difluoro(oxalato)borate and lithium tetrafluoroborate salts for lithium metal and anode-free cells

PatentWO2020146395A1

Innovation

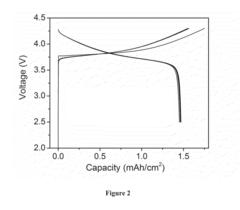

- A dual salt electrolyte solution combining lithium difluoro(oxalato)borate (LiDFOB) and lithium tetrafluoroborate (LiBF4) with a solvent component, including fluoroethylene carbonate and diethyl carbonate, applied under uniaxial stack pressure, significantly improves capacity retention in anode-free lithium battery systems.

Anode-free rechargeable battery

PatentActiveUS20160261000A1

Innovation

- An anode-free rechargeable battery design utilizing a lithium cation-based electrolyte with a porous polymer separator and specific lithium salts dissolved in non-aqueous solvents, where the anode is formed in situ during charging and consumed during discharge, eliminating the need for a traditional anode and enhancing Coulombic Efficiency.

Energy Storage Standardization and Interoperability Frameworks

The integration of anode-free batteries with smart grid infrastructure requires robust standardization and interoperability frameworks to ensure seamless communication, operation, and management across diverse energy storage systems. Currently, several key standardization bodies are working to establish protocols specifically addressing the unique characteristics of anode-free battery technologies within grid applications.

The IEEE 2030 series provides foundational standards for smart grid interoperability, with recent extensions being developed to accommodate advanced battery chemistries including anode-free designs. These standards define communication interfaces, data models, and operational parameters necessary for grid integration, focusing on the high energy density and unique charging profiles of anode-free systems.

IEC 61850, primarily designed for power utility automation, is being expanded to include specific object models for next-generation battery technologies. This framework enables standardized information exchange between anode-free battery management systems and grid control centers, facilitating real-time monitoring and control essential for grid stability when incorporating these high-performance storage solutions.

The development of unified Battery Management System (BMS) protocols represents another critical standardization effort. These protocols must address the specific safety monitoring requirements of anode-free batteries, which have different thermal and electrical characteristics compared to conventional lithium-ion systems. Standardized BMS interfaces allow grid operators to implement consistent safety measures across heterogeneous battery deployments.

Interoperability testing methodologies are being established to verify compliance with these emerging standards. Test procedures specifically evaluate how anode-free batteries respond to grid signals, maintain synchronization during frequency regulation services, and participate in demand response programs. These certification processes are essential for building confidence in the reliability of these advanced storage technologies.

Data exchange formats and communication protocols are being harmonized to support the integration of anode-free batteries into existing energy management systems. This standardization enables automated dispatch, performance monitoring, and financial settlement processes necessary for market participation. The OpenADR alliance and Modbus specifications are being extended to accommodate the unique operational parameters of anode-free technologies.

Regulatory frameworks across different regions are gradually converging toward consistent requirements for grid-connected energy storage, though significant regional variations remain. These frameworks increasingly recognize the unique value propositions of high-energy density solutions like anode-free batteries, particularly for applications requiring extended duration discharge capabilities.

The IEEE 2030 series provides foundational standards for smart grid interoperability, with recent extensions being developed to accommodate advanced battery chemistries including anode-free designs. These standards define communication interfaces, data models, and operational parameters necessary for grid integration, focusing on the high energy density and unique charging profiles of anode-free systems.

IEC 61850, primarily designed for power utility automation, is being expanded to include specific object models for next-generation battery technologies. This framework enables standardized information exchange between anode-free battery management systems and grid control centers, facilitating real-time monitoring and control essential for grid stability when incorporating these high-performance storage solutions.

The development of unified Battery Management System (BMS) protocols represents another critical standardization effort. These protocols must address the specific safety monitoring requirements of anode-free batteries, which have different thermal and electrical characteristics compared to conventional lithium-ion systems. Standardized BMS interfaces allow grid operators to implement consistent safety measures across heterogeneous battery deployments.

Interoperability testing methodologies are being established to verify compliance with these emerging standards. Test procedures specifically evaluate how anode-free batteries respond to grid signals, maintain synchronization during frequency regulation services, and participate in demand response programs. These certification processes are essential for building confidence in the reliability of these advanced storage technologies.

Data exchange formats and communication protocols are being harmonized to support the integration of anode-free batteries into existing energy management systems. This standardization enables automated dispatch, performance monitoring, and financial settlement processes necessary for market participation. The OpenADR alliance and Modbus specifications are being extended to accommodate the unique operational parameters of anode-free technologies.

Regulatory frameworks across different regions are gradually converging toward consistent requirements for grid-connected energy storage, though significant regional variations remain. These frameworks increasingly recognize the unique value propositions of high-energy density solutions like anode-free batteries, particularly for applications requiring extended duration discharge capabilities.

Grid Resilience and Security Implications

The integration of anode-free batteries with smart grid infrastructure introduces significant implications for grid resilience and security. These advanced energy storage systems fundamentally alter the vulnerability profile of modern power networks. Traditional grid architectures were designed with centralized generation and predictable load patterns, whereas anode-free battery integration creates a more distributed and dynamic system that requires new security paradigms.

From a resilience perspective, anode-free batteries offer enhanced grid stability during extreme weather events or cyberattacks by providing localized power reserves. Their higher energy density compared to conventional lithium-ion batteries enables longer-duration backup capabilities at critical infrastructure nodes. This distributed storage architecture creates multiple power islands that can operate independently when the main grid experiences disruption, significantly reducing cascading failure risks.

However, the integration also introduces new attack vectors that must be addressed. The bidirectional communication channels required for optimal battery-grid interaction expand the cyber-physical attack surface. Malicious actors could potentially manipulate battery charging/discharging patterns to destabilize grid frequency or voltage parameters. The sophisticated battery management systems (BMS) controlling these advanced batteries represent high-value targets for attackers seeking to compromise grid operations.

Physical security considerations also evolve with anode-free battery deployment. The higher energy density creates more concentrated points of vulnerability, requiring enhanced physical protection measures. Additionally, the thermal management systems necessary for safe operation of these high-performance batteries must be secured against tampering that could lead to thermal runaway events.

Data security becomes increasingly critical as anode-free battery systems generate vast amounts of operational data used for grid optimization. This data requires robust encryption and access controls to prevent unauthorized monitoring of energy consumption patterns or manipulation of demand response mechanisms. The potential for privacy breaches increases as more granular energy usage information becomes available through these advanced systems.

Regulatory frameworks must evolve to address these emerging security challenges. Current standards often lag behind technological innovation, creating compliance gaps for grid operators implementing anode-free battery solutions. International coordination becomes essential as supply chains for these advanced battery technologies span multiple jurisdictions with varying security requirements and oversight mechanisms.

Ultimately, realizing the full resilience benefits of anode-free batteries requires a comprehensive security-by-design approach that anticipates threats across the entire system lifecycle, from manufacturing to decommissioning. This approach must balance security requirements with the operational flexibility needed to maximize the grid-stabilizing potential of these innovative energy storage technologies.

From a resilience perspective, anode-free batteries offer enhanced grid stability during extreme weather events or cyberattacks by providing localized power reserves. Their higher energy density compared to conventional lithium-ion batteries enables longer-duration backup capabilities at critical infrastructure nodes. This distributed storage architecture creates multiple power islands that can operate independently when the main grid experiences disruption, significantly reducing cascading failure risks.

However, the integration also introduces new attack vectors that must be addressed. The bidirectional communication channels required for optimal battery-grid interaction expand the cyber-physical attack surface. Malicious actors could potentially manipulate battery charging/discharging patterns to destabilize grid frequency or voltage parameters. The sophisticated battery management systems (BMS) controlling these advanced batteries represent high-value targets for attackers seeking to compromise grid operations.

Physical security considerations also evolve with anode-free battery deployment. The higher energy density creates more concentrated points of vulnerability, requiring enhanced physical protection measures. Additionally, the thermal management systems necessary for safe operation of these high-performance batteries must be secured against tampering that could lead to thermal runaway events.

Data security becomes increasingly critical as anode-free battery systems generate vast amounts of operational data used for grid optimization. This data requires robust encryption and access controls to prevent unauthorized monitoring of energy consumption patterns or manipulation of demand response mechanisms. The potential for privacy breaches increases as more granular energy usage information becomes available through these advanced systems.

Regulatory frameworks must evolve to address these emerging security challenges. Current standards often lag behind technological innovation, creating compliance gaps for grid operators implementing anode-free battery solutions. International coordination becomes essential as supply chains for these advanced battery technologies span multiple jurisdictions with varying security requirements and oversight mechanisms.

Ultimately, realizing the full resilience benefits of anode-free batteries requires a comprehensive security-by-design approach that anticipates threats across the entire system lifecycle, from manufacturing to decommissioning. This approach must balance security requirements with the operational flexibility needed to maximize the grid-stabilizing potential of these innovative energy storage technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!