Anti-Reflective Coatings: UV Exposure, Abrasion Resistance And Outdoor Weathering

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR Coating Technology Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when F. Geffcken first developed multi-layer interference coatings. Initially utilized primarily in optical instruments and camera lenses, these coatings have progressively expanded into diverse applications including solar panels, displays, eyewear, architectural glass, and automotive components. The fundamental principle behind AR coatings—destructive interference of reflected light—remains unchanged, but the materials, deposition techniques, and performance characteristics have undergone substantial advancement.

The evolution of AR coating technology has been driven by increasing demands for enhanced optical performance across broader wavelength ranges, particularly in the ultraviolet spectrum where specialized applications in photolithography, UV sensors, and sterilization equipment require exceptional transmission properties. Concurrently, the expansion of AR coatings into outdoor applications has necessitated significant improvements in durability metrics, specifically abrasion resistance and weathering stability.

Current AR coating technologies predominantly employ vacuum deposition methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and atomic layer deposition (ALD), alongside solution-based approaches including sol-gel processes and layer-by-layer assembly. Each methodology presents distinct advantages and limitations regarding coating uniformity, adhesion strength, and scalability for mass production.

The primary technical objective of this research is to develop next-generation AR coatings that maintain optimal optical performance while significantly enhancing resistance to UV degradation, mechanical abrasion, and environmental weathering factors. Specifically, we aim to achieve less than 0.5% reflectance across the UV-visible spectrum (200-700nm) while withstanding 2000+ hours of accelerated weathering and meeting industry-standard abrasion tests without performance degradation.

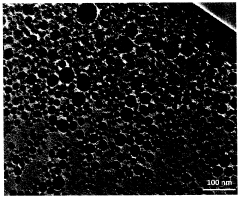

Recent technological trends indicate growing interest in hybrid organic-inorganic materials, nanostructured surfaces, and biomimetic approaches inspired by natural anti-reflective structures found in moth eyes and cicada wings. These innovations offer promising pathways toward achieving the desired combination of optical efficiency and durability. Additionally, emerging deposition technologies such as glancing angle deposition (GLAD) and atmospheric pressure plasma-enhanced chemical vapor deposition (AP-PECVD) are enabling more precise control over coating microstructure and composition.

The convergence of materials science, nanotechnology, and advanced manufacturing processes presents unprecedented opportunities to overcome the historical trade-offs between optical performance and mechanical durability in AR coatings. This research aims to capitalize on these developments to create commercially viable solutions that meet the increasingly demanding requirements of outdoor and UV-intensive applications.

The evolution of AR coating technology has been driven by increasing demands for enhanced optical performance across broader wavelength ranges, particularly in the ultraviolet spectrum where specialized applications in photolithography, UV sensors, and sterilization equipment require exceptional transmission properties. Concurrently, the expansion of AR coatings into outdoor applications has necessitated significant improvements in durability metrics, specifically abrasion resistance and weathering stability.

Current AR coating technologies predominantly employ vacuum deposition methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and atomic layer deposition (ALD), alongside solution-based approaches including sol-gel processes and layer-by-layer assembly. Each methodology presents distinct advantages and limitations regarding coating uniformity, adhesion strength, and scalability for mass production.

The primary technical objective of this research is to develop next-generation AR coatings that maintain optimal optical performance while significantly enhancing resistance to UV degradation, mechanical abrasion, and environmental weathering factors. Specifically, we aim to achieve less than 0.5% reflectance across the UV-visible spectrum (200-700nm) while withstanding 2000+ hours of accelerated weathering and meeting industry-standard abrasion tests without performance degradation.

Recent technological trends indicate growing interest in hybrid organic-inorganic materials, nanostructured surfaces, and biomimetic approaches inspired by natural anti-reflective structures found in moth eyes and cicada wings. These innovations offer promising pathways toward achieving the desired combination of optical efficiency and durability. Additionally, emerging deposition technologies such as glancing angle deposition (GLAD) and atmospheric pressure plasma-enhanced chemical vapor deposition (AP-PECVD) are enabling more precise control over coating microstructure and composition.

The convergence of materials science, nanotechnology, and advanced manufacturing processes presents unprecedented opportunities to overcome the historical trade-offs between optical performance and mechanical durability in AR coatings. This research aims to capitalize on these developments to create commercially viable solutions that meet the increasingly demanding requirements of outdoor and UV-intensive applications.

Market Analysis for UV-Resistant AR Coatings

The global market for UV-resistant anti-reflective (AR) coatings is experiencing robust growth, driven primarily by expanding applications in solar panels, automotive displays, eyewear, and architectural glass. The market value reached approximately $1.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.8% through 2028, potentially reaching $2.3 billion by the end of the forecast period.

Solar energy represents the largest application segment, accounting for nearly 40% of the total market share. The increasing installation of photovoltaic systems worldwide has created substantial demand for high-performance AR coatings that can withstand prolonged UV exposure while maintaining optimal light transmission properties. This segment is particularly sensitive to coating durability metrics, as performance degradation directly impacts energy generation efficiency and system economics.

The automotive industry constitutes the second-largest market segment, with growing implementation of AR-coated displays and sensors in vehicles. Premium and electric vehicle manufacturers are increasingly specifying UV-resistant AR coatings for heads-up displays and touchscreen interfaces, prioritizing solutions that maintain clarity and functionality throughout the vehicle's service life under varying weather conditions.

Consumer electronics and eyewear segments collectively represent approximately 25% of the market. The eyewear sector specifically demands coatings that combine UV protection with scratch resistance and anti-reflective properties, creating a specialized niche with higher margins but more stringent performance requirements.

Geographically, Asia-Pacific dominates the market with a 45% share, driven by the concentration of solar panel manufacturing in China, Japan, and South Korea. North America and Europe follow with approximately 25% and 20% market shares respectively, with higher demand for premium, high-durability solutions.

Customer requirements are increasingly focused on multi-functional coatings that combine anti-reflective properties with enhanced UV stability, abrasion resistance, and self-cleaning capabilities. Market research indicates willingness to pay premium prices for coatings that demonstrably extend product lifespans in outdoor applications, with particular emphasis on maintaining optical clarity after extended weathering.

The competitive landscape features both specialized coating manufacturers and vertically integrated producers. Key market drivers include stricter energy efficiency regulations, growing consumer awareness of UV protection, and the expanding outdoor electronics market. Barriers to market entry include high R&D costs for developing multi-functional coatings and the need for extensive weathering validation data to support performance claims.

Solar energy represents the largest application segment, accounting for nearly 40% of the total market share. The increasing installation of photovoltaic systems worldwide has created substantial demand for high-performance AR coatings that can withstand prolonged UV exposure while maintaining optimal light transmission properties. This segment is particularly sensitive to coating durability metrics, as performance degradation directly impacts energy generation efficiency and system economics.

The automotive industry constitutes the second-largest market segment, with growing implementation of AR-coated displays and sensors in vehicles. Premium and electric vehicle manufacturers are increasingly specifying UV-resistant AR coatings for heads-up displays and touchscreen interfaces, prioritizing solutions that maintain clarity and functionality throughout the vehicle's service life under varying weather conditions.

Consumer electronics and eyewear segments collectively represent approximately 25% of the market. The eyewear sector specifically demands coatings that combine UV protection with scratch resistance and anti-reflective properties, creating a specialized niche with higher margins but more stringent performance requirements.

Geographically, Asia-Pacific dominates the market with a 45% share, driven by the concentration of solar panel manufacturing in China, Japan, and South Korea. North America and Europe follow with approximately 25% and 20% market shares respectively, with higher demand for premium, high-durability solutions.

Customer requirements are increasingly focused on multi-functional coatings that combine anti-reflective properties with enhanced UV stability, abrasion resistance, and self-cleaning capabilities. Market research indicates willingness to pay premium prices for coatings that demonstrably extend product lifespans in outdoor applications, with particular emphasis on maintaining optical clarity after extended weathering.

The competitive landscape features both specialized coating manufacturers and vertically integrated producers. Key market drivers include stricter energy efficiency regulations, growing consumer awareness of UV protection, and the expanding outdoor electronics market. Barriers to market entry include high R&D costs for developing multi-functional coatings and the need for extensive weathering validation data to support performance claims.

Current Challenges in AR Coating Durability

Anti-reflective (AR) coatings face significant durability challenges that limit their performance and lifespan, particularly when exposed to harsh environmental conditions. The primary challenge lies in maintaining optical performance while ensuring mechanical robustness. Current AR coatings often experience degradation in their anti-reflective properties after exposure to UV radiation, which causes photochemical reactions that alter the coating's molecular structure and optical characteristics.

Mechanical abrasion represents another critical challenge, as most high-performance AR coatings utilize porous structures or multilayer designs that inherently compromise mechanical strength. These coatings typically demonstrate a trade-off relationship between optical efficiency and mechanical durability. When optimized for maximum light transmission, they often become more susceptible to scratching, delamination, and general wear during routine cleaning or handling.

Outdoor weathering introduces a complex combination of stressors including temperature fluctuations, humidity variations, and exposure to pollutants. These factors work synergistically to accelerate coating degradation. Thermal cycling causes expansion and contraction that can lead to microcracks and delamination at the coating-substrate interface. Moisture ingress into porous AR structures can dramatically reduce optical performance and promote hydrolytic degradation of coating materials.

Chemical resistance presents another significant hurdle, as AR coatings must withstand exposure to various cleaning agents, atmospheric pollutants, and acidic rain. Many current formulations show vulnerability to chemical attack, resulting in clouding, discoloration, or complete coating failure over time. This is particularly problematic for outdoor applications in industrial environments where air quality may be compromised.

The manufacturing process itself introduces durability challenges. Techniques like sol-gel deposition can create excellent optical properties but often result in coatings with suboptimal adhesion to substrates. Physical vapor deposition methods may produce more durable films but typically at higher cost and with more complex production requirements.

Standardization of durability testing represents a significant industry challenge. Current test protocols often fail to accurately simulate real-world conditions or predict actual field performance. Accelerated aging tests may not correlate well with natural weathering, making it difficult to reliably assess coating lifespans or compare different technologies.

The economic constraints further complicate solutions, as highly durable AR coatings typically require expensive materials or complex manufacturing processes. This creates a significant barrier to widespread adoption, particularly in cost-sensitive applications like consumer electronics or architectural glazing where the performance benefits must be balanced against increased production costs.

Mechanical abrasion represents another critical challenge, as most high-performance AR coatings utilize porous structures or multilayer designs that inherently compromise mechanical strength. These coatings typically demonstrate a trade-off relationship between optical efficiency and mechanical durability. When optimized for maximum light transmission, they often become more susceptible to scratching, delamination, and general wear during routine cleaning or handling.

Outdoor weathering introduces a complex combination of stressors including temperature fluctuations, humidity variations, and exposure to pollutants. These factors work synergistically to accelerate coating degradation. Thermal cycling causes expansion and contraction that can lead to microcracks and delamination at the coating-substrate interface. Moisture ingress into porous AR structures can dramatically reduce optical performance and promote hydrolytic degradation of coating materials.

Chemical resistance presents another significant hurdle, as AR coatings must withstand exposure to various cleaning agents, atmospheric pollutants, and acidic rain. Many current formulations show vulnerability to chemical attack, resulting in clouding, discoloration, or complete coating failure over time. This is particularly problematic for outdoor applications in industrial environments where air quality may be compromised.

The manufacturing process itself introduces durability challenges. Techniques like sol-gel deposition can create excellent optical properties but often result in coatings with suboptimal adhesion to substrates. Physical vapor deposition methods may produce more durable films but typically at higher cost and with more complex production requirements.

Standardization of durability testing represents a significant industry challenge. Current test protocols often fail to accurately simulate real-world conditions or predict actual field performance. Accelerated aging tests may not correlate well with natural weathering, making it difficult to reliably assess coating lifespans or compare different technologies.

The economic constraints further complicate solutions, as highly durable AR coatings typically require expensive materials or complex manufacturing processes. This creates a significant barrier to widespread adoption, particularly in cost-sensitive applications like consumer electronics or architectural glazing where the performance benefits must be balanced against increased production costs.

State-of-the-Art AR Coating Solutions

01 UV-resistant anti-reflective coating compositions

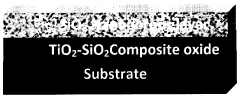

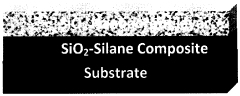

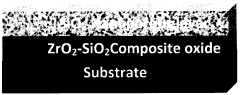

Anti-reflective coatings can be formulated with UV-resistant materials to enhance durability during outdoor exposure. These compositions typically include UV absorbers or stabilizers that prevent degradation of the coating when exposed to sunlight. The formulations may incorporate silica nanoparticles, fluoropolymers, or specialized acrylates that maintain optical clarity while providing protection against UV radiation, ensuring long-term performance in outdoor applications.- UV-resistant anti-reflective coating compositions: Anti-reflective coatings can be formulated with UV-resistant materials to enhance durability during outdoor exposure. These compositions typically include UV absorbers, stabilizers, or inherently UV-resistant polymers that prevent degradation when exposed to sunlight. The coatings maintain their anti-reflective properties while providing protection against yellowing, cracking, or other forms of UV-induced deterioration, making them suitable for outdoor applications like solar panels, architectural glass, and optical devices.

- Abrasion-resistant anti-reflective coating technologies: Specialized formulations incorporate hard materials such as silica, alumina, or other ceramic nanoparticles to improve the mechanical durability of anti-reflective coatings. These coatings often utilize multi-layer structures or hybrid organic-inorganic materials to achieve both optical clarity and scratch resistance. Advanced curing methods, including thermal or UV curing, create cross-linked networks that significantly enhance the coating's resistance to abrasion from cleaning, environmental particles, or regular handling while maintaining optimal anti-reflective properties.

- Weathering-resistant anti-reflective coating systems: Anti-reflective coatings designed for outdoor applications incorporate materials that resist multiple environmental stressors including moisture, temperature fluctuations, pollutants, and salt spray. These systems often feature hydrophobic or oleophobic top layers that repel water and contaminants, preventing degradation of optical performance over time. The coatings may include corrosion inhibitors, moisture barriers, or self-healing components that extend service life in harsh outdoor conditions while maintaining consistent anti-reflective performance.

- Testing and evaluation methods for anti-reflective coating durability: Specialized testing protocols have been developed to evaluate the performance of anti-reflective coatings under accelerated weathering conditions. These methods include simulated solar exposure using xenon arc or UV fluorescent lamps, cyclic temperature and humidity testing, salt fog exposure, and standardized abrasion tests like Taber abraser or steel wool testing. Advanced analytical techniques such as spectrophotometry, microscopy, and surface analysis are employed to quantify changes in optical performance, surface morphology, and chemical composition after exposure to environmental stressors.

- Novel deposition techniques for durable anti-reflective coatings: Advanced deposition methods enhance the durability of anti-reflective coatings against UV exposure, abrasion, and weathering. These techniques include plasma-enhanced chemical vapor deposition, atomic layer deposition, sol-gel processes, and magnetron sputtering. These methods allow precise control over coating thickness, density, and microstructure, resulting in improved adhesion to substrates and enhanced resistance to environmental degradation. The coatings produced by these techniques often feature gradient refractive index profiles or nanostructured surfaces that maintain anti-reflective properties while providing superior mechanical and environmental durability.

02 Abrasion-resistant anti-reflective coating technologies

Advanced anti-reflective coatings can be engineered with enhanced abrasion resistance through the incorporation of hard materials such as metal oxides or hybrid organic-inorganic compounds. These coatings often utilize multi-layer structures or nanocomposite materials to achieve both optical performance and mechanical durability. Surface treatments and specialized curing processes can further improve scratch resistance while maintaining the desired anti-reflective properties for applications requiring frequent handling or cleaning.Expand Specific Solutions03 Weathering-resistant coating application methods

Various application techniques can significantly improve the weathering resistance of anti-reflective coatings. Methods such as plasma-enhanced chemical vapor deposition, sol-gel processing, and specialized dip or spray coating procedures can create more uniform and defect-free films. These techniques often incorporate controlled curing environments, precise thickness control, and surface preparation protocols to ensure optimal adhesion and environmental stability, resulting in coatings that maintain their anti-reflective properties despite prolonged outdoor exposure.Expand Specific Solutions04 Testing and evaluation methods for coating durability

Specialized testing protocols have been developed to evaluate the performance of anti-reflective coatings under accelerated weathering and abrasion conditions. These methods include cyclic UV exposure tests, salt spray testing, temperature cycling, humidity resistance evaluation, and standardized abrasion tests using various media. Advanced analytical techniques such as spectrophotometry, microscopy, and surface analysis are employed to quantify changes in optical performance and surface characteristics after exposure to simulated environmental conditions.Expand Specific Solutions05 Multi-functional anti-reflective coating systems

Modern anti-reflective coatings often incorporate multiple functional properties beyond basic reflection reduction. These multi-functional systems can simultaneously provide UV protection, abrasion resistance, and weathering stability through carefully designed layer structures or composite materials. Some advanced formulations also include self-cleaning properties, anti-fogging capabilities, or hydrophobic characteristics that enhance performance in outdoor environments. These integrated approaches often utilize nanomaterials, functional polymers, or specialized additives to achieve multiple performance objectives without compromising optical clarity.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The anti-reflective coatings market is currently in a growth phase, with an estimated global market size of $4-5 billion and projected annual growth of 6-8%. The technology landscape shows varying degrees of maturity across applications, with established solutions for optical and electronic applications but emerging innovations for enhanced weathering resistance and UV protection. Key players demonstrate distinct technological specializations: Corning and EssilorLuxottica lead in optical applications; First Solar and Enki Technology focus on solar-specific coatings with superior weatherability; Brewer Science dominates semiconductor anti-reflective solutions; while Carl Zeiss SMT and Nikon excel in precision optical coatings with advanced abrasion resistance. Research institutions like Chongqing University and Emory University are advancing fundamental innovations in UV-resistant formulations, creating collaborative opportunities with commercial entities to address durability challenges in outdoor applications.

Corning, Inc.

Technical Solution: Corning has developed advanced anti-reflective coatings utilizing their proprietary fusion draw process that creates atomically smooth glass surfaces ideal for AR coating application. Their technology incorporates multi-layer thin film coatings with alternating high and low refractive index materials to achieve broadband anti-reflection properties. For UV exposure resistance, Corning employs specialized silica-based materials doped with metal oxides that absorb harmful UV radiation while maintaining transparency in the visible spectrum. Their abrasion-resistant AR coatings feature nanocomposite structures with embedded ceramic nanoparticles that significantly enhance mechanical durability while maintaining optical clarity. For outdoor weathering, Corning has implemented hydrophobic and oleophobic top layers that repel water and oils, preventing contamination and facilitating easy cleaning. Their coatings undergo accelerated weathering tests equivalent to 5+ years of outdoor exposure to ensure long-term performance stability.

Strengths: Superior optical clarity with >99% transmission in visible spectrum; exceptional abrasion resistance (9H pencil hardness); proprietary fusion process enables atomically smooth surfaces for perfect coating adhesion; established manufacturing infrastructure for large-scale production. Weaknesses: Higher production costs compared to conventional spray coatings; complex multi-layer deposition process requires specialized equipment; limited flexibility for application on curved surfaces.

EssilorLuxottica SA

Technical Solution: EssilorLuxottica has pioneered anti-reflective coating technology specifically designed for ophthalmic applications with enhanced UV protection and durability. Their Crizal series employs a multi-layer approach with up to 9 distinct nanolayers, each serving specific functions. The base layers provide anti-reflective properties through destructive interference principles, while middle layers incorporate UV-absorbing compounds that block harmful radiation up to 400nm. Their proprietary Hard Coat technology utilizes silicone-based materials reinforced with nanoparticles to achieve superior scratch resistance, tested to withstand over 20,000 abrasion cycles without significant degradation. For outdoor applications, EssilorLuxottica has developed hydrophobic and oleophobic surface treatments that repel water, oils, and dust, maintaining clarity in challenging environments. Their coatings undergo rigorous testing including salt spray exposure, humidity cycling, and accelerated UV aging to simulate years of outdoor use. Recent innovations include anti-static properties to reduce dust attraction and self-cleaning capabilities.

Strengths: Industry-leading scratch resistance (tested to withstand 20,000+ abrasion cycles); excellent anti-reflective properties with <0.5% residual reflection; comprehensive UV protection up to 400nm; established global manufacturing and distribution network. Weaknesses: Premium pricing positions products at higher market segments; primarily focused on ophthalmic applications with less presence in industrial or architectural markets; coating process requires multiple specialized application steps.

Key Patents and Innovations in AR Coating Resistance

Process for producing Anti-reflective coatings with Anti-fogging (super hydrophilic), UV , weather and scratch resistance properties

PatentActiveIN2919DEL2013A

Innovation

- A bilayer coating system comprising a low refractive index composite layer and a highly positive charge SiO2 nanoparticle layer, applied using a sol-gel process, with controlled thickness and refractive index, providing broadband anti-reflective, anti-fogging, UV, and weather resistance properties on various substrates.

Patent

Innovation

- Development of multi-layer anti-reflective coatings with enhanced UV resistance through incorporation of UV absorbers and stabilizers in the coating formulation.

- Implementation of silica-based nanoparticles with controlled porosity to achieve both high optical transmittance and superior mechanical durability against abrasion.

- Design of gradient refractive index structures in the coating to minimize reflection across a broader spectrum while maintaining resistance to environmental degradation.

Environmental Impact and Sustainability Considerations

The environmental impact of anti-reflective (AR) coating technologies has become increasingly significant as global sustainability concerns grow. Traditional AR coating processes often involve hazardous chemicals such as fluorinated compounds and volatile organic compounds (VOCs), which pose substantial environmental risks through air and water pollution. These chemicals contribute to greenhouse gas emissions and can persist in ecosystems for extended periods, potentially disrupting aquatic and terrestrial habitats.

Manufacturing processes for AR coatings typically require considerable energy consumption, particularly in vacuum deposition methods that demand high temperatures and specialized equipment. This energy intensity translates to a significant carbon footprint, especially when power sources are not renewable. Additionally, the extraction of raw materials for these coatings, including rare earth elements and precious metals, often involves environmentally destructive mining practices that lead to habitat destruction and soil contamination.

Recent sustainability innovations in AR coating technology show promising developments. Bio-inspired approaches mimicking natural anti-reflective structures found in moth eyes and butterfly wings offer environmentally friendly alternatives that reduce chemical usage while maintaining optical performance. These biomimetic designs can be produced using less energy-intensive methods and more sustainable materials, significantly reducing environmental impact.

Water-based coating formulations represent another important advancement, replacing solvent-based systems and dramatically reducing VOC emissions. These formulations minimize air pollution and worker exposure to harmful chemicals while offering comparable performance characteristics for many applications. Similarly, sol-gel processing techniques have emerged as more environmentally benign alternatives to traditional vacuum deposition methods, operating at lower temperatures and requiring less energy.

End-of-life considerations for AR coated products present ongoing challenges. Most current coatings are not designed for recyclability or biodegradability, contributing to electronic waste and landfill accumulation. Developing coating technologies that facilitate material recovery or natural decomposition represents a critical frontier in sustainable AR coating research. Some promising approaches include designing coatings that can be easily separated from substrates during recycling processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of certain hazardous substances in manufacturing processes, driving innovation toward greener alternatives. Companies adopting sustainable AR coating technologies not only comply with these regulations but often gain competitive advantages through improved brand reputation and reduced compliance costs.

Manufacturing processes for AR coatings typically require considerable energy consumption, particularly in vacuum deposition methods that demand high temperatures and specialized equipment. This energy intensity translates to a significant carbon footprint, especially when power sources are not renewable. Additionally, the extraction of raw materials for these coatings, including rare earth elements and precious metals, often involves environmentally destructive mining practices that lead to habitat destruction and soil contamination.

Recent sustainability innovations in AR coating technology show promising developments. Bio-inspired approaches mimicking natural anti-reflective structures found in moth eyes and butterfly wings offer environmentally friendly alternatives that reduce chemical usage while maintaining optical performance. These biomimetic designs can be produced using less energy-intensive methods and more sustainable materials, significantly reducing environmental impact.

Water-based coating formulations represent another important advancement, replacing solvent-based systems and dramatically reducing VOC emissions. These formulations minimize air pollution and worker exposure to harmful chemicals while offering comparable performance characteristics for many applications. Similarly, sol-gel processing techniques have emerged as more environmentally benign alternatives to traditional vacuum deposition methods, operating at lower temperatures and requiring less energy.

End-of-life considerations for AR coated products present ongoing challenges. Most current coatings are not designed for recyclability or biodegradability, contributing to electronic waste and landfill accumulation. Developing coating technologies that facilitate material recovery or natural decomposition represents a critical frontier in sustainable AR coating research. Some promising approaches include designing coatings that can be easily separated from substrates during recycling processes.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of coating technologies. The European Union's REACH regulations and similar initiatives in other regions are restricting the use of certain hazardous substances in manufacturing processes, driving innovation toward greener alternatives. Companies adopting sustainable AR coating technologies not only comply with these regulations but often gain competitive advantages through improved brand reputation and reduced compliance costs.

Testing Methodologies and Performance Standards

Standardized testing methodologies are essential for evaluating the performance of anti-reflective coatings, particularly when focusing on UV exposure, abrasion resistance, and outdoor weathering characteristics. The industry has developed several key testing protocols that manufacturers and researchers employ to ensure coating quality and durability under various environmental conditions.

For UV exposure testing, ASTM G154 and ISO 16474-3 standards provide comprehensive frameworks for accelerated weathering tests using fluorescent UV lamps. These tests typically subject coated samples to controlled cycles of UV radiation and moisture at elevated temperatures, simulating months or years of outdoor exposure within weeks. The QUV accelerated weathering tester represents the industry standard equipment for such evaluations, allowing for precise control of UV intensity, temperature, and humidity levels.

Abrasion resistance testing for anti-reflective coatings commonly follows the Taber Abraser method (ASTM D4060) or the falling sand test (ASTM D968). The Taber method quantifies coating wear by measuring weight loss or haze increase after a specified number of abrasion cycles with calibrated wheels under controlled pressure. Alternatively, the Crockmeter test (ASTM F1319) evaluates coating resistance to rubbing and scratching, which is particularly relevant for touchscreen applications with anti-reflective treatments.

Outdoor weathering performance requires both accelerated and real-time testing approaches. ASTM G7 provides guidelines for direct outdoor exposure testing, while ASTM D4587 outlines procedures for condensation testing that simulates dew and rain effects. The industry standard for salt spray resistance, ASTM B117, evaluates coating performance in coastal environments or areas with high salt content in the atmosphere.

Performance standards for anti-reflective coatings typically specify minimum requirements across multiple parameters. MIL-C-48497 and MIL-C-675 military specifications define stringent standards for optical coatings, including anti-reflective treatments. These standards typically require less than 0.5% reflectance in the target wavelength range, abrasion resistance surviving at least 50 strokes with a cheesecloth under specified pressure, and UV stability with less than 5% change in optical properties after 1000 hours of accelerated weathering.

The emerging ISO 18543 standard specifically addresses the durability of solar panel cover glass with anti-reflective coatings, establishing performance criteria for UV exposure (2000+ hours with less than 2% transmission loss) and abrasion resistance (maintaining at least 98% of original transmission after standardized testing). These standards continue to evolve as coating technologies advance and applications expand into new markets requiring enhanced durability under extreme environmental conditions.

For UV exposure testing, ASTM G154 and ISO 16474-3 standards provide comprehensive frameworks for accelerated weathering tests using fluorescent UV lamps. These tests typically subject coated samples to controlled cycles of UV radiation and moisture at elevated temperatures, simulating months or years of outdoor exposure within weeks. The QUV accelerated weathering tester represents the industry standard equipment for such evaluations, allowing for precise control of UV intensity, temperature, and humidity levels.

Abrasion resistance testing for anti-reflective coatings commonly follows the Taber Abraser method (ASTM D4060) or the falling sand test (ASTM D968). The Taber method quantifies coating wear by measuring weight loss or haze increase after a specified number of abrasion cycles with calibrated wheels under controlled pressure. Alternatively, the Crockmeter test (ASTM F1319) evaluates coating resistance to rubbing and scratching, which is particularly relevant for touchscreen applications with anti-reflective treatments.

Outdoor weathering performance requires both accelerated and real-time testing approaches. ASTM G7 provides guidelines for direct outdoor exposure testing, while ASTM D4587 outlines procedures for condensation testing that simulates dew and rain effects. The industry standard for salt spray resistance, ASTM B117, evaluates coating performance in coastal environments or areas with high salt content in the atmosphere.

Performance standards for anti-reflective coatings typically specify minimum requirements across multiple parameters. MIL-C-48497 and MIL-C-675 military specifications define stringent standards for optical coatings, including anti-reflective treatments. These standards typically require less than 0.5% reflectance in the target wavelength range, abrasion resistance surviving at least 50 strokes with a cheesecloth under specified pressure, and UV stability with less than 5% change in optical properties after 1000 hours of accelerated weathering.

The emerging ISO 18543 standard specifically addresses the durability of solar panel cover glass with anti-reflective coatings, establishing performance criteria for UV exposure (2000+ hours with less than 2% transmission loss) and abrasion resistance (maintaining at least 98% of original transmission after standardized testing). These standards continue to evolve as coating technologies advance and applications expand into new markets requiring enhanced durability under extreme environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!