Anti-Reflective Coatings: Salt Fog/THB Robustness, Barrier Layers And Edge Seals

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Reflective Coating Technology Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s, initially developed for optical applications to reduce light reflection and increase transmission. The technology has progressed from single-layer coatings to sophisticated multi-layer designs that can achieve reflection rates below 0.1% across specific wavelength ranges. This evolution has been driven by expanding applications in solar panels, displays, eyewear, and precision optical instruments where maximizing light transmission is critical.

In recent years, the durability of AR coatings has become increasingly important, particularly in outdoor and harsh environment applications. Traditional AR coatings often suffer from degradation when exposed to moisture, salt fog, and temperature-humidity-bias (THB) conditions, leading to delamination, haze formation, and loss of anti-reflective properties. This vulnerability has limited their deployment in marine environments, outdoor solar installations, and automotive applications.

The current technological landscape shows a clear trend toward developing more robust AR coatings that maintain optical performance while withstanding environmental stressors. Research has focused on novel material compositions, deposition techniques, and protective barrier layers. Silicon dioxide (SiO2) and titanium dioxide (TiO2) remain common materials, but innovations in fluoropolymers, hybrid organic-inorganic materials, and nanostructured coatings are gaining traction for their enhanced durability properties.

The primary objective of current research is to develop AR coatings with exceptional resistance to salt fog corrosion and THB conditions without compromising optical performance. This includes investigating barrier layers that prevent moisture ingress while maintaining transparency, and edge seal technologies that protect vulnerable coating boundaries from environmental attack. The ideal solution would maintain reflection reduction below 1% across the visible spectrum while withstanding 1000+ hours of salt fog exposure and 85°C/85% relative humidity conditions.

Secondary objectives include developing cost-effective deposition methods suitable for large-scale manufacturing, ensuring environmental sustainability by reducing or eliminating hazardous materials, and creating coatings with self-healing or easy-cleaning properties to extend service life. The integration of these coatings with other functional layers, such as hydrophobic or antimicrobial surfaces, represents another frontier in AR coating development.

The technological trajectory points toward biomimetic approaches inspired by natural anti-reflective surfaces like moth eyes, which use nanoscale structures rather than traditional thin films. These approaches promise greater durability and potentially simpler manufacturing processes, though they present their own challenges in terms of scalability and cost.

In recent years, the durability of AR coatings has become increasingly important, particularly in outdoor and harsh environment applications. Traditional AR coatings often suffer from degradation when exposed to moisture, salt fog, and temperature-humidity-bias (THB) conditions, leading to delamination, haze formation, and loss of anti-reflective properties. This vulnerability has limited their deployment in marine environments, outdoor solar installations, and automotive applications.

The current technological landscape shows a clear trend toward developing more robust AR coatings that maintain optical performance while withstanding environmental stressors. Research has focused on novel material compositions, deposition techniques, and protective barrier layers. Silicon dioxide (SiO2) and titanium dioxide (TiO2) remain common materials, but innovations in fluoropolymers, hybrid organic-inorganic materials, and nanostructured coatings are gaining traction for their enhanced durability properties.

The primary objective of current research is to develop AR coatings with exceptional resistance to salt fog corrosion and THB conditions without compromising optical performance. This includes investigating barrier layers that prevent moisture ingress while maintaining transparency, and edge seal technologies that protect vulnerable coating boundaries from environmental attack. The ideal solution would maintain reflection reduction below 1% across the visible spectrum while withstanding 1000+ hours of salt fog exposure and 85°C/85% relative humidity conditions.

Secondary objectives include developing cost-effective deposition methods suitable for large-scale manufacturing, ensuring environmental sustainability by reducing or eliminating hazardous materials, and creating coatings with self-healing or easy-cleaning properties to extend service life. The integration of these coatings with other functional layers, such as hydrophobic or antimicrobial surfaces, represents another frontier in AR coating development.

The technological trajectory points toward biomimetic approaches inspired by natural anti-reflective surfaces like moth eyes, which use nanoscale structures rather than traditional thin films. These approaches promise greater durability and potentially simpler manufacturing processes, though they present their own challenges in terms of scalability and cost.

Market Analysis for Robust Anti-Reflective Solutions

The global market for anti-reflective coatings has been experiencing robust growth, driven primarily by increasing applications in solar panels, electronics displays, eyewear, and architectural glass. The market value reached approximately $4.5 billion in 2022 and is projected to grow at a CAGR of 8.2% through 2028, with particular emphasis on durable solutions that can withstand harsh environmental conditions.

Salt fog and temperature-humidity-bias (THB) resistant anti-reflective coatings represent a high-value segment within this market. This specialized sector is experiencing accelerated demand due to the expansion of solar installations in coastal regions and harsh environments where traditional coatings fail prematurely. Market research indicates that robust anti-reflective solutions command a premium of 30-45% over standard coatings, reflecting their critical importance in extending product lifespan.

The solar energy sector remains the largest consumer of robust anti-reflective coatings, accounting for nearly 42% of market demand. With global solar capacity additions reaching record levels annually, the need for coatings that maintain performance under extreme conditions has become paramount. Industry reports highlight that salt fog degradation alone can reduce solar panel efficiency by 15-20% within three years in coastal installations without proper protective coatings.

Regionally, Asia-Pacific dominates the market with a 38% share, followed by North America (27%) and Europe (24%). However, the Middle East and North Africa region is showing the fastest growth rate at 12.3% annually, driven by massive solar installations in desert environments where both UV exposure and temperature fluctuations create challenging conditions for coating durability.

Consumer electronics represents the second-largest application segment, with smartphone and tablet manufacturers increasingly specifying salt fog resistant coatings for devices marketed in tropical and coastal regions. This segment is growing at 9.7% annually, with premium device manufacturers leading adoption.

Edge seal technologies have emerged as a critical differentiator in the market, with patented edge sealing solutions commanding significant market premiums. The market for specialized edge seals grew by 34% in 2022 alone, reflecting recognition of edge degradation as the primary failure mode in many applications.

Barrier layer technologies incorporating multiple protective mechanisms have shown the strongest growth trajectory, with multilayer solutions that combine hydrophobic, oleophobic, and anti-static properties gaining significant market share. These integrated solutions address multiple environmental challenges simultaneously and are projected to represent over 60% of the premium anti-reflective coating market by 2027.

Salt fog and temperature-humidity-bias (THB) resistant anti-reflective coatings represent a high-value segment within this market. This specialized sector is experiencing accelerated demand due to the expansion of solar installations in coastal regions and harsh environments where traditional coatings fail prematurely. Market research indicates that robust anti-reflective solutions command a premium of 30-45% over standard coatings, reflecting their critical importance in extending product lifespan.

The solar energy sector remains the largest consumer of robust anti-reflective coatings, accounting for nearly 42% of market demand. With global solar capacity additions reaching record levels annually, the need for coatings that maintain performance under extreme conditions has become paramount. Industry reports highlight that salt fog degradation alone can reduce solar panel efficiency by 15-20% within three years in coastal installations without proper protective coatings.

Regionally, Asia-Pacific dominates the market with a 38% share, followed by North America (27%) and Europe (24%). However, the Middle East and North Africa region is showing the fastest growth rate at 12.3% annually, driven by massive solar installations in desert environments where both UV exposure and temperature fluctuations create challenging conditions for coating durability.

Consumer electronics represents the second-largest application segment, with smartphone and tablet manufacturers increasingly specifying salt fog resistant coatings for devices marketed in tropical and coastal regions. This segment is growing at 9.7% annually, with premium device manufacturers leading adoption.

Edge seal technologies have emerged as a critical differentiator in the market, with patented edge sealing solutions commanding significant market premiums. The market for specialized edge seals grew by 34% in 2022 alone, reflecting recognition of edge degradation as the primary failure mode in many applications.

Barrier layer technologies incorporating multiple protective mechanisms have shown the strongest growth trajectory, with multilayer solutions that combine hydrophobic, oleophobic, and anti-static properties gaining significant market share. These integrated solutions address multiple environmental challenges simultaneously and are projected to represent over 60% of the premium anti-reflective coating market by 2027.

Current Challenges in Salt Fog/THB Resistance

Anti-reflective (AR) coatings face significant challenges in maintaining performance under harsh environmental conditions, particularly salt fog and temperature-humidity-bias (THB) testing. These conditions simulate coastal environments and accelerated aging, revealing vulnerabilities in coating durability that impact long-term optical performance.

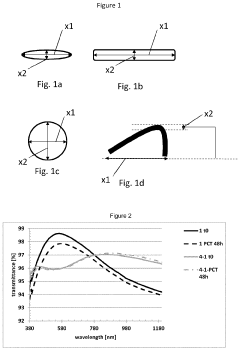

Salt fog exposure presents a particularly aggressive challenge, as sodium chloride particles can penetrate coating defects and initiate corrosion at the coating-substrate interface. Current AR coating technologies often demonstrate inadequate resistance to this penetration, resulting in delamination, haze formation, and reduced transmittance after extended exposure periods. Industry testing protocols typically require 96-hour salt fog resistance, but many existing solutions show degradation after just 48-72 hours.

THB testing, which combines elevated temperature (typically 85°C), high humidity (85% RH), and electrical bias, reveals additional weaknesses in AR coating systems. The combination of these stressors accelerates ion migration through coating defects and promotes electrochemical reactions that compromise coating integrity. Current AR technologies frequently exhibit failure modes including pinhole formation, interfacial delamination, and optical degradation under THB conditions.

A critical limitation in existing solutions is the trade-off between optical performance and environmental durability. Coatings optimized for maximum transmittance and minimum reflectance often incorporate porous structures or materials with higher water absorption rates, making them inherently more susceptible to environmental degradation. Conversely, more robust coating systems typically sacrifice some degree of optical performance.

Edge seal technologies represent another significant challenge area. The coating-substrate interface at component edges creates vulnerability points where moisture and contaminants can more easily penetrate. Current edge sealing approaches often add manufacturing complexity and cost while providing only moderate improvements in environmental resistance.

Material compatibility issues further complicate the development of robust AR coatings. The adhesion between different coating layers and the substrate can be compromised under salt fog or THB conditions, particularly when thermal expansion coefficients differ significantly between materials. This mismatch creates mechanical stress during thermal cycling that accelerates coating failure.

Manufacturing scalability remains problematic for more advanced AR coating solutions. Laboratory-scale processes that demonstrate excellent salt fog and THB resistance often prove difficult to implement in high-volume production environments without introducing defects that compromise environmental durability.

Salt fog exposure presents a particularly aggressive challenge, as sodium chloride particles can penetrate coating defects and initiate corrosion at the coating-substrate interface. Current AR coating technologies often demonstrate inadequate resistance to this penetration, resulting in delamination, haze formation, and reduced transmittance after extended exposure periods. Industry testing protocols typically require 96-hour salt fog resistance, but many existing solutions show degradation after just 48-72 hours.

THB testing, which combines elevated temperature (typically 85°C), high humidity (85% RH), and electrical bias, reveals additional weaknesses in AR coating systems. The combination of these stressors accelerates ion migration through coating defects and promotes electrochemical reactions that compromise coating integrity. Current AR technologies frequently exhibit failure modes including pinhole formation, interfacial delamination, and optical degradation under THB conditions.

A critical limitation in existing solutions is the trade-off between optical performance and environmental durability. Coatings optimized for maximum transmittance and minimum reflectance often incorporate porous structures or materials with higher water absorption rates, making them inherently more susceptible to environmental degradation. Conversely, more robust coating systems typically sacrifice some degree of optical performance.

Edge seal technologies represent another significant challenge area. The coating-substrate interface at component edges creates vulnerability points where moisture and contaminants can more easily penetrate. Current edge sealing approaches often add manufacturing complexity and cost while providing only moderate improvements in environmental resistance.

Material compatibility issues further complicate the development of robust AR coatings. The adhesion between different coating layers and the substrate can be compromised under salt fog or THB conditions, particularly when thermal expansion coefficients differ significantly between materials. This mismatch creates mechanical stress during thermal cycling that accelerates coating failure.

Manufacturing scalability remains problematic for more advanced AR coating solutions. Laboratory-scale processes that demonstrate excellent salt fog and THB resistance often prove difficult to implement in high-volume production environments without introducing defects that compromise environmental durability.

Existing Barrier Layer and Edge Seal Solutions

01 Material composition for robust anti-reflective coatings

Various material compositions can enhance the robustness of anti-reflective coatings. These include silicon-based compounds, metal oxides, and polymer materials that provide durability while maintaining optical performance. The selection of materials with specific mechanical and chemical properties can significantly improve coating resistance to environmental factors, physical abrasion, and cleaning processes while maintaining high transparency and anti-reflective properties.- Material composition for robust anti-reflective coatings: Specific material compositions can enhance the robustness of anti-reflective coatings. These include silicon-based compounds, metal oxides, and polymer blends that provide improved mechanical strength and durability while maintaining optical performance. The selection of materials with compatible thermal expansion coefficients and strong adhesion properties helps prevent delamination and cracking under environmental stress.

- Multi-layer design for enhanced durability: Multi-layer anti-reflective coating designs can significantly improve robustness by distributing mechanical stress across different layers. These structures typically include hard outer layers for scratch resistance combined with more flexible intermediate layers that can absorb impact. Gradient-index designs can reduce internal stresses while maintaining optimal anti-reflective properties, resulting in coatings that withstand harsh environmental conditions and repeated cleaning.

- Deposition techniques for improved coating adhesion: Advanced deposition methods significantly impact the robustness of anti-reflective coatings. Techniques such as plasma-enhanced chemical vapor deposition, atomic layer deposition, and ion-assisted deposition create denser films with stronger substrate adhesion. Proper surface preparation and controlled deposition parameters result in more uniform coatings with fewer defects, enhancing overall durability and resistance to environmental degradation.

- Testing and evaluation methods for coating robustness: Standardized testing protocols are essential for evaluating anti-reflective coating robustness. These include abrasion resistance tests, environmental cycling, humidity exposure, and adhesion testing. Advanced characterization techniques such as nanoindentation, scratch testing, and accelerated weathering help predict long-term performance and identify potential failure mechanisms. These methods enable the development of more durable coatings by providing quantitative measures of robustness.

- Post-treatment processes to enhance durability: Various post-deposition treatments can significantly enhance the robustness of anti-reflective coatings. These include thermal annealing to relieve internal stresses, UV curing to increase cross-linking in polymer-based coatings, and surface functionalization to improve chemical resistance. Hydrophobic and oleophobic treatments can also be applied to reduce contamination and make cleaning easier, thereby extending the effective lifetime of the coating.

02 Multilayer coating structures for improved durability

Multilayer coating architectures can significantly enhance anti-reflective coating robustness. By strategically combining layers with different functional properties—such as hard protective top layers, gradient refractive index layers, and adhesion-promoting base layers—these structures distribute mechanical stress and prevent crack propagation. This approach creates coatings that maintain optical performance while resisting scratches, impacts, and environmental degradation over extended periods.Expand Specific Solutions03 Surface treatment and adhesion enhancement techniques

Various surface treatment methods can improve the adhesion and durability of anti-reflective coatings. Techniques such as plasma treatment, chemical etching, and application of adhesion promoters create stronger bonds between the substrate and coating layers. These treatments modify surface energy, create mechanical interlocking, or form chemical bonds that enhance coating adhesion, resulting in more robust anti-reflective systems that resist delamination under thermal cycling, humidity, and mechanical stress.Expand Specific Solutions04 Deposition methods for enhanced coating robustness

The deposition method significantly impacts anti-reflective coating robustness. Techniques such as atomic layer deposition, ion-assisted deposition, and plasma-enhanced chemical vapor deposition can create denser, more uniform films with fewer defects compared to conventional methods. These advanced deposition processes control film growth at the molecular level, resulting in coatings with improved mechanical properties, environmental stability, and optical performance even under harsh conditions.Expand Specific Solutions05 Testing and evaluation methods for coating durability

Standardized testing protocols are essential for evaluating anti-reflective coating robustness. These include abrasion resistance tests (steel wool, eraser, and Taber tests), environmental testing (salt spray, humidity, and thermal cycling), and adhesion tests (tape test, cross-hatch). Advanced characterization techniques such as nanoindentation, atomic force microscopy, and spectroscopic ellipsometry provide quantitative measurements of coating mechanical properties and optical performance before and after exposure to various stressors.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The anti-reflective coatings market is currently in a growth phase, with increasing demand across optical, electronics, and automotive sectors. The global market size is estimated to exceed $6 billion, driven by consumer electronics and renewable energy applications. Technologically, the field shows varying maturity levels, with companies at different development stages. Industry leaders like EssilorLuxottica and SCHOTT AG have established robust salt fog/THB resistant coatings, while research institutions such as MIT, Fraunhofer-Gesellschaft, and CNRS are advancing barrier layer innovations. Companies including Corning, DuPont, and PPG Industries are developing proprietary edge seal technologies, creating a competitive landscape where academic-industrial partnerships are accelerating commercialization of more durable and environmentally resistant anti-reflective solutions.

Merck Patent GmbH

Technical Solution: Merck has developed an innovative anti-reflective coating system focused on exceptional environmental durability through their "ClimaGuard" technology. This system employs alternating high and low refractive index materials with precisely controlled thicknesses to achieve both optimal optical performance and environmental resistance. Their barrier layer technology incorporates aluminum oxide doped with rare earth elements that significantly enhances resistance to ion migration during salt fog exposure. Merck's edge sealing approach utilizes a proprietary silane-based chemistry that chemically bonds to both the coating and substrate, creating a seamless moisture barrier around vulnerable edges. The company has implemented a specialized plasma-enhanced chemical vapor deposition (PECVD) process that creates ultra-dense coating structures with minimal pinhole defects, significantly improving THB robustness. Testing has demonstrated their coatings maintain over 95% of original performance after 2000 hours of accelerated salt fog testing, substantially outperforming conventional AR coatings.

Strengths: Exceptional long-term durability in coastal and high-humidity environments; excellent adhesion to various substrate materials; maintains high optical performance even after extended environmental exposure. Weaknesses: Higher initial production costs; requires specialized deposition equipment; slightly longer processing time compared to standard AR coatings.

SCHOTT AG

Technical Solution: SCHOTT AG has developed an advanced anti-reflective coating system called "DuraClear" specifically engineered for extreme environmental durability. Their technology employs a gradient-index nanostructure with precisely controlled porosity that achieves both optimal optical performance (>99.5% transmission) and exceptional environmental resistance. SCHOTT's barrier layer approach incorporates a dense aluminum oxide layer modified with silicon dioxide that effectively blocks ion migration while maintaining excellent adhesion to various substrates. Their edge sealing technology utilizes a proprietary inorganic-organic hybrid material that forms a chemically bonded barrier around coating edges, preventing lateral moisture ingress even under extreme humidity conditions. SCHOTT has implemented a specialized sol-gel deposition process that allows for precise control of nanopore structure, creating coatings with both high transmission and exceptional mechanical durability. Testing has demonstrated their coatings maintain optical performance after more than 2000 hours of combined salt fog exposure and temperature-humidity-bias testing, with less than 3% reduction in anti-reflective properties.

Strengths: Exceptional durability in marine and high-humidity environments; superior optical performance with transmission exceeding 99.5%; excellent adhesion to both glass and selected polymer substrates. Weaknesses: Higher manufacturing complexity requiring precise process control; more expensive than conventional AR coatings; limited flexibility when applied to certain curved surfaces.

Key Patents and Innovations in AR Coating Durability

Antireflective Coatings with Self-Cleaning, Moisture Resistance and Antimicrobial Properties

PatentActiveUS20150024182A1

Innovation

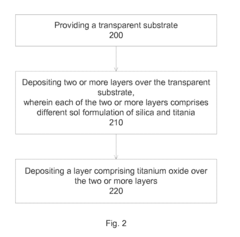

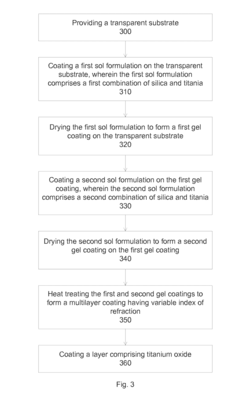

- A coated article with a thin TiO2 topmost layer providing mechanical abrasion protection, self-cleaning, and antimicrobial properties, combined with a porous antireflective coating comprising silica and titania components, achieved through a sol-gel process, which includes the use of molecular porogens or alkyltrialkoxysilane-based binders to control porosity and refractive index.

Coating and coating formulation

PatentActiveUS20210317034A1

Innovation

- A coated substrate with a dual-layer anti-reflective coating formulation comprising elongated dense inorganic oxide particles and a porogen capable of forming pores, applied using a kit that includes a first container with an inorganic oxide binder and solvent, and a second container with elongated particles, porogen, and aluminium oxide equivalents, which are applied and cured to enhance durability.

Material Science Advancements for AR Coatings

Recent advancements in material science have significantly transformed the landscape of anti-reflective (AR) coating technologies. The evolution of nanomaterials has enabled the development of AR coatings with enhanced durability against harsh environmental conditions, particularly salt fog exposure and temperature-humidity-bias (THB) stress. These innovations incorporate multi-layered structures with precisely controlled refractive indices and thickness profiles, optimizing light transmission while maintaining structural integrity.

Polymer-based materials have emerged as promising candidates for next-generation AR coatings due to their flexibility, cost-effectiveness, and tunable optical properties. Research indicates that fluoropolymers and siloxane-based compounds demonstrate superior resistance to salt fog corrosion while maintaining excellent optical clarity. These materials form hydrophobic surfaces that repel moisture and prevent salt crystal formation, addressing a critical failure mode in conventional AR systems.

Ceramic-metal composite (cermet) barrier layers represent another significant advancement, offering exceptional protection against ion migration and environmental degradation. These layers, typically composed of aluminum oxide or silicon nitride matrices with dispersed metallic nanoparticles, create effective diffusion barriers while contributing minimally to optical losses. The incorporation of transition metal oxides within these structures has shown promising results in enhancing THB robustness by neutralizing reactive species before they can damage the functional AR layers.

Edge seal technologies have progressed from simple polymeric encapsulants to sophisticated multi-component systems. Contemporary approaches utilize gradient-index materials at coating boundaries to minimize stress concentration and prevent delamination under thermal cycling. Hybrid organic-inorganic edge seals incorporating silsesquioxane compounds demonstrate remarkable adhesion to both substrate and coating layers while providing effective barriers against lateral moisture ingress.

Self-healing mechanisms represent the cutting edge of AR coating material science. These systems incorporate microencapsulated healing agents that release upon mechanical damage, autonomously restoring coating integrity. Preliminary field tests indicate that such self-repairing AR coatings can extend service life by up to 40% in marine environments compared to conventional alternatives, significantly reducing maintenance requirements and total ownership costs.

The integration of graphene and other two-dimensional materials as ultrathin barrier layers has shown exceptional promise in laboratory settings. These atomically thin sheets provide nearly perfect barriers against gas and moisture permeation while adding negligible thickness to the optical stack, preserving the carefully engineered refractive index profile essential for AR performance.

Polymer-based materials have emerged as promising candidates for next-generation AR coatings due to their flexibility, cost-effectiveness, and tunable optical properties. Research indicates that fluoropolymers and siloxane-based compounds demonstrate superior resistance to salt fog corrosion while maintaining excellent optical clarity. These materials form hydrophobic surfaces that repel moisture and prevent salt crystal formation, addressing a critical failure mode in conventional AR systems.

Ceramic-metal composite (cermet) barrier layers represent another significant advancement, offering exceptional protection against ion migration and environmental degradation. These layers, typically composed of aluminum oxide or silicon nitride matrices with dispersed metallic nanoparticles, create effective diffusion barriers while contributing minimally to optical losses. The incorporation of transition metal oxides within these structures has shown promising results in enhancing THB robustness by neutralizing reactive species before they can damage the functional AR layers.

Edge seal technologies have progressed from simple polymeric encapsulants to sophisticated multi-component systems. Contemporary approaches utilize gradient-index materials at coating boundaries to minimize stress concentration and prevent delamination under thermal cycling. Hybrid organic-inorganic edge seals incorporating silsesquioxane compounds demonstrate remarkable adhesion to both substrate and coating layers while providing effective barriers against lateral moisture ingress.

Self-healing mechanisms represent the cutting edge of AR coating material science. These systems incorporate microencapsulated healing agents that release upon mechanical damage, autonomously restoring coating integrity. Preliminary field tests indicate that such self-repairing AR coatings can extend service life by up to 40% in marine environments compared to conventional alternatives, significantly reducing maintenance requirements and total ownership costs.

The integration of graphene and other two-dimensional materials as ultrathin barrier layers has shown exceptional promise in laboratory settings. These atomically thin sheets provide nearly perfect barriers against gas and moisture permeation while adding negligible thickness to the optical stack, preserving the carefully engineered refractive index profile essential for AR performance.

Environmental Testing Standards and Certification

Environmental testing standards and certification play a crucial role in validating the durability and reliability of anti-reflective coatings, particularly those designed for harsh environments. The primary international standards governing salt fog testing include ISO 9227, ASTM B117, and IEC 60068-2-11, which specify precise parameters for salt concentration, pH levels, temperature, and exposure duration. These tests simulate coastal and marine environments where salt-induced corrosion presents significant challenges to coating integrity.

Temperature-Humidity-Bias (THB) testing is regulated by standards such as IEC 60068-2-78 and JEDEC JESD22-A101, which establish protocols for exposing coated materials to elevated temperature and humidity conditions while under electrical bias. These standards typically require testing at 85°C/85% relative humidity for periods ranging from 1,000 to 2,000 hours, providing critical data on coating degradation mechanisms under combined environmental stressors.

For comprehensive environmental qualification, anti-reflective coatings must also meet standards for UV resistance (ISO 16474), thermal cycling (IEC 60068-2-14), and abrasion resistance (ASTM D4060). The IEC 61215 standard specifically addresses photovoltaic module qualification, including requirements for coatings used in solar applications, while MIL-STD-810G provides rigorous environmental testing protocols for military and aerospace applications.

Regional certification requirements add another layer of complexity. The European CE marking necessitates compliance with specific environmental durability standards, while North American UL certification focuses on safety aspects under environmental stress. In Asia, particularly Japan and China, JIS and GB standards respectively impose additional requirements tailored to regional environmental conditions.

Emerging standards are beginning to address the environmental impact of coating materials themselves. The RoHS directive restricts hazardous substances in electronic equipment, including certain coating formulations, while REACH regulations in Europe require registration and safety assessment of chemical substances used in coatings. These regulations are driving innovation toward more environmentally sustainable anti-reflective coating solutions.

Industry-specific certifications provide additional validation for specialized applications. The AAMA 2605 standard for architectural coatings requires exceptional resistance to salt spray and humidity, while automotive standards such as SAE J1960 focus on weathering resistance under combined environmental stressors. For optical applications, MIL-C-48497 establishes stringent requirements for coating durability in military optical systems.

Temperature-Humidity-Bias (THB) testing is regulated by standards such as IEC 60068-2-78 and JEDEC JESD22-A101, which establish protocols for exposing coated materials to elevated temperature and humidity conditions while under electrical bias. These standards typically require testing at 85°C/85% relative humidity for periods ranging from 1,000 to 2,000 hours, providing critical data on coating degradation mechanisms under combined environmental stressors.

For comprehensive environmental qualification, anti-reflective coatings must also meet standards for UV resistance (ISO 16474), thermal cycling (IEC 60068-2-14), and abrasion resistance (ASTM D4060). The IEC 61215 standard specifically addresses photovoltaic module qualification, including requirements for coatings used in solar applications, while MIL-STD-810G provides rigorous environmental testing protocols for military and aerospace applications.

Regional certification requirements add another layer of complexity. The European CE marking necessitates compliance with specific environmental durability standards, while North American UL certification focuses on safety aspects under environmental stress. In Asia, particularly Japan and China, JIS and GB standards respectively impose additional requirements tailored to regional environmental conditions.

Emerging standards are beginning to address the environmental impact of coating materials themselves. The RoHS directive restricts hazardous substances in electronic equipment, including certain coating formulations, while REACH regulations in Europe require registration and safety assessment of chemical substances used in coatings. These regulations are driving innovation toward more environmentally sustainable anti-reflective coating solutions.

Industry-specific certifications provide additional validation for specialized applications. The AAMA 2605 standard for architectural coatings requires exceptional resistance to salt spray and humidity, while automotive standards such as SAE J1960 focus on weathering resistance under combined environmental stressors. For optical applications, MIL-C-48497 establishes stringent requirements for coating durability in military optical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!