How Anti-Reflective Coatings Achieve <0.5% Average Reflectance Across Wide Incidence?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Reflective Coating Technology Evolution and Objectives

Anti-reflective (AR) coating technology has evolved significantly since its inception in the 1930s when F. Geffcken first developed multilayer interference coatings. The fundamental principle behind AR coatings is to minimize the reflection of light at optical interfaces through destructive interference, allowing maximum light transmission. Early AR coatings were primarily single-layer designs with limited performance across narrow wavelength bands and specific incidence angles.

The 1950s and 1960s marked a significant advancement with the development of quarter-wavelength multilayer stacks, which expanded the effectiveness of AR coatings across broader spectral ranges. By the 1980s, gradient-index coatings emerged, mimicking the moth-eye structure found in nature, which demonstrated superior anti-reflective properties by creating a gradual transition in refractive index.

Recent decades have witnessed remarkable progress in achieving ultra-low reflectance (<0.5% average) across wide incidence angles, driven by demands from high-performance optical systems in photovoltaics, displays, and precision optics. This advancement has been enabled by sophisticated thin-film deposition technologies such as plasma-enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), and magnetron sputtering, allowing precise control over nanoscale structures.

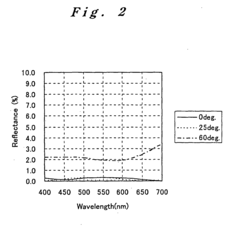

The current technological objective is to develop AR coatings that maintain reflectance below 0.5% across incident angles from 0° to 60° or wider, while covering the entire visible spectrum (400-700nm) or specific application-dependent wavelength ranges. This represents a significant challenge due to the inherent physics of light reflection, which typically increases at larger angles of incidence according to Fresnel's equations.

Additional objectives include enhancing durability against environmental factors, reducing production costs for commercial viability, and developing environmentally friendly manufacturing processes. The industry is also pursuing AR coatings that maintain performance under varying temperature conditions and resist degradation from UV exposure, humidity, and mechanical abrasion.

The evolution trajectory points toward biomimetic nanostructured surfaces that can outperform traditional thin-film interference coatings, particularly for wide-angle applications. Computational design methods, including machine learning algorithms, are increasingly employed to optimize complex multilayer structures that would be difficult to design using conventional analytical approaches.

Future objectives include the development of active or tunable AR coatings that can adapt to changing environmental conditions or application requirements, potentially through the integration of responsive materials or electro-optical components that modify optical properties in real-time.

The 1950s and 1960s marked a significant advancement with the development of quarter-wavelength multilayer stacks, which expanded the effectiveness of AR coatings across broader spectral ranges. By the 1980s, gradient-index coatings emerged, mimicking the moth-eye structure found in nature, which demonstrated superior anti-reflective properties by creating a gradual transition in refractive index.

Recent decades have witnessed remarkable progress in achieving ultra-low reflectance (<0.5% average) across wide incidence angles, driven by demands from high-performance optical systems in photovoltaics, displays, and precision optics. This advancement has been enabled by sophisticated thin-film deposition technologies such as plasma-enhanced chemical vapor deposition (PECVD), atomic layer deposition (ALD), and magnetron sputtering, allowing precise control over nanoscale structures.

The current technological objective is to develop AR coatings that maintain reflectance below 0.5% across incident angles from 0° to 60° or wider, while covering the entire visible spectrum (400-700nm) or specific application-dependent wavelength ranges. This represents a significant challenge due to the inherent physics of light reflection, which typically increases at larger angles of incidence according to Fresnel's equations.

Additional objectives include enhancing durability against environmental factors, reducing production costs for commercial viability, and developing environmentally friendly manufacturing processes. The industry is also pursuing AR coatings that maintain performance under varying temperature conditions and resist degradation from UV exposure, humidity, and mechanical abrasion.

The evolution trajectory points toward biomimetic nanostructured surfaces that can outperform traditional thin-film interference coatings, particularly for wide-angle applications. Computational design methods, including machine learning algorithms, are increasingly employed to optimize complex multilayer structures that would be difficult to design using conventional analytical approaches.

Future objectives include the development of active or tunable AR coatings that can adapt to changing environmental conditions or application requirements, potentially through the integration of responsive materials or electro-optical components that modify optical properties in real-time.

Market Demand Analysis for High-Performance AR Coatings

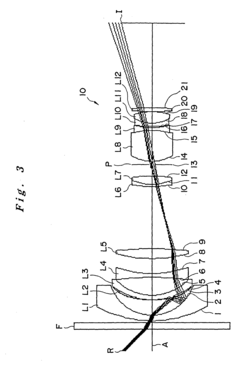

The global market for high-performance anti-reflective (AR) coatings achieving <0.5% average reflectance across wide incidence angles is experiencing robust growth, driven by increasing demand across multiple industries. The optical components sector represents the largest market segment, with precision optics manufacturers requiring superior AR performance for applications in scientific instruments, high-end cameras, and astronomical equipment.

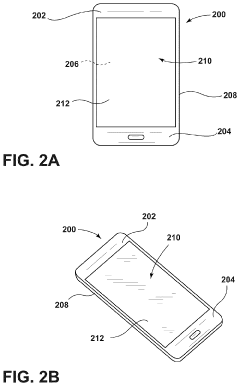

Consumer electronics constitutes a rapidly expanding market, with smartphone manufacturers incorporating advanced AR coatings on camera lenses, display screens, and sensors. The premium smartphone segment particularly values coatings that maintain low reflectance at various viewing angles, enhancing user experience in diverse lighting conditions. Market research indicates the consumer electronics segment is growing at approximately 8% annually for high-performance AR coating applications.

The photovoltaic industry demonstrates significant demand growth as manufacturers seek to maximize solar panel efficiency. High-performance AR coatings that maintain effectiveness across wide incidence angles directly translate to improved energy capture throughout the day as the sun's position changes. This application segment shows particular promise in regions pursuing aggressive renewable energy targets.

Military and aerospace applications represent a premium market segment where performance requirements justify higher costs. These sectors demand AR coatings that maintain effectiveness across extreme environmental conditions while providing consistent optical performance at various angles for sensing, targeting, and communication systems.

Medical imaging and diagnostic equipment manufacturers constitute another high-value market segment. Advanced endoscopes, surgical microscopes, and diagnostic imaging systems benefit substantially from wide-angle AR coatings that improve light transmission and reduce glare during critical procedures.

Market barriers include production costs and scalability challenges. While demand exists across multiple sectors, the precision manufacturing processes required for achieving <0.5% reflectance across wide angles currently limit mass adoption in cost-sensitive applications. The market shows clear segmentation between high-value applications willing to bear premium costs and volume applications seeking cost-effective solutions.

Regional analysis reveals concentrated demand in North America, Europe, and East Asia, with emerging markets in South Asia showing accelerated growth as manufacturing capabilities expand. The automotive industry represents a potentially massive future market as advanced driver assistance systems and autonomous vehicles increasingly rely on optical sensors requiring superior performance across varying environmental conditions.

Consumer electronics constitutes a rapidly expanding market, with smartphone manufacturers incorporating advanced AR coatings on camera lenses, display screens, and sensors. The premium smartphone segment particularly values coatings that maintain low reflectance at various viewing angles, enhancing user experience in diverse lighting conditions. Market research indicates the consumer electronics segment is growing at approximately 8% annually for high-performance AR coating applications.

The photovoltaic industry demonstrates significant demand growth as manufacturers seek to maximize solar panel efficiency. High-performance AR coatings that maintain effectiveness across wide incidence angles directly translate to improved energy capture throughout the day as the sun's position changes. This application segment shows particular promise in regions pursuing aggressive renewable energy targets.

Military and aerospace applications represent a premium market segment where performance requirements justify higher costs. These sectors demand AR coatings that maintain effectiveness across extreme environmental conditions while providing consistent optical performance at various angles for sensing, targeting, and communication systems.

Medical imaging and diagnostic equipment manufacturers constitute another high-value market segment. Advanced endoscopes, surgical microscopes, and diagnostic imaging systems benefit substantially from wide-angle AR coatings that improve light transmission and reduce glare during critical procedures.

Market barriers include production costs and scalability challenges. While demand exists across multiple sectors, the precision manufacturing processes required for achieving <0.5% reflectance across wide angles currently limit mass adoption in cost-sensitive applications. The market shows clear segmentation between high-value applications willing to bear premium costs and volume applications seeking cost-effective solutions.

Regional analysis reveals concentrated demand in North America, Europe, and East Asia, with emerging markets in South Asia showing accelerated growth as manufacturing capabilities expand. The automotive industry represents a potentially massive future market as advanced driver assistance systems and autonomous vehicles increasingly rely on optical sensors requiring superior performance across varying environmental conditions.

Current Challenges in Wide-Angle AR Coating Development

Despite significant advancements in anti-reflective (AR) coating technology, achieving average reflectance below 0.5% across wide incidence angles remains a formidable challenge. The fundamental physics of light interaction with surfaces creates inherent limitations that engineers must overcome through innovative approaches. Traditional quarter-wavelength stack designs perform well at normal incidence but deteriorate rapidly as angles increase beyond 30°, particularly for s-polarized light.

Material selection presents another significant hurdle. High-index materials needed for effective index matching often exhibit absorption in critical wavelength ranges, compromising overall transmission. Meanwhile, low-index materials with ideal optical properties frequently lack the mechanical durability required for practical applications, leading to premature coating failure under environmental stress.

Manufacturing precision continues to be a critical constraint. Achieving sub-0.5% reflectance requires layer thickness control at the nanometer scale across large surface areas. Current deposition technologies struggle to maintain this precision consistently, resulting in performance variations that can exceed design tolerances. This challenge is magnified when coating complex curved surfaces, where thickness uniformity becomes even more difficult to maintain.

Environmental stability represents another major obstacle. Coatings that perform excellently in laboratory conditions often degrade when exposed to humidity, temperature fluctuations, and mechanical abrasion. The incorporation of protective layers can mitigate these issues but typically comes at the cost of reduced optical performance, creating a difficult engineering trade-off.

Cost-effectiveness remains a persistent challenge, particularly for consumer applications. Multi-layer designs with 20+ layers can achieve the desired optical performance but at prohibitively high manufacturing costs. Simplified designs that maintain performance while reducing layer count represent an ongoing research focus but have yet to yield broadly applicable solutions.

Polarization dependence presents additional complexity. Most wide-angle AR coatings show significant performance disparities between s- and p-polarized light, with s-polarization typically exhibiting much higher reflectance at oblique angles. Creating polarization-insensitive designs that maintain sub-0.5% reflectance across the entire angular range requires sophisticated optimization algorithms and novel material combinations.

Bandwidth limitations further complicate matters. Designs optimized for wide angular coverage often sacrifice spectral bandwidth, making it difficult to simultaneously achieve wide-angle and broadband performance. This trade-off is particularly problematic for applications requiring both characteristics, such as high-end camera lenses and solar panels.

Material selection presents another significant hurdle. High-index materials needed for effective index matching often exhibit absorption in critical wavelength ranges, compromising overall transmission. Meanwhile, low-index materials with ideal optical properties frequently lack the mechanical durability required for practical applications, leading to premature coating failure under environmental stress.

Manufacturing precision continues to be a critical constraint. Achieving sub-0.5% reflectance requires layer thickness control at the nanometer scale across large surface areas. Current deposition technologies struggle to maintain this precision consistently, resulting in performance variations that can exceed design tolerances. This challenge is magnified when coating complex curved surfaces, where thickness uniformity becomes even more difficult to maintain.

Environmental stability represents another major obstacle. Coatings that perform excellently in laboratory conditions often degrade when exposed to humidity, temperature fluctuations, and mechanical abrasion. The incorporation of protective layers can mitigate these issues but typically comes at the cost of reduced optical performance, creating a difficult engineering trade-off.

Cost-effectiveness remains a persistent challenge, particularly for consumer applications. Multi-layer designs with 20+ layers can achieve the desired optical performance but at prohibitively high manufacturing costs. Simplified designs that maintain performance while reducing layer count represent an ongoing research focus but have yet to yield broadly applicable solutions.

Polarization dependence presents additional complexity. Most wide-angle AR coatings show significant performance disparities between s- and p-polarized light, with s-polarization typically exhibiting much higher reflectance at oblique angles. Creating polarization-insensitive designs that maintain sub-0.5% reflectance across the entire angular range requires sophisticated optimization algorithms and novel material combinations.

Bandwidth limitations further complicate matters. Designs optimized for wide angular coverage often sacrifice spectral bandwidth, making it difficult to simultaneously achieve wide-angle and broadband performance. This trade-off is particularly problematic for applications requiring both characteristics, such as high-end camera lenses and solar panels.

Current Technical Solutions for Ultra-Low Reflectance

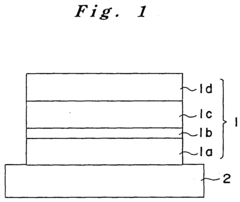

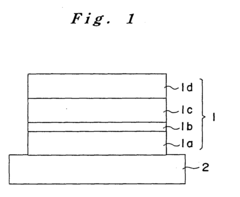

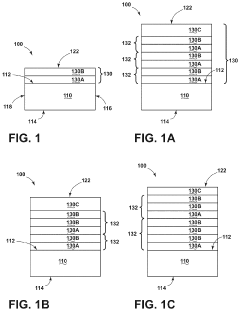

01 Multi-layer anti-reflective coating structures

Multi-layer anti-reflective coatings consist of alternating high and low refractive index materials to minimize reflectance across a broad spectrum of wavelengths. These structures can be designed with specific thickness and material combinations to achieve optimal anti-reflective properties. The interference effects between the layers help to cancel out reflected light, resulting in significantly reduced reflectance compared to uncoated surfaces.- Multi-layer anti-reflective coating structures: Multi-layer anti-reflective coatings consist of alternating high and low refractive index materials to achieve broadband reflectance reduction. These structures utilize destructive interference principles to cancel out reflected light at specific wavelengths. The thickness and refractive index of each layer are carefully engineered to minimize reflectance across desired wavelength ranges, typically achieving reflectance values below 0.5% for optical applications.

- Nanostructured anti-reflective surfaces: Nanostructured surfaces provide anti-reflective properties through gradual refractive index transitions rather than discrete layers. These structures often mimic natural anti-reflective surfaces like moth eyes, featuring arrays of nanoscale protrusions that effectively reduce reflectance by creating a gradient refractive index profile. Fabrication methods include lithography, etching, and self-assembly techniques to create sub-wavelength features that minimize light reflection across broad spectral ranges and viewing angles.

- Sol-gel derived anti-reflective coatings: Sol-gel processes enable the creation of porous anti-reflective coatings with controlled refractive indices. These coatings typically incorporate silica-based materials with nanoscale porosity to achieve low refractive indices (around 1.2-1.3) necessary for effective anti-reflection properties. The porosity level can be adjusted through processing parameters to optimize reflectance reduction. These coatings offer advantages including low-temperature processing, compatibility with various substrates, and tunable optical properties.

- Photolithographic anti-reflective materials: Anti-reflective coatings specifically designed for photolithography applications help minimize substrate reflectance during semiconductor manufacturing. These materials typically include bottom anti-reflective coatings (BARCs) that absorb light and prevent reflection from underlying layers, improving pattern resolution and reducing standing wave effects. The formulations often contain chromophores that absorb at specific wavelengths used in lithographic exposure systems, with reflectance values typically reduced to below 1% at the target wavelength.

- Deposition methods for anti-reflective coatings: Various deposition techniques are employed to create anti-reflective coatings with precise thickness control and uniformity. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and solution-based approaches. Each technique offers different advantages in terms of conformality, scalability, and compatibility with substrate materials. The deposition parameters significantly impact coating quality, with precise control needed to achieve minimum reflectance values, typically targeting less than 0.2% for high-performance optical applications.

02 Nanostructured anti-reflective surfaces

Nanostructured surfaces with features smaller than the wavelength of light can provide excellent anti-reflective properties through a gradual change in refractive index. These structures often mimic natural anti-reflective surfaces like moth eyes. The nanoscale textures create an effective medium with a gradient refractive index that minimizes the abrupt interface between air and substrate, thereby reducing reflectance across a wide range of incident angles and wavelengths.Expand Specific Solutions03 Sol-gel derived anti-reflective coatings

Sol-gel processes are used to create porous anti-reflective coatings with controlled refractive indices. These coatings typically involve silica-based materials with nanopores that lower the effective refractive index. The porosity can be adjusted to optimize anti-reflective performance, and the sol-gel approach allows for low-temperature processing compatible with various substrates. These coatings can achieve very low reflectance values while maintaining good mechanical and environmental durability.Expand Specific Solutions04 Polymer-based anti-reflective coatings

Polymer-based anti-reflective coatings offer advantages in flexibility, processability, and compatibility with organic substrates. These coatings can incorporate various functional additives to enhance performance and durability. Techniques such as spin coating, dip coating, or spray coating are commonly used for application. The polymer matrix can be designed with specific optical properties to minimize reflectance while providing additional benefits such as scratch resistance or self-cleaning capabilities.Expand Specific Solutions05 Photolithographic patterning for anti-reflective structures

Photolithographic techniques are used to create precisely patterned anti-reflective structures with controlled dimensions and geometries. These methods enable the fabrication of subwavelength features that effectively reduce reflectance. The process typically involves photoresist patterning followed by etching or deposition steps to create the final anti-reflective structure. This approach allows for high precision in controlling the optical properties and can be integrated with semiconductor manufacturing processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions in AR Coatings

The anti-reflective coating market is currently in a growth phase, with increasing demand across optical, electronics, automotive, and solar industries. The technology to achieve <0.5% average reflectance across wide incidence angles has reached commercial maturity, with key players like Corning, Schott AG, and Carl Zeiss leading innovation through multi-layer coating designs and nano-structured surfaces. Major corporations including EssilorLuxottica, Nikon, and FUJIFILM have established strong market positions by leveraging proprietary coating technologies. Research institutions such as Rensselaer Polytechnic Institute and Fraunhofer-Gesellschaft continue advancing the field through novel materials and deposition techniques. The market is expected to expand further as applications in displays, photovoltaics, and precision optics drive demand for higher-performance anti-reflective solutions.

Corning, Inc.

Technical Solution: Corning has developed advanced multi-layer anti-reflective coating systems that achieve <0.5% average reflectance across wide incidence angles. Their proprietary technology utilizes alternating high and low refractive index materials (typically metal oxides like SiO2 and TiO2) deposited via magnetron sputtering processes. The coating architecture employs a gradient index design where the refractive index gradually transitions from air to substrate, minimizing reflection at each interface. Corning's approach includes precision-controlled layer thicknesses at quarter-wavelength multiples optimized for destructive interference of reflected light. Their coatings incorporate moth-eye inspired nanostructures with dimensions smaller than the wavelength of visible light, creating an effective medium with gradually changing refractive index[1]. Recent innovations include integration of hydrophobic and oleophobic properties for self-cleaning capabilities while maintaining optical performance across incident angles from 0° to 60°.

Strengths: Superior durability and scratch resistance compared to competitors; excellent environmental stability in harsh conditions; established manufacturing infrastructure for large-scale production. Weaknesses: Higher production costs than simpler coating systems; complex deposition process requires sophisticated equipment; some formulations may have limited temperature range for optimal performance.

EssilorLuxottica SA

Technical Solution: EssilorLuxottica has developed advanced anti-reflective coating systems achieving <0.5% average reflectance across wide incidence angles through their Crizal® technology platform. Their approach utilizes a sophisticated multi-layer stack design with precisely controlled thicknesses of alternating high and low refractive index materials. The company employs ion-assisted deposition techniques to create dense, highly adherent films with exceptional uniformity. Their coating architecture incorporates both quarter-wavelength designs for normal incidence and modified thickness distributions specifically optimized for oblique angles. EssilorLuxottica's innovation includes gradient-index layers where the composition gradually changes throughout the thickness, creating a smoother refractive index transition that minimizes reflection across broader wavelength ranges and incident angles[5]. Their manufacturing process incorporates in-situ optical monitoring systems that allow real-time adjustment of deposition parameters to achieve target specifications. Additionally, their latest generation coatings integrate hydrophobic, oleophobic, and anti-static properties while maintaining the primary anti-reflective function across wide viewing angles. The company has also pioneered the integration of scratch-resistant base layers with their AR coating systems to enhance durability without compromising optical performance.

Strengths: Excellent balance of optical performance and durability; integrated scratch resistance and easy-clean properties; established high-volume manufacturing capabilities with consistent quality. Weaknesses: Slightly higher reflectance at extreme angles compared to some specialized research-grade coatings; optimization for eyewear applications may limit performance in other applications; proprietary nature of technology limits customization options.

Key Patents and Innovations in Wide-Angle AR Coatings

Anti-reflection coating in the visible range for wide incident angles

PatentInactiveEP1584954A2

Innovation

- An anti-reflection coating comprising multiple layers, including aluminum oxide, titanium oxide, zirconium oxide, and magnesium fluoride, formed using vacuum deposition and sol-gel methods, with specific refractive indices and thicknesses, to achieve low reflectance across a wide range of angles from 0 to 60 degrees within the visible light spectrum.

Low reflectance, anti-reflective film structures with controlled color and articles with the same

PatentActiveUS11815657B2

Innovation

- A translucent substrate with an anti-reflective coating comprising a plurality of layers, including at least one low refractive index layer and one high refractive index layer, with a refractive index range of less than 1.7 and greater than 2.0 respectively, and a physical thickness of 50 nm to less than 500 nm, providing enhanced abrasion resistance and maintaining optical properties while minimizing color shift across viewing angles.

Material Science Advancements for AR Coating Performance

Recent advancements in material science have revolutionized anti-reflective (AR) coating performance, enabling the achievement of less than 0.5% average reflectance across wide incidence angles. This breakthrough has been primarily driven by innovations in nanomaterial engineering and multi-layer thin film technologies.

The foundation of modern AR coating materials lies in the development of high-refractive-index contrast materials that can be precisely deposited in nanometer-scale layers. Silicon dioxide (SiO₂) and titanium dioxide (TiO₂) combinations have emerged as industry standards due to their complementary optical properties and excellent durability. These materials, when arranged in specific thickness sequences, create destructive interference patterns that effectively cancel out reflected light.

Gradient-index (GRIN) technology represents a significant leap forward in AR coating materials. Unlike traditional discrete-layer approaches, GRIN materials feature a continuous change in refractive index perpendicular to the substrate surface. This gradual transition minimizes the abrupt interfaces where reflection typically occurs, allowing for exceptional performance across varying angles of incidence. Recent developments in sol-gel chemistry have enabled precise control over these gradient profiles.

Moth-eye nanostructures, inspired by the corneal surface of nocturnal moths, have been successfully replicated using advanced nanofabrication techniques. These biomimetic structures consist of arrays of sub-wavelength protuberances that create an effective medium with gradually changing refractive index. Materials science innovations in nanoimprint lithography and reactive ion etching have made commercial-scale production of these structures increasingly viable.

Hydrophobic and oleophobic properties have been integrated into AR coatings through the incorporation of fluoropolymers and silane-based compounds. These materials create self-cleaning surfaces that maintain optical performance over extended periods by preventing contamination buildup. The challenge of maintaining mechanical durability while incorporating these functional materials has been addressed through cross-linking chemistry and hybrid organic-inorganic compositions.

Quantum dot and plasmonic nanoparticle integration represents the cutting edge of AR coating material science. These nanomaterials can be precisely tuned to manipulate light at specific wavelengths, enabling spectral selectivity while maintaining broadband anti-reflective properties. Recent breakthroughs in colloidal synthesis methods have improved the stability and optical performance of these advanced materials.

Environmental considerations have also driven material innovations, with the development of water-based deposition processes and elimination of hazardous substances like lead and hexavalent chromium. These eco-friendly approaches maintain performance standards while reducing environmental impact throughout the coating lifecycle.

The foundation of modern AR coating materials lies in the development of high-refractive-index contrast materials that can be precisely deposited in nanometer-scale layers. Silicon dioxide (SiO₂) and titanium dioxide (TiO₂) combinations have emerged as industry standards due to their complementary optical properties and excellent durability. These materials, when arranged in specific thickness sequences, create destructive interference patterns that effectively cancel out reflected light.

Gradient-index (GRIN) technology represents a significant leap forward in AR coating materials. Unlike traditional discrete-layer approaches, GRIN materials feature a continuous change in refractive index perpendicular to the substrate surface. This gradual transition minimizes the abrupt interfaces where reflection typically occurs, allowing for exceptional performance across varying angles of incidence. Recent developments in sol-gel chemistry have enabled precise control over these gradient profiles.

Moth-eye nanostructures, inspired by the corneal surface of nocturnal moths, have been successfully replicated using advanced nanofabrication techniques. These biomimetic structures consist of arrays of sub-wavelength protuberances that create an effective medium with gradually changing refractive index. Materials science innovations in nanoimprint lithography and reactive ion etching have made commercial-scale production of these structures increasingly viable.

Hydrophobic and oleophobic properties have been integrated into AR coatings through the incorporation of fluoropolymers and silane-based compounds. These materials create self-cleaning surfaces that maintain optical performance over extended periods by preventing contamination buildup. The challenge of maintaining mechanical durability while incorporating these functional materials has been addressed through cross-linking chemistry and hybrid organic-inorganic compositions.

Quantum dot and plasmonic nanoparticle integration represents the cutting edge of AR coating material science. These nanomaterials can be precisely tuned to manipulate light at specific wavelengths, enabling spectral selectivity while maintaining broadband anti-reflective properties. Recent breakthroughs in colloidal synthesis methods have improved the stability and optical performance of these advanced materials.

Environmental considerations have also driven material innovations, with the development of water-based deposition processes and elimination of hazardous substances like lead and hexavalent chromium. These eco-friendly approaches maintain performance standards while reducing environmental impact throughout the coating lifecycle.

Optical Testing and Validation Methodologies

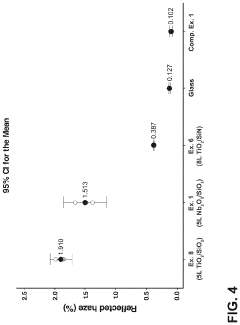

Optical Testing and Validation Methodologies for anti-reflective (AR) coatings require sophisticated approaches to verify performance claims of <0.5% average reflectance across wide incidence angles. The foundation of these methodologies lies in spectrophotometric analysis, where specialized instruments measure reflectance across the target wavelength spectrum, typically 400-700nm for visible light applications or extended ranges for specialized uses.

Angle-dependent reflectance measurements represent a critical testing component, utilizing variable angle spectrophotometers that can assess coating performance from normal incidence (0°) to oblique angles (often up to 60° or 80°). These measurements generate comprehensive reflectance profiles that validate coating effectiveness across real-world usage conditions where light rarely strikes surfaces at perfect normal incidence.

Environmental durability testing constitutes another essential validation methodology, subjecting coated samples to accelerated aging protocols including temperature cycling (-40°C to 85°C), humidity exposure (95% RH), and salt spray tests. These procedures ensure the AR coating maintains its <0.5% reflectance performance throughout the product's expected lifetime despite environmental stressors.

Abrasion resistance validation employs standardized tests such as the Taber abraser method (ASTM D1044) or cheesecloth rubbing tests to quantify coating durability against mechanical wear. Advanced AR coatings must balance optical performance with physical resilience, as excessive softness would render the coating impractical despite excellent optical properties.

Uniformity mapping techniques utilize imaging spectrophotometers or ellipsometers to create spatial maps of reflectance variation across coated surfaces. This methodology identifies potential manufacturing inconsistencies that could compromise overall performance, particularly critical for large-area applications like solar panels or architectural glass.

Comparative benchmark testing against industry standards provides context for performance claims, with organizations like ISO, ASTM, and JIS offering standardized testing protocols. These benchmarks establish whether a coating truly achieves exceptional performance relative to established industry norms rather than selective test conditions.

Statistical validation approaches employ multiple sample testing with rigorous data analysis to ensure manufacturing repeatability. This methodology typically requires testing dozens of production samples to establish confidence intervals for reflectance values, confirming that the <0.5% claim represents typical performance rather than exceptional cases.

Angle-dependent reflectance measurements represent a critical testing component, utilizing variable angle spectrophotometers that can assess coating performance from normal incidence (0°) to oblique angles (often up to 60° or 80°). These measurements generate comprehensive reflectance profiles that validate coating effectiveness across real-world usage conditions where light rarely strikes surfaces at perfect normal incidence.

Environmental durability testing constitutes another essential validation methodology, subjecting coated samples to accelerated aging protocols including temperature cycling (-40°C to 85°C), humidity exposure (95% RH), and salt spray tests. These procedures ensure the AR coating maintains its <0.5% reflectance performance throughout the product's expected lifetime despite environmental stressors.

Abrasion resistance validation employs standardized tests such as the Taber abraser method (ASTM D1044) or cheesecloth rubbing tests to quantify coating durability against mechanical wear. Advanced AR coatings must balance optical performance with physical resilience, as excessive softness would render the coating impractical despite excellent optical properties.

Uniformity mapping techniques utilize imaging spectrophotometers or ellipsometers to create spatial maps of reflectance variation across coated surfaces. This methodology identifies potential manufacturing inconsistencies that could compromise overall performance, particularly critical for large-area applications like solar panels or architectural glass.

Comparative benchmark testing against industry standards provides context for performance claims, with organizations like ISO, ASTM, and JIS offering standardized testing protocols. These benchmarks establish whether a coating truly achieves exceptional performance relative to established industry norms rather than selective test conditions.

Statistical validation approaches employ multiple sample testing with rigorous data analysis to ensure manufacturing repeatability. This methodology typically requires testing dozens of production samples to establish confidence intervals for reflectance values, confirming that the <0.5% claim represents typical performance rather than exceptional cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!