Anti-Reflective Coatings: Ghosting Suppression, Stray Light Control And Metrology

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Reflective Coating Technology Background and Objectives

Anti-reflective (AR) coating technology has evolved significantly since its inception in the 1930s when F. Geffcken first developed multilayer interference coatings. The fundamental principle behind AR coatings involves creating destructive interference of reflected light waves, thereby minimizing reflection and maximizing transmission. Over the decades, this technology has progressed from simple single-layer coatings to sophisticated multi-layer designs that can achieve reflectance levels below 0.1% across specific wavelength ranges.

The evolution of AR coating technology has been driven by increasing demands in optical systems across various industries including photography, astronomy, consumer electronics, and precision instrumentation. Traditional AR coatings primarily focused on improving light transmission, but contemporary applications require more sophisticated performance characteristics including ghosting suppression and stray light control, which are critical for high-precision optical measurements and imaging systems.

Ghosting phenomena, caused by multiple reflections between optical surfaces, create secondary images that degrade optical performance. Similarly, stray light—unwanted scattered light within an optical system—reduces contrast and measurement accuracy. These challenges have become increasingly significant as optical systems advance in complexity and precision requirements escalate in fields such as semiconductor metrology, astronomical instrumentation, and medical imaging.

Recent technological advancements have expanded AR coating capabilities beyond simple transmission enhancement. Modern coatings incorporate gradient-index designs, nanostructured surfaces, and hybrid organic-inorganic materials to achieve broader spectral performance and enhanced durability. The integration of computational design methods, including machine learning algorithms, has accelerated the development of optimized coating structures tailored for specific applications.

The primary objectives of current AR coating research for ghosting suppression and stray light control include developing coatings with ultra-low reflectance (<0.01%) across broader spectral ranges, improving angular performance to maintain effectiveness at oblique incidence angles, enhancing durability under harsh environmental conditions, and creating manufacturing processes that ensure consistency across large optical elements. Additionally, there is significant focus on developing metrology techniques that can accurately characterize these advanced coatings.

The convergence of nanotechnology, materials science, and optical engineering is expected to drive the next generation of AR coatings. Biomimetic approaches, inspired by natural anti-reflective structures like moth eyes, represent a promising frontier. These developments aim not only to improve optical performance but also to address sustainability concerns by reducing dependence on rare earth materials and developing environmentally friendly manufacturing processes.

The evolution of AR coating technology has been driven by increasing demands in optical systems across various industries including photography, astronomy, consumer electronics, and precision instrumentation. Traditional AR coatings primarily focused on improving light transmission, but contemporary applications require more sophisticated performance characteristics including ghosting suppression and stray light control, which are critical for high-precision optical measurements and imaging systems.

Ghosting phenomena, caused by multiple reflections between optical surfaces, create secondary images that degrade optical performance. Similarly, stray light—unwanted scattered light within an optical system—reduces contrast and measurement accuracy. These challenges have become increasingly significant as optical systems advance in complexity and precision requirements escalate in fields such as semiconductor metrology, astronomical instrumentation, and medical imaging.

Recent technological advancements have expanded AR coating capabilities beyond simple transmission enhancement. Modern coatings incorporate gradient-index designs, nanostructured surfaces, and hybrid organic-inorganic materials to achieve broader spectral performance and enhanced durability. The integration of computational design methods, including machine learning algorithms, has accelerated the development of optimized coating structures tailored for specific applications.

The primary objectives of current AR coating research for ghosting suppression and stray light control include developing coatings with ultra-low reflectance (<0.01%) across broader spectral ranges, improving angular performance to maintain effectiveness at oblique incidence angles, enhancing durability under harsh environmental conditions, and creating manufacturing processes that ensure consistency across large optical elements. Additionally, there is significant focus on developing metrology techniques that can accurately characterize these advanced coatings.

The convergence of nanotechnology, materials science, and optical engineering is expected to drive the next generation of AR coatings. Biomimetic approaches, inspired by natural anti-reflective structures like moth eyes, represent a promising frontier. These developments aim not only to improve optical performance but also to address sustainability concerns by reducing dependence on rare earth materials and developing environmentally friendly manufacturing processes.

Market Demand Analysis for Ghosting Suppression Solutions

The global market for ghosting suppression solutions has experienced significant growth in recent years, driven primarily by the expanding optical and imaging industries. The demand for anti-reflective coatings specifically designed for ghosting suppression has seen a compound annual growth rate of approximately 7% between 2018 and 2023, with projections indicating continued strong performance through 2028.

Consumer electronics represents the largest market segment, with smartphone manufacturers, digital camera producers, and display technology companies increasingly prioritizing optical clarity and image quality as key differentiators in their products. Market research indicates that consumers are willing to pay premium prices for devices offering superior visual experiences, creating strong pull demand for advanced anti-reflective solutions.

The automotive sector has emerged as a rapidly growing market for ghosting suppression technologies, particularly with the rise of advanced driver-assistance systems (ADAS) and autonomous driving capabilities. These systems rely heavily on optical sensors and cameras that must function with exceptional clarity under diverse lighting conditions. Industry analysts report that automotive applications for anti-reflective coatings have doubled in market share over the past five years.

Healthcare and medical imaging constitute another significant market segment, where diagnostic accuracy depends critically on image quality. Hospitals and medical equipment manufacturers are increasingly specifying advanced anti-reflective coatings for everything from endoscopes to surgical microscopes and diagnostic imaging systems. The precision requirements in this sector typically exceed those of consumer applications, commanding higher margins for coating providers.

Aerospace and defense applications represent a smaller but highly profitable market segment. These applications demand the highest performance standards for optical systems operating in extreme environments, with ghosting suppression being critical for surveillance, targeting, and navigation systems.

Market research indicates regional variations in demand patterns. North America and Europe currently lead in adoption of premium ghosting suppression solutions, while the Asia-Pacific region shows the fastest growth rate, driven by both manufacturing capacity expansion and increasing domestic consumption of high-end optical products.

Industry surveys reveal that end-users across sectors consistently rank ghosting and stray light issues among their top three concerns regarding optical system performance. This prioritization has translated into procurement specifications that increasingly mandate quantifiable standards for ghosting suppression, creating clear market signals for technology providers to address these challenges.

Consumer electronics represents the largest market segment, with smartphone manufacturers, digital camera producers, and display technology companies increasingly prioritizing optical clarity and image quality as key differentiators in their products. Market research indicates that consumers are willing to pay premium prices for devices offering superior visual experiences, creating strong pull demand for advanced anti-reflective solutions.

The automotive sector has emerged as a rapidly growing market for ghosting suppression technologies, particularly with the rise of advanced driver-assistance systems (ADAS) and autonomous driving capabilities. These systems rely heavily on optical sensors and cameras that must function with exceptional clarity under diverse lighting conditions. Industry analysts report that automotive applications for anti-reflective coatings have doubled in market share over the past five years.

Healthcare and medical imaging constitute another significant market segment, where diagnostic accuracy depends critically on image quality. Hospitals and medical equipment manufacturers are increasingly specifying advanced anti-reflective coatings for everything from endoscopes to surgical microscopes and diagnostic imaging systems. The precision requirements in this sector typically exceed those of consumer applications, commanding higher margins for coating providers.

Aerospace and defense applications represent a smaller but highly profitable market segment. These applications demand the highest performance standards for optical systems operating in extreme environments, with ghosting suppression being critical for surveillance, targeting, and navigation systems.

Market research indicates regional variations in demand patterns. North America and Europe currently lead in adoption of premium ghosting suppression solutions, while the Asia-Pacific region shows the fastest growth rate, driven by both manufacturing capacity expansion and increasing domestic consumption of high-end optical products.

Industry surveys reveal that end-users across sectors consistently rank ghosting and stray light issues among their top three concerns regarding optical system performance. This prioritization has translated into procurement specifications that increasingly mandate quantifiable standards for ghosting suppression, creating clear market signals for technology providers to address these challenges.

Current State and Challenges in Anti-Reflective Technologies

The global anti-reflective (AR) coating technology landscape has evolved significantly over the past decade, with major advancements in both materials science and application techniques. Currently, the market is dominated by multi-layer dielectric coatings that can achieve reflectance levels below 0.5% across specified wavelength ranges. However, these solutions still face significant limitations when addressing complex optical systems requiring ghosting suppression and stray light control.

Traditional AR coatings typically employ quarter-wavelength stacks of alternating high and low refractive index materials, with materials like MgF2, SiO2, Ta2O5, and TiO2 being industry standards. Recent innovations have introduced gradient-index coatings and moth-eye nanostructures that can achieve broadband anti-reflection properties, but manufacturing scalability remains challenging for these advanced solutions.

A critical challenge in current AR technology is the trade-off between performance metrics. Coatings optimized for maximum transmission often compromise on durability, while those designed for environmental resistance may not achieve optimal anti-reflection properties. This becomes particularly problematic in high-precision optical systems where both performance and longevity are non-negotiable requirements.

The metrology of AR coatings presents another significant hurdle. Current measurement techniques struggle to accurately characterize coating performance in real-world conditions, especially for complex optical systems where ghosting and stray light effects manifest differently than in controlled laboratory environments. Spectrophotometric measurements often fail to predict actual system performance when multiple optical interfaces are involved.

Geographically, AR coating technology development shows distinct regional characteristics. North American and European research institutions lead in fundamental materials research and theoretical modeling, while Asian manufacturers, particularly in Japan and South Korea, excel in high-volume production techniques. This distribution creates challenges in technology transfer and standardization across global supply chains.

Environmental concerns are increasingly constraining AR coating development. Traditional high-performance coatings often contain environmentally problematic materials like lead or fluorine compounds. Regulatory pressures are pushing the industry toward greener alternatives, but these typically underperform compared to conventional options, creating a significant technical challenge.

The integration of AR coatings with other functional properties (such as scratch resistance, hydrophobicity, or anti-static characteristics) remains technically difficult. Current multi-functional coatings typically require complex deposition processes that are difficult to scale and control, limiting their practical application in mass-produced optical systems requiring ghosting suppression and stray light control.

Traditional AR coatings typically employ quarter-wavelength stacks of alternating high and low refractive index materials, with materials like MgF2, SiO2, Ta2O5, and TiO2 being industry standards. Recent innovations have introduced gradient-index coatings and moth-eye nanostructures that can achieve broadband anti-reflection properties, but manufacturing scalability remains challenging for these advanced solutions.

A critical challenge in current AR technology is the trade-off between performance metrics. Coatings optimized for maximum transmission often compromise on durability, while those designed for environmental resistance may not achieve optimal anti-reflection properties. This becomes particularly problematic in high-precision optical systems where both performance and longevity are non-negotiable requirements.

The metrology of AR coatings presents another significant hurdle. Current measurement techniques struggle to accurately characterize coating performance in real-world conditions, especially for complex optical systems where ghosting and stray light effects manifest differently than in controlled laboratory environments. Spectrophotometric measurements often fail to predict actual system performance when multiple optical interfaces are involved.

Geographically, AR coating technology development shows distinct regional characteristics. North American and European research institutions lead in fundamental materials research and theoretical modeling, while Asian manufacturers, particularly in Japan and South Korea, excel in high-volume production techniques. This distribution creates challenges in technology transfer and standardization across global supply chains.

Environmental concerns are increasingly constraining AR coating development. Traditional high-performance coatings often contain environmentally problematic materials like lead or fluorine compounds. Regulatory pressures are pushing the industry toward greener alternatives, but these typically underperform compared to conventional options, creating a significant technical challenge.

The integration of AR coatings with other functional properties (such as scratch resistance, hydrophobicity, or anti-static characteristics) remains technically difficult. Current multi-functional coatings typically require complex deposition processes that are difficult to scale and control, limiting their practical application in mass-produced optical systems requiring ghosting suppression and stray light control.

Current Technical Solutions for Stray Light Control

01 Multi-layer anti-reflective coating structures

Multi-layer anti-reflective coatings can be designed with specific layer compositions and thicknesses to minimize ghosting and control stray light. These structures typically consist of alternating high and low refractive index materials that work together to reduce reflections across a broad spectrum of wavelengths. The precise arrangement of these layers can be optimized to suppress unwanted reflections that cause ghosting effects in optical systems.- Multi-layer anti-reflective coating structures: Multi-layer anti-reflective coatings can be designed with specific layer compositions and thicknesses to minimize reflection and control stray light. These structures typically consist of alternating high and low refractive index materials that create destructive interference for reflected light. By optimizing the number of layers, their thickness, and material properties, these coatings can effectively suppress ghosting effects and improve optical performance in various applications such as lenses, displays, and solar panels.

- Surface texturing and microstructure designs: Surface texturing and microstructure designs can be incorporated into anti-reflective coatings to reduce ghosting and control stray light. These include moth-eye structures, nanoporous surfaces, and gradient-index profiles that gradually change the refractive index from air to substrate. Such structures effectively reduce the abrupt change in refractive index at interfaces, minimizing reflection and scattering. These approaches can be particularly effective for wide-angle applications where conventional coatings may fail.

- Light-absorbing materials and black matrices: Incorporating light-absorbing materials and black matrices into optical systems can significantly reduce stray light and ghosting effects. These materials can be strategically placed to absorb unwanted light reflections and prevent them from reaching the detector or viewer. Specialized absorptive coatings can be applied to edges, mounting structures, or specific areas of optical components to trap stray light. This approach is particularly useful in high-precision optical instruments, cameras, and displays where even minimal stray light can degrade image quality.

- Advanced deposition techniques for coating uniformity: Advanced deposition techniques can improve the uniformity and performance of anti-reflective coatings for better ghosting suppression. Methods such as atomic layer deposition, ion-assisted deposition, and plasma-enhanced chemical vapor deposition enable precise control over film thickness, composition, and interface quality. These techniques can produce coatings with minimal defects and excellent adhesion, which are critical for maintaining anti-reflective properties and reducing light scattering that contributes to ghosting and stray light.

- Optical system design with integrated stray light control: Comprehensive optical system design approaches incorporate stray light control measures beyond just surface coatings. These include optimized component placement, aperture design, baffling systems, and light traps that work together with anti-reflective coatings to minimize ghosting. Computer modeling and simulation tools help predict and mitigate stray light paths before physical prototyping. This holistic approach addresses stray light at multiple points in the optical path, resulting in superior ghosting suppression for complex optical systems like telescopes, spectrometers, and high-end camera lenses.

02 Surface treatment techniques for stray light control

Various surface treatment methods can be applied to optical components to reduce stray light and ghosting. These include micro-texturing, etching, or applying specialized coatings that scatter or absorb unwanted light. By modifying the surface characteristics of optical elements, light that would otherwise cause ghosting or stray reflections can be effectively managed, improving the overall performance of optical systems.Expand Specific Solutions03 Gradient-index anti-reflective coatings

Gradient-index anti-reflective coatings feature a gradual change in refractive index from the substrate to the air interface, rather than distinct layers. This smooth transition minimizes the interfaces where reflections can occur, effectively reducing ghosting and controlling stray light. These coatings can be created through various deposition techniques that allow for precise control of the refractive index profile throughout the coating thickness.Expand Specific Solutions04 Specialized materials for enhanced anti-reflective performance

Novel materials with specific optical properties can be incorporated into anti-reflective coatings to enhance ghosting suppression and stray light control. These may include nanostructured materials, metamaterials, or compounds with unique absorption characteristics. By selecting materials with optimal optical properties, coatings can be designed to address specific wavelength ranges or angles of incidence that are problematic for ghosting in particular applications.Expand Specific Solutions05 Optical system design integration with anti-reflective coatings

Comprehensive approaches that integrate anti-reflective coating design with the overall optical system architecture can effectively minimize ghosting and stray light. This involves analyzing the entire optical path to identify potential sources of unwanted reflections and designing coatings specifically tailored to address these issues. By considering factors such as incidence angles, wavelength requirements, and environmental conditions, anti-reflective solutions can be optimized for specific optical systems.Expand Specific Solutions

Key Industry Players in Anti-Reflective Coating Development

The anti-reflective coatings market for ghosting suppression, stray light control, and metrology is currently in a growth phase, with increasing applications across optical, semiconductor, and consumer electronics industries. The global market size is estimated to be expanding at a CAGR of 6-8%, driven by demand for high-performance optical systems. Technology maturity varies across application segments, with established players like Merck Patent GmbH, Nikon Corp., and Canon Inc. leading in traditional optical applications, while companies such as Magic Leap and Newsight Reality are pushing innovations in AR/VR applications. Academic institutions like Zhejiang University and MIT collaborate with industry leaders to advance fundamental coating technologies, while specialized manufacturers like Brewer Science and Xiamen Hengkun focus on niche applications requiring superior anti-reflective performance.

Merck Patent GmbH

Technical Solution: Merck has developed proprietary liquid crystal-based anti-reflective coating technologies that provide exceptional control over refractive index profiles. Their approach utilizes self-assembling liquid crystal molecules that create nanoscale structures with precisely controlled optical properties. For ghosting suppression, Merck implements reactive mesogen technology that enables the creation of birefringent coating layers with direction-dependent refractive indices, allowing unprecedented control over polarization-dependent reflection. Their manufacturing process employs solution-based deposition methods compatible with large-area substrates, followed by UV-curing to lock the liquid crystal structure in place. Merck's coatings achieve reflection reduction to approximately 0.3% across the visible spectrum while maintaining excellent durability. For metrology applications, they've developed specialized formulations with minimal wavelength dependence in the near-IR region, ensuring measurement consistency across multiple wavelengths. Recent innovations include integration of quantum dot materials within the liquid crystal matrix to create spectrally selective anti-reflective coatings that can be tuned to specific wavelength bands of interest.

Strengths: Excellent scalability for large-area applications; unique ability to control polarization-dependent reflection; compatible with existing manufacturing infrastructure in display and optical industries. Weaknesses: Slightly less durable than some hard-coated alternatives; temperature sensitivity in extreme environments; requires careful handling during application process to ensure uniform self-assembly.

Nikon Corp.

Technical Solution: Nikon has pioneered Nano Crystal Coat technology, an anti-reflective coating system specifically engineered to address ghosting and flare in high-end optical systems. This technology utilizes ultra-fine crystalline particles arranged in a random pattern with spaces smaller than the wavelength of visible light. The coating creates multiple layers with gradually decreasing refractive indices from glass to air, effectively eliminating internal reflections across a wide incident angle range (up to 85°). For metrology applications, Nikon implements super-multi-layer coatings with up to 16 precisely controlled nanolayers that reduce reflection to less than 0.2% at target wavelengths. Their manufacturing process employs proprietary vapor deposition techniques with in-situ optical monitoring to achieve layer thickness precision within ±1nm. Recent advancements include integration of computational design optimization that predicts and minimizes stray light paths through complex optical systems, reducing ghosting artifacts by over 90% compared to conventional coatings.

Strengths: Superior performance at extreme incident angles; exceptional ghosting suppression in complex optical systems; highly optimized for photography and precision optical instruments. Weaknesses: Premium pricing positions technology primarily in high-end products; manufacturing complexity limits production volume capabilities; specialized coating equipment required for implementation.

Core Patents and Innovations in Ghosting Suppression

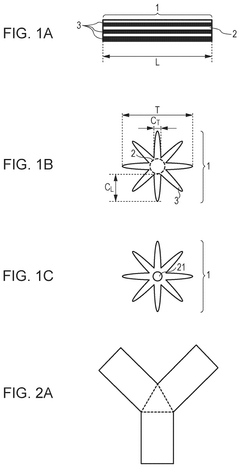

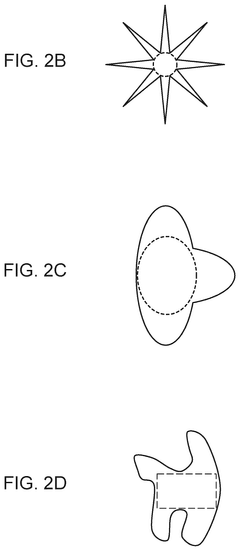

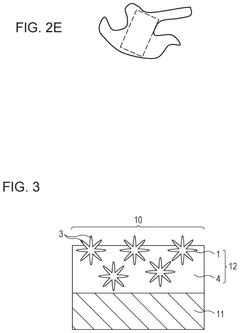

Antireflection coating material, optical member with antireflection coating, optical device, and image capturing apparatus

PatentPendingUS20250258320A1

Innovation

- An antireflection coating material using modified cross-section fibers with a core and protrusions, which are bound to a resin layer, ensuring strong adhesion and effective light scattering at large incident angles.

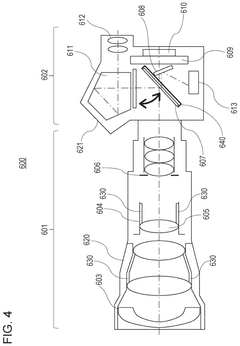

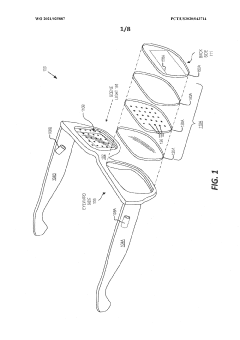

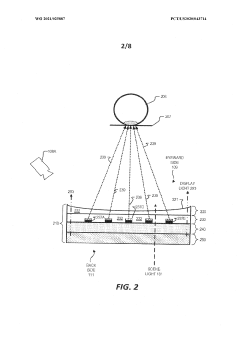

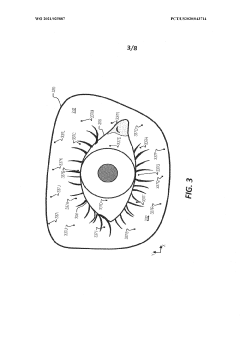

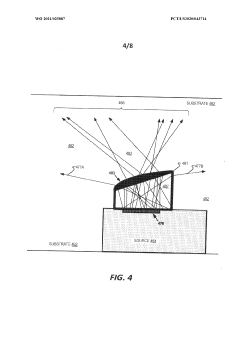

Stray light suppression in eye-tracking imaging

PatentWO2021025887A1

Innovation

- Incorporating anti-reflection (AR) coatings with high transmission spectra for both visible and infrared light over wide angle of incidence ranges, along with ghost suppression components like micro-Louver array films and obscuration elements, to minimize stray light and enhance image clarity.

Optical Performance Metrics and Testing Methodologies

Effective evaluation of anti-reflective coatings requires comprehensive optical performance metrics and standardized testing methodologies. The primary quantitative measure for AR coating effectiveness is reflectance, typically expressed as a percentage of incident light reflected from the surface. Industry standards generally aim for reflectance values below 0.5% for high-performance optical systems, with premium coatings achieving less than 0.2% across specified wavelength ranges.

Transmittance measurements complement reflectance data, quantifying the percentage of light passing through the coated optical element. For precision optical systems, transmittance values exceeding 99.5% are often targeted. The relationship between these metrics must be carefully analyzed considering absorption losses within the coating layers.

Spectral performance characterization is essential, requiring measurements across the entire operational wavelength range. This includes analyzing wavelength-dependent variations in reflectance and transmittance, with particular attention to maintaining consistent performance at critical wavelengths. Advanced AR coatings must demonstrate minimal spectral ripple to ensure uniform optical behavior.

Angular dependence testing represents another critical metric, as AR coating performance typically varies with incident angle. Standard protocols involve measuring reflectance at angles ranging from normal incidence to 60° or beyond, depending on the application requirements. High-quality coatings maintain effectiveness across wider angular ranges, though all designs show degradation at extreme angles.

Ghost reflection quantification employs specialized testing setups to measure secondary reflections between optical surfaces. These measurements typically involve high-dynamic-range imaging techniques to capture low-intensity ghost reflections against brighter primary images. The ghost intensity ratio (GIR) serves as a key metric, expressing ghost reflection intensity as a percentage of the primary image.

Durability testing constitutes an equally important aspect of AR coating evaluation. Standard protocols include abrasion resistance testing (per MIL-C-48497 or ISO standards), adhesion testing (tape test per ASTM D3359), and environmental exposure testing (temperature cycling, humidity exposure, and salt fog testing). These tests ensure coating performance remains stable throughout the product lifecycle.

Stray light measurement techniques include point source transmission (PST) testing and bidirectional reflectance distribution function (BRDF) analysis. These methods quantify how effectively AR coatings suppress unwanted light scatter, with results typically expressed as scatter percentage or angular distribution profiles.

Metrology for AR coating thickness and uniformity employs ellipsometry, reflectometry, and interferometric techniques. These methods provide nanometer-scale precision in determining layer thicknesses and identifying coating defects that might compromise optical performance.

Transmittance measurements complement reflectance data, quantifying the percentage of light passing through the coated optical element. For precision optical systems, transmittance values exceeding 99.5% are often targeted. The relationship between these metrics must be carefully analyzed considering absorption losses within the coating layers.

Spectral performance characterization is essential, requiring measurements across the entire operational wavelength range. This includes analyzing wavelength-dependent variations in reflectance and transmittance, with particular attention to maintaining consistent performance at critical wavelengths. Advanced AR coatings must demonstrate minimal spectral ripple to ensure uniform optical behavior.

Angular dependence testing represents another critical metric, as AR coating performance typically varies with incident angle. Standard protocols involve measuring reflectance at angles ranging from normal incidence to 60° or beyond, depending on the application requirements. High-quality coatings maintain effectiveness across wider angular ranges, though all designs show degradation at extreme angles.

Ghost reflection quantification employs specialized testing setups to measure secondary reflections between optical surfaces. These measurements typically involve high-dynamic-range imaging techniques to capture low-intensity ghost reflections against brighter primary images. The ghost intensity ratio (GIR) serves as a key metric, expressing ghost reflection intensity as a percentage of the primary image.

Durability testing constitutes an equally important aspect of AR coating evaluation. Standard protocols include abrasion resistance testing (per MIL-C-48497 or ISO standards), adhesion testing (tape test per ASTM D3359), and environmental exposure testing (temperature cycling, humidity exposure, and salt fog testing). These tests ensure coating performance remains stable throughout the product lifecycle.

Stray light measurement techniques include point source transmission (PST) testing and bidirectional reflectance distribution function (BRDF) analysis. These methods quantify how effectively AR coatings suppress unwanted light scatter, with results typically expressed as scatter percentage or angular distribution profiles.

Metrology for AR coating thickness and uniformity employs ellipsometry, reflectometry, and interferometric techniques. These methods provide nanometer-scale precision in determining layer thicknesses and identifying coating defects that might compromise optical performance.

Environmental Impact and Sustainability Considerations

The environmental impact of anti-reflective (AR) coating technologies has become increasingly significant as optical industries expand. Traditional AR coating processes often involve hazardous chemicals such as fluorinated compounds and volatile organic compounds (VOCs), which pose substantial environmental risks through air and water pollution. These substances contribute to greenhouse gas emissions and can persist in ecosystems for extended periods, affecting both wildlife and human health.

Manufacturing processes for AR coatings typically require considerable energy consumption, particularly in vacuum deposition systems that operate at high temperatures. This energy demand translates to a significant carbon footprint, especially when powered by non-renewable energy sources. Additionally, the extraction and processing of raw materials for these coatings, including rare earth elements and precious metals, often involve environmentally destructive mining practices and resource depletion.

Recent sustainability initiatives in the AR coating industry have focused on developing water-based alternatives to solvent-based systems, significantly reducing VOC emissions. Bio-inspired AR coatings that mimic natural anti-reflective structures found in moth eyes and other organisms represent a promising direction, potentially eliminating the need for hazardous materials altogether. These biomimetic approaches often require less energy-intensive manufacturing processes and utilize more abundant, less environmentally harmful materials.

Life cycle assessment (LCA) studies of AR coating technologies reveal opportunities for improvement in waste management. The optical industry generates substantial waste during coating application, with material utilization rates sometimes below 30%. Advanced technologies like atomic layer deposition (ALD) offer more precise material application, reducing waste significantly while maintaining or improving coating performance for ghosting suppression and stray light control.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of optical coating technologies. The European Union's REACH regulations and RoHS directive have restricted certain hazardous substances commonly used in AR coatings, driving innovation toward greener alternatives. Companies developing environmentally friendly AR coating solutions may gain competitive advantages as regulations tighten and consumer awareness increases.

End-of-life considerations for AR coated products present both challenges and opportunities. Recycling processes must address the complex multi-layer nature of these coatings without compromising the base materials. Emerging technologies for selective coating removal and material recovery show promise for closing the loop in AR coating life cycles, potentially transforming what was once waste into valuable recovered materials for new applications.

Manufacturing processes for AR coatings typically require considerable energy consumption, particularly in vacuum deposition systems that operate at high temperatures. This energy demand translates to a significant carbon footprint, especially when powered by non-renewable energy sources. Additionally, the extraction and processing of raw materials for these coatings, including rare earth elements and precious metals, often involve environmentally destructive mining practices and resource depletion.

Recent sustainability initiatives in the AR coating industry have focused on developing water-based alternatives to solvent-based systems, significantly reducing VOC emissions. Bio-inspired AR coatings that mimic natural anti-reflective structures found in moth eyes and other organisms represent a promising direction, potentially eliminating the need for hazardous materials altogether. These biomimetic approaches often require less energy-intensive manufacturing processes and utilize more abundant, less environmentally harmful materials.

Life cycle assessment (LCA) studies of AR coating technologies reveal opportunities for improvement in waste management. The optical industry generates substantial waste during coating application, with material utilization rates sometimes below 30%. Advanced technologies like atomic layer deposition (ALD) offer more precise material application, reducing waste significantly while maintaining or improving coating performance for ghosting suppression and stray light control.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of optical coating technologies. The European Union's REACH regulations and RoHS directive have restricted certain hazardous substances commonly used in AR coatings, driving innovation toward greener alternatives. Companies developing environmentally friendly AR coating solutions may gain competitive advantages as regulations tighten and consumer awareness increases.

End-of-life considerations for AR coated products present both challenges and opportunities. Recycling processes must address the complex multi-layer nature of these coatings without compromising the base materials. Emerging technologies for selective coating removal and material recovery show promise for closing the loop in AR coating life cycles, potentially transforming what was once waste into valuable recovered materials for new applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!