Anti-Reflective Coatings: Plasma Pretreatments, Nucleation Control And Adhesion

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR Coating Evolution and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when F. Geffcken first demonstrated the principle of using thin film interference to reduce reflection. Initially, these coatings were primarily developed for optical instruments and camera lenses, utilizing single-layer magnesium fluoride (MgF2) films that could reduce reflection to approximately 1.5% per surface.

The 1970s marked a pivotal shift with the introduction of multi-layer AR coatings, which dramatically improved performance by reducing reflection to less than 0.5% across visible wavelengths. This advancement enabled critical applications in precision optics, solar panels, and display technologies. The subsequent decades witnessed further refinement with the development of broadband AR coatings capable of functioning effectively across wider spectral ranges.

Recent technological evolution has focused on three critical aspects: plasma pretreatment processes, nucleation control mechanisms, and adhesion enhancement techniques. Plasma pretreatments have emerged as essential preparation steps that modify surface properties at the molecular level, creating optimal conditions for coating deposition and bonding. These treatments can remove contaminants, alter surface energy, and create functional groups that promote adhesion.

Nucleation control represents another frontier in AR coating technology, addressing the fundamental challenge of how coating materials initially form and grow on substrate surfaces. By precisely controlling nucleation sites and growth patterns, manufacturers can achieve more uniform, defect-free coatings with superior optical properties and durability.

Adhesion improvement remains perhaps the most persistent challenge in AR coating development. Even coatings with excellent optical properties fail if they cannot maintain long-term adhesion to the substrate under real-world conditions including temperature fluctuations, humidity exposure, and mechanical stress.

The primary objectives of current AR coating research include developing pretreatment protocols that optimize surface conditions without damaging sensitive substrates, establishing precise nucleation control mechanisms that ensure coating uniformity across diverse substrate materials, and enhancing adhesion strength to extend coating lifespans in demanding environments.

Additional goals include reducing environmental impact by eliminating hazardous chemicals from coating processes, lowering production costs through more efficient deposition techniques, and creating multifunctional AR coatings that combine anti-reflective properties with features such as self-cleaning, anti-fogging, or antimicrobial capabilities.

The ultimate aim is to develop AR coating systems that maintain optimal performance throughout the entire lifecycle of the coated product, with particular emphasis on applications in renewable energy, advanced displays, precision optics, and architectural glass where even marginal improvements in light transmission can yield significant practical benefits.

The 1970s marked a pivotal shift with the introduction of multi-layer AR coatings, which dramatically improved performance by reducing reflection to less than 0.5% across visible wavelengths. This advancement enabled critical applications in precision optics, solar panels, and display technologies. The subsequent decades witnessed further refinement with the development of broadband AR coatings capable of functioning effectively across wider spectral ranges.

Recent technological evolution has focused on three critical aspects: plasma pretreatment processes, nucleation control mechanisms, and adhesion enhancement techniques. Plasma pretreatments have emerged as essential preparation steps that modify surface properties at the molecular level, creating optimal conditions for coating deposition and bonding. These treatments can remove contaminants, alter surface energy, and create functional groups that promote adhesion.

Nucleation control represents another frontier in AR coating technology, addressing the fundamental challenge of how coating materials initially form and grow on substrate surfaces. By precisely controlling nucleation sites and growth patterns, manufacturers can achieve more uniform, defect-free coatings with superior optical properties and durability.

Adhesion improvement remains perhaps the most persistent challenge in AR coating development. Even coatings with excellent optical properties fail if they cannot maintain long-term adhesion to the substrate under real-world conditions including temperature fluctuations, humidity exposure, and mechanical stress.

The primary objectives of current AR coating research include developing pretreatment protocols that optimize surface conditions without damaging sensitive substrates, establishing precise nucleation control mechanisms that ensure coating uniformity across diverse substrate materials, and enhancing adhesion strength to extend coating lifespans in demanding environments.

Additional goals include reducing environmental impact by eliminating hazardous chemicals from coating processes, lowering production costs through more efficient deposition techniques, and creating multifunctional AR coatings that combine anti-reflective properties with features such as self-cleaning, anti-fogging, or antimicrobial capabilities.

The ultimate aim is to develop AR coating systems that maintain optimal performance throughout the entire lifecycle of the coated product, with particular emphasis on applications in renewable energy, advanced displays, precision optics, and architectural glass where even marginal improvements in light transmission can yield significant practical benefits.

Market Analysis for AR Coating Applications

The global anti-reflective (AR) coating market continues to experience robust growth, driven by increasing applications across multiple industries. Currently valued at approximately 4.2 billion USD, the market is projected to reach 6.5 billion USD by 2027, representing a compound annual growth rate of 8.9% during the forecast period.

The electronics and display sector constitutes the largest application segment, accounting for nearly 40% of the total market share. This dominance is primarily attributed to the rising demand for smartphones, tablets, laptops, and television displays where AR coatings significantly enhance visual clarity and reduce eye strain. The growing consumer preference for high-definition displays with minimal reflection has further accelerated adoption in this segment.

Solar energy applications represent the fastest-growing market segment with a growth rate exceeding 12% annually. As global renewable energy initiatives expand, the demand for more efficient photovoltaic cells has intensified. AR coatings can increase solar panel efficiency by 3-5% through reduced light reflection, translating to substantial energy gains when implemented at scale.

The automotive industry has emerged as another significant consumer of AR coatings, particularly for instrument panels, navigation displays, and sensors for advanced driver assistance systems (ADAS). The market penetration in this sector has grown from 18% to 27% over the past five years, with luxury vehicle manufacturers leading adoption.

Eyewear applications maintain steady growth at 6.5% annually, with AR coatings being standard in premium prescription glasses and increasingly common in mid-range products. The optical clarity and durability improvements offered by plasma pretreatment processes have been key factors driving consumer willingness to pay premium prices for coated lenses.

Regionally, Asia-Pacific dominates the market with 45% share, followed by North America (28%) and Europe (20%). China and South Korea lead manufacturing capacity, while Japan maintains technological leadership in high-precision coating processes. The fastest market expansion is occurring in India and Southeast Asian countries, where electronics manufacturing is rapidly growing.

Key market challenges include cost-sensitivity in mass-market applications and durability concerns in harsh environments. Recent innovations in plasma pretreatment techniques have addressed adhesion issues that previously limited coating longevity, potentially expanding applications to outdoor and industrial environments where coating persistence under extreme conditions is essential.

The electronics and display sector constitutes the largest application segment, accounting for nearly 40% of the total market share. This dominance is primarily attributed to the rising demand for smartphones, tablets, laptops, and television displays where AR coatings significantly enhance visual clarity and reduce eye strain. The growing consumer preference for high-definition displays with minimal reflection has further accelerated adoption in this segment.

Solar energy applications represent the fastest-growing market segment with a growth rate exceeding 12% annually. As global renewable energy initiatives expand, the demand for more efficient photovoltaic cells has intensified. AR coatings can increase solar panel efficiency by 3-5% through reduced light reflection, translating to substantial energy gains when implemented at scale.

The automotive industry has emerged as another significant consumer of AR coatings, particularly for instrument panels, navigation displays, and sensors for advanced driver assistance systems (ADAS). The market penetration in this sector has grown from 18% to 27% over the past five years, with luxury vehicle manufacturers leading adoption.

Eyewear applications maintain steady growth at 6.5% annually, with AR coatings being standard in premium prescription glasses and increasingly common in mid-range products. The optical clarity and durability improvements offered by plasma pretreatment processes have been key factors driving consumer willingness to pay premium prices for coated lenses.

Regionally, Asia-Pacific dominates the market with 45% share, followed by North America (28%) and Europe (20%). China and South Korea lead manufacturing capacity, while Japan maintains technological leadership in high-precision coating processes. The fastest market expansion is occurring in India and Southeast Asian countries, where electronics manufacturing is rapidly growing.

Key market challenges include cost-sensitivity in mass-market applications and durability concerns in harsh environments. Recent innovations in plasma pretreatment techniques have addressed adhesion issues that previously limited coating longevity, potentially expanding applications to outdoor and industrial environments where coating persistence under extreme conditions is essential.

Plasma Pretreatment Technical Challenges

Plasma pretreatment in anti-reflective coating applications faces several significant technical challenges that impact coating performance, manufacturing efficiency, and cost-effectiveness. One primary challenge is achieving uniform plasma distribution across substrate surfaces, particularly for complex geometries and large-area substrates. Non-uniform plasma treatment leads to inconsistent surface activation, resulting in coating adhesion variations and optical performance discrepancies across the treated surface.

Process parameter optimization presents another substantial hurdle. The complex interplay between plasma power, exposure time, gas composition, pressure, and flow rate requires precise calibration for each specific substrate material. Even minor deviations in these parameters can significantly alter surface properties, making standardization difficult across different production batches and substrate types.

Surface damage during plasma treatment constitutes a critical concern, especially for sensitive optical materials. Excessive ion bombardment or thermal loading can induce subsurface damage, creating scattering centers that degrade the anti-reflective performance. For polymeric substrates, plasma-induced degradation may alter the bulk optical properties, counteracting the benefits of the anti-reflective coating.

The transient nature of plasma-activated surfaces presents a significant manufacturing challenge. The highly reactive surface states created during plasma treatment have limited temporal stability, with surface energy decreasing rapidly after treatment. This necessitates strict timing control between pretreatment and coating deposition steps, complicating production logistics and limiting manufacturing flexibility.

Equipment scaling and integration issues emerge when transitioning from laboratory to industrial production. Maintaining plasma uniformity and treatment consistency becomes increasingly difficult with larger substrate dimensions. Additionally, integrating plasma systems into existing production lines requires careful engineering to ensure compatibility with upstream and downstream processes while maintaining throughput rates.

Environmental and safety considerations add another layer of complexity. Many plasma processes utilize fluorinated or chlorinated gases with significant environmental impact. Transitioning to more environmentally benign alternatives often results in reduced treatment effectiveness or requires substantial process redesign. Worker safety concerns related to high voltage, radiation, and potentially hazardous process gases necessitate robust containment and monitoring systems.

Cost-effectiveness remains a persistent challenge, with high-quality plasma equipment representing a significant capital investment. Operating costs including power consumption, specialty gases, and maintenance further impact the economic viability of plasma pretreatment processes, particularly for cost-sensitive applications.

Process parameter optimization presents another substantial hurdle. The complex interplay between plasma power, exposure time, gas composition, pressure, and flow rate requires precise calibration for each specific substrate material. Even minor deviations in these parameters can significantly alter surface properties, making standardization difficult across different production batches and substrate types.

Surface damage during plasma treatment constitutes a critical concern, especially for sensitive optical materials. Excessive ion bombardment or thermal loading can induce subsurface damage, creating scattering centers that degrade the anti-reflective performance. For polymeric substrates, plasma-induced degradation may alter the bulk optical properties, counteracting the benefits of the anti-reflective coating.

The transient nature of plasma-activated surfaces presents a significant manufacturing challenge. The highly reactive surface states created during plasma treatment have limited temporal stability, with surface energy decreasing rapidly after treatment. This necessitates strict timing control between pretreatment and coating deposition steps, complicating production logistics and limiting manufacturing flexibility.

Equipment scaling and integration issues emerge when transitioning from laboratory to industrial production. Maintaining plasma uniformity and treatment consistency becomes increasingly difficult with larger substrate dimensions. Additionally, integrating plasma systems into existing production lines requires careful engineering to ensure compatibility with upstream and downstream processes while maintaining throughput rates.

Environmental and safety considerations add another layer of complexity. Many plasma processes utilize fluorinated or chlorinated gases with significant environmental impact. Transitioning to more environmentally benign alternatives often results in reduced treatment effectiveness or requires substantial process redesign. Worker safety concerns related to high voltage, radiation, and potentially hazardous process gases necessitate robust containment and monitoring systems.

Cost-effectiveness remains a persistent challenge, with high-quality plasma equipment representing a significant capital investment. Operating costs including power consumption, specialty gases, and maintenance further impact the economic viability of plasma pretreatment processes, particularly for cost-sensitive applications.

Current Nucleation Control Methodologies

01 Surface treatment methods for improved adhesion

Various surface treatment methods can be employed to enhance the adhesion of anti-reflective coatings to substrates. These methods include plasma treatment, chemical etching, and surface activation techniques that modify the surface properties of the substrate to create stronger bonds with the coating material. Such treatments can remove contaminants, increase surface energy, and create micro-roughness that promotes mechanical interlocking between the coating and substrate.- Surface treatment methods for improved adhesion: Various surface treatment methods can be employed to enhance the adhesion of anti-reflective coatings to substrates. These include plasma treatment, chemical etching, and surface activation techniques that modify the surface energy and create better bonding sites. Such treatments remove contaminants and create micro-roughness that increases the effective surface area for adhesion, resulting in stronger bonds between the anti-reflective coating and the substrate material.

- Adhesion promoting interlayers: Incorporating adhesion promoting interlayers between the substrate and anti-reflective coating significantly improves coating durability. These intermediate layers are designed to have chemical compatibility with both the substrate and the anti-reflective material, creating strong chemical bonds at both interfaces. Common interlayer materials include silanes, titanates, and specialized polymers that can form covalent bonds with both organic and inorganic surfaces.

- Chemical composition modifications for enhanced adhesion: Modifying the chemical composition of anti-reflective coatings can significantly improve their adhesion properties. This includes incorporating functional groups that promote chemical bonding with substrate materials, adjusting the ratio of hard and soft segments in polymer-based coatings, and adding cross-linking agents that enhance the mechanical stability of the coating. These modifications create stronger interfacial bonds while maintaining the optical performance of the anti-reflective coating.

- Deposition techniques affecting adhesion: The method of deposition significantly impacts the adhesion of anti-reflective coatings. Techniques such as plasma-enhanced chemical vapor deposition, atomic layer deposition, and ion-assisted deposition can create denser films with better adhesion compared to conventional methods. Controlling parameters like deposition rate, substrate temperature, and chamber pressure during the coating process helps optimize the interfacial bonding and microstructure of the anti-reflective layer, resulting in superior adhesion properties.

- Post-deposition treatments for adhesion enhancement: Post-deposition treatments can significantly improve the adhesion of anti-reflective coatings. These include thermal annealing processes that promote diffusion at the interface, UV curing that enhances cross-linking, and humidity conditioning that stabilizes the coating structure. Such treatments help relieve internal stresses, promote chemical bonding at the interface, and improve the overall durability of the anti-reflective coating system without compromising its optical performance.

02 Adhesion promoting interlayers

Incorporating adhesion promoting interlayers between the substrate and anti-reflective coating significantly improves coating durability. These intermediate layers can be composed of materials specifically designed to have good adhesion to both the substrate and the anti-reflective coating. Common interlayer materials include silanes, titanates, and various polymer-based compounds that create strong chemical bonds at both interfaces, resulting in enhanced overall coating adhesion.Expand Specific Solutions03 Photosensitive anti-reflective coating formulations

Photosensitive anti-reflective coating formulations can be designed to undergo chemical changes upon exposure to specific wavelengths of light, enhancing their adhesion properties. These formulations typically contain photoactive compounds that create crosslinking or other chemical reactions when exposed to light, resulting in improved bonding to the substrate. This approach is particularly useful in semiconductor and photolithography applications where precise patterning and strong adhesion are required.Expand Specific Solutions04 Nanostructured anti-reflective coatings

Nanostructured anti-reflective coatings utilize nanoscale features to not only reduce reflection but also enhance adhesion to substrates. By incorporating nanoparticles, creating nanoporous structures, or designing nanoscale surface patterns, these coatings can achieve superior mechanical interlocking with the substrate. The increased surface area at the interface between the coating and substrate results in stronger adhesion while maintaining excellent optical properties.Expand Specific Solutions05 Environmental durability enhancement techniques

Various techniques can be employed to enhance the environmental durability of anti-reflective coatings, ensuring long-term adhesion under challenging conditions. These include incorporating hydrophobic components to prevent moisture ingress, adding UV stabilizers to prevent degradation from sunlight exposure, and utilizing flexible polymer matrices that can accommodate thermal expansion differences between coating and substrate. These approaches help maintain coating adhesion despite exposure to temperature fluctuations, humidity, and other environmental stressors.Expand Specific Solutions

Industry Leaders in AR Coating Manufacturing

The anti-reflective coatings market is in a growth phase, with increasing applications across semiconductor, optical, automotive, and solar industries. The market is projected to expand significantly due to rising demand for high-performance optical components and electronics. Technologically, the field is moderately mature but continues to evolve, with innovations focusing on plasma pretreatment processes, nucleation control mechanisms, and adhesion enhancement. Key players demonstrate varying levels of specialization: Brewer Science and Tokyo Electron lead in semiconductor applications; Carl Zeiss and EssilorLuxottica dominate optical applications; while DuPont, SCHOTT, and Nissan Chemical offer broader material solutions. Research institutions like ITRI and NDSU Research Foundation are advancing fundamental technologies, creating opportunities for commercial partnerships and technology transfer in this competitive landscape.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a comprehensive anti-reflective coating system utilizing proprietary plasma pretreatment technology that enhances adhesion while controlling nucleation at the molecular level. Their approach combines fluorocarbon-based plasma modification with silane coupling agents to create gradient-index anti-reflective surfaces with reflection reduction exceeding 99.5% across visible wavelengths[2]. The company's nucleation control technology employs precisely timed plasma pulses that create nanoscale surface texturing, providing anchor points for subsequent coating layers without compromising optical clarity. DuPont's multi-layer AR coating system incorporates hydrophobic outer layers with controlled nucleation intermediary layers, resulting in coatings that maintain performance after 1000+ abrasion cycles. Their plasma pretreatment process operates at atmospheric pressure using a proprietary gas mixture that enables treatment of temperature-sensitive substrates including polymers and flexible displays[4]. This technology has been successfully implemented in consumer electronics, automotive displays, and military optical systems.

Strengths: Industry-leading durability and abrasion resistance; atmospheric pressure processing enables inline manufacturing; exceptional optical performance across broad wavelength ranges. Weaknesses: Requires specialized equipment for precise plasma control; higher material costs than conventional coatings; process sensitivity to environmental humidity variations.

SCHOTT AG

Technical Solution: SCHOTT has developed a sophisticated anti-reflective coating technology utilizing controlled plasma pretreatment processes specifically optimized for high-performance optical glass. Their approach combines low-pressure oxygen plasma activation with proprietary nucleation control agents to achieve ultra-low reflection values (<0.1%) across targeted wavelength bands[5]. SCHOTT's process employs a multi-stage plasma treatment that first removes organic contaminants, then creates precisely controlled surface roughness at the nanoscale to promote ideal nucleation conditions. The company has pioneered a gradient-index coating architecture where plasma-modified interfaces between layers enhance adhesion while minimizing internal stress. Their technology incorporates real-time plasma monitoring with feedback control to ensure consistent surface activation across complex geometries. SCHOTT's AR coatings demonstrate exceptional environmental stability, maintaining optical performance after 2000+ hours of accelerated weathering tests[6]. The company has successfully applied this technology to astronomical optics, laser systems, and medical imaging devices where minimal reflection and maximum durability are critical requirements.

Strengths: Exceptional optical performance with ultra-low reflection values; superior adhesion on difficult substrates like high-index glasses; excellent environmental stability including humidity resistance. Weaknesses: Requires sophisticated vacuum equipment; higher production costs than conventional spray coatings; process complexity increases with substrate size.

Key Patents in Adhesion Enhancement Techniques

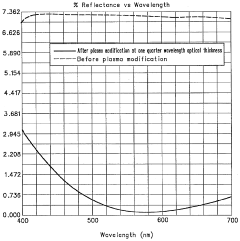

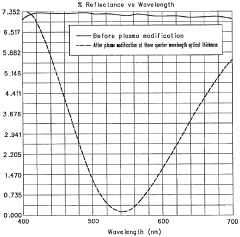

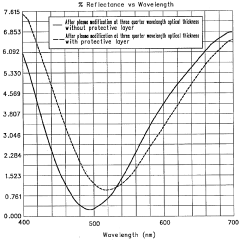

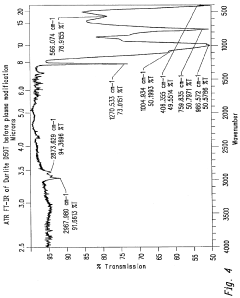

Method for forming interference anti-reflective coatings by plasma surface modification

PatentInactiveUS5580606A

Innovation

- The use of microwave plasma modification to apply a hard organo-silica coating on plastic substrates, followed by curing and immersion in a fluorine-containing solution, to achieve interference anti-reflective coatings with low reflectance, high abrasion resistance, and chemical resistance, using specific organic silicon compounds and plasma parameters like downstream microwave plasma.

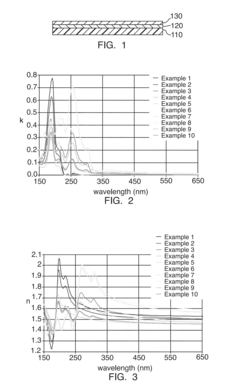

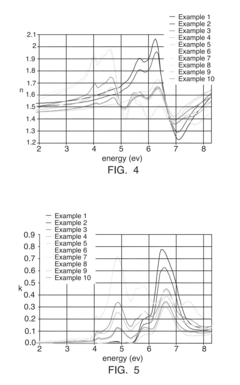

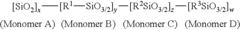

Hybrid inorganic-organic polymer compositions for anti-reflective coatings

PatentActiveUS9284455B2

Innovation

- Development of novel organo-siloxane compositions with a siloxane main-chain and organic side groups or chains attached to silicon atoms, synthesized using silane precursors with hydrolysable groups, allowing for cross-linking and tailored refractive index and absorption coefficients, enabling the creation of anti-reflective coatings with improved mechanical and thermal properties.

Environmental Impact of AR Coating Processes

The environmental impact of anti-reflective (AR) coating processes has become increasingly significant as global sustainability concerns grow. Traditional AR coating methods often involve chemical processes that utilize volatile organic compounds (VOCs), heavy metals, and other environmentally harmful substances. These chemicals can lead to air pollution, water contamination, and soil degradation when improperly managed or disposed of.

Plasma pretreatment processes, while offering superior adhesion and coating performance, present their own environmental challenges. The gases used in plasma generation—such as argon, oxygen, and fluorinated compounds—may contribute to greenhouse gas emissions if released untreated. Additionally, plasma systems require substantial energy input, potentially increasing the carbon footprint of manufacturing operations unless powered by renewable energy sources.

Water consumption represents another critical environmental concern in AR coating production. Wet chemical processes and post-coating cleaning steps can consume significant quantities of ultra-pure water, a resource becoming increasingly scarce globally. The resulting wastewater often contains chemical residues requiring specialized treatment before discharge, adding to the environmental burden.

Recent advancements in nucleation control techniques have shown promise for reducing environmental impact. Precision-controlled deposition methods minimize material waste by optimizing coating thickness and uniformity. This approach not only conserves raw materials but also reduces energy consumption during the manufacturing process, as thinner coatings require less deposition time and energy.

Life cycle assessments of AR coating technologies reveal that the environmental impact extends beyond manufacturing to include raw material extraction, transportation, and end-of-life disposal. Silicon dioxide-based coatings generally show lower environmental impact compared to metal oxide alternatives, particularly when considering full lifecycle emissions and resource depletion metrics.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and RoHS directive have restricted certain chemicals commonly used in coating processes, driving innovation toward greener alternatives. Similarly, the United States EPA has established guidelines for emissions control and waste management in coating operations.

Industry leaders are responding with sustainable innovations, including water-based coating formulations, solvent recovery systems, and closed-loop manufacturing processes. These approaches significantly reduce emissions and waste while maintaining coating performance standards. Additionally, biomimetic AR coating technologies inspired by natural anti-reflective surfaces found in moth eyes and butterfly wings offer potentially less resource-intensive manufacturing pathways.

Plasma pretreatment processes, while offering superior adhesion and coating performance, present their own environmental challenges. The gases used in plasma generation—such as argon, oxygen, and fluorinated compounds—may contribute to greenhouse gas emissions if released untreated. Additionally, plasma systems require substantial energy input, potentially increasing the carbon footprint of manufacturing operations unless powered by renewable energy sources.

Water consumption represents another critical environmental concern in AR coating production. Wet chemical processes and post-coating cleaning steps can consume significant quantities of ultra-pure water, a resource becoming increasingly scarce globally. The resulting wastewater often contains chemical residues requiring specialized treatment before discharge, adding to the environmental burden.

Recent advancements in nucleation control techniques have shown promise for reducing environmental impact. Precision-controlled deposition methods minimize material waste by optimizing coating thickness and uniformity. This approach not only conserves raw materials but also reduces energy consumption during the manufacturing process, as thinner coatings require less deposition time and energy.

Life cycle assessments of AR coating technologies reveal that the environmental impact extends beyond manufacturing to include raw material extraction, transportation, and end-of-life disposal. Silicon dioxide-based coatings generally show lower environmental impact compared to metal oxide alternatives, particularly when considering full lifecycle emissions and resource depletion metrics.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and RoHS directive have restricted certain chemicals commonly used in coating processes, driving innovation toward greener alternatives. Similarly, the United States EPA has established guidelines for emissions control and waste management in coating operations.

Industry leaders are responding with sustainable innovations, including water-based coating formulations, solvent recovery systems, and closed-loop manufacturing processes. These approaches significantly reduce emissions and waste while maintaining coating performance standards. Additionally, biomimetic AR coating technologies inspired by natural anti-reflective surfaces found in moth eyes and butterfly wings offer potentially less resource-intensive manufacturing pathways.

Quality Control Standards for AR Coatings

Quality control standards for anti-reflective (AR) coatings represent a critical framework that ensures consistent performance, durability, and optical efficiency across manufacturing processes. These standards typically encompass multiple testing protocols designed to evaluate key performance indicators such as reflection reduction, transmission enhancement, adhesion strength, and environmental durability.

The optical performance standards for AR coatings generally require reflection values below 0.5% across the target wavelength range, with premium applications demanding values as low as 0.1%. Spectrophotometric measurements are conducted at multiple angles of incidence to verify performance under various viewing conditions, with particular attention to the specific wavelength bands relevant to the application.

Adhesion quality represents a fundamental parameter in AR coating standards, typically evaluated through standardized tests such as ASTM D3359 (tape test) and ISO 2409 (cross-cut test). For applications requiring exceptional durability, more rigorous testing protocols like ASTM D2247 (humidity resistance) and MIL-C-48497 (abrasion resistance) are implemented. Plasma pretreatment quality is verified through contact angle measurements, with optimal values typically falling below 20 degrees to ensure proper surface activation.

Environmental durability standards include accelerated weathering tests (ASTM G154), salt spray resistance (ASTM B117), and temperature cycling tests (-40°C to +85°C). High-performance AR coatings must maintain optical properties after exposure to these conditions, with allowable degradation typically limited to less than 5% of initial performance values.

Nucleation control quality is assessed through advanced microscopy techniques including AFM and SEM, with standards specifying maximum allowable particle sizes (typically <10nm) and density distributions to ensure optimal coating morphology. Uniformity standards require thickness variations to remain within ±2% across the substrate surface, with more stringent requirements (±1%) for precision optical applications.

Industry-specific standards further refine these requirements, with medical device AR coatings subject to biocompatibility testing (ISO 10993), automotive applications requiring resistance to specific chemical agents (gasoline, windshield washer fluid), and aerospace applications demanding compliance with outgassing standards (ASTM E595).

Documentation and traceability form the final component of quality control standards, requiring detailed records of plasma pretreatment parameters, deposition conditions, and post-deposition treatments. Statistical process control methodologies are increasingly incorporated into these standards, establishing control limits for critical parameters and implementing real-time monitoring systems to detect process deviations before they impact product quality.

The optical performance standards for AR coatings generally require reflection values below 0.5% across the target wavelength range, with premium applications demanding values as low as 0.1%. Spectrophotometric measurements are conducted at multiple angles of incidence to verify performance under various viewing conditions, with particular attention to the specific wavelength bands relevant to the application.

Adhesion quality represents a fundamental parameter in AR coating standards, typically evaluated through standardized tests such as ASTM D3359 (tape test) and ISO 2409 (cross-cut test). For applications requiring exceptional durability, more rigorous testing protocols like ASTM D2247 (humidity resistance) and MIL-C-48497 (abrasion resistance) are implemented. Plasma pretreatment quality is verified through contact angle measurements, with optimal values typically falling below 20 degrees to ensure proper surface activation.

Environmental durability standards include accelerated weathering tests (ASTM G154), salt spray resistance (ASTM B117), and temperature cycling tests (-40°C to +85°C). High-performance AR coatings must maintain optical properties after exposure to these conditions, with allowable degradation typically limited to less than 5% of initial performance values.

Nucleation control quality is assessed through advanced microscopy techniques including AFM and SEM, with standards specifying maximum allowable particle sizes (typically <10nm) and density distributions to ensure optimal coating morphology. Uniformity standards require thickness variations to remain within ±2% across the substrate surface, with more stringent requirements (±1%) for precision optical applications.

Industry-specific standards further refine these requirements, with medical device AR coatings subject to biocompatibility testing (ISO 10993), automotive applications requiring resistance to specific chemical agents (gasoline, windshield washer fluid), and aerospace applications demanding compliance with outgassing standards (ASTM E595).

Documentation and traceability form the final component of quality control standards, requiring detailed records of plasma pretreatment parameters, deposition conditions, and post-deposition treatments. Statistical process control methodologies are increasingly incorporated into these standards, establishing control limits for critical parameters and implementing real-time monitoring systems to detect process deviations before they impact product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!