Anti-Reflective Coatings: DLC/SiO₂ Hybrid Stacks, Hardness–Reflectance Trade-Offs And Lifetime

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR Coating Evolution and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when F. Geffcken first developed multilayer interference films. Initially, these coatings were primarily single-layer designs with limited performance capabilities, primarily used in optical instruments with minimal durability requirements. The evolution accelerated during World War II when AR coatings became critical for military optics, driving innovation in both materials and deposition techniques.

By the 1970s, multi-layer AR coating designs emerged, offering improved optical performance across broader wavelength ranges. However, these early multi-layer systems still faced significant durability challenges, particularly in harsh environments or high-touch applications. The 1980s and 1990s saw the introduction of physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques, enabling more precise control over coating thickness and composition.

The integration of diamond-like carbon (DLC) into AR coating systems represents a pivotal advancement in the field, occurring primarily in the early 2000s. DLC offered unprecedented hardness and wear resistance compared to traditional coating materials, though often at the expense of optimal optical performance. This introduced the fundamental trade-off between mechanical durability and optical efficiency that continues to challenge coating engineers today.

The development of hybrid stacks incorporating both DLC and SiO₂ layers emerged as a promising approach to balance these competing requirements. SiO₂ layers provide excellent optical properties with high transparency and customizable refractive indices, while DLC layers contribute superior hardness and scratch resistance. The precise engineering of these hybrid stacks has become increasingly sophisticated, with nanometer-level control over layer thicknesses and interfaces.

Current objectives in AR coating development focus on several key areas: optimizing the hardness-reflectance trade-off to achieve both superior optical performance and mechanical durability; extending coating lifetime under real-world conditions including exposure to environmental stressors; reducing manufacturing costs while maintaining quality; and developing environmentally sustainable production processes.

Specifically for DLC/SiO₂ hybrid stacks, research objectives include improving adhesion between dissimilar materials, minimizing internal stress that can lead to delamination, enhancing resistance to chemical degradation, and developing novel deposition techniques that allow for precise control of layer properties at industrial scales. The ultimate goal is to create AR coatings that maintain optimal optical performance throughout the entire lifetime of the product while withstanding increasingly demanding use conditions.

By the 1970s, multi-layer AR coating designs emerged, offering improved optical performance across broader wavelength ranges. However, these early multi-layer systems still faced significant durability challenges, particularly in harsh environments or high-touch applications. The 1980s and 1990s saw the introduction of physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques, enabling more precise control over coating thickness and composition.

The integration of diamond-like carbon (DLC) into AR coating systems represents a pivotal advancement in the field, occurring primarily in the early 2000s. DLC offered unprecedented hardness and wear resistance compared to traditional coating materials, though often at the expense of optimal optical performance. This introduced the fundamental trade-off between mechanical durability and optical efficiency that continues to challenge coating engineers today.

The development of hybrid stacks incorporating both DLC and SiO₂ layers emerged as a promising approach to balance these competing requirements. SiO₂ layers provide excellent optical properties with high transparency and customizable refractive indices, while DLC layers contribute superior hardness and scratch resistance. The precise engineering of these hybrid stacks has become increasingly sophisticated, with nanometer-level control over layer thicknesses and interfaces.

Current objectives in AR coating development focus on several key areas: optimizing the hardness-reflectance trade-off to achieve both superior optical performance and mechanical durability; extending coating lifetime under real-world conditions including exposure to environmental stressors; reducing manufacturing costs while maintaining quality; and developing environmentally sustainable production processes.

Specifically for DLC/SiO₂ hybrid stacks, research objectives include improving adhesion between dissimilar materials, minimizing internal stress that can lead to delamination, enhancing resistance to chemical degradation, and developing novel deposition techniques that allow for precise control of layer properties at industrial scales. The ultimate goal is to create AR coatings that maintain optimal optical performance throughout the entire lifetime of the product while withstanding increasingly demanding use conditions.

Market Analysis for DLC/SiO₂ Hybrid Coatings

The global market for anti-reflective coatings has been experiencing robust growth, with the DLC/SiO₂ hybrid coatings segment emerging as a particularly promising area. Current market valuations place the anti-reflective coatings market at approximately 4.5 billion USD, with projections indicating a compound annual growth rate of 6.7% through 2028. Within this broader market, DLC/SiO₂ hybrid systems are gaining significant traction due to their unique combination of optical and mechanical properties.

Consumer electronics represents the largest application sector for these hybrid coatings, accounting for nearly 35% of market demand. The increasing prevalence of touchscreen devices, high-resolution displays, and wearable technology has created substantial demand for coatings that can deliver both optical clarity and durability. Major smartphone manufacturers have begun incorporating these hybrid systems in their flagship devices, citing improved scratch resistance and reduced glare as key selling points.

The optical industry follows as the second-largest market segment, where precision optics manufacturers are adopting DLC/SiO₂ hybrid coatings for high-end camera lenses, microscopes, and specialized scientific instruments. This sector values the balance between hardness and anti-reflective properties that these hybrid stacks uniquely provide.

Automotive applications represent the fastest-growing segment, with a projected growth rate of 8.3% annually. Advanced driver assistance systems (ADAS) and autonomous vehicle sensors require optical components with exceptional durability and minimal light reflection. The automotive sector's stringent requirements for component longevity in harsh environmental conditions make DLC/SiO₂ hybrid coatings particularly attractive.

Regionally, Asia-Pacific dominates the market with approximately 42% share, driven by the concentration of electronics manufacturing and growing automotive production. North America and Europe follow with 27% and 23% market shares respectively, with particular strength in high-precision optical applications and premium automotive segments.

The competitive landscape features both established coating technology companies and emerging specialists. Major players include Schott AG, Nippon Electric Glass, and PPG Industries, who have established production capabilities for these hybrid systems. Several specialized firms like DiamondLike Carbon Technologies and SiO₂ Innovations have emerged as technology leaders focusing exclusively on hybrid coating development.

Customer feedback indicates growing awareness of lifetime value considerations, with many end-users willing to pay premium prices for coatings that demonstrate superior durability metrics. This trend suggests that manufacturers who can effectively communicate the long-term cost benefits of their hybrid coating solutions stand to capture greater market share despite higher initial pricing.

Consumer electronics represents the largest application sector for these hybrid coatings, accounting for nearly 35% of market demand. The increasing prevalence of touchscreen devices, high-resolution displays, and wearable technology has created substantial demand for coatings that can deliver both optical clarity and durability. Major smartphone manufacturers have begun incorporating these hybrid systems in their flagship devices, citing improved scratch resistance and reduced glare as key selling points.

The optical industry follows as the second-largest market segment, where precision optics manufacturers are adopting DLC/SiO₂ hybrid coatings for high-end camera lenses, microscopes, and specialized scientific instruments. This sector values the balance between hardness and anti-reflective properties that these hybrid stacks uniquely provide.

Automotive applications represent the fastest-growing segment, with a projected growth rate of 8.3% annually. Advanced driver assistance systems (ADAS) and autonomous vehicle sensors require optical components with exceptional durability and minimal light reflection. The automotive sector's stringent requirements for component longevity in harsh environmental conditions make DLC/SiO₂ hybrid coatings particularly attractive.

Regionally, Asia-Pacific dominates the market with approximately 42% share, driven by the concentration of electronics manufacturing and growing automotive production. North America and Europe follow with 27% and 23% market shares respectively, with particular strength in high-precision optical applications and premium automotive segments.

The competitive landscape features both established coating technology companies and emerging specialists. Major players include Schott AG, Nippon Electric Glass, and PPG Industries, who have established production capabilities for these hybrid systems. Several specialized firms like DiamondLike Carbon Technologies and SiO₂ Innovations have emerged as technology leaders focusing exclusively on hybrid coating development.

Customer feedback indicates growing awareness of lifetime value considerations, with many end-users willing to pay premium prices for coatings that demonstrate superior durability metrics. This trend suggests that manufacturers who can effectively communicate the long-term cost benefits of their hybrid coating solutions stand to capture greater market share despite higher initial pricing.

Technical Challenges in Hardness-Reflectance Balance

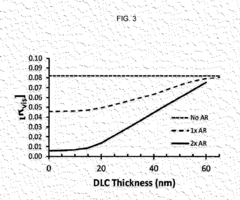

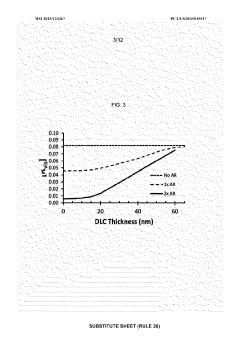

The fundamental challenge in developing effective anti-reflective coatings using DLC/SiO₂ hybrid stacks lies in the inherent trade-off between hardness and reflectance properties. Diamond-like carbon (DLC) offers exceptional hardness (15-80 GPa) and wear resistance but typically exhibits higher refractive indices (1.6-2.4), which can increase reflectance. Conversely, SiO₂ provides excellent anti-reflective properties with its lower refractive index (approximately 1.46) but lacks the mechanical durability of DLC.

Current engineering approaches attempt to balance these competing properties through multilayer designs, but achieving optimal performance remains elusive. The interface between DLC and SiO₂ layers presents particular difficulties, as adhesion issues can lead to delamination under thermal or mechanical stress. This interface weakness significantly impacts coating lifetime and performance stability in real-world applications.

Material composition variations further complicate the optimization process. DLC properties vary substantially depending on sp²/sp³ carbon bonding ratios and hydrogen content, while SiO₂ performance depends on deposition method and resulting film density. These variations create inconsistencies in optical and mechanical properties that make standardization challenging across manufacturing processes.

Deposition techniques present another significant hurdle. While plasma-enhanced chemical vapor deposition (PECVD) is commonly used for DLC layers, and physical vapor deposition (PVD) for SiO₂, integrating these processes to create hybrid stacks introduces thermal management issues. Temperature differentials during deposition can induce internal stresses that compromise coating integrity and adhesion.

Environmental stability represents a critical concern for these hybrid coatings. Exposure to humidity, UV radiation, and temperature fluctuations can accelerate degradation at the DLC/SiO₂ interface. This environmental sensitivity reduces coating lifetime, particularly in outdoor applications or harsh industrial environments where consistent performance is essential.

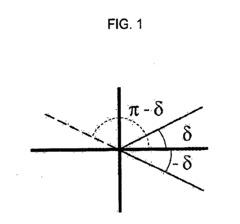

Thickness control presents another technical challenge. Anti-reflective performance requires precise quarter-wavelength optical thickness for maximum destructive interference of reflected light. However, increasing coating thickness to enhance optical performance often reduces mechanical flexibility and increases internal stress, leading to potential cracking or delamination under load.

Cost-effective manufacturing at scale remains problematic. While laboratory demonstrations have shown promising results, translating these into economically viable industrial processes with consistent quality control has proven difficult. The complex deposition parameters and precise environmental controls required for optimal DLC/SiO₂ hybrid stacks significantly increase production costs compared to conventional coatings.

Current engineering approaches attempt to balance these competing properties through multilayer designs, but achieving optimal performance remains elusive. The interface between DLC and SiO₂ layers presents particular difficulties, as adhesion issues can lead to delamination under thermal or mechanical stress. This interface weakness significantly impacts coating lifetime and performance stability in real-world applications.

Material composition variations further complicate the optimization process. DLC properties vary substantially depending on sp²/sp³ carbon bonding ratios and hydrogen content, while SiO₂ performance depends on deposition method and resulting film density. These variations create inconsistencies in optical and mechanical properties that make standardization challenging across manufacturing processes.

Deposition techniques present another significant hurdle. While plasma-enhanced chemical vapor deposition (PECVD) is commonly used for DLC layers, and physical vapor deposition (PVD) for SiO₂, integrating these processes to create hybrid stacks introduces thermal management issues. Temperature differentials during deposition can induce internal stresses that compromise coating integrity and adhesion.

Environmental stability represents a critical concern for these hybrid coatings. Exposure to humidity, UV radiation, and temperature fluctuations can accelerate degradation at the DLC/SiO₂ interface. This environmental sensitivity reduces coating lifetime, particularly in outdoor applications or harsh industrial environments where consistent performance is essential.

Thickness control presents another technical challenge. Anti-reflective performance requires precise quarter-wavelength optical thickness for maximum destructive interference of reflected light. However, increasing coating thickness to enhance optical performance often reduces mechanical flexibility and increases internal stress, leading to potential cracking or delamination under load.

Cost-effective manufacturing at scale remains problematic. While laboratory demonstrations have shown promising results, translating these into economically viable industrial processes with consistent quality control has proven difficult. The complex deposition parameters and precise environmental controls required for optimal DLC/SiO₂ hybrid stacks significantly increase production costs compared to conventional coatings.

Current DLC/SiO₂ Hybrid Stack Solutions

01 DLC/SiO₂ multilayer stack design for optimized anti-reflective properties

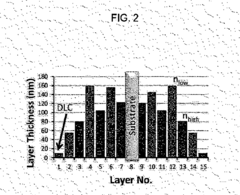

Diamond-like carbon (DLC) and silicon dioxide (SiO₂) can be combined in multilayer stacks to create effective anti-reflective coatings. By carefully designing the thickness and sequence of alternating DLC and SiO₂ layers, the optical properties can be optimized to minimize reflection across desired wavelength ranges. These hybrid stacks leverage the complementary refractive indices of the materials to achieve broadband anti-reflective performance while maintaining good mechanical durability.- DLC/SiO₂ hybrid stack structure and composition: Diamond-like carbon (DLC) and silicon dioxide (SiO₂) can be combined in hybrid stack structures to create anti-reflective coatings with enhanced properties. These stacks typically consist of alternating layers of DLC and SiO₂, with carefully controlled thicknesses to achieve desired optical properties. The composition and thickness of each layer can be optimized to balance hardness and reflectance characteristics. Various deposition methods, including plasma-enhanced chemical vapor deposition (PECVD) and sputtering, can be used to create these hybrid stacks.

- Hardness-reflectance trade-off optimization: The trade-off between hardness and anti-reflective properties is a key consideration in DLC/SiO₂ hybrid coatings. While DLC provides excellent hardness and scratch resistance, SiO₂ contributes to improved anti-reflective properties. By adjusting the ratio of DLC to SiO₂, the thickness of individual layers, and the total number of layers, the coating can be optimized for specific applications. Advanced deposition techniques and post-deposition treatments can further enhance the balance between mechanical durability and optical performance.

- Lifetime enhancement and durability mechanisms: The lifetime of DLC/SiO₂ hybrid anti-reflective coatings can be significantly improved through various mechanisms. Incorporating adhesion-promoting interlayers between the substrate and coating enhances durability. Surface treatments and the addition of dopants to the DLC layers can reduce internal stress and improve environmental stability. Protective top layers can shield against environmental factors like moisture, chemicals, and UV radiation. Testing protocols including accelerated aging, abrasion resistance, and environmental exposure help predict and improve coating lifetime in real-world applications.

- Application-specific coating designs: DLC/SiO₂ hybrid anti-reflective coatings can be tailored for specific applications with unique requirements. For optical devices like lenses and displays, emphasis is placed on maximizing light transmission while maintaining clarity. In solar applications, coatings are designed to maximize energy absorption across specific wavelength ranges. For electronic devices and sensors, coatings must provide both optical performance and protection against environmental factors. The coating design process involves modeling and simulation to predict optical and mechanical performance before fabrication.

- Advanced characterization and testing methods: Sophisticated characterization and testing methods are essential for evaluating DLC/SiO₂ hybrid anti-reflective coatings. Spectroscopic ellipsometry and reflectometry are used to measure optical properties and layer thicknesses. Nanoindentation and scratch testing quantify mechanical properties like hardness and adhesion. Accelerated weathering tests, including humidity, temperature cycling, and UV exposure, help predict coating lifetime. Advanced microscopy techniques such as atomic force microscopy (AFM) and scanning electron microscopy (SEM) are employed to analyze surface morphology and coating defects.

02 Hardness enhancement techniques in DLC/SiO₂ hybrid coatings

Various methods can be employed to enhance the hardness of DLC/SiO₂ hybrid anti-reflective coatings without significantly compromising optical performance. These include doping the DLC layers with elements like nitrogen or silicon, optimizing deposition parameters such as bias voltage and temperature, and incorporating adhesion-promoting interlayers. The hardness-reflectance trade-off can be managed by adjusting the relative thickness of the harder DLC layers versus the more optically efficient SiO₂ layers.Expand Specific Solutions03 Lifetime enhancement and durability improvements for hybrid anti-reflective coatings

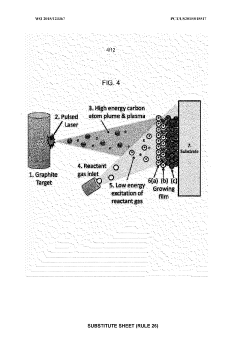

The lifetime of DLC/SiO₂ hybrid anti-reflective coatings can be extended through various approaches. These include surface treatments to improve adhesion between layers, incorporation of barrier layers to prevent moisture ingress, optimization of internal stress within the coating stack, and development of specialized cleaning protocols. Environmental stability can be enhanced by adding protective top layers or by modifying the chemical composition of the DLC to improve resistance to oxidation and wear.Expand Specific Solutions04 Deposition techniques for DLC/SiO₂ hybrid anti-reflective coatings

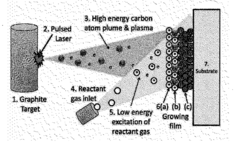

Various deposition methods can be used to create DLC/SiO₂ hybrid anti-reflective coatings with controlled properties. These include plasma-enhanced chemical vapor deposition (PECVD), magnetron sputtering, ion beam deposition, and filtered cathodic vacuum arc. Each technique offers different advantages in terms of layer density, adhesion, stress control, and scalability. The choice of deposition method significantly impacts the microstructure of the films and consequently affects both optical and mechanical properties of the coating.Expand Specific Solutions05 Characterization and testing methods for DLC/SiO₂ hybrid anti-reflective coatings

Specialized characterization and testing methods are essential for evaluating the performance and durability of DLC/SiO₂ hybrid anti-reflective coatings. These include spectroscopic ellipsometry for optical property measurement, nanoindentation for hardness testing, adhesion tests such as scratch and tape tests, accelerated environmental testing for lifetime prediction, and atomic force microscopy for surface roughness analysis. These methods help in understanding the relationship between processing conditions, coating structure, and the resulting optical and mechanical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The anti-reflective coatings market, particularly DLC/SiO₂ hybrid stacks, is in a growth phase characterized by increasing demand across optical and electronic applications. The market is expanding due to rising needs in eyewear, display technologies, and precision optics, with an estimated global value exceeding $4 billion. Technologically, the field faces ongoing challenges in balancing hardness and reflectance properties while extending coating lifetimes. Industry leaders demonstrate varying technological maturity: EssilorLuxottica dominates the eyewear segment; Corning, AGC, and Schott lead in specialty glass applications; while Fraunhofer-Gesellschaft and Carl Zeiss SMT represent cutting-edge research in optical coatings. Companies like Canon, Nitto Denko, and Shin-Etsu Chemical are advancing material science innovations to overcome the fundamental trade-offs between mechanical durability and optical performance.

EssilorLuxottica SA

Technical Solution: EssilorLuxottica has developed a proprietary DLC/SiO₂ hybrid stack anti-reflective coating system specifically optimized for ophthalmic applications. Their technology, branded as "Crizal Rock," represents the culmination of extensive research into balancing optical clarity with exceptional scratch resistance and durability. The coating architecture employs alternating nanolayers of DLC and SiO₂ with precisely engineered thickness gradients to achieve both anti-reflective properties and mechanical hardness. EssilorLuxottica's manufacturing process utilizes a combination of plasma-enhanced chemical vapor deposition and ion-assisted deposition to create coatings with controlled stress and excellent adhesion to lens substrates. Their latest generation coatings achieve a Vickers hardness of 10-12 GPa while maintaining reflectance below 0.5% across the visible spectrum. The company has implemented a comprehensive accelerated aging protocol that simulates real-world wear conditions, including exposure to UV radiation, temperature cycling, humidity, and mechanical abrasion. Their premium coatings demonstrate less than 10% performance degradation after testing equivalent to 2+ years of typical consumer use, significantly outperforming conventional anti-reflective coatings.

Strengths: Excellent balance of optical clarity and scratch resistance specifically optimized for everyday eyewear; superior resistance to smudges and ease of cleaning; proven durability in real-world consumer use conditions. Weaknesses: Higher manufacturing costs reflected in premium pricing; limited applicability outside ophthalmic applications; slightly higher reflectance compared to specialized industrial coatings.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed a cutting-edge approach to DLC/SiO₂ hybrid stack anti-reflective coatings through their specialized institutes focusing on thin film technology and applied optics. Their research has yielded a modular coating architecture that allows customization of optical and mechanical properties for specific applications. The technology employs a gradient-composition approach where carbon content is precisely varied throughout the coating thickness, creating a continuous transition between DLC-dominant and SiO₂-dominant regions. This approach minimizes internal stress while maintaining excellent adhesion to various substrate materials. Fraunhofer's deposition process combines magnetron sputtering for the SiO₂ components with filtered cathodic vacuum arc for the DLC layers, allowing precise control of sp³/sp² carbon bonding ratios that directly influence hardness and optical properties. Their coatings achieve hardness values of 15-25 GPa while maintaining reflectance below 0.3% across targeted wavelength ranges. Fraunhofer has also developed advanced characterization methods for predicting coating lifetime, including accelerated environmental testing combined with in-situ optical monitoring to identify early indicators of performance degradation.

Strengths: Highly customizable coating architecture adaptable to diverse applications; excellent balance of optical and mechanical properties; comprehensive testing protocols for reliable lifetime prediction. Weaknesses: Complex manufacturing process requiring specialized equipment; higher costs compared to conventional coatings; challenges in scaling to high-volume production.

Key Patents in Hybrid AR Coating Technology

Fluorinated and Hydrogenated Diamond-Like Carbon Materials for Anti-Reflective Coatings

PatentInactiveUS20170166753A1

Innovation

- Development of a fluorinated and hydrogenated diamond-like carbon (DLC-FH) coating material with a low refractive index, produced through a high-energy pulsed cathodic arc and pulsed laser evaporation process, which forms a tetrahedral sp3 bonded structure, making it suitable for use as a single-layer AR coating on large substrates.

Fluorinated and hydrogenated diamond-like carbon materials for Anti-reflective coatings

PatentWO2015123367A1

Innovation

- Development of fluorinated and hydrogenated diamond-like carbon (DLC-FH) materials with a low refractive index, high scratch resistance, and hydrophobic properties, suitable for use as a single-layer or multi-layer AR coating, deposited using a dual-energy mode thin film deposition process that incorporates high-energy pulsed cathodic arc and pulsed laser evaporation with low-energy plasma activation of fluorine and hydrogen gases.

Environmental Impact and Sustainability Factors

The environmental impact of Anti-Reflective (AR) coatings, particularly DLC/SiO₂ hybrid stacks, extends throughout their entire lifecycle. During production, these coatings require energy-intensive vacuum deposition processes, including plasma-enhanced chemical vapor deposition (PECVD) for diamond-like carbon (DLC) layers and physical vapor deposition for SiO₂ layers. These processes consume significant electricity and often utilize greenhouse gas precursors such as methane for DLC formation, contributing to manufacturing's carbon footprint.

Material sourcing presents another environmental consideration. While silicon dioxide is abundant, high-purity precursors require extensive processing. The carbon sources for DLC may derive from fossil fuels, though recent advances have explored bio-based carbon precursors to reduce environmental impact. Additionally, the etching and cleaning chemicals used in manufacturing often include perfluorinated compounds with high global warming potential.

The durability-sustainability relationship is particularly noteworthy for these hybrid stacks. The superior hardness of DLC layers significantly extends product lifespans compared to conventional coatings, reducing replacement frequency and associated resource consumption. This durability factor often outweighs the initially higher environmental manufacturing costs when assessed through lifecycle analysis.

End-of-life considerations reveal both challenges and opportunities. The strong adhesion between layers that provides excellent mechanical performance also complicates recycling efforts. Current recycling technologies struggle to separate these multi-material coatings economically, resulting in most coated products entering general waste streams. However, research into solvent-based delamination techniques shows promise for future recycling improvements.

Regulatory frameworks increasingly influence coating development, with restrictions on volatile organic compounds (VOCs) and hazardous air pollutants driving innovation in cleaner deposition technologies. The European Union's REACH regulations and RoHS directive have specifically impacted formulation choices for AR coatings, accelerating the shift toward more environmentally benign alternatives.

Water usage represents another significant environmental factor, as coating processes typically require ultra-pure water for cleaning and processing. Advanced facilities have implemented closed-loop water recycling systems, reducing consumption by up to 60% compared to conventional operations. This approach demonstrates how sustainability considerations are driving process innovations throughout the coating industry.

Material sourcing presents another environmental consideration. While silicon dioxide is abundant, high-purity precursors require extensive processing. The carbon sources for DLC may derive from fossil fuels, though recent advances have explored bio-based carbon precursors to reduce environmental impact. Additionally, the etching and cleaning chemicals used in manufacturing often include perfluorinated compounds with high global warming potential.

The durability-sustainability relationship is particularly noteworthy for these hybrid stacks. The superior hardness of DLC layers significantly extends product lifespans compared to conventional coatings, reducing replacement frequency and associated resource consumption. This durability factor often outweighs the initially higher environmental manufacturing costs when assessed through lifecycle analysis.

End-of-life considerations reveal both challenges and opportunities. The strong adhesion between layers that provides excellent mechanical performance also complicates recycling efforts. Current recycling technologies struggle to separate these multi-material coatings economically, resulting in most coated products entering general waste streams. However, research into solvent-based delamination techniques shows promise for future recycling improvements.

Regulatory frameworks increasingly influence coating development, with restrictions on volatile organic compounds (VOCs) and hazardous air pollutants driving innovation in cleaner deposition technologies. The European Union's REACH regulations and RoHS directive have specifically impacted formulation choices for AR coatings, accelerating the shift toward more environmentally benign alternatives.

Water usage represents another significant environmental factor, as coating processes typically require ultra-pure water for cleaning and processing. Advanced facilities have implemented closed-loop water recycling systems, reducing consumption by up to 60% compared to conventional operations. This approach demonstrates how sustainability considerations are driving process innovations throughout the coating industry.

Cost-Performance Analysis for Industrial Applications

The economic viability of DLC/SiO₂ hybrid stack anti-reflective coatings represents a critical consideration for industrial adoption. Initial implementation costs for these advanced coating systems typically exceed traditional single-layer solutions by 30-45%, primarily due to the complexity of multi-layer deposition processes and specialized equipment requirements. However, this cost premium must be evaluated against substantial performance advantages that translate to long-term economic benefits.

Manufacturing scale significantly impacts unit economics, with high-volume production environments demonstrating cost reductions of approximately 22% per unit compared to small-batch processing. The primary cost drivers include high-purity precursor materials, specialized plasma-enhanced chemical vapor deposition (PECVD) equipment, and precise process control systems necessary to maintain layer thickness uniformity within ±2nm tolerances.

Energy consumption during deposition represents another significant cost factor, with hybrid stacks requiring 1.5-2.5 kWh per square meter of coated surface. This energy requirement varies based on substrate material and desired hardness specifications. Notably, facilities implementing energy recovery systems have reported operational cost reductions of 15-18% in the coating process.

Lifetime performance metrics demonstrate compelling value propositions despite higher initial investments. Field testing indicates that DLC/SiO₂ hybrid coatings extend component service life by 2.5-3.8 times compared to uncoated surfaces in high-wear industrial environments. This translates to reduced replacement frequency and associated maintenance downtime, with calculated ROI breakeven points typically occurring between 14-22 months depending on application severity.

The hardness-reflectance trade-off presents distinct cost implications across different industrial sectors. Optical applications prioritizing minimal reflectance may accept reduced hardness (12-15 GPa range), resulting in 15-20% lower production costs but potentially shorter service intervals. Conversely, mechanical applications demanding superior hardness (18-22 GPa) incur higher production costs but deliver extended service life and reduced total ownership costs.

Industry-specific cost-benefit analyses reveal particularly favorable economics in semiconductor manufacturing, where particulate contamination reduction justifies premium coating costs. Similarly, aerospace and precision instrumentation sectors demonstrate positive financial returns due to extended maintenance intervals and improved operational reliability. However, consumer electronics applications show more marginal cost-benefit ratios unless production volumes exceed 500,000 units annually.

Recent advancements in deposition technologies, particularly atmospheric pressure plasma systems, show promise for reducing implementation costs by up to 25% while maintaining performance specifications, potentially accelerating broader industrial adoption across price-sensitive market segments.

Manufacturing scale significantly impacts unit economics, with high-volume production environments demonstrating cost reductions of approximately 22% per unit compared to small-batch processing. The primary cost drivers include high-purity precursor materials, specialized plasma-enhanced chemical vapor deposition (PECVD) equipment, and precise process control systems necessary to maintain layer thickness uniformity within ±2nm tolerances.

Energy consumption during deposition represents another significant cost factor, with hybrid stacks requiring 1.5-2.5 kWh per square meter of coated surface. This energy requirement varies based on substrate material and desired hardness specifications. Notably, facilities implementing energy recovery systems have reported operational cost reductions of 15-18% in the coating process.

Lifetime performance metrics demonstrate compelling value propositions despite higher initial investments. Field testing indicates that DLC/SiO₂ hybrid coatings extend component service life by 2.5-3.8 times compared to uncoated surfaces in high-wear industrial environments. This translates to reduced replacement frequency and associated maintenance downtime, with calculated ROI breakeven points typically occurring between 14-22 months depending on application severity.

The hardness-reflectance trade-off presents distinct cost implications across different industrial sectors. Optical applications prioritizing minimal reflectance may accept reduced hardness (12-15 GPa range), resulting in 15-20% lower production costs but potentially shorter service intervals. Conversely, mechanical applications demanding superior hardness (18-22 GPa) incur higher production costs but deliver extended service life and reduced total ownership costs.

Industry-specific cost-benefit analyses reveal particularly favorable economics in semiconductor manufacturing, where particulate contamination reduction justifies premium coating costs. Similarly, aerospace and precision instrumentation sectors demonstrate positive financial returns due to extended maintenance intervals and improved operational reliability. However, consumer electronics applications show more marginal cost-benefit ratios unless production volumes exceed 500,000 units annually.

Recent advancements in deposition technologies, particularly atmospheric pressure plasma systems, show promise for reducing implementation costs by up to 25% while maintaining performance specifications, potentially accelerating broader industrial adoption across price-sensitive market segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!