Anti-Reflective Coatings: Sol–Gel Vs PVD Stacks, Adhesion Windows And Humidity Endurance

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Reflective Coating Technologies Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when they were first developed for optical applications. Initially used primarily in camera lenses and scientific instruments, these coatings have become essential components in numerous industries including consumer electronics, solar energy, automotive, and medical devices. The fundamental principle behind AR coatings remains consistent: reducing light reflection at optical interfaces to improve transmission and visual clarity.

The technological evolution of AR coatings has followed several distinct phases. Early coatings utilized single-layer designs with limited effectiveness across wavelength ranges. This progressed to multi-layer interference coatings in the mid-20th century, significantly improving performance. The 1980s and 1990s saw the emergence of sol-gel technology as a cost-effective alternative to traditional vacuum deposition methods, while the 2000s brought advanced Physical Vapor Deposition (PVD) stack technologies offering precise control over optical properties.

Current market demands are driving AR coating technology toward solutions that combine superior optical performance with enhanced durability. The increasing prevalence of touch-enabled devices, outdoor displays, and wearable technology has created a need for coatings that maintain optical clarity while withstanding environmental challenges, particularly humidity and mechanical stress. This has positioned adhesion strength and humidity resistance as critical performance metrics in modern AR coating development.

The primary objective of this technical research is to conduct a comprehensive comparison between sol-gel and PVD stack technologies for AR coating applications, with specific focus on their adhesion windows and humidity endurance characteristics. This analysis aims to identify the optimal technology pathway for next-generation AR coatings that can meet increasingly demanding performance requirements across diverse application environments.

Secondary objectives include mapping the processing parameters that influence adhesion strength in both technologies, quantifying humidity resistance under various environmental conditions, and evaluating the scalability of each approach for mass production scenarios. The research also seeks to identify potential hybrid approaches that might combine the advantages of both technologies while minimizing their respective limitations.

The findings from this investigation will inform strategic technology development decisions, helping to establish a roadmap for AR coating innovation that aligns with projected market needs and manufacturing capabilities over the next five to ten years.

The technological evolution of AR coatings has followed several distinct phases. Early coatings utilized single-layer designs with limited effectiveness across wavelength ranges. This progressed to multi-layer interference coatings in the mid-20th century, significantly improving performance. The 1980s and 1990s saw the emergence of sol-gel technology as a cost-effective alternative to traditional vacuum deposition methods, while the 2000s brought advanced Physical Vapor Deposition (PVD) stack technologies offering precise control over optical properties.

Current market demands are driving AR coating technology toward solutions that combine superior optical performance with enhanced durability. The increasing prevalence of touch-enabled devices, outdoor displays, and wearable technology has created a need for coatings that maintain optical clarity while withstanding environmental challenges, particularly humidity and mechanical stress. This has positioned adhesion strength and humidity resistance as critical performance metrics in modern AR coating development.

The primary objective of this technical research is to conduct a comprehensive comparison between sol-gel and PVD stack technologies for AR coating applications, with specific focus on their adhesion windows and humidity endurance characteristics. This analysis aims to identify the optimal technology pathway for next-generation AR coatings that can meet increasingly demanding performance requirements across diverse application environments.

Secondary objectives include mapping the processing parameters that influence adhesion strength in both technologies, quantifying humidity resistance under various environmental conditions, and evaluating the scalability of each approach for mass production scenarios. The research also seeks to identify potential hybrid approaches that might combine the advantages of both technologies while minimizing their respective limitations.

The findings from this investigation will inform strategic technology development decisions, helping to establish a roadmap for AR coating innovation that aligns with projected market needs and manufacturing capabilities over the next five to ten years.

Market Analysis for AR Coating Applications

The anti-reflective (AR) coating market has experienced substantial growth in recent years, driven by increasing demand across multiple industries. The global AR coating market was valued at approximately $4.1 billion in 2021 and is projected to reach $6.8 billion by 2027, growing at a CAGR of 8.7% during the forecast period. This growth trajectory is supported by expanding applications in consumer electronics, automotive, eyewear, solar panels, and architectural glass sectors.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The proliferation of smartphones, tablets, and display devices with enhanced visual clarity requirements has significantly boosted demand for high-performance AR coatings. Manufacturers are increasingly prioritizing coatings that offer superior humidity resistance and adhesion properties to extend device longevity in various environmental conditions.

The eyewear industry follows as the second-largest application segment, where AR coatings are essential for reducing glare and improving visual comfort. This sector demands coatings with exceptional durability and scratch resistance, making the adhesion properties of coating technologies particularly critical. The market has seen a shift toward premium AR coatings that maintain performance even after repeated cleaning and exposure to varying humidity levels.

Solar energy applications represent the fastest-growing segment, with a CAGR exceeding 12%. As renewable energy adoption accelerates globally, the demand for high-efficiency solar panels has intensified the need for AR coatings that maximize light transmission while withstanding harsh outdoor conditions. Here, humidity endurance becomes a paramount consideration for ensuring long-term performance.

Regionally, Asia-Pacific dominates the AR coating market with approximately 42% share, driven by the concentration of electronics manufacturing and rapid industrialization. North America and Europe follow with 28% and 22% respectively, with higher adoption rates in premium applications requiring advanced coating technologies.

The market shows distinct technology preferences across applications. Sol-gel technology currently holds approximately 38% market share due to its cost-effectiveness and versatility, while PVD stack technologies account for around 33% and are growing faster due to superior performance characteristics, particularly in humidity resistance and adhesion stability.

End-users increasingly demand coatings with extended durability under varying environmental conditions, with humidity resistance emerging as a key purchasing criterion. Market research indicates that products offering demonstrable improvements in humidity endurance command premium pricing, with customers willing to pay 15-25% more for coatings that maintain optical performance after extended exposure to high humidity environments.

Consumer electronics represents the largest application segment, accounting for nearly 35% of the market share. The proliferation of smartphones, tablets, and display devices with enhanced visual clarity requirements has significantly boosted demand for high-performance AR coatings. Manufacturers are increasingly prioritizing coatings that offer superior humidity resistance and adhesion properties to extend device longevity in various environmental conditions.

The eyewear industry follows as the second-largest application segment, where AR coatings are essential for reducing glare and improving visual comfort. This sector demands coatings with exceptional durability and scratch resistance, making the adhesion properties of coating technologies particularly critical. The market has seen a shift toward premium AR coatings that maintain performance even after repeated cleaning and exposure to varying humidity levels.

Solar energy applications represent the fastest-growing segment, with a CAGR exceeding 12%. As renewable energy adoption accelerates globally, the demand for high-efficiency solar panels has intensified the need for AR coatings that maximize light transmission while withstanding harsh outdoor conditions. Here, humidity endurance becomes a paramount consideration for ensuring long-term performance.

Regionally, Asia-Pacific dominates the AR coating market with approximately 42% share, driven by the concentration of electronics manufacturing and rapid industrialization. North America and Europe follow with 28% and 22% respectively, with higher adoption rates in premium applications requiring advanced coating technologies.

The market shows distinct technology preferences across applications. Sol-gel technology currently holds approximately 38% market share due to its cost-effectiveness and versatility, while PVD stack technologies account for around 33% and are growing faster due to superior performance characteristics, particularly in humidity resistance and adhesion stability.

End-users increasingly demand coatings with extended durability under varying environmental conditions, with humidity resistance emerging as a key purchasing criterion. Market research indicates that products offering demonstrable improvements in humidity endurance command premium pricing, with customers willing to pay 15-25% more for coatings that maintain optical performance after extended exposure to high humidity environments.

Sol-Gel vs PVD Stack: Current Status and Challenges

Anti-reflective (AR) coatings technology has evolved significantly over recent decades, with Sol-Gel and Physical Vapor Deposition (PVD) Stack emerging as the two dominant methodologies in the industry. Currently, these technologies exist at different maturity levels and face distinct challenges in commercial applications.

Sol-Gel technology, developed in the 1980s and refined through the 1990s, has reached commercial maturity for certain applications. The current implementation typically involves silica-based nanoparticles suspended in alcohol solutions that form porous structures when applied to substrates. This approach has gained traction in consumer electronics, eyewear, and solar panel industries due to its cost-effectiveness and relatively simple application process.

PVD Stack technology represents a more sophisticated approach, utilizing vacuum deposition techniques to create precisely controlled multilayer structures. This technology has seen significant advancement in the past decade, particularly in high-performance optical systems, semiconductor manufacturing, and premium display technologies where precise optical properties are critical.

The primary technical challenge for Sol-Gel coatings remains their limited durability, particularly regarding adhesion stability across varying environmental conditions. Current research indicates that Sol-Gel coatings typically maintain optimal adhesion within a relatively narrow temperature and humidity window. Laboratory tests show significant degradation in adhesion strength when exposed to humidity levels exceeding 80% for extended periods, especially when combined with temperature fluctuations.

PVD Stack coatings demonstrate superior durability but face challenges in production scalability and cost-effectiveness. The vacuum deposition process requires sophisticated equipment and precise control parameters, resulting in higher production costs and lower throughput compared to Sol-Gel methods. Recent industry data suggests that PVD coating processes can be 3-5 times more expensive per unit area than comparable Sol-Gel applications.

Geographically, advanced PVD Stack technology development is concentrated in East Asia, particularly Japan and South Korea, where major display and semiconductor manufacturers have invested heavily in this technology. Sol-Gel innovation is more distributed, with significant research centers in Europe, North America, and increasingly in China.

The humidity endurance gap between these technologies remains substantial. Current-generation PVD Stack coatings can withstand 95%+ humidity environments for thousands of hours with minimal performance degradation, while most commercial Sol-Gel formulations show significant performance loss after 500-1000 hours under similar conditions. This performance differential represents one of the key technical barriers that must be overcome for Sol-Gel to compete in high-reliability applications.

Sol-Gel technology, developed in the 1980s and refined through the 1990s, has reached commercial maturity for certain applications. The current implementation typically involves silica-based nanoparticles suspended in alcohol solutions that form porous structures when applied to substrates. This approach has gained traction in consumer electronics, eyewear, and solar panel industries due to its cost-effectiveness and relatively simple application process.

PVD Stack technology represents a more sophisticated approach, utilizing vacuum deposition techniques to create precisely controlled multilayer structures. This technology has seen significant advancement in the past decade, particularly in high-performance optical systems, semiconductor manufacturing, and premium display technologies where precise optical properties are critical.

The primary technical challenge for Sol-Gel coatings remains their limited durability, particularly regarding adhesion stability across varying environmental conditions. Current research indicates that Sol-Gel coatings typically maintain optimal adhesion within a relatively narrow temperature and humidity window. Laboratory tests show significant degradation in adhesion strength when exposed to humidity levels exceeding 80% for extended periods, especially when combined with temperature fluctuations.

PVD Stack coatings demonstrate superior durability but face challenges in production scalability and cost-effectiveness. The vacuum deposition process requires sophisticated equipment and precise control parameters, resulting in higher production costs and lower throughput compared to Sol-Gel methods. Recent industry data suggests that PVD coating processes can be 3-5 times more expensive per unit area than comparable Sol-Gel applications.

Geographically, advanced PVD Stack technology development is concentrated in East Asia, particularly Japan and South Korea, where major display and semiconductor manufacturers have invested heavily in this technology. Sol-Gel innovation is more distributed, with significant research centers in Europe, North America, and increasingly in China.

The humidity endurance gap between these technologies remains substantial. Current-generation PVD Stack coatings can withstand 95%+ humidity environments for thousands of hours with minimal performance degradation, while most commercial Sol-Gel formulations show significant performance loss after 500-1000 hours under similar conditions. This performance differential represents one of the key technical barriers that must be overcome for Sol-Gel to compete in high-reliability applications.

Technical Comparison of Sol-Gel and PVD Stack Solutions

01 Adhesion promoters for anti-reflective coatings

Various adhesion promoters can be incorporated into anti-reflective coatings to enhance their bonding to substrates. These promoters create stronger chemical bonds between the coating and the substrate surface, improving durability under humid conditions. Silane coupling agents and other adhesion-promoting compounds can significantly increase the coating's resistance to delamination when exposed to high humidity environments.- Adhesion promoters for anti-reflective coatings: Various adhesion promoters can be incorporated into anti-reflective coatings to enhance their bonding to substrates. These include silane coupling agents, titanates, and organic adhesion promoters that create strong chemical bonds between the coating and substrate. Improved adhesion helps maintain coating integrity during exposure to humidity and environmental stressors, preventing delamination and ensuring long-term performance.

- Humidity-resistant coating compositions: Specialized coating compositions can be formulated to withstand high humidity environments without degradation. These formulations typically include hydrophobic components, moisture-resistant polymers, and cross-linking agents that create a dense network structure. Some compositions incorporate fluorinated compounds or siloxanes to repel water and prevent moisture ingress, maintaining optical performance and adhesion even under challenging environmental conditions.

- Multi-layer structures for enhanced durability: Multi-layer anti-reflective coating systems can be designed with specific layers dedicated to enhancing humidity resistance and adhesion. These structures often include a base adhesion layer, intermediate functional layers, and a top protective layer. The strategic arrangement of hydrophilic and hydrophobic layers creates a system that maintains optical performance while providing superior environmental protection and substrate adhesion.

- Surface treatment and preparation methods: Proper surface preparation techniques significantly improve anti-reflective coating adhesion and humidity resistance. Methods include plasma treatment, chemical etching, UV-ozone cleaning, and application of primer layers. These treatments modify surface energy, remove contaminants, and create anchor points for coating adhesion, resulting in more durable coatings that maintain their properties even when exposed to high humidity environments.

- Testing and evaluation protocols: Specialized testing methods have been developed to evaluate anti-reflective coating adhesion and humidity resistance. These include accelerated aging tests in controlled humidity chambers, adhesion tests like cross-hatch and pull-off testing, and optical performance measurements before and after environmental exposure. Advanced analytical techniques such as FTIR spectroscopy and electron microscopy help identify failure mechanisms and guide formulation improvements.

02 Multilayer coating structures for humidity resistance

Multilayer anti-reflective coating designs can provide superior humidity endurance through the strategic arrangement of layers with different properties. By incorporating hydrophobic layers or moisture barrier layers between optical layers, these structures protect sensitive materials from humidity damage. The interface engineering between layers plays a crucial role in preventing moisture penetration and maintaining coating integrity in humid environments.Expand Specific Solutions03 Hydrophobic treatments and moisture-resistant materials

Anti-reflective coatings can be formulated with hydrophobic materials or post-treated with hydrophobic agents to repel moisture and improve humidity resistance. Fluoropolymers, silicones, and other water-repellent compounds can be incorporated into the coating formulation or applied as a top layer. These treatments significantly reduce water absorption and protect the optical and adhesive properties of the coating under humid conditions.Expand Specific Solutions04 Curing and crosslinking methods for improved durability

Advanced curing and crosslinking techniques can enhance the humidity resistance of anti-reflective coatings by creating more stable polymer networks. UV curing, thermal curing, and chemical crosslinking methods can be optimized to produce coatings with higher density and fewer pathways for moisture penetration. These methods increase the coating's resistance to hydrolysis and other degradation mechanisms in humid environments.Expand Specific Solutions05 Testing and evaluation methods for humidity endurance

Specialized testing protocols have been developed to evaluate the humidity endurance of anti-reflective coatings. These include accelerated aging tests in controlled humidity chambers, temperature cycling under humid conditions, and adhesion testing after humidity exposure. These methods help in predicting the long-term performance of coatings and optimizing formulations for specific environmental conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in AR Coatings

The anti-reflective coatings market is in a growth phase, with increasing demand across optical, electronics, and solar industries. The market is projected to reach significant scale due to expanding applications in consumer electronics and renewable energy sectors. Technologically, both Sol-Gel and PVD Stack approaches show varying maturity levels, with companies demonstrating different specialization patterns. SCHOTT AG, Corning, and AGC have established strong positions in PVD technology with advanced multi-layer solutions offering superior humidity resistance, while research institutions like Fraunhofer-Gesellschaft and Industrial Technology Research Institute focus on Sol-Gel innovations for cost-effective applications. EssilorLuxottica and Guardian Glass are leveraging both technologies to address specific adhesion challenges in their respective markets, indicating the industry's movement toward hybrid approaches that optimize performance across diverse environmental conditions.

SCHOTT AG

Technical Solution: SCHOTT has developed advanced PVD stack anti-reflective coatings utilizing magnetron sputtering technology with precise thickness control at the nanometer scale. Their proprietary multi-layer designs incorporate alternating high and low refractive index materials (typically SiO2, Ta2O5, and TiO2) with precisely controlled thicknesses to create destructive interference patterns across targeted wavelength ranges. SCHOTT's PVD process includes ion-assisted deposition that significantly enhances film density and adhesion strength, achieving bond strengths exceeding 20 MPa on glass substrates. Their coatings feature specialized transition layers between the substrate and functional layers to expand the adhesion window across varying environmental conditions. For humidity resistance, SCHOTT employs hermetic sealing layers and densification treatments that have demonstrated less than 2% performance degradation after 3000 hours in 85°C/85% RH conditions. Their AR coatings achieve reflectance values below 0.5% across customizable wavelength bands while maintaining transmission above 99% in optimized spectral regions.

Strengths: Exceptional thickness precision and uniformity; superior mechanical durability compared to Sol-Gel; excellent long-term stability in harsh environments; customizable optical properties. Weaknesses: Higher energy consumption during manufacturing; limited porosity control compared to Sol-Gel methods; typically higher refractive index than optimal Sol-Gel structures.

Industrial Technology Research Institute

Technical Solution: ITRI has developed an innovative Sol-Gel anti-reflective coating technology featuring gradient-index nanostructures. Their process utilizes controlled phase separation during sol-gel transition to create self-assembled nanoporous structures with porosity gradually decreasing from surface to substrate interface (60% to 30%). This gradient structure eliminates discrete interfaces that typically limit adhesion and humidity resistance. ITRI's coatings incorporate organically modified silica precursors with hydrophobic functional groups that significantly enhance moisture resistance while maintaining optical clarity. Their multi-layer deposition technique achieves reflectance below 0.3% across 400-2500nm wavelength range, making it particularly suitable for solar applications. The coatings demonstrate exceptional adhesion stability across temperature ranges from -40°C to 120°C through incorporation of flexible organic-inorganic hybrid networks that accommodate thermal expansion differences. ITRI's process includes a proprietary low-temperature curing protocol (120°C) that enables application on temperature-sensitive substrates while still achieving humidity resistance that maintains performance after 2000+ hours at 85°C/85% RH conditions.

Strengths: Excellent broad-spectrum anti-reflective performance; superior thermal stability across wide temperature ranges; good humidity resistance through hydrophobic modification; low-temperature processing compatible with diverse substrates. Weaknesses: More complex quality control requirements than PVD methods; potential for mechanical abrasion damage; higher material costs for specialized precursors.

Adhesion and Humidity Resistance: Key Technical Innovations

anti-reflection coating

PatentInactiveJP2015507765A

Innovation

- A coating composition comprising hydrolyzable silane and metal compounds, along with organic compounds having coordinating groups, is used to form coordination polymers like MOFs, allowing precise control over porosity and refractive index through heat treatment, resulting in a homogeneous and efficient single-layer anti-reflection coating.

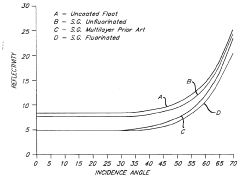

Anti-reflective coatings comprising light metal fluorides

PatentInactiveUS5208101A

Innovation

- A sol-gel process is used to form a coating with a concentration gradient of light metal fluorides on the substrate, where a reactive composition of light metal oxide precursors, solvents, and water is applied and then densified, followed by exposure to a fluorine atmosphere to replace oxygen atoms with fluoride atoms, creating a coating with varying refractive indices that maintains low reflectivity even at large angles and across the visible spectrum.

Environmental Impact and Sustainability Considerations

The environmental impact of anti-reflective coating technologies has become increasingly significant as sustainability considerations gain prominence in manufacturing processes. Sol-Gel and Physical Vapor Deposition (PVD) technologies present distinctly different environmental profiles throughout their lifecycle, from raw material extraction to end-of-life disposal.

Sol-Gel technology demonstrates several environmental advantages, primarily due to its lower energy requirements during application. The process typically operates at ambient or moderately elevated temperatures, resulting in substantially reduced energy consumption compared to vacuum-based alternatives. Additionally, many Sol-Gel formulations utilize water as a primary solvent, reducing dependence on volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to workers.

However, Sol-Gel processes are not without environmental concerns. Certain precursors used in Sol-Gel chemistry contain toxic compounds such as metal alkoxides that require careful handling and disposal. The shelf-life limitations of Sol-Gel solutions also create potential waste management challenges when unused materials expire before application.

In contrast, PVD Stack technology operates under high-vacuum conditions requiring significant energy inputs for both vacuum generation and material deposition. The energy-intensive nature of PVD processes contributes to higher carbon footprints, particularly in regions where electricity generation relies heavily on fossil fuels. This represents a substantial environmental disadvantage compared to Sol-Gel approaches.

The material efficiency of these technologies also differs considerably. PVD processes typically achieve higher material utilization rates with precise deposition control, minimizing waste generation. Sol-Gel applications may experience greater material losses during application, particularly in dip-coating or spray methods where excess solution cannot always be recovered effectively.

From a product lifecycle perspective, the superior humidity endurance of PVD coatings potentially extends product lifespans, reducing replacement frequency and associated environmental impacts. This durability advantage must be weighed against the higher initial environmental cost of production.

Regulatory frameworks increasingly influence coating technology selection, with restrictions on hazardous substances and emissions driving innovation in both fields. Recent developments in Sol-Gel chemistry have focused on bio-based precursors and environmentally benign catalysts, while PVD technology improvements target energy efficiency through optimized process parameters and equipment design.

As industries prioritize sustainability metrics in technology evaluation, comprehensive life cycle assessments comparing these coating technologies become essential for informed decision-making that balances performance requirements with environmental responsibility.

Sol-Gel technology demonstrates several environmental advantages, primarily due to its lower energy requirements during application. The process typically operates at ambient or moderately elevated temperatures, resulting in substantially reduced energy consumption compared to vacuum-based alternatives. Additionally, many Sol-Gel formulations utilize water as a primary solvent, reducing dependence on volatile organic compounds (VOCs) that contribute to air pollution and pose health risks to workers.

However, Sol-Gel processes are not without environmental concerns. Certain precursors used in Sol-Gel chemistry contain toxic compounds such as metal alkoxides that require careful handling and disposal. The shelf-life limitations of Sol-Gel solutions also create potential waste management challenges when unused materials expire before application.

In contrast, PVD Stack technology operates under high-vacuum conditions requiring significant energy inputs for both vacuum generation and material deposition. The energy-intensive nature of PVD processes contributes to higher carbon footprints, particularly in regions where electricity generation relies heavily on fossil fuels. This represents a substantial environmental disadvantage compared to Sol-Gel approaches.

The material efficiency of these technologies also differs considerably. PVD processes typically achieve higher material utilization rates with precise deposition control, minimizing waste generation. Sol-Gel applications may experience greater material losses during application, particularly in dip-coating or spray methods where excess solution cannot always be recovered effectively.

From a product lifecycle perspective, the superior humidity endurance of PVD coatings potentially extends product lifespans, reducing replacement frequency and associated environmental impacts. This durability advantage must be weighed against the higher initial environmental cost of production.

Regulatory frameworks increasingly influence coating technology selection, with restrictions on hazardous substances and emissions driving innovation in both fields. Recent developments in Sol-Gel chemistry have focused on bio-based precursors and environmentally benign catalysts, while PVD technology improvements target energy efficiency through optimized process parameters and equipment design.

As industries prioritize sustainability metrics in technology evaluation, comprehensive life cycle assessments comparing these coating technologies become essential for informed decision-making that balances performance requirements with environmental responsibility.

Cost-Benefit Analysis of AR Coating Technologies

The economic comparison between Sol-Gel and Physical Vapor Deposition (PVD) Stack technologies for anti-reflective (AR) coatings reveals significant differences in both initial investment and long-term operational costs. Sol-Gel technology typically requires lower capital expenditure, with equipment costs ranging from $50,000 to $200,000, making it accessible for small to medium enterprises. In contrast, PVD Stack systems demand substantial initial investment, often between $500,000 and $2 million, due to the sophisticated vacuum chambers and precise control systems required.

Production efficiency metrics further differentiate these technologies. Sol-Gel processes offer faster coating cycles, typically 30-60 minutes per batch, compared to PVD's 2-4 hours. However, PVD Stack technology demonstrates superior scalability for high-volume manufacturing, with automated systems capable of processing up to 1,000 units daily versus Sol-Gel's 200-400 units.

Material consumption represents another critical cost factor. Sol-Gel processes utilize relatively inexpensive precursors, with material costs averaging $0.15-0.30 per coated surface. PVD target materials, particularly for multi-layer stacks, can cost significantly more at $0.40-0.80 per surface, though they offer more precise thickness control and reduced material waste.

Energy consumption patterns differ substantially between these technologies. Sol-Gel processes operate at near-ambient temperatures, consuming approximately 2-5 kWh per production cycle. PVD systems require high vacuum and elevated temperatures, consuming 15-25 kWh per cycle, translating to significantly higher operational costs over time.

Maintenance requirements present another economic consideration. Sol-Gel equipment typically requires simple maintenance procedures costing $5,000-10,000 annually. PVD systems demand specialized technical expertise and more frequent interventions, with annual maintenance costs ranging from $20,000-50,000, including vacuum pump servicing and target replacement.

When evaluating return on investment (ROI), Sol-Gel technology typically achieves breakeven within 1-2 years for moderate production volumes. PVD Stack systems, despite higher initial costs, can demonstrate superior ROI for high-volume operations over 3-5 years, particularly when coating performance requirements are stringent regarding humidity endurance and adhesion stability.

The total cost of ownership analysis reveals that while Sol-Gel offers lower barriers to entry and operational simplicity, PVD Stack technology provides superior long-term value for applications requiring exceptional optical performance and durability under challenging environmental conditions.

Production efficiency metrics further differentiate these technologies. Sol-Gel processes offer faster coating cycles, typically 30-60 minutes per batch, compared to PVD's 2-4 hours. However, PVD Stack technology demonstrates superior scalability for high-volume manufacturing, with automated systems capable of processing up to 1,000 units daily versus Sol-Gel's 200-400 units.

Material consumption represents another critical cost factor. Sol-Gel processes utilize relatively inexpensive precursors, with material costs averaging $0.15-0.30 per coated surface. PVD target materials, particularly for multi-layer stacks, can cost significantly more at $0.40-0.80 per surface, though they offer more precise thickness control and reduced material waste.

Energy consumption patterns differ substantially between these technologies. Sol-Gel processes operate at near-ambient temperatures, consuming approximately 2-5 kWh per production cycle. PVD systems require high vacuum and elevated temperatures, consuming 15-25 kWh per cycle, translating to significantly higher operational costs over time.

Maintenance requirements present another economic consideration. Sol-Gel equipment typically requires simple maintenance procedures costing $5,000-10,000 annually. PVD systems demand specialized technical expertise and more frequent interventions, with annual maintenance costs ranging from $20,000-50,000, including vacuum pump servicing and target replacement.

When evaluating return on investment (ROI), Sol-Gel technology typically achieves breakeven within 1-2 years for moderate production volumes. PVD Stack systems, despite higher initial costs, can demonstrate superior ROI for high-volume operations over 3-5 years, particularly when coating performance requirements are stringent regarding humidity endurance and adhesion stability.

The total cost of ownership analysis reveals that while Sol-Gel offers lower barriers to entry and operational simplicity, PVD Stack technology provides superior long-term value for applications requiring exceptional optical performance and durability under challenging environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!