Anti-Reflective Coatings: Hydrophobic–Oleophobic Topcoats, Contamination Control And Cleanability

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR Coating Evolution and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when F. Geffcken first developed single-layer coatings. The initial applications were primarily limited to optical instruments and camera lenses, where light transmission was critical. By the 1950s, multi-layer AR coatings emerged, offering improved performance across broader wavelength ranges, which revolutionized the optics industry.

The 1970s and 1980s witnessed substantial advancements with the introduction of gradient-index AR coatings, which provided smoother transitions between air and substrate, reducing reflection more effectively than discrete layers. Concurrently, vacuum deposition techniques improved, enabling more precise control over coating thickness and composition.

The 1990s marked a paradigm shift with the development of biomimetic AR coatings inspired by moth eyes, featuring nanoscale structures that minimize reflection through gradual refractive index changes. These innovations expanded AR coating applications beyond traditional optics into solar panels, displays, and architectural glass.

Recent developments have focused on combining AR properties with additional functionalities. The integration of hydrophobic and oleophobic properties represents a significant advancement, addressing persistent challenges in maintaining optical performance in real-world conditions where contamination from water, oils, and particulates degrades effectiveness.

Current state-of-the-art AR coatings with hydrophobic-oleophobic topcoats utilize fluorinated compounds or silicone-based materials to create surfaces that repel both water and oils while maintaining excellent anti-reflective properties. These coatings typically employ a multi-layer structure with the AR layers providing optical functionality and the topcoat delivering contamination resistance.

The primary objectives of research in this field include developing coatings with enhanced durability under harsh environmental conditions, improving adhesion between the AR layers and hydrophobic-oleophobic topcoats, reducing manufacturing costs through simplified deposition processes, and addressing environmental concerns by eliminating perfluorinated compounds while maintaining performance.

Additionally, researchers aim to achieve self-cleaning capabilities through optimized surface topographies that facilitate the removal of contaminants with minimal external intervention. Another critical goal is to maintain optical performance across broader wavelength ranges while simultaneously providing robust contamination resistance, particularly for applications in outdoor environments, touchscreens, and medical devices where cleanliness is paramount.

The 1970s and 1980s witnessed substantial advancements with the introduction of gradient-index AR coatings, which provided smoother transitions between air and substrate, reducing reflection more effectively than discrete layers. Concurrently, vacuum deposition techniques improved, enabling more precise control over coating thickness and composition.

The 1990s marked a paradigm shift with the development of biomimetic AR coatings inspired by moth eyes, featuring nanoscale structures that minimize reflection through gradual refractive index changes. These innovations expanded AR coating applications beyond traditional optics into solar panels, displays, and architectural glass.

Recent developments have focused on combining AR properties with additional functionalities. The integration of hydrophobic and oleophobic properties represents a significant advancement, addressing persistent challenges in maintaining optical performance in real-world conditions where contamination from water, oils, and particulates degrades effectiveness.

Current state-of-the-art AR coatings with hydrophobic-oleophobic topcoats utilize fluorinated compounds or silicone-based materials to create surfaces that repel both water and oils while maintaining excellent anti-reflective properties. These coatings typically employ a multi-layer structure with the AR layers providing optical functionality and the topcoat delivering contamination resistance.

The primary objectives of research in this field include developing coatings with enhanced durability under harsh environmental conditions, improving adhesion between the AR layers and hydrophobic-oleophobic topcoats, reducing manufacturing costs through simplified deposition processes, and addressing environmental concerns by eliminating perfluorinated compounds while maintaining performance.

Additionally, researchers aim to achieve self-cleaning capabilities through optimized surface topographies that facilitate the removal of contaminants with minimal external intervention. Another critical goal is to maintain optical performance across broader wavelength ranges while simultaneously providing robust contamination resistance, particularly for applications in outdoor environments, touchscreens, and medical devices where cleanliness is paramount.

Market Analysis for Self-Cleaning Optical Surfaces

The global market for self-cleaning optical surfaces is experiencing robust growth, driven by increasing demand across multiple sectors including consumer electronics, automotive, solar energy, and architectural glass. The market value reached approximately $1.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.2% through 2028, potentially reaching $2.4 billion by the end of the forecast period.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The proliferation of smartphones, tablets, and wearable devices with camera lenses and display screens has created substantial demand for anti-reflective coatings with hydrophobic-oleophobic properties. Major manufacturers like Apple, Samsung, and Huawei have increasingly incorporated these technologies into their flagship devices.

The automotive sector follows closely, with applications in windshields, side windows, mirrors, and increasingly in sensors and cameras for advanced driver assistance systems (ADAS). This segment is expected to witness the fastest growth rate of 10.5% annually, as autonomous driving technologies become more prevalent and require consistently clean optical surfaces for reliable operation.

Solar energy applications constitute another significant market segment, where self-cleaning properties can improve energy conversion efficiency by up to 6% by preventing dust and contaminant accumulation. The architectural glass industry also shows strong adoption rates, particularly in commercial buildings and skyscrapers in urban environments with high pollution levels.

Regionally, North America and Europe currently lead the market with combined share of approximately 60%, owing to higher adoption rates of advanced technologies and stringent environmental regulations. However, the Asia-Pacific region is expected to demonstrate the highest growth potential, driven by rapid industrialization, expanding middle-class population, and increasing technological adoption in countries like China, Japan, and South Korea.

Key market drivers include increasing awareness about energy efficiency, growing demand for maintenance-free products, and technological advancements in coating materials. The COVID-19 pandemic has further accelerated market growth due to heightened awareness about surface cleanliness and hygiene, particularly in public spaces and shared devices.

Market challenges include relatively high initial costs compared to conventional coatings, durability concerns in harsh environmental conditions, and technical limitations in achieving optimal balance between anti-reflective properties and hydrophobic-oleophobic characteristics. Despite these challenges, ongoing research and development efforts are expected to address these limitations and expand market opportunities.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The proliferation of smartphones, tablets, and wearable devices with camera lenses and display screens has created substantial demand for anti-reflective coatings with hydrophobic-oleophobic properties. Major manufacturers like Apple, Samsung, and Huawei have increasingly incorporated these technologies into their flagship devices.

The automotive sector follows closely, with applications in windshields, side windows, mirrors, and increasingly in sensors and cameras for advanced driver assistance systems (ADAS). This segment is expected to witness the fastest growth rate of 10.5% annually, as autonomous driving technologies become more prevalent and require consistently clean optical surfaces for reliable operation.

Solar energy applications constitute another significant market segment, where self-cleaning properties can improve energy conversion efficiency by up to 6% by preventing dust and contaminant accumulation. The architectural glass industry also shows strong adoption rates, particularly in commercial buildings and skyscrapers in urban environments with high pollution levels.

Regionally, North America and Europe currently lead the market with combined share of approximately 60%, owing to higher adoption rates of advanced technologies and stringent environmental regulations. However, the Asia-Pacific region is expected to demonstrate the highest growth potential, driven by rapid industrialization, expanding middle-class population, and increasing technological adoption in countries like China, Japan, and South Korea.

Key market drivers include increasing awareness about energy efficiency, growing demand for maintenance-free products, and technological advancements in coating materials. The COVID-19 pandemic has further accelerated market growth due to heightened awareness about surface cleanliness and hygiene, particularly in public spaces and shared devices.

Market challenges include relatively high initial costs compared to conventional coatings, durability concerns in harsh environmental conditions, and technical limitations in achieving optimal balance between anti-reflective properties and hydrophobic-oleophobic characteristics. Despite these challenges, ongoing research and development efforts are expected to address these limitations and expand market opportunities.

Current Challenges in Anti-Reflective Hydrophobic Coatings

Despite significant advancements in anti-reflective (AR) coating technologies, the integration of hydrophobic and oleophobic properties while maintaining optimal optical performance presents several persistent challenges. Current AR coatings typically achieve excellent light transmission but often lack sufficient resistance to environmental contaminants, creating a fundamental technical contradiction that researchers continue to struggle with.

The primary challenge lies in the inherent trade-off between anti-reflective properties and surface repellency. Traditional AR coatings rely on porous structures to create gradient refractive indices, but these same porous structures readily trap contaminants, compromising long-term performance. When attempting to add hydrophobic-oleophobic topcoats, the additional layer often diminishes the AR effect by altering the carefully engineered refractive index profile.

Durability represents another significant obstacle. Many hydrophobic-oleophobic treatments exhibit poor mechanical stability, with surface properties degrading rapidly under normal cleaning procedures, environmental exposure, or abrasion. This is particularly problematic for applications in consumer electronics, automotive displays, and solar panels where extended service life under harsh conditions is essential.

Chemical compatibility issues further complicate development efforts. The fluorinated compounds traditionally used for oleophobic properties face increasing regulatory scrutiny due to environmental persistence concerns. Alternative chemistries often fail to provide comparable oil repellency or require complex application processes incompatible with high-volume manufacturing.

Adhesion between the AR coating stack and the hydrophobic-oleophobic topcoat presents another technical hurdle. The low surface energy necessary for repellency inherently reduces adhesion potential, leading to delamination and coating failure, particularly when exposed to temperature cycling or humidity fluctuations.

Cost-effectiveness remains a significant barrier to widespread adoption. Current manufacturing processes for high-performance AR coatings with hydrophobic-oleophobic properties typically involve multiple deposition steps, specialized equipment, and expensive materials. This complexity drives up production costs and limits application to premium products.

Optical clarity under varying environmental conditions poses additional challenges. Many existing solutions exhibit "fogging" effects when transitioning between temperature extremes, temporarily reducing visibility and functionality. Furthermore, maintaining consistent optical performance across wide viewing angles while preserving repellent properties has proven technically difficult.

The primary challenge lies in the inherent trade-off between anti-reflective properties and surface repellency. Traditional AR coatings rely on porous structures to create gradient refractive indices, but these same porous structures readily trap contaminants, compromising long-term performance. When attempting to add hydrophobic-oleophobic topcoats, the additional layer often diminishes the AR effect by altering the carefully engineered refractive index profile.

Durability represents another significant obstacle. Many hydrophobic-oleophobic treatments exhibit poor mechanical stability, with surface properties degrading rapidly under normal cleaning procedures, environmental exposure, or abrasion. This is particularly problematic for applications in consumer electronics, automotive displays, and solar panels where extended service life under harsh conditions is essential.

Chemical compatibility issues further complicate development efforts. The fluorinated compounds traditionally used for oleophobic properties face increasing regulatory scrutiny due to environmental persistence concerns. Alternative chemistries often fail to provide comparable oil repellency or require complex application processes incompatible with high-volume manufacturing.

Adhesion between the AR coating stack and the hydrophobic-oleophobic topcoat presents another technical hurdle. The low surface energy necessary for repellency inherently reduces adhesion potential, leading to delamination and coating failure, particularly when exposed to temperature cycling or humidity fluctuations.

Cost-effectiveness remains a significant barrier to widespread adoption. Current manufacturing processes for high-performance AR coatings with hydrophobic-oleophobic properties typically involve multiple deposition steps, specialized equipment, and expensive materials. This complexity drives up production costs and limits application to premium products.

Optical clarity under varying environmental conditions poses additional challenges. Many existing solutions exhibit "fogging" effects when transitioning between temperature extremes, temporarily reducing visibility and functionality. Furthermore, maintaining consistent optical performance across wide viewing angles while preserving repellent properties has proven technically difficult.

State-of-the-Art Multilayer Coating Solutions

01 Fluorinated compounds for hydrophobic-oleophobic properties

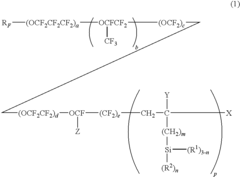

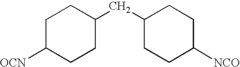

Fluorinated compounds such as perfluoropolyethers and fluorosilanes are incorporated into topcoat formulations to provide both hydrophobic and oleophobic properties to anti-reflective coatings. These compounds create a low surface energy layer that repels both water and oil-based contaminants, making the surface easier to clean and maintaining optical clarity. The fluorinated structures form strong chemical bonds with the substrate while presenting fluorine groups at the surface interface.- Fluorinated compounds for hydrophobic-oleophobic properties: Fluorinated compounds are widely used in anti-reflective coatings to impart both hydrophobic and oleophobic properties. These compounds create a low surface energy layer that repels both water and oil-based contaminants, making the coated surface easier to clean. The fluorinated compounds can be incorporated as topcoats over anti-reflective layers, providing protection while maintaining optical clarity. This approach significantly improves contamination resistance and cleanability of optical surfaces.

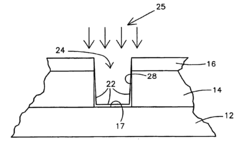

- Multilayer coating structures with anti-reflective and protective functions: Multilayer coating structures combine anti-reflective properties with protective hydrophobic-oleophobic topcoats. These systems typically consist of an anti-reflective base layer that reduces light reflection, followed by a protective topcoat that provides contamination resistance. The multilayer approach allows optimization of both optical performance and surface protection independently. The interfaces between layers are carefully designed to maintain adhesion while preserving the desired functional properties of each layer.

- Silica-based anti-reflective coatings with hydrophobic modifications: Silica-based materials form the foundation of many anti-reflective coatings due to their excellent optical properties. These coatings can be modified with hydrophobic-oleophobic agents through various methods including vapor deposition, sol-gel processes, or surface treatments. The porous nature of silica-based coatings provides anti-reflective properties through refractive index gradient, while surface modifications with hydrophobic groups prevent contamination and facilitate cleaning without compromising optical performance.

- Nanostructured surfaces for enhanced anti-reflective and self-cleaning properties: Nanostructured surfaces combine anti-reflective properties with hydrophobic-oleophobic characteristics through controlled surface topography. These surfaces often mimic natural structures like moth eyes or lotus leaves, creating nanoscale features that reduce reflection while increasing contact angles for water and oil repellency. The nanostructures can be created through various methods including etching, lithography, or nanoparticle deposition, resulting in surfaces that resist contamination and are easily cleaned while maintaining excellent optical properties.

- Durable hydrophobic-oleophobic topcoats for harsh environments: Specialized topcoat formulations provide long-lasting hydrophobic and oleophobic properties in challenging environments. These coatings incorporate abrasion-resistant materials, UV stabilizers, and chemical-resistant compounds to maintain functionality despite exposure to harsh conditions. Advanced bonding techniques ensure strong adhesion between the anti-reflective layer and the protective topcoat, preventing delamination. These durable coatings are particularly valuable for outdoor applications, touchscreens, and other surfaces subject to frequent handling or environmental exposure.

02 Multi-layer coating structures with anti-reflective base and functional topcoat

Multi-layer coating systems combine an anti-reflective base layer with a hydrophobic-oleophobic topcoat to achieve both optical performance and contamination resistance. The base layer typically consists of alternating high and low refractive index materials to reduce light reflection, while the topcoat provides protection against fingerprints, oils, and other contaminants. This structure allows for independent optimization of optical and surface properties while maintaining strong adhesion between layers.Expand Specific Solutions03 Nanoparticle incorporation for enhanced durability and performance

Nanoparticles are integrated into hydrophobic-oleophobic topcoats to enhance mechanical durability, scratch resistance, and long-term performance. Materials such as silica, alumina, and zirconia nanoparticles create a reinforced network within the coating while maintaining transparency. The nanostructured surface can also enhance the hydrophobic properties by creating hierarchical roughness patterns that increase contact angles and reduce contaminant adhesion.Expand Specific Solutions04 Self-cleaning and easy-to-clean surface technologies

Advanced topcoat formulations incorporate self-cleaning or easy-to-clean technologies that actively repel or facilitate removal of contaminants. These include photocatalytic materials that break down organic contaminants under light exposure, slippery liquid-infused porous surfaces that prevent adhesion of particles, and specially designed surface textures that minimize contact area with contaminants. These technologies reduce maintenance requirements and extend the functional lifetime of anti-reflective coatings in various applications.Expand Specific Solutions05 Application-specific coating formulations for different environments

Specialized coating formulations are developed for specific environmental challenges and applications. These include coatings optimized for high-humidity environments, coatings resistant to specific chemical exposures, coatings for touchscreen applications with enhanced fingerprint resistance, and coatings for outdoor applications with UV stability. The formulations balance optical performance, contamination resistance, and durability requirements specific to each use case.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The anti-reflective coatings market with hydrophobic-oleophobic topcoats is in a growth phase, with increasing demand across optical, electronics, and solar industries. Market size is expanding due to rising applications in consumer electronics, automotive displays, and photovoltaics. Technology maturity varies across players, with established companies like 3M, DSM, and EssilorLuxottica leading in optical applications, while specialized firms like Enki Technology focus on solar-specific solutions. Companies including Dow Silicones, FUJIFILM, and Samsung Electronics are advancing multi-functional coating technologies that combine anti-reflective properties with contamination resistance. First Solar and LG Chem are developing industry-specific applications, while research partnerships with institutions like Cambridge Enterprise and Soochow University are driving next-generation innovations.

EssilorLuxottica SA

Technical Solution: EssilorLuxottica has pioneered Crizal® technology, an advanced anti-reflective coating system with integrated hydrophobic-oleophobic properties specifically designed for eyewear applications. Their multi-layer approach combines high-performance anti-reflective properties with superior contamination resistance. The technology employs nanoscale surface engineering to create an ultra-smooth topcoat that prevents the adhesion of fingerprints, dust, and other contaminants. Their latest generation incorporates fluorinated compounds that maintain a contact angle exceeding 110° for water and 80° for oils, while preserving optical clarity. The company's proprietary High-Surface Density Process™ creates a densely packed molecular structure that enhances durability while maintaining excellent cleanability. Independent testing has shown their coatings can withstand over 20,000 cleaning cycles without significant degradation of either anti-reflective or hydrophobic-oleophobic properties, making them particularly suitable for high-touch consumer applications like eyeglasses.

Strengths: Exceptional durability in real-world consumer applications; optimized for high-touch surfaces like eyewear; established global manufacturing and distribution network. Weaknesses: Technology primarily optimized for eyewear rather than broader industrial applications; relatively higher cost compared to standard coatings; some formulations may require specialized cleaning solutions.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed a comprehensive suite of silicone-based anti-reflective coatings with hydrophobic-oleophobic properties. Their technology utilizes modified siloxane chemistry to create durable, optically clear surfaces with excellent contamination resistance. The company's approach involves a two-step process: first applying a gradient-index anti-reflective base layer, followed by a functionalized silicone topcoat with nanoscale surface texturing. This creates a hierarchical surface structure that simultaneously reduces reflection while repelling both water and oil-based contaminants. Their SILASTIC™ optical coatings achieve water contact angles exceeding 115° and oil contact angles above 75° while maintaining over 99% light transmission. The coatings incorporate proprietary silicone-fluoropolymer hybrid materials that provide exceptional environmental stability, including resistance to UV degradation, temperature cycling, and humidity. Testing has demonstrated these coatings maintain performance after more than 1,000 abrasion cycles, making them suitable for outdoor applications including solar panels, automotive displays, and architectural glass.

Strengths: Excellent chemical stability and weatherability; strong adhesion to various substrates including glass, polycarbonate, and acrylic; environmentally friendly formulations with reduced fluorine content. Weaknesses: Higher processing temperatures required for optimal performance; more complex application process compared to conventional coatings; slightly lower oleophobicity compared to pure fluoropolymer solutions.

Key Patents in Hydrophobic-Oleophobic Technologies

Optical Article Comprising a Temporary Layer of Aliphatic Thermoplastic Polyurethane and Use in Edging

PatentInactiveUS20100247890A1

Innovation

- A temporary coating of aliphatic thermoplastic polyurethane with a polyether or polyester backbone is directly applied onto the external hydrophobic and oleophobic coating, increasing surface energy and allowing for reliable edging and potential restarts without compromising the initial coating's properties.

Anti-reflective coatings and methods for forming and using same

PatentInactiveUS6784094B2

Innovation

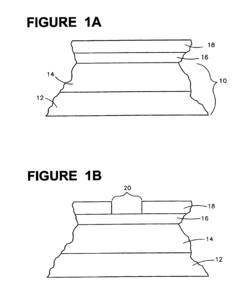

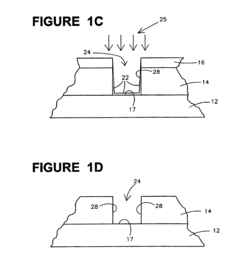

- The use of inorganic anti-reflective coating layers, specifically Si_x O_y N_z:H, deposited using a gas mixture of silicon, nitrogen, and oxygen precursors in a glow discharge, allowing for simultaneous removal with wet etching without affecting critical dimensions, thus reducing processing steps.

Environmental Impact and Sustainability Considerations

The environmental impact of anti-reflective coatings with hydrophobic-oleophobic topcoats extends throughout their entire lifecycle, from raw material extraction to disposal. Traditional coating processes often involve volatile organic compounds (VOCs) and fluorinated chemicals that pose significant environmental concerns. These substances contribute to air pollution, ozone depletion, and can persist in the environment for extended periods, potentially bioaccumulating in living organisms.

Recent advancements have focused on developing more sustainable alternatives that maintain performance while reducing environmental footprint. Water-based formulations have emerged as promising substitutes for solvent-based systems, significantly reducing VOC emissions during application and curing processes. Additionally, bio-inspired coatings derived from natural hydrophobic materials such as plant waxes offer biodegradable alternatives to synthetic fluorinated compounds.

Manufacturing processes for these advanced coatings are also evolving toward greater sustainability. Energy-efficient deposition techniques like atmospheric plasma treatment and room-temperature curing methods reduce carbon emissions associated with coating production. Some manufacturers have implemented closed-loop systems that recover and recycle solvents and other materials, minimizing waste generation and resource consumption.

The durability of hydrophobic-oleophobic anti-reflective coatings directly impacts their sustainability profile. Longer-lasting coatings reduce replacement frequency, decreasing overall material consumption and waste generation. Research indicates that high-performance coatings can extend the functional lifetime of optical components by up to 300%, significantly reducing lifecycle environmental impact despite potentially higher initial manufacturing footprints.

End-of-life considerations present ongoing challenges. While some newer coating formulations are designed for easier removal and recycling of substrate materials, many current solutions create composite materials that are difficult to separate and recycle effectively. Emerging technologies such as solvent-free mechanical removal methods and biodegradable temporary protective films show promise for improving end-of-life management.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of persistent, bioaccumulative substances commonly found in traditional hydrophobic formulations, driving innovation toward greener alternatives. Life cycle assessment (LCA) methodologies are becoming standard practice for evaluating the comprehensive environmental impact of coating technologies, enabling more informed development and application decisions.

Recent advancements have focused on developing more sustainable alternatives that maintain performance while reducing environmental footprint. Water-based formulations have emerged as promising substitutes for solvent-based systems, significantly reducing VOC emissions during application and curing processes. Additionally, bio-inspired coatings derived from natural hydrophobic materials such as plant waxes offer biodegradable alternatives to synthetic fluorinated compounds.

Manufacturing processes for these advanced coatings are also evolving toward greater sustainability. Energy-efficient deposition techniques like atmospheric plasma treatment and room-temperature curing methods reduce carbon emissions associated with coating production. Some manufacturers have implemented closed-loop systems that recover and recycle solvents and other materials, minimizing waste generation and resource consumption.

The durability of hydrophobic-oleophobic anti-reflective coatings directly impacts their sustainability profile. Longer-lasting coatings reduce replacement frequency, decreasing overall material consumption and waste generation. Research indicates that high-performance coatings can extend the functional lifetime of optical components by up to 300%, significantly reducing lifecycle environmental impact despite potentially higher initial manufacturing footprints.

End-of-life considerations present ongoing challenges. While some newer coating formulations are designed for easier removal and recycling of substrate materials, many current solutions create composite materials that are difficult to separate and recycle effectively. Emerging technologies such as solvent-free mechanical removal methods and biodegradable temporary protective films show promise for improving end-of-life management.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of persistent, bioaccumulative substances commonly found in traditional hydrophobic formulations, driving innovation toward greener alternatives. Life cycle assessment (LCA) methodologies are becoming standard practice for evaluating the comprehensive environmental impact of coating technologies, enabling more informed development and application decisions.

Durability and Performance Testing Methodologies

The evaluation of anti-reflective coatings with hydrophobic-oleophobic topcoats requires comprehensive durability and performance testing methodologies to ensure their effectiveness in real-world applications. These methodologies must assess both the optical properties and the contamination resistance capabilities under various environmental conditions.

Standard abrasion resistance tests, such as the Taber abraser method (ASTM D4060) and pencil hardness test (ASTM D3363), provide quantitative measurements of coating durability against mechanical wear. For anti-reflective coatings specifically, modified versions of these tests using lower loads and specialized abrasive materials better simulate real-world cleaning scenarios without damaging the delicate optical surfaces.

Environmental durability testing involves subjecting coated samples to accelerated weathering conditions using QUV accelerated weathering testers (ASTM G154) and salt spray chambers (ASTM B117). These tests evaluate coating performance under UV exposure, temperature cycling, and high humidity environments. For hydrophobic-oleophobic topcoats, additional testing for chemical resistance against common contaminants like fingerprint oils, cosmetics, and cleaning agents is essential.

Optical performance testing methodologies include spectrophotometric measurements to quantify transmittance, reflectance, and haze before and after durability testing. The maintenance of anti-reflective properties after exposure to harsh conditions serves as a critical performance indicator. Specialized equipment such as angle-dependent spectrophotometers can assess optical performance at various viewing angles, which is particularly important for display applications.

Hydrophobic and oleophobic properties require specific testing protocols. Contact angle measurements for both water and oil droplets (ASTM D7334) provide quantitative data on surface repellency. Dynamic contact angle analysis, which measures advancing and receding contact angles, offers insights into the coating's self-cleaning capabilities. Sliding angle measurements determine the minimum tilt angle required for droplet movement, directly correlating to ease of cleaning.

Long-term performance evaluation involves cyclic contamination and cleaning tests. Standardized contaminants (fingerprint oils, dust particles, marker inks) are applied and removed repeatedly using defined cleaning protocols. The number of cycles before significant degradation in optical or repellent properties occurs indicates the coating's practical lifespan.

Adhesion testing between the anti-reflective layer and the hydrophobic-oleophobic topcoat is crucial for ensuring coating integrity. Cross-hatch adhesion tests (ASTM D3359) and pull-off adhesion tests (ASTM D4541) evaluate the interfacial strength between coating layers and with the substrate, predicting long-term delamination resistance.

Standard abrasion resistance tests, such as the Taber abraser method (ASTM D4060) and pencil hardness test (ASTM D3363), provide quantitative measurements of coating durability against mechanical wear. For anti-reflective coatings specifically, modified versions of these tests using lower loads and specialized abrasive materials better simulate real-world cleaning scenarios without damaging the delicate optical surfaces.

Environmental durability testing involves subjecting coated samples to accelerated weathering conditions using QUV accelerated weathering testers (ASTM G154) and salt spray chambers (ASTM B117). These tests evaluate coating performance under UV exposure, temperature cycling, and high humidity environments. For hydrophobic-oleophobic topcoats, additional testing for chemical resistance against common contaminants like fingerprint oils, cosmetics, and cleaning agents is essential.

Optical performance testing methodologies include spectrophotometric measurements to quantify transmittance, reflectance, and haze before and after durability testing. The maintenance of anti-reflective properties after exposure to harsh conditions serves as a critical performance indicator. Specialized equipment such as angle-dependent spectrophotometers can assess optical performance at various viewing angles, which is particularly important for display applications.

Hydrophobic and oleophobic properties require specific testing protocols. Contact angle measurements for both water and oil droplets (ASTM D7334) provide quantitative data on surface repellency. Dynamic contact angle analysis, which measures advancing and receding contact angles, offers insights into the coating's self-cleaning capabilities. Sliding angle measurements determine the minimum tilt angle required for droplet movement, directly correlating to ease of cleaning.

Long-term performance evaluation involves cyclic contamination and cleaning tests. Standardized contaminants (fingerprint oils, dust particles, marker inks) are applied and removed repeatedly using defined cleaning protocols. The number of cycles before significant degradation in optical or repellent properties occurs indicates the coating's practical lifespan.

Adhesion testing between the anti-reflective layer and the hydrophobic-oleophobic topcoat is crucial for ensuring coating integrity. Cross-hatch adhesion tests (ASTM D3359) and pull-off adhesion tests (ASTM D4541) evaluate the interfacial strength between coating layers and with the substrate, predicting long-term delamination resistance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!