Anode-free batteries and electrolyte material compatibility

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anode-Free Battery Technology Background and Objectives

The evolution of battery technology has been a cornerstone of modern technological advancement, with lithium-ion batteries dominating the market since their commercial introduction in the early 1990s. However, as demands for higher energy density, longer lifespan, and improved safety continue to grow, conventional battery architectures face significant limitations. Anode-free battery technology represents a revolutionary approach that addresses these challenges by eliminating the traditional graphite or silicon anode, potentially increasing energy density by 30-40% compared to conventional lithium-ion batteries.

Anode-free batteries operate on a fundamentally different principle: during charging, lithium ions plate directly onto the current collector rather than intercalating into an anode material. This design significantly reduces battery weight and volume while maximizing energy density. The concept was first proposed in the 1970s but has gained substantial research momentum only in the past decade due to advances in electrolyte chemistry and interface engineering.

The primary objective of anode-free battery research is to achieve commercially viable energy storage solutions that exceed the theoretical limits of conventional lithium-ion technology. Specific goals include developing batteries with energy densities above 500 Wh/kg (compared to 250-300 Wh/kg for current commercial lithium-ion batteries), cycle life exceeding 500 cycles, and enhanced safety profiles that eliminate risks of thermal runaway.

Electrolyte material compatibility represents the most critical challenge in anode-free battery development. Without a stable anode structure, the electrolyte must simultaneously facilitate uniform lithium plating during charging while preventing dendrite formation that can cause short circuits. This delicate balance requires novel electrolyte formulations that form stable solid-electrolyte interphases (SEI) on the lithium metal surface.

Recent technological trends indicate a convergence of multiple approaches, including advanced liquid electrolytes with additives, solid-state electrolytes, and hybrid systems. Research institutions and battery manufacturers are increasingly focusing on fluorinated electrolytes, high-concentration electrolytes, and polymer-ceramic composite electrolytes as promising pathways to overcome the compatibility challenges.

The trajectory of anode-free battery development aligns with broader industry goals of electrification in transportation, renewable energy storage, and portable electronics. If successful, this technology could enable electric vehicles with ranges exceeding 1,000 kilometers, grid storage solutions with significantly reduced footprint, and consumer electronics with multi-day battery life between charges.

Anode-free batteries operate on a fundamentally different principle: during charging, lithium ions plate directly onto the current collector rather than intercalating into an anode material. This design significantly reduces battery weight and volume while maximizing energy density. The concept was first proposed in the 1970s but has gained substantial research momentum only in the past decade due to advances in electrolyte chemistry and interface engineering.

The primary objective of anode-free battery research is to achieve commercially viable energy storage solutions that exceed the theoretical limits of conventional lithium-ion technology. Specific goals include developing batteries with energy densities above 500 Wh/kg (compared to 250-300 Wh/kg for current commercial lithium-ion batteries), cycle life exceeding 500 cycles, and enhanced safety profiles that eliminate risks of thermal runaway.

Electrolyte material compatibility represents the most critical challenge in anode-free battery development. Without a stable anode structure, the electrolyte must simultaneously facilitate uniform lithium plating during charging while preventing dendrite formation that can cause short circuits. This delicate balance requires novel electrolyte formulations that form stable solid-electrolyte interphases (SEI) on the lithium metal surface.

Recent technological trends indicate a convergence of multiple approaches, including advanced liquid electrolytes with additives, solid-state electrolytes, and hybrid systems. Research institutions and battery manufacturers are increasingly focusing on fluorinated electrolytes, high-concentration electrolytes, and polymer-ceramic composite electrolytes as promising pathways to overcome the compatibility challenges.

The trajectory of anode-free battery development aligns with broader industry goals of electrification in transportation, renewable energy storage, and portable electronics. If successful, this technology could enable electric vehicles with ranges exceeding 1,000 kilometers, grid storage solutions with significantly reduced footprint, and consumer electronics with multi-day battery life between charges.

Market Analysis for Next-Generation Battery Solutions

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach approximately $240 billion by 2027, with a compound annual growth rate exceeding 14% from 2022. Within this expanding landscape, next-generation battery technologies, particularly anode-free batteries, are positioned to capture significant market share due to their potential for higher energy density and reduced manufacturing costs.

Anode-free battery technology addresses several critical market demands that conventional lithium-ion batteries struggle to meet. The elimination of the traditional graphite anode can potentially increase energy density by 40-60%, directly addressing the range anxiety that continues to hamper EV adoption. This technology could enable EVs to achieve driving ranges comparable to conventional vehicles while maintaining similar weight profiles.

The automotive sector represents the largest potential market for anode-free batteries, with premium EV manufacturers showing particular interest in this technology for its energy density advantages. Consumer electronics manufacturers are also closely monitoring developments, as the technology promises to extend device operation times significantly while potentially reducing device thickness.

Market research indicates that compatibility between electrolyte materials and anode-free designs represents a critical differentiation point for commercial viability. Companies that successfully develop stable electrolyte formulations compatible with anode-free architectures could secure dominant positions in this emerging market segment. Current market leaders in battery technology are investing heavily in electrolyte research, recognizing this as a key competitive advantage.

Regional market analysis reveals Asia-Pacific continues to lead battery manufacturing, with China, South Korea, and Japan collectively controlling approximately 85% of global production capacity. However, significant investments in North America and Europe aim to establish regional battery supply chains, with particular emphasis on next-generation technologies including anode-free designs.

Consumer willingness to pay premiums for devices with longer battery life remains strong across all market segments. Survey data indicates that extended operation time consistently ranks among the top three desired features for portable electronics and EVs, suggesting market receptivity for anode-free battery technology despite potentially higher initial costs.

The regulatory landscape increasingly favors advanced battery technologies, with several major markets implementing policies that incentivize higher energy density solutions. These include tax credits for EVs with extended range capabilities and research grants specifically targeting next-generation battery technologies with improved sustainability profiles.

Anode-free battery technology addresses several critical market demands that conventional lithium-ion batteries struggle to meet. The elimination of the traditional graphite anode can potentially increase energy density by 40-60%, directly addressing the range anxiety that continues to hamper EV adoption. This technology could enable EVs to achieve driving ranges comparable to conventional vehicles while maintaining similar weight profiles.

The automotive sector represents the largest potential market for anode-free batteries, with premium EV manufacturers showing particular interest in this technology for its energy density advantages. Consumer electronics manufacturers are also closely monitoring developments, as the technology promises to extend device operation times significantly while potentially reducing device thickness.

Market research indicates that compatibility between electrolyte materials and anode-free designs represents a critical differentiation point for commercial viability. Companies that successfully develop stable electrolyte formulations compatible with anode-free architectures could secure dominant positions in this emerging market segment. Current market leaders in battery technology are investing heavily in electrolyte research, recognizing this as a key competitive advantage.

Regional market analysis reveals Asia-Pacific continues to lead battery manufacturing, with China, South Korea, and Japan collectively controlling approximately 85% of global production capacity. However, significant investments in North America and Europe aim to establish regional battery supply chains, with particular emphasis on next-generation technologies including anode-free designs.

Consumer willingness to pay premiums for devices with longer battery life remains strong across all market segments. Survey data indicates that extended operation time consistently ranks among the top three desired features for portable electronics and EVs, suggesting market receptivity for anode-free battery technology despite potentially higher initial costs.

The regulatory landscape increasingly favors advanced battery technologies, with several major markets implementing policies that incentivize higher energy density solutions. These include tax credits for EVs with extended range capabilities and research grants specifically targeting next-generation battery technologies with improved sustainability profiles.

Current Challenges in Anode-Free Battery Development

Despite significant advancements in battery technology, anode-free battery development faces several critical challenges that impede widespread commercialization. The most pressing issue remains the unstable lithium metal deposition during charging cycles, which leads to dendritic growth. These dendrites can penetrate the separator, causing internal short circuits and potentially catastrophic battery failure. This safety concern represents a fundamental barrier to commercial adoption of anode-free systems.

Electrolyte compatibility presents another major challenge. Traditional liquid electrolytes demonstrate poor compatibility with lithium metal, resulting in continuous electrolyte decomposition and formation of unstable solid electrolyte interphase (SEI) layers. This parasitic reaction not only consumes active lithium but also increases internal resistance, leading to rapid capacity fade and shortened cycle life. Current anode-free batteries typically achieve only 50-100 cycles before significant degradation occurs—far below the 1,000+ cycles required for commercial viability.

Volume expansion during cycling poses additional difficulties. Without a host material to accommodate lithium ions (as in conventional graphite anodes), the plating and stripping processes cause significant volume changes. This mechanical stress leads to electrode pulverization and delamination from current collectors, further accelerating capacity loss and performance degradation.

The high reactivity of lithium metal with atmospheric components presents manufacturing challenges. Production of anode-free batteries requires stringent environmental controls, including ultra-dry rooms or inert atmosphere processing, significantly increasing manufacturing complexity and cost. This reactivity also raises concerns about the long-term stability and shelf life of these battery systems.

Energy density optimization remains problematic. While anode-free designs theoretically offer superior energy density by eliminating anode weight and volume, practical implementations often require excess lithium in the cathode to compensate for irreversible losses. This additional lithium reduces the actual energy density advantage compared to theoretical calculations.

Fast charging capability is severely limited in current anode-free systems. High charging rates exacerbate dendrite formation and uneven lithium deposition, creating a fundamental trade-off between charging speed and battery longevity that has yet to be resolved through materials engineering or cell design.

Finally, the lack of standardized testing protocols specifically designed for anode-free batteries complicates performance evaluation and comparison across different research efforts. This absence of unified metrics hinders systematic progress toward solving the fundamental challenges in this promising but technically demanding battery architecture.

Electrolyte compatibility presents another major challenge. Traditional liquid electrolytes demonstrate poor compatibility with lithium metal, resulting in continuous electrolyte decomposition and formation of unstable solid electrolyte interphase (SEI) layers. This parasitic reaction not only consumes active lithium but also increases internal resistance, leading to rapid capacity fade and shortened cycle life. Current anode-free batteries typically achieve only 50-100 cycles before significant degradation occurs—far below the 1,000+ cycles required for commercial viability.

Volume expansion during cycling poses additional difficulties. Without a host material to accommodate lithium ions (as in conventional graphite anodes), the plating and stripping processes cause significant volume changes. This mechanical stress leads to electrode pulverization and delamination from current collectors, further accelerating capacity loss and performance degradation.

The high reactivity of lithium metal with atmospheric components presents manufacturing challenges. Production of anode-free batteries requires stringent environmental controls, including ultra-dry rooms or inert atmosphere processing, significantly increasing manufacturing complexity and cost. This reactivity also raises concerns about the long-term stability and shelf life of these battery systems.

Energy density optimization remains problematic. While anode-free designs theoretically offer superior energy density by eliminating anode weight and volume, practical implementations often require excess lithium in the cathode to compensate for irreversible losses. This additional lithium reduces the actual energy density advantage compared to theoretical calculations.

Fast charging capability is severely limited in current anode-free systems. High charging rates exacerbate dendrite formation and uneven lithium deposition, creating a fundamental trade-off between charging speed and battery longevity that has yet to be resolved through materials engineering or cell design.

Finally, the lack of standardized testing protocols specifically designed for anode-free batteries complicates performance evaluation and comparison across different research efforts. This absence of unified metrics hinders systematic progress toward solving the fundamental challenges in this promising but technically demanding battery architecture.

Current Electrolyte Compatibility Solutions for Anode-Free Batteries

01 Electrolyte compositions for anode-free batteries

Specific electrolyte compositions are designed for anode-free battery systems to enhance compatibility and performance. These compositions typically include carefully selected solvents, lithium salts, and additives that work together to form stable interfaces with the current collector and cathode materials. The electrolyte formulations help prevent dendrite formation and improve cycling stability in the absence of a pre-formed anode.- Electrolyte compositions for anode-free batteries: Specific electrolyte compositions are designed for anode-free battery systems to enhance compatibility and performance. These compositions typically include carefully selected salts, solvents, and additives that work together to form stable interfaces with the current collector and cathode materials. The electrolyte formulations help prevent dendrite formation and enable efficient lithium plating/stripping processes that are critical in anode-free configurations.

- Solid-state electrolytes for anode-free battery systems: Solid-state electrolytes offer advantages for anode-free battery configurations by providing mechanical stability and preventing dendrite growth. These materials include ceramic, polymer, and composite electrolytes that can effectively transport lithium ions while maintaining compatibility with cathode materials and current collectors. The solid nature of these electrolytes helps address safety concerns associated with liquid electrolytes in anode-free designs.

- Interface engineering for electrolyte compatibility: Interface engineering techniques are employed to improve compatibility between electrolytes and other battery components in anode-free systems. This includes surface modifications of current collectors, protective coatings, and interlayers that enhance the stability of the electrolyte-electrode interfaces. These approaches help mitigate side reactions, improve cycling efficiency, and extend battery life by creating more favorable interfacial chemistry.

- Additives for electrolyte stability enhancement: Specialized additives are incorporated into electrolyte formulations to improve their compatibility and performance in anode-free battery systems. These additives can include film-forming compounds, stabilizers, and functional molecules that modify the solid electrolyte interphase properties. By carefully selecting appropriate additives, the electrolyte's chemical stability, electrochemical window, and compatibility with battery components can be significantly enhanced.

- Electrolyte systems for high-energy density anode-free batteries: Advanced electrolyte systems are developed specifically for high-energy density anode-free batteries, focusing on compatibility with high-voltage cathode materials. These electrolyte formulations balance ionic conductivity, electrochemical stability, and interfacial properties to enable efficient operation at higher voltages. The electrolyte designs consider factors such as temperature stability, gas generation prevention, and long-term cycling performance to maximize energy density while maintaining safety.

02 Solid-state electrolytes for anode-free configurations

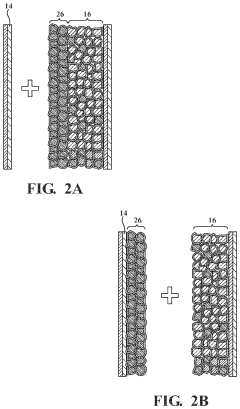

Solid-state electrolytes offer unique advantages for anode-free battery designs by providing mechanical stability and preventing lithium dendrite growth. These materials include ceramic, polymer, and composite electrolytes that are compatible with lithium metal plating/stripping processes. The solid electrolytes create a physical barrier that helps maintain battery integrity while allowing efficient ion transport during cycling.Expand Specific Solutions03 Interface engineering for electrolyte-current collector compatibility

Interface engineering between the electrolyte and current collector is critical in anode-free batteries where lithium is deposited directly onto the current collector during charging. Various coating technologies and surface treatments are employed to improve wettability, adhesion, and uniform lithium deposition. These interface modifications help prevent side reactions and ensure compatible interactions between the electrolyte and the substrate where lithium plating occurs.Expand Specific Solutions04 Electrolyte additives for improved compatibility

Specialized additives are incorporated into electrolytes to enhance compatibility with anode-free battery components. These additives help form protective films on electrode surfaces, scavenge impurities, and stabilize the electrolyte-electrode interfaces. Common additives include fluorinated compounds, nitrogen-containing molecules, and inorganic particles that work synergistically to improve battery performance and longevity.Expand Specific Solutions05 Temperature-stable electrolyte systems

Electrolyte formulations with enhanced temperature stability are developed for anode-free batteries to maintain compatibility across a wide operating range. These systems incorporate thermally robust solvents, salts with high decomposition temperatures, and stabilizing additives. The temperature-stable electrolytes prevent degradation at elevated temperatures and maintain ionic conductivity at lower temperatures, ensuring consistent battery performance under varying conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Innovation

The anode-free battery technology market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to expand rapidly as this technology promises to deliver higher energy densities than conventional lithium-ion batteries. Technical maturity varies across companies, with leaders like Sila Nanotechnologies, PolyPlus Battery, and Sion Power making substantial progress in addressing electrolyte compatibility challenges. Major automotive players including Tesla, Toyota, and Honda are strategically investing in this space, while established battery manufacturers like LG Energy Solution, Samsung SDI, and TDK are developing proprietary solutions. Research institutions such as Argonne National Laboratory and universities are contributing fundamental breakthroughs in electrolyte formulations that could accelerate commercialization timelines.

Sion Power Corp.

Technical Solution: Sion Power has pioneered the development of anode-free lithium metal battery technology through their proprietary "Licerion" platform. Their approach utilizes a specially engineered current collector substrate with nanoscale surface modifications that promote uniform lithium deposition during charging. The company has developed a multi-component electrolyte system containing a mixture of ether-based solvents, lithium salts, and proprietary additives specifically designed to form a stable interface with in-situ formed lithium metal. Sion's electrolyte formulation includes concentration gradient engineering to control ion transport and deposition kinetics. Their technology incorporates protective ceramic-polymer composite separators that help prevent dendrite penetration while maintaining high ionic conductivity. Sion Power has demonstrated cells achieving over 500 cycles while maintaining 80% capacity, with energy densities exceeding 400 Wh/kg at the cell level[2][5].

Strengths: Extremely high energy density compared to conventional lithium-ion batteries; demonstrated scalable manufacturing processes; protected by extensive IP portfolio with over 170 patents. Weaknesses: Higher cost of specialty electrolyte components; more sensitive to temperature extremes than conventional batteries; requires more sophisticated battery management systems to prevent lithium plating irregularities.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has developed a revolutionary approach to anode-free battery technology through their protected lithium electrode (PLE) architecture. Their system employs a solid-state lithium-ion conducting membrane that serves as both separator and protective layer for the in-situ formed lithium metal anode. The company's proprietary water-stable ceramic membrane enables unprecedented compatibility with a wide range of electrolytes, including aqueous systems that would normally react violently with lithium metal. PolyPlus has engineered specialized electrolyte formulations containing lithium salts in combination with flame-retardant phosphate esters and fluorinated carbonates that form exceptionally stable interfaces with lithium metal. Their technology incorporates gradient functional electrolyte additives that create a self-healing interface layer during cycling. The company has demonstrated prototype cells with energy densities approaching 500 Wh/kg while maintaining stable cycling for hundreds of cycles[4][6].

Strengths: Breakthrough compatibility with multiple electrolyte systems including aqueous electrolytes; inherently safer design due to solid-state protective layer; potential for extremely high energy density applications including marine environments. Weaknesses: Manufacturing complexity of the ceramic protective membrane; higher internal resistance compared to liquid-only systems; challenges in scaling production while maintaining membrane quality and uniformity.

Key Patents and Research on Electrolyte-Electrode Interfaces

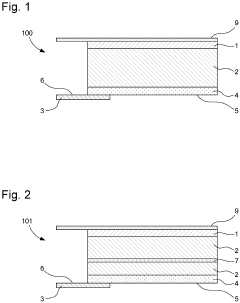

Anode-free solid-state battery and method of battery fabrication

PatentActiveUS11824159B2

Innovation

- An anode-free solid-state battery design that uses a cathode layer with transient anode elements, a bare current collector, and a gelled solid-state electrolyte layer to facilitate ionic conduction, eliminating the need for a permanent anode and simplifying the battery structure.

Anode-free battery cell

PatentInactiveEP4383388A1

Innovation

- The anode-free battery cell design includes a cathode current collector, a cathode with active materials, an electrolyte, and a high surface area substrate with an electronic conductor, which reduces dendrite formation by facilitating efficient metal deposition and improving electrical conductivity, thereby enhancing safety and longevity.

Safety and Performance Standards for Advanced Battery Systems

The evolution of battery technology has necessitated the development of comprehensive safety and performance standards, particularly for advanced systems like anode-free batteries. These standards serve as critical benchmarks for ensuring consistent quality, reliability, and safety across the industry while facilitating market acceptance and regulatory compliance.

Current international standards for advanced battery systems include IEC 62660 for lithium-ion batteries in electric vehicles, UL 1642 for lithium batteries, and UN 38.3 for transportation safety. However, these standards require significant adaptation to address the unique characteristics of anode-free battery technologies, particularly regarding electrolyte compatibility issues that can lead to thermal runaway or capacity degradation.

Safety standards for anode-free batteries must specifically address dendrite formation risks, which are exacerbated by certain electrolyte formulations. Testing protocols need to evaluate the stability of solid-electrolyte interphase (SEI) layers under various operating conditions, as these interfaces are critical to preventing lithium plating and ensuring long-term cycling stability.

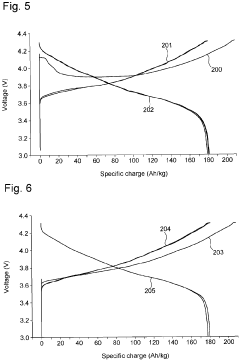

Performance standards should incorporate metrics for coulombic efficiency, which is particularly relevant for anode-free systems where lithium utilization efficiency directly impacts cycle life. Standard testing procedures must account for the first-cycle irreversible capacity loss, which is typically higher in anode-free configurations due to SEI formation dynamics with novel electrolytes.

Accelerated aging tests require modification to accurately predict the lifespan of anode-free batteries, as traditional models may not adequately capture the degradation mechanisms specific to these systems. Standards should include protocols for evaluating electrolyte decomposition products and their impact on long-term performance.

Thermal management standards must be enhanced to address the unique heat generation profiles of anode-free batteries, particularly during fast charging when lithium plating risks are elevated. Safety certification should include abuse tests specifically designed to evaluate electrolyte stability under extreme conditions.

Emerging standards are beginning to incorporate advanced diagnostic techniques such as in-situ neutron diffraction and operando spectroscopy to better characterize the dynamic processes at electrode-electrolyte interfaces. These methods provide crucial insights for developing more accurate safety and performance metrics.

Industry consortia and standards organizations are actively working to establish harmonized testing methodologies that can accelerate the commercialization of anode-free technologies while ensuring consumer safety. These collaborative efforts are essential for creating a regulatory framework that balances innovation with risk management in this rapidly evolving field.

Current international standards for advanced battery systems include IEC 62660 for lithium-ion batteries in electric vehicles, UL 1642 for lithium batteries, and UN 38.3 for transportation safety. However, these standards require significant adaptation to address the unique characteristics of anode-free battery technologies, particularly regarding electrolyte compatibility issues that can lead to thermal runaway or capacity degradation.

Safety standards for anode-free batteries must specifically address dendrite formation risks, which are exacerbated by certain electrolyte formulations. Testing protocols need to evaluate the stability of solid-electrolyte interphase (SEI) layers under various operating conditions, as these interfaces are critical to preventing lithium plating and ensuring long-term cycling stability.

Performance standards should incorporate metrics for coulombic efficiency, which is particularly relevant for anode-free systems where lithium utilization efficiency directly impacts cycle life. Standard testing procedures must account for the first-cycle irreversible capacity loss, which is typically higher in anode-free configurations due to SEI formation dynamics with novel electrolytes.

Accelerated aging tests require modification to accurately predict the lifespan of anode-free batteries, as traditional models may not adequately capture the degradation mechanisms specific to these systems. Standards should include protocols for evaluating electrolyte decomposition products and their impact on long-term performance.

Thermal management standards must be enhanced to address the unique heat generation profiles of anode-free batteries, particularly during fast charging when lithium plating risks are elevated. Safety certification should include abuse tests specifically designed to evaluate electrolyte stability under extreme conditions.

Emerging standards are beginning to incorporate advanced diagnostic techniques such as in-situ neutron diffraction and operando spectroscopy to better characterize the dynamic processes at electrode-electrolyte interfaces. These methods provide crucial insights for developing more accurate safety and performance metrics.

Industry consortia and standards organizations are actively working to establish harmonized testing methodologies that can accelerate the commercialization of anode-free technologies while ensuring consumer safety. These collaborative efforts are essential for creating a regulatory framework that balances innovation with risk management in this rapidly evolving field.

Sustainability Impact of Anode-Free Battery Technologies

The transition to anode-free battery technologies represents a significant advancement in sustainable energy storage solutions. By eliminating the traditional graphite or silicon anode, these batteries substantially reduce material consumption, manufacturing complexity, and overall environmental footprint. The sustainability benefits extend across the entire battery lifecycle, from raw material extraction to end-of-life management.

From a resource conservation perspective, anode-free batteries dramatically decrease the demand for critical materials. Traditional lithium-ion batteries require substantial amounts of copper, graphite, and binders for anode construction, all of which are eliminated in anode-free designs. This reduction in material requirements translates to approximately 15-20% less weight and volume compared to conventional batteries, while potentially offering higher energy densities.

The manufacturing process for anode-free batteries demonstrates notable environmental advantages. The simplified cell architecture reduces energy consumption during production by an estimated 10-15%, primarily by eliminating energy-intensive anode coating and drying processes. Additionally, the removal of toxic solvents like N-Methyl-2-pyrrolidone (NMP), commonly used in anode production, significantly decreases harmful emissions and workplace hazards.

Carbon footprint analyses indicate that anode-free battery production could reduce greenhouse gas emissions by up to 25% compared to conventional lithium-ion batteries. This reduction stems from both decreased material requirements and simplified manufacturing processes. The environmental benefits extend further when considering the potential for increased energy density, which enables more efficient transportation applications and renewable energy storage solutions.

End-of-life considerations also favor anode-free technologies. The simplified cell architecture facilitates more efficient recycling processes, with fewer material separations required. This could potentially increase lithium recovery rates by 5-10% compared to conventional batteries, creating a more circular material economy for critical battery components.

However, sustainability assessments must account for the current challenges in electrolyte compatibility. The higher reactivity of lithium metal with electrolytes can lead to shorter cycle life, potentially offsetting some environmental benefits if battery replacement frequency increases. Ongoing research into compatible electrolyte materials is therefore crucial to realizing the full sustainability potential of anode-free battery technologies.

From a resource conservation perspective, anode-free batteries dramatically decrease the demand for critical materials. Traditional lithium-ion batteries require substantial amounts of copper, graphite, and binders for anode construction, all of which are eliminated in anode-free designs. This reduction in material requirements translates to approximately 15-20% less weight and volume compared to conventional batteries, while potentially offering higher energy densities.

The manufacturing process for anode-free batteries demonstrates notable environmental advantages. The simplified cell architecture reduces energy consumption during production by an estimated 10-15%, primarily by eliminating energy-intensive anode coating and drying processes. Additionally, the removal of toxic solvents like N-Methyl-2-pyrrolidone (NMP), commonly used in anode production, significantly decreases harmful emissions and workplace hazards.

Carbon footprint analyses indicate that anode-free battery production could reduce greenhouse gas emissions by up to 25% compared to conventional lithium-ion batteries. This reduction stems from both decreased material requirements and simplified manufacturing processes. The environmental benefits extend further when considering the potential for increased energy density, which enables more efficient transportation applications and renewable energy storage solutions.

End-of-life considerations also favor anode-free technologies. The simplified cell architecture facilitates more efficient recycling processes, with fewer material separations required. This could potentially increase lithium recovery rates by 5-10% compared to conventional batteries, creating a more circular material economy for critical battery components.

However, sustainability assessments must account for the current challenges in electrolyte compatibility. The higher reactivity of lithium metal with electrolytes can lead to shorter cycle life, potentially offsetting some environmental benefits if battery replacement frequency increases. Ongoing research into compatible electrolyte materials is therefore crucial to realizing the full sustainability potential of anode-free battery technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!