Anti-Reflective Coatings: High-Temperature Substrates, CTE Mismatch And Stress Management

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature AR Coating Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when they were first developed for optical applications. The technology has progressed from single-layer coatings to sophisticated multi-layer designs that can achieve near-zero reflectance across specific wavelength ranges. In high-temperature environments, these coatings face unique challenges that have driven continuous innovation in materials science and deposition techniques.

The evolution of high-temperature AR coatings has been closely tied to advancements in thin film technology and the growing demands of industries such as aerospace, solar energy, and high-power lasers. Early coatings primarily focused on optical performance at ambient temperatures, with limited consideration for thermal stability. However, as applications expanded into more extreme environments, the need for thermally resilient AR coatings became increasingly apparent.

Recent technological trends show a shift toward nano-engineered structures and composite materials that can maintain optical performance while withstanding thermal cycling. The integration of ceramic materials, refractory metal oxides, and advanced nitrides has opened new possibilities for coatings that can operate reliably at temperatures exceeding 1000°C.

A critical challenge in this field has been addressing the coefficient of thermal expansion (CTE) mismatch between coating layers and substrates. This mismatch creates significant stress during thermal cycling, leading to delamination, cracking, and ultimately coating failure. Traditional approaches have often sacrificed optical performance for thermal stability, creating a technological gap that requires innovative solutions.

The primary objective of current research is to develop AR coatings for high-temperature substrates that can maintain optimal anti-reflective properties while effectively managing thermal stress. Specifically, the goals include: achieving reflectance below 0.5% across target wavelength ranges at operating temperatures up to 1200°C; ensuring coating durability through at least 1000 thermal cycles; developing stress management strategies that accommodate CTE differences between coating and substrate; and creating manufacturing processes that are scalable for industrial applications.

Secondary objectives include reducing production costs compared to current high-temperature coating solutions, minimizing the use of rare or environmentally problematic materials, and developing predictive models that can accelerate the design of customized coating systems for specific substrate materials and operating conditions.

This research aims to bridge fundamental materials science with practical engineering solutions, potentially revolutionizing industries where optical performance must be maintained under extreme thermal conditions. Success in this domain would enable more efficient solar thermal systems, more durable aerospace sensors, and more powerful laser systems with enhanced thermal management capabilities.

The evolution of high-temperature AR coatings has been closely tied to advancements in thin film technology and the growing demands of industries such as aerospace, solar energy, and high-power lasers. Early coatings primarily focused on optical performance at ambient temperatures, with limited consideration for thermal stability. However, as applications expanded into more extreme environments, the need for thermally resilient AR coatings became increasingly apparent.

Recent technological trends show a shift toward nano-engineered structures and composite materials that can maintain optical performance while withstanding thermal cycling. The integration of ceramic materials, refractory metal oxides, and advanced nitrides has opened new possibilities for coatings that can operate reliably at temperatures exceeding 1000°C.

A critical challenge in this field has been addressing the coefficient of thermal expansion (CTE) mismatch between coating layers and substrates. This mismatch creates significant stress during thermal cycling, leading to delamination, cracking, and ultimately coating failure. Traditional approaches have often sacrificed optical performance for thermal stability, creating a technological gap that requires innovative solutions.

The primary objective of current research is to develop AR coatings for high-temperature substrates that can maintain optimal anti-reflective properties while effectively managing thermal stress. Specifically, the goals include: achieving reflectance below 0.5% across target wavelength ranges at operating temperatures up to 1200°C; ensuring coating durability through at least 1000 thermal cycles; developing stress management strategies that accommodate CTE differences between coating and substrate; and creating manufacturing processes that are scalable for industrial applications.

Secondary objectives include reducing production costs compared to current high-temperature coating solutions, minimizing the use of rare or environmentally problematic materials, and developing predictive models that can accelerate the design of customized coating systems for specific substrate materials and operating conditions.

This research aims to bridge fundamental materials science with practical engineering solutions, potentially revolutionizing industries where optical performance must be maintained under extreme thermal conditions. Success in this domain would enable more efficient solar thermal systems, more durable aerospace sensors, and more powerful laser systems with enhanced thermal management capabilities.

Market Analysis for High-Temperature Optical Applications

The high-temperature optical applications market is experiencing significant growth driven by expanding demands across multiple industries. Aerospace and defense sectors represent the largest market segment, where anti-reflective coatings on high-temperature substrates are critical for infrared guidance systems, thermal imaging, and optical targeting equipment operating in extreme environments. These applications require coatings that maintain optical performance while withstanding temperatures exceeding 800°C.

The semiconductor manufacturing industry constitutes another substantial market, with an increasing need for high-temperature optical components in lithography systems, inspection equipment, and laser processing tools. As chip manufacturing processes advance toward smaller nodes, the optical requirements become more stringent, necessitating superior anti-reflective coatings that can withstand thermal cycling.

Energy sector applications, particularly in concentrated solar power systems and high-temperature sensing for power generation, represent a rapidly growing segment. These systems require durable anti-reflective coatings that maintain performance under constant thermal stress and environmental exposure, directly impacting system efficiency and operational costs.

The automotive industry is emerging as a significant market driver with the integration of advanced driver-assistance systems (ADAS) and LiDAR technologies. These systems incorporate high-temperature optical components that must maintain performance integrity in challenging operational environments, creating demand for specialized coating solutions.

Market analysis indicates that customers across these sectors prioritize three key performance attributes: thermal stability under repeated cycling, optical performance consistency at elevated temperatures, and long-term durability. The ability to manage coefficient of thermal expansion (CTE) mismatch between coating and substrate represents a critical competitive advantage, as this directly impacts product lifetime and reliability.

Regional market distribution shows North America leading in aerospace and defense applications, while Asia dominates in semiconductor-related implementations. Europe shows particular strength in automotive and precision industrial applications, with significant research investment in advanced coating technologies.

The market exhibits a compound annual growth rate of approximately 7.8% globally, with higher growth rates in emerging applications such as quantum computing optical interfaces and space-based observation systems. These emerging applications present unique challenges regarding thermal management and stress distribution in optical coatings, driving innovation in material science and deposition techniques.

The semiconductor manufacturing industry constitutes another substantial market, with an increasing need for high-temperature optical components in lithography systems, inspection equipment, and laser processing tools. As chip manufacturing processes advance toward smaller nodes, the optical requirements become more stringent, necessitating superior anti-reflective coatings that can withstand thermal cycling.

Energy sector applications, particularly in concentrated solar power systems and high-temperature sensing for power generation, represent a rapidly growing segment. These systems require durable anti-reflective coatings that maintain performance under constant thermal stress and environmental exposure, directly impacting system efficiency and operational costs.

The automotive industry is emerging as a significant market driver with the integration of advanced driver-assistance systems (ADAS) and LiDAR technologies. These systems incorporate high-temperature optical components that must maintain performance integrity in challenging operational environments, creating demand for specialized coating solutions.

Market analysis indicates that customers across these sectors prioritize three key performance attributes: thermal stability under repeated cycling, optical performance consistency at elevated temperatures, and long-term durability. The ability to manage coefficient of thermal expansion (CTE) mismatch between coating and substrate represents a critical competitive advantage, as this directly impacts product lifetime and reliability.

Regional market distribution shows North America leading in aerospace and defense applications, while Asia dominates in semiconductor-related implementations. Europe shows particular strength in automotive and precision industrial applications, with significant research investment in advanced coating technologies.

The market exhibits a compound annual growth rate of approximately 7.8% globally, with higher growth rates in emerging applications such as quantum computing optical interfaces and space-based observation systems. These emerging applications present unique challenges regarding thermal management and stress distribution in optical coatings, driving innovation in material science and deposition techniques.

Technical Challenges in AR Coatings for High-Temperature Substrates

Anti-reflective (AR) coatings for high-temperature substrates face several significant technical challenges that limit their widespread application and effectiveness. The primary challenge stems from the coefficient of thermal expansion (CTE) mismatch between the coating materials and the substrate. When exposed to high temperatures, different materials expand at varying rates, creating substantial interfacial stresses that can lead to coating delamination, cracking, or complete failure of the optical system.

Traditional AR coating materials like silicon dioxide (SiO2) and titanium dioxide (TiO2) exhibit CTE values that differ significantly from high-temperature substrates such as sapphire, silicon carbide, or specialized ceramics. This mismatch becomes particularly problematic during thermal cycling, where repeated heating and cooling cycles progressively weaken the coating-substrate interface.

Another critical challenge is maintaining optical performance at elevated temperatures. Many coating materials undergo phase transitions or crystallization at high temperatures, altering their refractive indices and compromising anti-reflective properties. Additionally, high-temperature environments often accelerate diffusion processes between coating layers and substrates, leading to the formation of unwanted interfacial compounds that degrade optical performance.

Mechanical stress management presents further complications. Residual stresses from the deposition process combine with thermally induced stresses during operation, creating complex stress fields that are difficult to model and mitigate. These stresses not only affect adhesion but can also induce optical birefringence, distorting the transmitted light and reducing system efficiency.

Environmental stability poses additional challenges, as high-temperature environments are often accompanied by oxidizing or corrosive conditions. Coating materials must simultaneously resist chemical attack while maintaining their optical and mechanical properties, a combination that severely limits material selection.

Deposition techniques themselves present limitations, as conventional methods like physical vapor deposition or sputtering may not produce coatings with sufficient density or adhesion for high-temperature applications. Alternative techniques such as atomic layer deposition offer better conformality but at significantly higher costs and lower throughput.

The thickness control of multilayer AR coatings becomes increasingly difficult when designing for high-temperature applications, as thermal expansion affects not only lateral dimensions but also layer thicknesses, shifting the wavelength response of the coating system and potentially negating its anti-reflective properties at the target wavelengths.

Traditional AR coating materials like silicon dioxide (SiO2) and titanium dioxide (TiO2) exhibit CTE values that differ significantly from high-temperature substrates such as sapphire, silicon carbide, or specialized ceramics. This mismatch becomes particularly problematic during thermal cycling, where repeated heating and cooling cycles progressively weaken the coating-substrate interface.

Another critical challenge is maintaining optical performance at elevated temperatures. Many coating materials undergo phase transitions or crystallization at high temperatures, altering their refractive indices and compromising anti-reflective properties. Additionally, high-temperature environments often accelerate diffusion processes between coating layers and substrates, leading to the formation of unwanted interfacial compounds that degrade optical performance.

Mechanical stress management presents further complications. Residual stresses from the deposition process combine with thermally induced stresses during operation, creating complex stress fields that are difficult to model and mitigate. These stresses not only affect adhesion but can also induce optical birefringence, distorting the transmitted light and reducing system efficiency.

Environmental stability poses additional challenges, as high-temperature environments are often accompanied by oxidizing or corrosive conditions. Coating materials must simultaneously resist chemical attack while maintaining their optical and mechanical properties, a combination that severely limits material selection.

Deposition techniques themselves present limitations, as conventional methods like physical vapor deposition or sputtering may not produce coatings with sufficient density or adhesion for high-temperature applications. Alternative techniques such as atomic layer deposition offer better conformality but at significantly higher costs and lower throughput.

The thickness control of multilayer AR coatings becomes increasingly difficult when designing for high-temperature applications, as thermal expansion affects not only lateral dimensions but also layer thicknesses, shifting the wavelength response of the coating system and potentially negating its anti-reflective properties at the target wavelengths.

Current CTE Mismatch Mitigation Strategies

01 Multilayer coating structures to manage CTE mismatch

Anti-reflective coatings can be designed with multiple layers of different materials to manage thermal expansion coefficient mismatches. By carefully selecting materials with complementary properties and creating gradient structures, stress between layers can be minimized. These multilayer designs often incorporate alternating high and low refractive index materials with intermediate layers that help distribute stress and prevent delamination during thermal cycling.- Multilayer coating structures to manage CTE mismatch: Anti-reflective coatings can be designed with multiple layers of different materials to manage thermal expansion coefficient mismatches. By using gradient layers or buffer layers between the substrate and the main anti-reflective coating, stress can be distributed more evenly. These intermediate layers help to accommodate the different expansion rates between materials, preventing delamination and cracking during thermal cycling. The multilayer approach allows for a gradual transition of properties, reducing overall stress at interfaces.

- Material selection and composition for stress management: Careful selection of coating materials with compatible thermal expansion coefficients is crucial for stress management in anti-reflective coatings. By incorporating stress-relieving additives or using materials with inherent flexibility, the coating can better accommodate thermal expansion differences. Composite materials that combine organic and inorganic components can provide both the optical properties needed for anti-reflection and the mechanical properties required for stress management. Some formulations include specialized polymers or nanoparticles that enhance the coating's ability to withstand thermal cycling.

- Deposition techniques to minimize stress: The method of applying anti-reflective coatings significantly impacts stress management. Techniques such as atomic layer deposition, ion-assisted deposition, and plasma-enhanced chemical vapor deposition can create coatings with controlled microstructure and reduced internal stress. By optimizing deposition parameters like temperature, pressure, and deposition rate, the coating's stress state can be engineered. Post-deposition annealing processes can also be employed to relieve residual stress in the coating system, improving its resistance to thermal cycling and mechanical strain.

- Stress compensation and relief structures: Anti-reflective coatings can incorporate specific structural features designed to compensate for or relieve stress caused by CTE mismatch. These may include patterned substrates, micro-crack networks that prevent catastrophic failure, or engineered interfaces that allow for controlled deformation. Some designs utilize segmented coating structures that can expand and contract independently, reducing overall stress accumulation. Stress-relief channels or expansion joints within the coating system can also be implemented to accommodate dimensional changes during thermal cycling.

- Testing and characterization methods for CTE mismatch: Advanced testing and characterization techniques are essential for understanding and managing CTE mismatch in anti-reflective coatings. These include thermal cycling tests, in-situ stress measurements, and optical performance monitoring under varying temperature conditions. Finite element analysis and computational modeling help predict stress distribution and potential failure points before manufacturing. Non-destructive evaluation methods such as interferometry and acoustic microscopy can detect early signs of coating failure due to thermal stress, allowing for design optimization and quality control in production environments.

02 Stress-relieving buffer layers and adhesion promoters

Specialized buffer layers can be incorporated between the substrate and anti-reflective coating to accommodate CTE differences. These intermediate layers often contain materials that can flex or deform slightly to absorb thermal stress. Additionally, adhesion promoters can be used to enhance the bonding between layers with different expansion coefficients, preventing delamination under thermal stress while maintaining optical performance.Expand Specific Solutions03 Material selection and composition optimization

Careful selection of coating materials with compatible thermal expansion properties is crucial for stress management. By modifying the chemical composition of anti-reflective materials through dopants, additives, or nanoparticles, the CTE can be tuned to better match the substrate. Some approaches include using silica-based materials with controlled porosity, organic-inorganic hybrid materials, or specialized polymers with engineered thermal properties.Expand Specific Solutions04 Deposition techniques and process optimization

The method of coating deposition significantly impacts stress management in anti-reflective coatings. Techniques such as atomic layer deposition, ion-assisted deposition, and plasma-enhanced chemical vapor deposition can be optimized to create coatings with reduced intrinsic stress. Process parameters including temperature, pressure, and deposition rate can be carefully controlled to minimize thermal mismatch effects and improve coating durability.Expand Specific Solutions05 Post-deposition treatments for stress relief

Various post-deposition treatments can be employed to relieve stress in anti-reflective coatings. These include thermal annealing processes that allow for gradual stress relaxation, laser treatment to modify coating properties, and specialized curing methods. Some approaches incorporate controlled cooling rates after deposition to minimize thermal shock and allow for gradual accommodation of CTE differences between the coating and substrate.Expand Specific Solutions

Leading Companies in High-Temperature Optical Coatings

The anti-reflective coating market for high-temperature substrates is in a growth phase, driven by increasing demand in semiconductor, optical, and solar industries. The market is projected to expand significantly due to advancements in materials science addressing CTE mismatch challenges. Technology maturity varies across players: established leaders like Brewer Science, SCHOTT AG, and Taiwan Semiconductor Manufacturing Co. have developed proprietary solutions for stress management, while research institutions like Fraunhofer-Gesellschaft and Delft University contribute fundamental innovations. Companies including First Solar and Enki Technology focus on specialized applications for solar panels, demonstrating the technology's diversification. The competitive landscape features both large integrated manufacturers and specialized coating technology providers, with increasing collaboration between material scientists and semiconductor manufacturers to overcome thermal expansion challenges.

Brewer Science, Inc.

Technical Solution: Brewer Science has developed advanced anti-reflective coating (ARC) solutions specifically designed for high-temperature substrates in semiconductor manufacturing. Their proprietary OptiStack® system incorporates multi-layer coating technology that addresses CTE mismatch through gradient-engineered interfaces between the substrate and coating layers[1]. The company's approach involves silicon-based inorganic-organic hybrid materials that maintain structural integrity at temperatures exceeding 400°C while providing excellent optical properties with reflectance below 0.5% across targeted wavelengths[3]. Their patented stress-relief additives create microscopic flexibility zones within the coating matrix, allowing for thermal expansion differences without delamination or cracking during thermal cycling. Brewer Science has also pioneered plasma-enhanced deposition techniques that improve adhesion at the molecular level between dissimilar materials with varying thermal expansion coefficients[5].

Strengths: Superior adhesion properties at high temperatures; excellent optical performance with minimal reflectance; proven reliability in semiconductor manufacturing environments. Weaknesses: Higher cost compared to conventional coatings; requires specialized application equipment; some formulations have limited shelf life requiring careful storage and handling.

SCHOTT AG

Technical Solution: SCHOTT AG has pioneered HeatSafe™ technology, an advanced anti-reflective coating system specifically engineered for high-temperature glass and ceramic substrates. Their approach utilizes a gradient-index nanostructured coating architecture that gradually transitions material properties from the substrate to the outer layer, effectively distributing thermal stress[2]. The company employs sol-gel deposition methods combined with precisely controlled thermal annealing to create coatings with engineered porosity that can accommodate thermal expansion differences up to 300°C temperature differentials without failure[4]. SCHOTT's proprietary ceramic-based interlayers act as CTE-matching transition zones, with nanoscale silica particles dispersed in a matrix that provides both optical clarity and mechanical flexibility during thermal cycling. Their coatings achieve reflectance values below 0.3% across visible and near-IR spectra while maintaining performance through thousands of thermal cycles from room temperature to 600°C[7]. Recent innovations include self-healing mechanisms where microscopic cracks that might form during extreme thermal events can partially recover during cooling phases.

Strengths: Exceptional thermal cycling durability; industry-leading optical performance; compatible with a wide range of substrate materials including specialized glasses and ceramics. Weaknesses: Complex multi-step manufacturing process increases production costs; limited scalability for very large substrate dimensions; requires highly specialized application expertise.

Key Innovations in Stress Management for AR Coatings

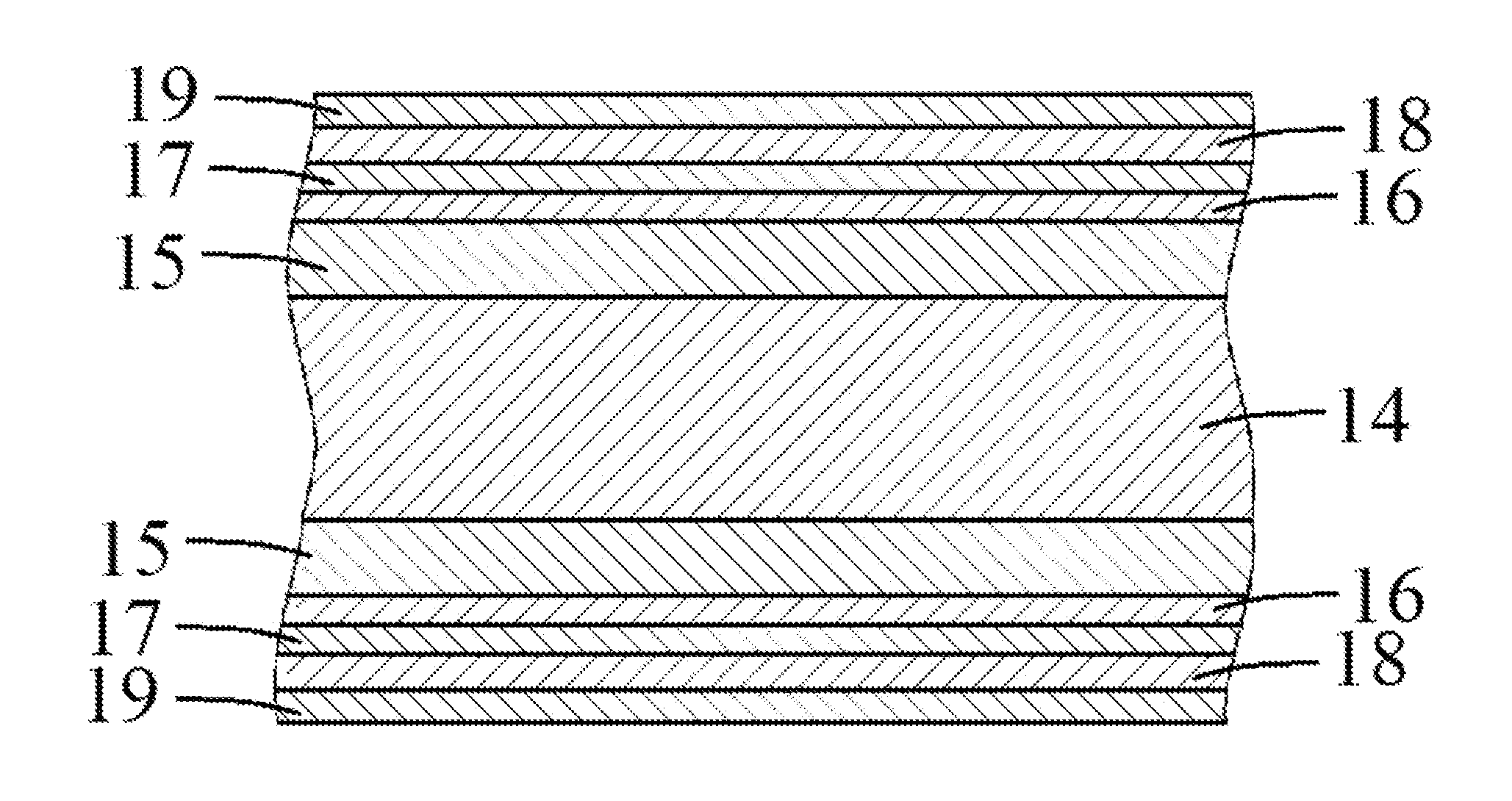

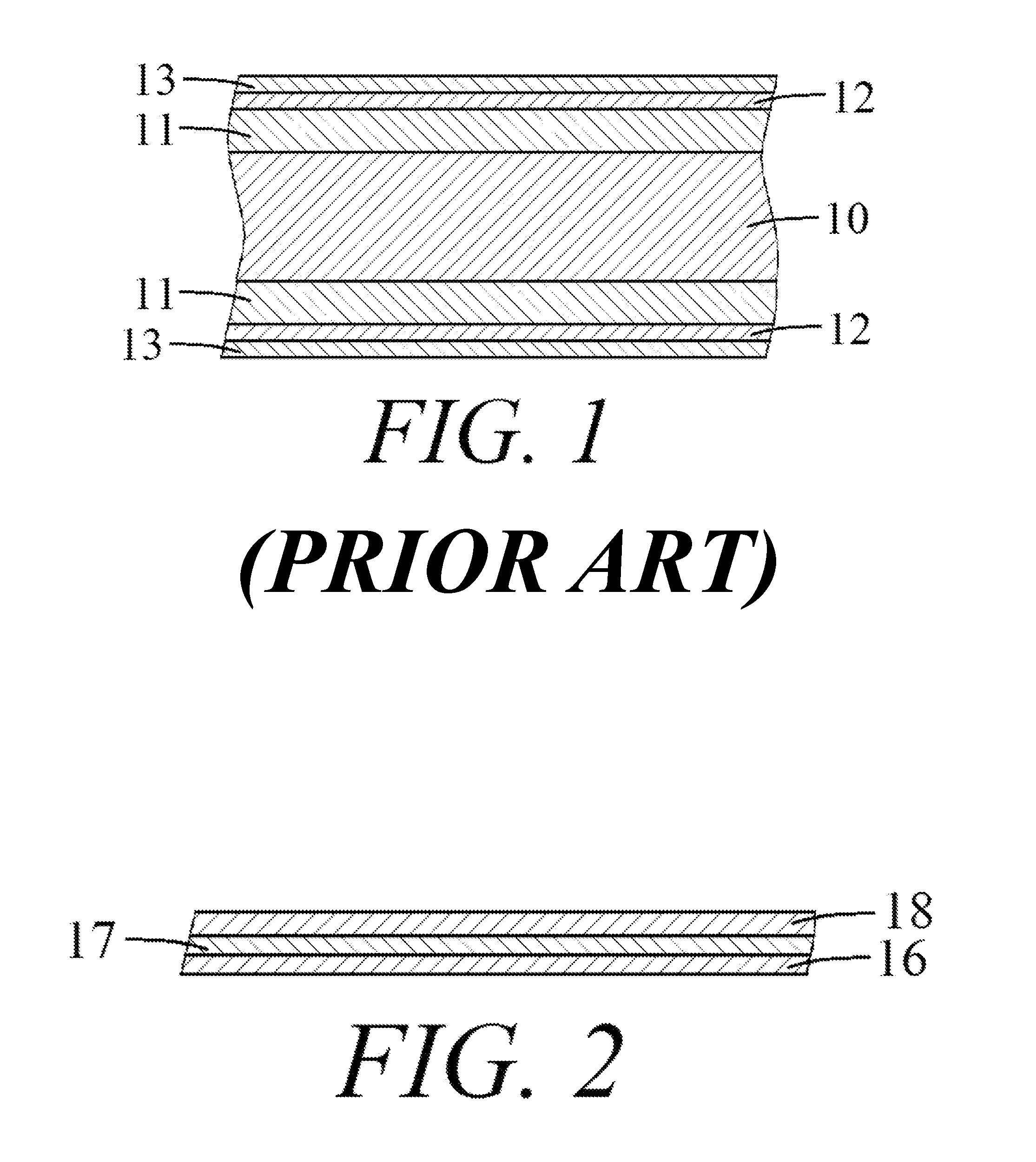

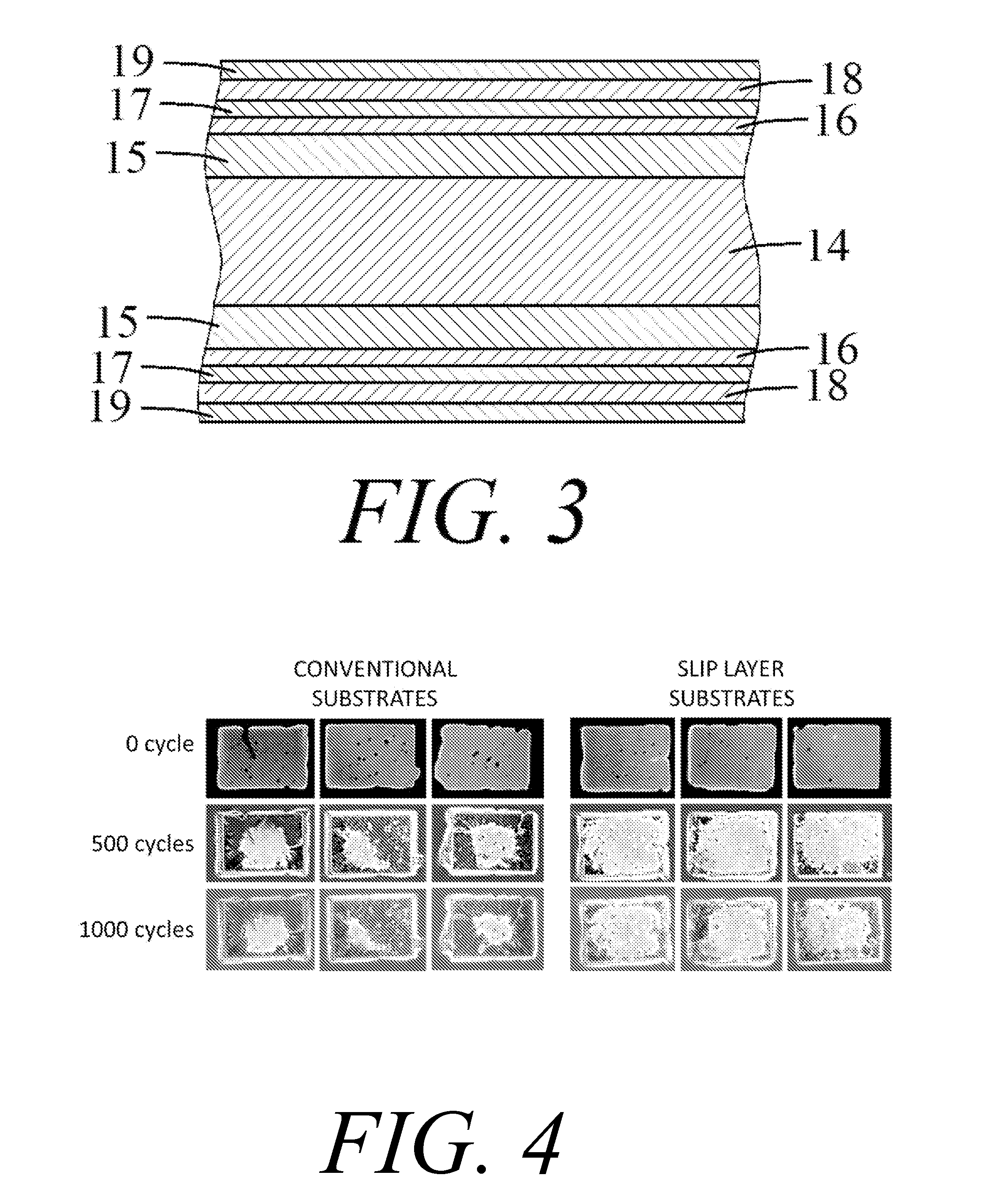

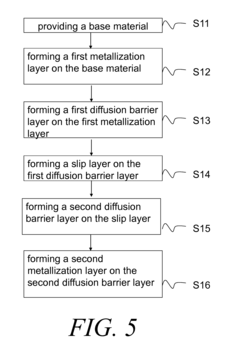

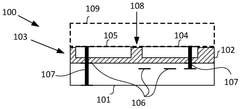

Multilayer substrate and method for manufacturing the same

PatentInactiveUS20150237724A1

Innovation

- A slip layer substrate is introduced, comprising a base material, a first metallization layer, a first diffusion barrier layer, a malleable slip layer, a second diffusion barrier layer, and a second metallization layer, where the slip layer is made of ductile materials like gold, silver, or copper, and the diffusion barrier layers are nickel or cobalt, to accommodate thermal expansion mismatch and reduce stress.

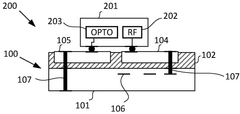

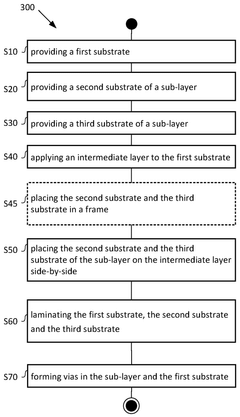

A carrier substrate and a method for producing a carrier substrate

PatentWO2025113785A1

Innovation

- A carrier substrate is designed with a first substrate, an intermediate layer, and a sub-layer comprising at least two substrates with different CTE arranged side-by-side, where the intermediate layer alleviates thermal expansion differences and reduces stress transfer to the first substrate.

Material Science Advancements for High-Temperature Applications

Material science has witnessed remarkable advancements in developing materials capable of withstanding extreme temperatures while maintaining structural integrity and functionality. Recent innovations in ceramic matrix composites (CMCs) have demonstrated exceptional thermal stability up to 1600°C, significantly outperforming traditional metallic alloys that typically fail beyond 1000°C. These CMCs incorporate silicon carbide and aluminum oxide matrices reinforced with ceramic fibers, creating systems with superior thermal shock resistance and mechanical strength at elevated temperatures.

Refractory metal alloys based on niobium, molybdenum, and tungsten have undergone substantial refinement through precise control of microstructure and addition of stabilizing elements like rhenium and hafnium. These modifications have addressed historical limitations related to oxidation resistance and brittleness at room temperature, expanding their application potential in aerospace and energy sectors.

Thermal barrier coating systems have evolved to incorporate multiple functional layers, each engineered to address specific challenges of high-temperature operation. Advanced yttria-stabilized zirconia (YSZ) formulations with tailored porosity profiles now provide enhanced thermal insulation while maintaining necessary mechanical compliance. The integration of rare earth elements into these coatings has improved phase stability and extended service life under thermal cycling conditions.

Nano-engineered materials represent a frontier in high-temperature applications, with significant progress in developing nanocomposites that exhibit unprecedented combinations of thermal, mechanical, and chemical properties. Silicon nitride nanocomposites reinforced with carbon nanotubes have demonstrated exceptional thermal conductivity control and mechanical strength retention at temperatures exceeding 1200°C, opening new possibilities for thermal management in extreme environments.

Surface modification techniques have advanced considerably, with atomic layer deposition and plasma-enhanced chemical vapor deposition enabling the creation of ultra-thin protective layers with precisely controlled composition and structure. These technologies allow for the deposition of complex oxide and nitride coatings that provide oxidation protection while maintaining thermal expansion compatibility with underlying substrates.

Computational materials science has accelerated development through high-throughput screening and machine learning approaches that predict material behavior under extreme conditions. These methods have identified promising new compositions and processing routes for high-temperature materials that would have been prohibitively time-consuming to discover through traditional experimental approaches, significantly reducing development cycles for next-generation materials.

Refractory metal alloys based on niobium, molybdenum, and tungsten have undergone substantial refinement through precise control of microstructure and addition of stabilizing elements like rhenium and hafnium. These modifications have addressed historical limitations related to oxidation resistance and brittleness at room temperature, expanding their application potential in aerospace and energy sectors.

Thermal barrier coating systems have evolved to incorporate multiple functional layers, each engineered to address specific challenges of high-temperature operation. Advanced yttria-stabilized zirconia (YSZ) formulations with tailored porosity profiles now provide enhanced thermal insulation while maintaining necessary mechanical compliance. The integration of rare earth elements into these coatings has improved phase stability and extended service life under thermal cycling conditions.

Nano-engineered materials represent a frontier in high-temperature applications, with significant progress in developing nanocomposites that exhibit unprecedented combinations of thermal, mechanical, and chemical properties. Silicon nitride nanocomposites reinforced with carbon nanotubes have demonstrated exceptional thermal conductivity control and mechanical strength retention at temperatures exceeding 1200°C, opening new possibilities for thermal management in extreme environments.

Surface modification techniques have advanced considerably, with atomic layer deposition and plasma-enhanced chemical vapor deposition enabling the creation of ultra-thin protective layers with precisely controlled composition and structure. These technologies allow for the deposition of complex oxide and nitride coatings that provide oxidation protection while maintaining thermal expansion compatibility with underlying substrates.

Computational materials science has accelerated development through high-throughput screening and machine learning approaches that predict material behavior under extreme conditions. These methods have identified promising new compositions and processing routes for high-temperature materials that would have been prohibitively time-consuming to discover through traditional experimental approaches, significantly reducing development cycles for next-generation materials.

Environmental and Durability Testing Standards

Environmental and durability testing standards for anti-reflective coatings on high-temperature substrates must be rigorous to ensure long-term performance under extreme conditions. The primary testing protocols include thermal cycling tests (ASTM C1171), which subject coated substrates to rapid temperature fluctuations between -40°C and 800°C to evaluate coating adhesion and stress resistance during thermal expansion and contraction cycles.

Humidity resistance testing (ISO 9022-2) is critical for assessing coating stability in moisture-rich environments, particularly important for applications where temperature gradients may cause condensation. These tests typically involve exposure to 85% relative humidity at elevated temperatures for 1000+ hours, monitoring for delamination, cracking, or optical property degradation.

Salt spray testing (ASTM B117) evaluates corrosion resistance by exposing coatings to salt-fog environments for extended periods, simulating coastal or industrial atmospheric conditions. This is particularly relevant for outdoor applications where environmental contaminants may interact with high-temperature substrates during cooling phases.

Abrasion resistance standards (MIL-C-48497) measure coating durability against mechanical wear through standardized rubbing tests with specified materials and pressures. For high-temperature applications, these tests are often modified to evaluate performance after thermal cycling to account for potential hardness changes in the coating structure.

Radiation stability testing (ASTM E490) assesses coating performance under UV, solar, or other radiation exposure, critical for space applications or solar energy systems where coatings must maintain anti-reflective properties despite constant radiation bombardment at elevated temperatures.

Adhesion testing standards (ASTM D3359) evaluate the bonding strength between coating and substrate after environmental exposure, with particular attention to CTE mismatch effects after thermal cycling. Cross-hatch and pull-off tests are commonly employed, with modifications for high-temperature materials.

Chemical resistance testing protocols (ISO 2812) expose coatings to relevant chemicals at various temperatures to simulate operational environments. For high-temperature applications, these tests often include exposure to combustion byproducts or process chemicals at elevated temperatures.

Accelerated weathering standards (ASTM G154) combine multiple environmental stressors to predict long-term performance, typically incorporating UV exposure, moisture, and temperature cycling in programmed sequences designed to simulate years of natural exposure in compressed timeframes.

Humidity resistance testing (ISO 9022-2) is critical for assessing coating stability in moisture-rich environments, particularly important for applications where temperature gradients may cause condensation. These tests typically involve exposure to 85% relative humidity at elevated temperatures for 1000+ hours, monitoring for delamination, cracking, or optical property degradation.

Salt spray testing (ASTM B117) evaluates corrosion resistance by exposing coatings to salt-fog environments for extended periods, simulating coastal or industrial atmospheric conditions. This is particularly relevant for outdoor applications where environmental contaminants may interact with high-temperature substrates during cooling phases.

Abrasion resistance standards (MIL-C-48497) measure coating durability against mechanical wear through standardized rubbing tests with specified materials and pressures. For high-temperature applications, these tests are often modified to evaluate performance after thermal cycling to account for potential hardness changes in the coating structure.

Radiation stability testing (ASTM E490) assesses coating performance under UV, solar, or other radiation exposure, critical for space applications or solar energy systems where coatings must maintain anti-reflective properties despite constant radiation bombardment at elevated temperatures.

Adhesion testing standards (ASTM D3359) evaluate the bonding strength between coating and substrate after environmental exposure, with particular attention to CTE mismatch effects after thermal cycling. Cross-hatch and pull-off tests are commonly employed, with modifications for high-temperature materials.

Chemical resistance testing protocols (ISO 2812) expose coatings to relevant chemicals at various temperatures to simulate operational environments. For high-temperature applications, these tests often include exposure to combustion byproducts or process chemicals at elevated temperatures.

Accelerated weathering standards (ASTM G154) combine multiple environmental stressors to predict long-term performance, typically incorporating UV exposure, moisture, and temperature cycling in programmed sequences designed to simulate years of natural exposure in compressed timeframes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!