How Anti-Reflective Coatings Maintain Color Neutrality After UV–Humidity Cycling?

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AR Coating Durability Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s, initially developed for optical applications to reduce light reflection and improve transmission. The technology has progressed from single-layer coatings to sophisticated multi-layer designs that can achieve reflection reduction across broad wavelength ranges. Today, AR coatings are ubiquitous in various industries including optics, electronics, solar energy, and automotive, with the global market valued at approximately $4.3 billion in 2021 and projected to reach $6.8 billion by 2026.

A critical challenge in AR coating technology is maintaining performance stability under environmental stressors, particularly UV radiation and humidity cycling. These environmental factors can cause degradation of coating materials, leading to reduced effectiveness and, notably, shifts in color neutrality. Color neutrality—the ability of AR coatings to reduce reflection without introducing color bias—is essential for applications requiring true color reproduction, such as camera lenses, display screens, and precision optical instruments.

The primary objective of this technical research is to investigate and analyze how AR coatings can maintain color neutrality after exposure to UV–humidity cycling. This involves understanding the fundamental mechanisms of degradation, identifying material compositions and structural designs that demonstrate superior resistance to environmental stressors, and exploring innovative approaches to enhance durability without compromising optical performance.

Current industry standards require AR coatings to maintain color neutrality with a deviation of less than 2% in chromaticity coordinates after 1000 hours of accelerated aging tests. However, achieving this benchmark while simultaneously meeting other performance requirements—such as scratch resistance, adhesion strength, and cost-effectiveness—presents significant technical challenges that necessitate continuous innovation.

Recent technological advancements have introduced promising solutions, including hybrid organic-inorganic materials, nanostructured coatings, and advanced deposition techniques like atomic layer deposition (ALD). These approaches offer potential pathways to enhance durability while maintaining optical performance, but each comes with its own set of challenges related to scalability, cost, and integration with existing manufacturing processes.

By comprehensively examining the current state of AR coating technology and identifying emerging trends and innovations, this research aims to provide strategic insights for future development directions. The ultimate goal is to establish a technical foundation for next-generation AR coatings that can maintain color neutrality under harsh environmental conditions while meeting increasingly demanding performance requirements across diverse application domains.

A critical challenge in AR coating technology is maintaining performance stability under environmental stressors, particularly UV radiation and humidity cycling. These environmental factors can cause degradation of coating materials, leading to reduced effectiveness and, notably, shifts in color neutrality. Color neutrality—the ability of AR coatings to reduce reflection without introducing color bias—is essential for applications requiring true color reproduction, such as camera lenses, display screens, and precision optical instruments.

The primary objective of this technical research is to investigate and analyze how AR coatings can maintain color neutrality after exposure to UV–humidity cycling. This involves understanding the fundamental mechanisms of degradation, identifying material compositions and structural designs that demonstrate superior resistance to environmental stressors, and exploring innovative approaches to enhance durability without compromising optical performance.

Current industry standards require AR coatings to maintain color neutrality with a deviation of less than 2% in chromaticity coordinates after 1000 hours of accelerated aging tests. However, achieving this benchmark while simultaneously meeting other performance requirements—such as scratch resistance, adhesion strength, and cost-effectiveness—presents significant technical challenges that necessitate continuous innovation.

Recent technological advancements have introduced promising solutions, including hybrid organic-inorganic materials, nanostructured coatings, and advanced deposition techniques like atomic layer deposition (ALD). These approaches offer potential pathways to enhance durability while maintaining optical performance, but each comes with its own set of challenges related to scalability, cost, and integration with existing manufacturing processes.

By comprehensively examining the current state of AR coating technology and identifying emerging trends and innovations, this research aims to provide strategic insights for future development directions. The ultimate goal is to establish a technical foundation for next-generation AR coatings that can maintain color neutrality under harsh environmental conditions while meeting increasingly demanding performance requirements across diverse application domains.

Market Analysis for UV-Resistant AR Coatings

The global market for UV-resistant anti-reflective (AR) coatings has experienced significant growth in recent years, driven by increasing demand across multiple industries including optics, electronics, solar energy, and automotive sectors. The market value reached approximately $4.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.3% through 2028, potentially reaching $6.7 billion by the end of the forecast period.

The optical industry represents the largest market segment, accounting for roughly 35% of the total market share. This dominance stems from the critical need for color-neutral AR coatings in high-precision optical instruments, camera lenses, and eyewear. The eyewear segment alone has shown remarkable growth at 9.1% annually, driven by consumer preference for glasses with superior visual clarity and UV protection.

The electronics sector follows closely behind, with display technologies requiring increasingly sophisticated AR coatings that maintain color neutrality under various environmental conditions. Smartphone and tablet manufacturers have become particularly demanding customers, as these devices are frequently exposed to UV radiation and humidity fluctuations during everyday use.

Solar energy applications represent the fastest-growing segment, with a CAGR of 11.2%. The performance of photovoltaic cells is directly impacted by the quality and durability of AR coatings, making UV-humidity resistance a critical factor in improving energy conversion efficiency and extending product lifespan.

Regionally, Asia-Pacific dominates the market with approximately 42% share, attributed to the region's robust electronics manufacturing ecosystem and growing solar energy installations. North America and Europe follow with 28% and 23% market shares respectively, with particular strength in high-end optical applications and automotive implementations.

Consumer behavior analysis indicates a growing willingness to pay premium prices for products with demonstrably superior UV-resistant coatings. This trend is particularly evident in the luxury eyewear market, where consumers increasingly recognize the value of coatings that maintain optical clarity and aesthetic appearance over time.

Market challenges include price sensitivity in mass-market applications and the technical difficulty of achieving both high performance and cost-effectiveness. The average production cost for advanced UV-resistant AR coatings remains 30-40% higher than standard alternatives, creating adoption barriers in price-sensitive segments.

Emerging opportunities exist in architectural glass applications, where energy efficiency requirements are driving demand for windows with stable optical properties despite prolonged exposure to environmental stressors. The architectural segment is projected to grow at 7.8% annually through 2028.

The optical industry represents the largest market segment, accounting for roughly 35% of the total market share. This dominance stems from the critical need for color-neutral AR coatings in high-precision optical instruments, camera lenses, and eyewear. The eyewear segment alone has shown remarkable growth at 9.1% annually, driven by consumer preference for glasses with superior visual clarity and UV protection.

The electronics sector follows closely behind, with display technologies requiring increasingly sophisticated AR coatings that maintain color neutrality under various environmental conditions. Smartphone and tablet manufacturers have become particularly demanding customers, as these devices are frequently exposed to UV radiation and humidity fluctuations during everyday use.

Solar energy applications represent the fastest-growing segment, with a CAGR of 11.2%. The performance of photovoltaic cells is directly impacted by the quality and durability of AR coatings, making UV-humidity resistance a critical factor in improving energy conversion efficiency and extending product lifespan.

Regionally, Asia-Pacific dominates the market with approximately 42% share, attributed to the region's robust electronics manufacturing ecosystem and growing solar energy installations. North America and Europe follow with 28% and 23% market shares respectively, with particular strength in high-end optical applications and automotive implementations.

Consumer behavior analysis indicates a growing willingness to pay premium prices for products with demonstrably superior UV-resistant coatings. This trend is particularly evident in the luxury eyewear market, where consumers increasingly recognize the value of coatings that maintain optical clarity and aesthetic appearance over time.

Market challenges include price sensitivity in mass-market applications and the technical difficulty of achieving both high performance and cost-effectiveness. The average production cost for advanced UV-resistant AR coatings remains 30-40% higher than standard alternatives, creating adoption barriers in price-sensitive segments.

Emerging opportunities exist in architectural glass applications, where energy efficiency requirements are driving demand for windows with stable optical properties despite prolonged exposure to environmental stressors. The architectural segment is projected to grow at 7.8% annually through 2028.

Current Challenges in AR Coating Color Stability

Anti-reflective (AR) coatings face significant challenges in maintaining color neutrality when subjected to UV-humidity cycling conditions. The primary issue stems from the degradation of coating materials under prolonged exposure to ultraviolet radiation combined with fluctuating humidity levels. These environmental stressors trigger photochemical reactions within the coating layers, leading to molecular structure alterations that manifest as color shifts, typically toward yellow or brown tints.

Material composition represents a critical factor affecting color stability. Traditional AR coatings utilizing metal oxide layers (such as SiO2, TiO2, and ZrO2) exhibit varying degrees of susceptibility to UV-induced degradation. Particularly, coatings containing organic binding agents or adhesion promoters demonstrate accelerated deterioration rates under combined UV-humidity stress, as these organic components undergo photo-oxidation processes that alter their optical properties.

Interface stability between coating layers presents another significant challenge. The differential expansion and contraction of dissimilar materials during humidity cycling creates microscopic delamination at layer interfaces. These physical separations introduce air gaps that modify the optical path length and consequently shift the wavelength-dependent reflectance characteristics, resulting in perceptible color changes even when individual materials remain chemically stable.

Manufacturing inconsistencies further exacerbate color stability issues. Variations in deposition parameters during production—including temperature, pressure, and deposition rate—create subtle differences in film density, crystallinity, and stoichiometry. These variations, while initially imperceptible, can lead to dramatically different degradation patterns when exposed to UV-humidity cycling, making quality control exceptionally challenging for high-volume production.

The industry currently lacks standardized accelerated testing protocols that accurately predict long-term color stability performance. Existing test methods often fail to replicate real-world conditions where UV exposure, temperature fluctuations, and humidity cycles occur simultaneously rather than sequentially. This testing gap results in coatings that perform well in laboratory evaluations but exhibit unexpected color shifts when deployed in actual applications.

Quantification and measurement standards for color neutrality represent another unresolved challenge. The industry employs various metrics—including yellowness index, color rendering index (CRI), and colorimetric coordinates—without consensus on acceptable thresholds for different applications. This measurement inconsistency complicates comparative analysis between different coating technologies and hinders the establishment of meaningful performance benchmarks.

Cost-performance optimization remains a persistent obstacle, as solutions that demonstrate excellent color stability often require expensive materials or complex deposition processes that significantly increase production costs. Finding the optimal balance between color stability, optical performance, and economic viability continues to challenge manufacturers seeking competitive advantages in price-sensitive markets.

Material composition represents a critical factor affecting color stability. Traditional AR coatings utilizing metal oxide layers (such as SiO2, TiO2, and ZrO2) exhibit varying degrees of susceptibility to UV-induced degradation. Particularly, coatings containing organic binding agents or adhesion promoters demonstrate accelerated deterioration rates under combined UV-humidity stress, as these organic components undergo photo-oxidation processes that alter their optical properties.

Interface stability between coating layers presents another significant challenge. The differential expansion and contraction of dissimilar materials during humidity cycling creates microscopic delamination at layer interfaces. These physical separations introduce air gaps that modify the optical path length and consequently shift the wavelength-dependent reflectance characteristics, resulting in perceptible color changes even when individual materials remain chemically stable.

Manufacturing inconsistencies further exacerbate color stability issues. Variations in deposition parameters during production—including temperature, pressure, and deposition rate—create subtle differences in film density, crystallinity, and stoichiometry. These variations, while initially imperceptible, can lead to dramatically different degradation patterns when exposed to UV-humidity cycling, making quality control exceptionally challenging for high-volume production.

The industry currently lacks standardized accelerated testing protocols that accurately predict long-term color stability performance. Existing test methods often fail to replicate real-world conditions where UV exposure, temperature fluctuations, and humidity cycles occur simultaneously rather than sequentially. This testing gap results in coatings that perform well in laboratory evaluations but exhibit unexpected color shifts when deployed in actual applications.

Quantification and measurement standards for color neutrality represent another unresolved challenge. The industry employs various metrics—including yellowness index, color rendering index (CRI), and colorimetric coordinates—without consensus on acceptable thresholds for different applications. This measurement inconsistency complicates comparative analysis between different coating technologies and hinders the establishment of meaningful performance benchmarks.

Cost-performance optimization remains a persistent obstacle, as solutions that demonstrate excellent color stability often require expensive materials or complex deposition processes that significantly increase production costs. Finding the optimal balance between color stability, optical performance, and economic viability continues to challenge manufacturers seeking competitive advantages in price-sensitive markets.

Current Methods for Enhancing AR Coating Durability

01 Multi-layer anti-reflective coatings for color neutrality

Multi-layer anti-reflective coatings can be designed with specific thickness and refractive index combinations to achieve color neutrality. These coatings typically consist of alternating high and low refractive index materials that work together to minimize reflection across the visible spectrum, resulting in a neutral appearance without color tinting. The layer structure can be optimized to provide broadband anti-reflection properties while maintaining color balance.- Multi-layer anti-reflective coating design for color neutrality: Multi-layer anti-reflective coatings can be designed with specific thickness and material combinations to achieve color neutrality. By carefully controlling the optical thickness of each layer and selecting materials with appropriate refractive indices, these coatings can minimize reflections across the visible spectrum without introducing color tint. This approach often involves alternating high and low refractive index materials to create destructive interference patterns that cancel out reflections while maintaining neutral color appearance.

- Graded-index anti-reflective coatings for improved color neutrality: Graded-index anti-reflective coatings feature a gradual change in refractive index from the substrate to the air interface, which helps achieve color-neutral performance. These coatings minimize reflections across a broader spectrum of wavelengths compared to traditional step-index designs. The gradual transition in refractive index can be achieved through various deposition techniques that create nanostructured surfaces or by using materials with continuously varying composition, resulting in anti-reflective properties with minimal color bias.

- Nanostructured surfaces for color-neutral anti-reflection: Nanostructured surfaces can provide color-neutral anti-reflective properties by creating sub-wavelength features that effectively reduce the refractive index at the interface. These structures, often inspired by natural examples like moth eyes, gradually transition from the substrate material to air, minimizing reflections across the visible spectrum without color bias. Fabrication methods include lithography, etching, and self-assembly techniques to create precisely controlled nanopatterns that maintain color neutrality while providing excellent anti-reflective performance.

- Material selection and composition for color-neutral anti-reflective coatings: The selection of materials and their composition plays a crucial role in achieving color-neutral anti-reflective coatings. Materials with specific optical properties, such as metal oxides, fluorides, and nitrides, can be combined to create coatings that minimize reflections across the visible spectrum without introducing color tint. By carefully controlling the stoichiometry and incorporating dopants or additives, the refractive index and absorption characteristics can be fine-tuned to achieve optimal color neutrality while maintaining high transparency.

- Deposition techniques and process control for color-neutral anti-reflective coatings: Various deposition techniques and precise process control are essential for manufacturing color-neutral anti-reflective coatings. Methods such as physical vapor deposition, chemical vapor deposition, atomic layer deposition, and sol-gel processes can be optimized to achieve the required layer thickness uniformity and material properties. Real-time monitoring and feedback control during deposition help maintain consistent optical properties across the substrate, ensuring color neutrality. Post-deposition treatments like annealing may also be employed to stabilize the coating structure and enhance color neutrality.

02 Material selection for color-neutral anti-reflective coatings

The choice of materials significantly impacts the color neutrality of anti-reflective coatings. Materials with specific optical properties can be selected to minimize wavelength-dependent reflection that causes color tinting. Common materials include silicon dioxide, titanium dioxide, magnesium fluoride, and various metal oxides. The precise combination and proportion of these materials can be tailored to achieve a balanced spectral response across the visible light range.Expand Specific Solutions03 Deposition techniques for uniform anti-reflective coatings

Various deposition methods can be employed to create uniform anti-reflective coatings with consistent color neutrality. Techniques such as physical vapor deposition, chemical vapor deposition, sputtering, and sol-gel processes allow precise control over layer thickness and composition. The uniformity of the coating is crucial for maintaining color neutrality across the entire surface, as variations in thickness can lead to unwanted color effects.Expand Specific Solutions04 Optical interference design for color neutrality

Anti-reflective coatings achieve color neutrality through carefully designed optical interference patterns. By controlling the phase relationships between light waves reflected from different interfaces within the coating, destructive interference can be achieved across the visible spectrum rather than at specific wavelengths. This approach requires precise mathematical modeling of light interaction with the coating structure to ensure balanced reduction of reflection across all visible wavelengths.Expand Specific Solutions05 Testing and quality control for color-neutral anti-reflective coatings

Specialized testing methods are essential for verifying the color neutrality of anti-reflective coatings. Spectrophotometric analysis, colorimetry, and visual inspection under standardized lighting conditions can be used to assess color performance. Quality control processes may include monitoring of coating thickness during deposition, post-production optical testing, and accelerated aging tests to ensure the coating maintains its color neutrality over time under various environmental conditions.Expand Specific Solutions

Leading AR Coating Manufacturers and Research Institutions

The anti-reflective coating market is currently in a growth phase, with an estimated global market size of $4-5 billion and projected annual growth of 6-8%. The technology has reached moderate maturity but continues to evolve, particularly in addressing color neutrality challenges after environmental exposure. Leading players include established optical companies like EssilorLuxottica and Carl Zeiss Vision, which focus on consumer applications, alongside materials specialists such as Corning, SCHOTT AG, and 3M Innovative Properties developing advanced solutions for electronics and specialty glass. Asian manufacturers including SK Hynix, LG Chem, and Shanghai Sinyang Semiconductor are increasingly competitive in the semiconductor and electronics segments, while research institutions like Polytechnique Montréal and University of Florida contribute to fundamental coating technology advancements.

EssilorLuxottica SA

Technical Solution: EssilorLuxottica has developed a proprietary anti-reflective coating technology called Crizal UV that specifically addresses color neutrality maintenance after UV-humidity cycling. Their approach utilizes a multi-layer stack design with alternating high and low refractive index materials, precisely engineered to maintain spectral neutrality across the visible spectrum. The coating incorporates hydrophobic and oleophobic top layers with integrated UV stabilizers that prevent degradation of the underlying structure. Their SR Booster™ technology creates an integrated super-slick surface that resists environmental contaminants while maintaining optical clarity. The manufacturing process employs high-vacuum sputtering techniques with ion-assisted deposition to create dense, highly adherent layers with minimal internal stress. EssilorLuxottica's coatings undergo rigorous testing including 24-hour salt fog exposure, 20,000 cleaning cycles, and extended UV-humidity cycling (95% humidity at 50°C with concurrent UV exposure) to ensure long-term color stability. Their latest generation coatings show less than 1% deviation in color neutrality metrics after the equivalent of 3 years of environmental exposure.

Strengths: Industry-leading scratch resistance combined with color stability; extensive real-world validation across diverse climatic conditions; highly optimized for ophthalmic applications. Weaknesses: Premium pricing compared to standard AR coatings; specialized application equipment required; primarily optimized for curved surfaces rather than flat panel applications.

SCHOTT AG

Technical Solution: SCHOTT AG has developed an advanced anti-reflective coating technology called CONTURAN® that specifically addresses color neutrality maintenance after UV-humidity cycling. Their solution employs a sol-gel dip coating process to create nanoporous silica layers with precisely controlled refractive indices. The coating architecture features a gradient-index design that minimizes reflections across the visible spectrum while maintaining neutral color transmission. SCHOTT's proprietary formulation incorporates UV-stable chemical modifiers and specialized silane coupling agents that enhance durability during environmental exposure. Their manufacturing process achieves exceptional uniformity through controlled withdrawal rates and precisely managed curing conditions, resulting in coatings with less than 1% thickness variation across large surface areas. The CONTURAN® technology has demonstrated remarkable stability in accelerated aging tests, showing less than 0.7% change in color coordinates after 2000 hours of combined UV exposure (equivalent to 5 years outdoor exposure) and humidity cycling (95% RH at 55°C). SCHOTT has further enhanced their coating's performance through a specialized densification process that creates a mechanically robust structure while maintaining the anti-reflective properties and color neutrality.

Strengths: Exceptional chemical resistance to cleaning agents; excellent long-term stability in diverse environmental conditions; highly scalable manufacturing process suitable for large glass panels. Weaknesses: Limited flexibility for application on polymer substrates; requires specialized processing equipment; higher initial investment compared to conventional spray-applied coatings.

Key Innovations in UV-Humidity Resistant Materials

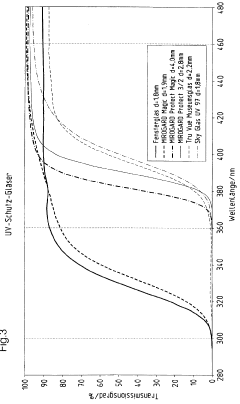

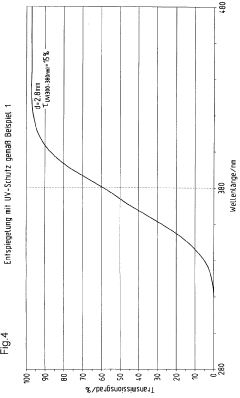

UV-reflective interference layer system

PatentInactiveEP1248959A2

Innovation

- A UV-reflecting interference layer system comprising at least four individual layers with specific refractive indices, applied using sol-gel technology or other deposition methods, providing broadband antireflection and UV filtering without temperature-unstable polymers, suitable for various substrates including glass.

UV-reflective interference layer system

PatentWO2001046718A2

Innovation

- A UV-reflecting interference layer system comprising at least four individual layers with different refractive indices, specifically a structure of Glass+M1/T1/M2/T2/S, using inorganic materials like titanium oxide and silicon dioxide, applied via sol-gel technology or other deposition methods, providing broadband anti-reflection and UV filtering without temperature-unstable polymers.

Environmental Testing Standards for Optical Coatings

Environmental testing standards for optical coatings play a crucial role in ensuring the reliability and performance of anti-reflective (AR) coatings under various environmental conditions. These standards provide systematic methodologies to evaluate how coatings maintain their optical properties, particularly color neutrality, when subjected to harsh environmental factors like UV radiation and humidity.

The primary international standards governing environmental testing of optical coatings include ISO 9022 (Environmental test methods for optics and optical instruments), MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests), and IEC 60068 (Environmental testing). These standards outline specific test procedures for simulating environmental stressors that optical coatings encounter during their lifecycle.

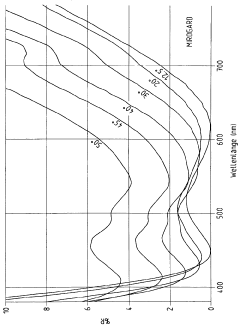

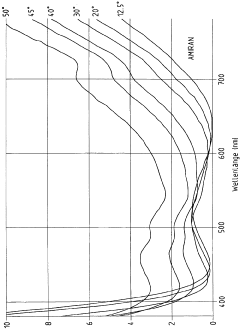

For UV-humidity cycling specifically, ISO 9022-11 provides detailed protocols for combined climatic tests, while ASTM G154 focuses on standard practices for operating fluorescent ultraviolet lamps for exposure testing. These standards typically specify precise parameters including UV wavelength ranges (280-400 nm), radiation intensity (typically 0.5-1.0 W/m²/nm), relative humidity levels (85-95%), temperature cycles (40-65°C), and exposure durations (500-2000 hours).

The testing methodology for AR coating color neutrality typically involves cyclic exposure to UV radiation followed by high humidity conditions. Measurements of spectral transmittance and reflectance are taken before testing and at predetermined intervals during cycling. Color neutrality is quantified using colorimetric parameters such as CIE L*a*b* values, with ΔE values below 2.0 typically considered acceptable for maintaining color neutrality in precision optical applications.

Industry-specific standards have also emerged to address particular application requirements. For example, automotive standards (SAE J576) focus on resistance to solar radiation, while aerospace standards (RTCA DO-160) emphasize temperature and altitude variations. Medical device standards (ISO 10993) incorporate biocompatibility considerations alongside environmental durability.

Recent developments in testing standards have introduced accelerated aging protocols that compress years of environmental exposure into weeks of laboratory testing. These protocols typically increase the intensity of UV radiation and employ rapid cycling between extreme humidity and temperature conditions to induce accelerated degradation mechanisms in optical coatings.

Compliance with these standards has become increasingly important as AR coatings find applications in more demanding environments, from outdoor solar installations to aerospace components. Manufacturers now routinely incorporate these standardized tests into their quality assurance processes to validate coating performance and provide meaningful warranty periods for their products.

The primary international standards governing environmental testing of optical coatings include ISO 9022 (Environmental test methods for optics and optical instruments), MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests), and IEC 60068 (Environmental testing). These standards outline specific test procedures for simulating environmental stressors that optical coatings encounter during their lifecycle.

For UV-humidity cycling specifically, ISO 9022-11 provides detailed protocols for combined climatic tests, while ASTM G154 focuses on standard practices for operating fluorescent ultraviolet lamps for exposure testing. These standards typically specify precise parameters including UV wavelength ranges (280-400 nm), radiation intensity (typically 0.5-1.0 W/m²/nm), relative humidity levels (85-95%), temperature cycles (40-65°C), and exposure durations (500-2000 hours).

The testing methodology for AR coating color neutrality typically involves cyclic exposure to UV radiation followed by high humidity conditions. Measurements of spectral transmittance and reflectance are taken before testing and at predetermined intervals during cycling. Color neutrality is quantified using colorimetric parameters such as CIE L*a*b* values, with ΔE values below 2.0 typically considered acceptable for maintaining color neutrality in precision optical applications.

Industry-specific standards have also emerged to address particular application requirements. For example, automotive standards (SAE J576) focus on resistance to solar radiation, while aerospace standards (RTCA DO-160) emphasize temperature and altitude variations. Medical device standards (ISO 10993) incorporate biocompatibility considerations alongside environmental durability.

Recent developments in testing standards have introduced accelerated aging protocols that compress years of environmental exposure into weeks of laboratory testing. These protocols typically increase the intensity of UV radiation and employ rapid cycling between extreme humidity and temperature conditions to induce accelerated degradation mechanisms in optical coatings.

Compliance with these standards has become increasingly important as AR coatings find applications in more demanding environments, from outdoor solar installations to aerospace components. Manufacturers now routinely incorporate these standardized tests into their quality assurance processes to validate coating performance and provide meaningful warranty periods for their products.

Lifecycle Assessment of AR Coating Materials

The lifecycle assessment of anti-reflective (AR) coating materials reveals critical insights into their environmental impact and performance sustainability throughout their service life. Traditional AR coatings, while effective initially, often demonstrate significant degradation when exposed to UV radiation and humidity cycling, compromising their color neutrality and optical performance over time.

Primary materials used in AR coatings include metal oxides (SiO2, TiO2, Al2O3), fluoropolymers, and hybrid organic-inorganic compounds. Each material category presents distinct environmental footprints during extraction, processing, application, and end-of-life phases. Metal oxide-based coatings typically require energy-intensive deposition processes but offer extended durability. Conversely, fluoropolymer coatings present concerns regarding persistent environmental pollutants despite their excellent water repellency properties.

Manufacturing processes significantly influence the environmental impact of AR coatings. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods consume substantial energy but produce minimal waste. Solution-based techniques generate more chemical waste yet operate at lower energy thresholds. Recent advancements in sol-gel processes have reduced both energy requirements and hazardous waste generation by approximately 30% compared to traditional methods.

The service life analysis of AR coatings reveals that maintaining color neutrality after UV-humidity cycling depends heavily on material composition and structural design. Multilayer systems with alternating high and low refractive index materials demonstrate superior resistance to environmental degradation compared to single-layer alternatives. Hydrophobic top layers significantly extend coating longevity by preventing moisture penetration that catalyzes photochemical degradation processes.

End-of-life considerations present substantial challenges for AR coating materials. Most current AR coatings cannot be effectively recycled or separated from their substrates, resulting in landfill disposal of valuable materials. Emerging biodegradable AR coating formulations show promise but currently sacrifice performance longevity for environmental benefits.

Recent innovations focus on self-healing AR coatings incorporating microencapsulated repair agents that activate upon environmental damage. These materials have demonstrated up to 85% restoration of optical properties after UV-humidity cycling in laboratory conditions. Additionally, biomimetic approaches inspired by moth eye structures are yielding AR coatings with inherently greater resistance to environmental degradation while reducing dependence on rare or toxic materials.

Primary materials used in AR coatings include metal oxides (SiO2, TiO2, Al2O3), fluoropolymers, and hybrid organic-inorganic compounds. Each material category presents distinct environmental footprints during extraction, processing, application, and end-of-life phases. Metal oxide-based coatings typically require energy-intensive deposition processes but offer extended durability. Conversely, fluoropolymer coatings present concerns regarding persistent environmental pollutants despite their excellent water repellency properties.

Manufacturing processes significantly influence the environmental impact of AR coatings. Physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods consume substantial energy but produce minimal waste. Solution-based techniques generate more chemical waste yet operate at lower energy thresholds. Recent advancements in sol-gel processes have reduced both energy requirements and hazardous waste generation by approximately 30% compared to traditional methods.

The service life analysis of AR coatings reveals that maintaining color neutrality after UV-humidity cycling depends heavily on material composition and structural design. Multilayer systems with alternating high and low refractive index materials demonstrate superior resistance to environmental degradation compared to single-layer alternatives. Hydrophobic top layers significantly extend coating longevity by preventing moisture penetration that catalyzes photochemical degradation processes.

End-of-life considerations present substantial challenges for AR coating materials. Most current AR coatings cannot be effectively recycled or separated from their substrates, resulting in landfill disposal of valuable materials. Emerging biodegradable AR coating formulations show promise but currently sacrifice performance longevity for environmental benefits.

Recent innovations focus on self-healing AR coatings incorporating microencapsulated repair agents that activate upon environmental damage. These materials have demonstrated up to 85% restoration of optical properties after UV-humidity cycling in laboratory conditions. Additionally, biomimetic approaches inspired by moth eye structures are yielding AR coatings with inherently greater resistance to environmental degradation while reducing dependence on rare or toxic materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!