How Anti-Reflective Coatings Are Qualified With Spectral Targets And Environmental Acceptance?

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Anti-Reflective Coating Technology Background and Objectives

Anti-reflective (AR) coatings have evolved significantly since their inception in the 1930s when F. Geffcken first developed the concept of using thin film interference to reduce reflection. Initially applied primarily in optical instruments and camera lenses, these coatings have become ubiquitous in modern technology, spanning applications from eyewear and solar panels to display screens and precision optics for scientific instruments.

The fundamental principle behind AR coatings involves creating destructive interference between light waves reflected from different interfaces of a thin film stack. By carefully controlling the thickness and refractive index of each layer, engineers can minimize reflection at specific wavelengths or across broad spectral ranges. Early AR coatings were single-layer designs with limited performance, but technological advancements have enabled the development of sophisticated multi-layer systems capable of achieving near-zero reflection across customized spectral bands.

Recent technological evolution has focused on enhancing durability, expanding spectral coverage, and improving environmental resistance. Modern AR coatings must withstand increasingly demanding conditions while maintaining optical performance. This has driven innovation in materials science, deposition techniques, and quality control methodologies. The integration of nanotechnology has further revolutionized the field, enabling biomimetic structures inspired by moth eyes and other natural anti-reflective surfaces.

The qualification of AR coatings represents a critical challenge in the industry. As applications become more specialized and performance requirements more stringent, traditional qualification methods have proven insufficient. This has necessitated the development of comprehensive spectral targets that precisely define reflection characteristics across relevant wavelength ranges. Additionally, environmental acceptance criteria have become increasingly important to ensure coating performance under real-world conditions including temperature fluctuations, humidity exposure, and mechanical abrasion.

The primary objective of current AR coating technology development is to establish standardized, reliable qualification methodologies that accurately predict in-field performance. This includes defining appropriate spectral targets that align with application-specific requirements and developing environmental testing protocols that simulate actual usage conditions. The goal is to bridge the gap between laboratory qualification and real-world performance, ensuring that coatings meet increasingly demanding specifications across diverse applications.

Industry trends indicate a move toward more customized AR solutions with application-specific performance characteristics. This customization requires more sophisticated qualification methods that can accurately assess specialized coating designs. Additionally, sustainability concerns are driving research into environmentally friendly coating materials and processes that maintain high optical performance while reducing environmental impact.

The fundamental principle behind AR coatings involves creating destructive interference between light waves reflected from different interfaces of a thin film stack. By carefully controlling the thickness and refractive index of each layer, engineers can minimize reflection at specific wavelengths or across broad spectral ranges. Early AR coatings were single-layer designs with limited performance, but technological advancements have enabled the development of sophisticated multi-layer systems capable of achieving near-zero reflection across customized spectral bands.

Recent technological evolution has focused on enhancing durability, expanding spectral coverage, and improving environmental resistance. Modern AR coatings must withstand increasingly demanding conditions while maintaining optical performance. This has driven innovation in materials science, deposition techniques, and quality control methodologies. The integration of nanotechnology has further revolutionized the field, enabling biomimetic structures inspired by moth eyes and other natural anti-reflective surfaces.

The qualification of AR coatings represents a critical challenge in the industry. As applications become more specialized and performance requirements more stringent, traditional qualification methods have proven insufficient. This has necessitated the development of comprehensive spectral targets that precisely define reflection characteristics across relevant wavelength ranges. Additionally, environmental acceptance criteria have become increasingly important to ensure coating performance under real-world conditions including temperature fluctuations, humidity exposure, and mechanical abrasion.

The primary objective of current AR coating technology development is to establish standardized, reliable qualification methodologies that accurately predict in-field performance. This includes defining appropriate spectral targets that align with application-specific requirements and developing environmental testing protocols that simulate actual usage conditions. The goal is to bridge the gap between laboratory qualification and real-world performance, ensuring that coatings meet increasingly demanding specifications across diverse applications.

Industry trends indicate a move toward more customized AR solutions with application-specific performance characteristics. This customization requires more sophisticated qualification methods that can accurately assess specialized coating designs. Additionally, sustainability concerns are driving research into environmentally friendly coating materials and processes that maintain high optical performance while reducing environmental impact.

Market Demand Analysis for AR Coating Applications

The anti-reflective (AR) coating market has experienced significant growth in recent years, driven by increasing demand across multiple industries. The global AR coating market was valued at approximately $4.1 billion in 2021 and is projected to reach $6.8 billion by 2027, representing a compound annual growth rate of 8.5%. This growth trajectory is underpinned by expanding applications in consumer electronics, automotive, eyewear, solar panels, and architectural glass sectors.

Consumer electronics represents the largest market segment for AR coatings, with displays for smartphones, tablets, laptops, and televisions requiring high-performance optical coatings to enhance visibility and reduce eye strain. The proliferation of high-resolution displays and the growing consumer preference for glare-free viewing experiences have intensified demand for advanced AR solutions that meet stringent spectral targets.

The eyewear industry constitutes another significant market, with AR coatings being essential components of prescription glasses, sunglasses, and specialized protective eyewear. The market is witnessing a shift toward premium AR coatings that offer enhanced durability, scratch resistance, and water repellency while maintaining optimal light transmission properties.

In the solar energy sector, AR coatings play a crucial role in improving the efficiency of photovoltaic panels by maximizing light absorption. As global renewable energy initiatives accelerate, the demand for high-performance AR coatings that can withstand harsh environmental conditions while maintaining spectral performance has increased substantially.

The automotive industry represents an emerging growth area for AR coatings, particularly for application on instrument clusters, heads-up displays, and autonomous driving sensors. These applications require coatings that maintain optical clarity under varying temperature and humidity conditions, driving innovation in environmental qualification standards.

Market research indicates that customers across all segments are increasingly demanding AR coatings with verified environmental durability. This trend is reflected in the growing emphasis on qualification testing that simulates real-world conditions such as temperature cycling, humidity exposure, salt spray resistance, and abrasion testing. Manufacturers who can demonstrate compliance with these environmental acceptance criteria gain significant competitive advantage.

Regional analysis shows that Asia-Pacific dominates the AR coating market, accounting for approximately 45% of global demand, followed by North America and Europe. This geographic distribution aligns with the concentration of electronics manufacturing and solar panel production facilities in these regions.

Consumer electronics represents the largest market segment for AR coatings, with displays for smartphones, tablets, laptops, and televisions requiring high-performance optical coatings to enhance visibility and reduce eye strain. The proliferation of high-resolution displays and the growing consumer preference for glare-free viewing experiences have intensified demand for advanced AR solutions that meet stringent spectral targets.

The eyewear industry constitutes another significant market, with AR coatings being essential components of prescription glasses, sunglasses, and specialized protective eyewear. The market is witnessing a shift toward premium AR coatings that offer enhanced durability, scratch resistance, and water repellency while maintaining optimal light transmission properties.

In the solar energy sector, AR coatings play a crucial role in improving the efficiency of photovoltaic panels by maximizing light absorption. As global renewable energy initiatives accelerate, the demand for high-performance AR coatings that can withstand harsh environmental conditions while maintaining spectral performance has increased substantially.

The automotive industry represents an emerging growth area for AR coatings, particularly for application on instrument clusters, heads-up displays, and autonomous driving sensors. These applications require coatings that maintain optical clarity under varying temperature and humidity conditions, driving innovation in environmental qualification standards.

Market research indicates that customers across all segments are increasingly demanding AR coatings with verified environmental durability. This trend is reflected in the growing emphasis on qualification testing that simulates real-world conditions such as temperature cycling, humidity exposure, salt spray resistance, and abrasion testing. Manufacturers who can demonstrate compliance with these environmental acceptance criteria gain significant competitive advantage.

Regional analysis shows that Asia-Pacific dominates the AR coating market, accounting for approximately 45% of global demand, followed by North America and Europe. This geographic distribution aligns with the concentration of electronics manufacturing and solar panel production facilities in these regions.

Current State and Challenges in AR Coating Qualification

The qualification of anti-reflective (AR) coatings currently faces significant challenges across both spectral performance verification and environmental durability assessment. Global standards for AR coating qualification vary considerably, with organizations like ISO, ASTM, and MIL-SPEC each maintaining different testing protocols and acceptance criteria. This fragmentation creates difficulties for manufacturers operating in multiple markets, necessitating redundant testing to meet diverse regional requirements.

Spectral target qualification represents a critical challenge, as measurement methodologies lack standardization across the industry. Different spectrophotometer models, measurement geometries, and calibration procedures can yield varying results for identical coatings. The absence of universally accepted reference materials for AR coating calibration further complicates comparative analysis between testing facilities. Additionally, the industry struggles with defining appropriate spectral targets that balance optical performance with manufacturing feasibility and cost constraints.

Environmental qualification testing presents even greater complexity. Accelerated aging protocols attempt to compress years of real-world exposure into days or weeks of laboratory testing, but correlation between accelerated test results and actual field performance remains problematic. Current humidity, temperature cycling, and abrasion resistance tests often fail to accurately predict coating longevity in diverse real-world environments. The qualification challenge is particularly acute for AR coatings on plastic substrates, which exhibit different failure mechanisms than glass-based systems.

Advanced AR coating technologies, including nanostructured surfaces and hybrid organic-inorganic materials, have outpaced the development of appropriate qualification methodologies. Traditional testing approaches designed for conventional multilayer coatings may not adequately assess these novel technologies, creating barriers to innovation adoption. Furthermore, qualification procedures rarely account for the complete lifecycle performance of AR coatings, including degradation patterns and end-of-life characteristics.

Data management and interpretation represent another significant hurdle. The volume of spectral and environmental test data generated during qualification is substantial, yet standardized approaches for data analysis and visualization remain limited. This impedes effective decision-making and complicates the establishment of meaningful pass/fail criteria that correlate with actual application requirements.

Cost and time constraints further exacerbate these challenges. Comprehensive qualification testing can delay product launches and increase development expenses, creating pressure to abbreviate testing protocols. This often results in qualification procedures that prioritize speed over thoroughness, potentially missing critical failure modes or performance limitations that only become apparent after market introduction.

Spectral target qualification represents a critical challenge, as measurement methodologies lack standardization across the industry. Different spectrophotometer models, measurement geometries, and calibration procedures can yield varying results for identical coatings. The absence of universally accepted reference materials for AR coating calibration further complicates comparative analysis between testing facilities. Additionally, the industry struggles with defining appropriate spectral targets that balance optical performance with manufacturing feasibility and cost constraints.

Environmental qualification testing presents even greater complexity. Accelerated aging protocols attempt to compress years of real-world exposure into days or weeks of laboratory testing, but correlation between accelerated test results and actual field performance remains problematic. Current humidity, temperature cycling, and abrasion resistance tests often fail to accurately predict coating longevity in diverse real-world environments. The qualification challenge is particularly acute for AR coatings on plastic substrates, which exhibit different failure mechanisms than glass-based systems.

Advanced AR coating technologies, including nanostructured surfaces and hybrid organic-inorganic materials, have outpaced the development of appropriate qualification methodologies. Traditional testing approaches designed for conventional multilayer coatings may not adequately assess these novel technologies, creating barriers to innovation adoption. Furthermore, qualification procedures rarely account for the complete lifecycle performance of AR coatings, including degradation patterns and end-of-life characteristics.

Data management and interpretation represent another significant hurdle. The volume of spectral and environmental test data generated during qualification is substantial, yet standardized approaches for data analysis and visualization remain limited. This impedes effective decision-making and complicates the establishment of meaningful pass/fail criteria that correlate with actual application requirements.

Cost and time constraints further exacerbate these challenges. Comprehensive qualification testing can delay product launches and increase development expenses, creating pressure to abbreviate testing protocols. This often results in qualification procedures that prioritize speed over thoroughness, potentially missing critical failure modes or performance limitations that only become apparent after market introduction.

Current Spectral Target Qualification Techniques

01 Multi-layer anti-reflective coating designs

Multi-layer anti-reflective coatings are designed with specific spectral targets to minimize reflection across desired wavelength ranges. These designs typically involve alternating high and low refractive index materials with precisely controlled thicknesses to create destructive interference patterns. The optical thickness of each layer is calculated to achieve specific spectral performance targets, such as broadband anti-reflection or wavelength-selective properties. Advanced designs may incorporate gradient index profiles or quarter-wavelength stacks optimized for particular applications.- Multi-layer anti-reflective coating designs: Multi-layer anti-reflective coatings are designed with specific spectral targets to minimize reflection across desired wavelength ranges. These designs typically involve alternating high and low refractive index materials with precisely controlled thicknesses to create destructive interference patterns. The number of layers, material selection, and thickness of each layer are optimized to achieve specific spectral performance targets such as broadband anti-reflection or wavelength-selective properties.

- Spectral optimization techniques for anti-reflective coatings: Various computational and experimental techniques are employed to optimize anti-reflective coatings to meet specific spectral targets. These include thin-film design software, optical modeling algorithms, and machine learning approaches that can predict and fine-tune coating performance. The optimization process considers factors such as incident angle dependence, polarization effects, and environmental stability while targeting specific reflection minima at key wavelengths or across broad spectral bands.

- Material selection for spectral performance in anti-reflective coatings: The selection of materials for anti-reflective coatings is critical to achieving desired spectral targets. Materials with specific refractive indices, absorption characteristics, and dispersion properties are chosen based on the intended application wavelength range. Common materials include metal oxides (like SiO2, TiO2, Al2O3), fluorides (like MgF2), nitrides, and organic polymers. The material combination determines the achievable spectral performance, including the minimum reflectance value and bandwidth of the anti-reflective effect.

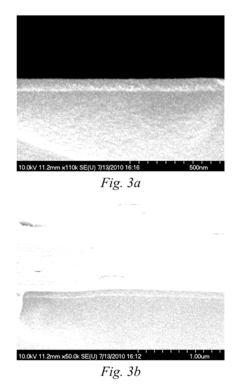

- Fabrication methods for precise spectral control: Various deposition and fabrication techniques are employed to achieve precise spectral targets in anti-reflective coatings. These include physical vapor deposition, chemical vapor deposition, atomic layer deposition, sol-gel processes, and lithographic patterning. Real-time monitoring systems are often integrated into the fabrication process to measure and control optical thickness during deposition, ensuring that the final coating meets the intended spectral targets with high precision.

- Application-specific spectral targets for anti-reflective coatings: Anti-reflective coatings are designed with spectral targets tailored to specific applications. For photovoltaic cells, coatings maximize transmission in the solar spectrum range. For optical instruments and displays, coatings minimize reflection in the visible spectrum. For laser applications, coatings target specific laser wavelengths. For infrared sensors, coatings optimize performance in the thermal infrared range. Each application requires unique spectral targets that balance factors such as reflection reduction, durability, cost, and manufacturing complexity.

02 Material selection for spectral performance

The selection of materials for anti-reflective coatings significantly impacts their spectral performance. Materials with specific refractive indices and low absorption characteristics are chosen based on the target wavelength range. Silicon nitride, silicon dioxide, titanium dioxide, and various metal oxides are commonly used due to their optical properties. Polymer-based coatings may be employed for flexible substrates. The material composition can be adjusted to fine-tune the spectral response and achieve desired reflection minima at specific wavelengths while maintaining durability and environmental stability.Expand Specific Solutions03 Deposition techniques for precise spectral control

Various deposition techniques are employed to achieve precise spectral targets in anti-reflective coatings. Physical vapor deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), and sol-gel processes allow for nanometer-level thickness control. Each technique offers different advantages in terms of conformality, uniformity, and material compatibility. In-situ monitoring systems using ellipsometry or reflectometry enable real-time adjustments during deposition to meet exact spectral specifications. Post-deposition treatments may be used to fine-tune optical properties and enhance coating performance.Expand Specific Solutions04 Spectral optimization for specific applications

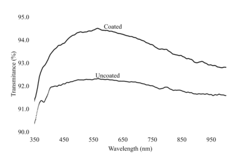

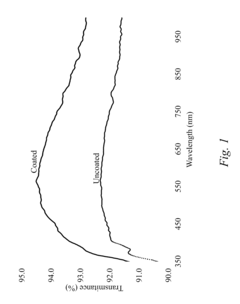

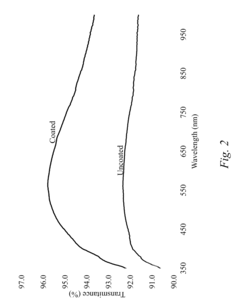

Anti-reflective coatings are spectrally optimized for specific applications such as photovoltaics, displays, ophthalmic lenses, or precision optics. For solar applications, coatings are designed to maximize transmission in the solar spectrum range. Display applications require minimizing reflection across the visible spectrum while maintaining color neutrality. Laser applications need wavelength-specific performance at operating frequencies. Computational methods including thin-film design software and optimization algorithms are used to achieve application-specific spectral targets while balancing other requirements such as environmental durability.Expand Specific Solutions05 Characterization and testing of spectral performance

Specialized techniques are employed to characterize and test the spectral performance of anti-reflective coatings against target specifications. Spectrophotometry, ellipsometry, and reflectometry are used to measure reflection and transmission across relevant wavelength ranges. Angular-dependent measurements assess performance at various incidence angles. Quality control processes involve mapping uniformity across substrates and batch-to-batch consistency. Advanced imaging techniques can visualize coating defects that affect spectral performance. Accelerated environmental testing evaluates the stability of spectral properties under various conditions including temperature cycling, humidity, and UV exposure.Expand Specific Solutions

Key Industry Players in AR Coating Development

The anti-reflective coating market is currently in a growth phase, with an estimated global market size exceeding $4 billion and projected to expand at a CAGR of 6-8% through 2028. The competitive landscape features established players like Corning, PPG Industries, and Applied Materials dominating with comprehensive qualification processes, while specialized firms such as Enki Technology and Quantum Innovations focus on niche applications. The technology maturity varies across sectors, with companies like First Solar and Guardian Glass advancing solar applications, EssilorLuxottica leading in ophthalmic solutions, and Schott AG and Carl Zeiss SMT developing high-precision optical coatings. Environmental qualification standards are increasingly stringent, requiring companies to demonstrate coating durability against humidity, temperature cycling, and UV exposure through standardized testing protocols.

Corning, Inc.

Technical Solution: Corning has developed advanced anti-reflective coating qualification methodologies that combine spectral performance targets with rigorous environmental testing. Their approach utilizes precision spectrophotometry to measure transmission and reflection across visible and near-IR wavelengths, establishing quantifiable spectral targets with tolerances typically within ±0.5% of design specifications. Environmental qualification includes standardized testing under ASTM G173 solar radiation conditions, temperature cycling (-40°C to 85°C), humidity resistance (85°C/85% RH for 1000+ hours), and salt fog exposure. Corning's proprietary sol-gel deposition technology creates multi-layer gradient index coatings with controlled porosity, allowing them to achieve <0.5% reflection across specified wavelength bands while maintaining durability. Their qualification process incorporates accelerated lifetime testing that simulates 20+ years of environmental exposure, with spectral measurements taken at intervals to verify coating stability and adherence to original spectral targets.

Strengths: Industry-leading durability in harsh environments while maintaining optical performance; proprietary sol-gel technology enables precise refractive index control; comprehensive qualification protocols that exceed industry standards. Weakness: Higher manufacturing costs compared to standard coatings; longer processing times required for multi-layer gradient structures; some specialized formulations may have limited temperature range.

Carl Zeiss SMT GmbH

Technical Solution: Carl Zeiss SMT has pioneered an integrated qualification framework for anti-reflective coatings specifically designed for high-precision optical systems. Their methodology employs advanced spectral ellipsometry and variable-angle spectrophotometry to characterize coating performance across multiple incident angles (0-60°), crucial for complex optical systems. Zeiss's qualification process establishes spectral targets based on both absolute transmission values and spectral curve shapes, with tolerances defined by optical system MTF (Modulation Transfer Function) requirements rather than simple percentage deviations. Their environmental testing protocol includes specialized tests for laser damage threshold (LDT) according to ISO 21254, abrasion resistance per MIL-C-48497, and adhesion testing using tape tests (ASTM D3359) and thermal shock cycling. For semiconductor and lithography applications, Zeiss implements additional qualification for chemical resistance against process chemicals and cleaning agents. Their proprietary ion-assisted deposition technology enables creation of dense, shift-free coatings that maintain spectral performance even after environmental exposure, with documented stability showing <0.2% spectral shift after 2000 hours of environmental testing.

Strengths: Exceptional spectral stability under extreme conditions; industry-leading precision in meeting complex spectral targets; comprehensive angle-dependent performance qualification; superior chemical resistance for industrial environments. Weaknesses: Significantly higher production costs; specialized equipment requirements limit manufacturing scalability; longer production cycles compared to conventional coating technologies.

Critical Technologies for Environmental Testing of AR Coatings

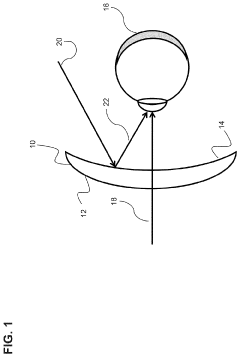

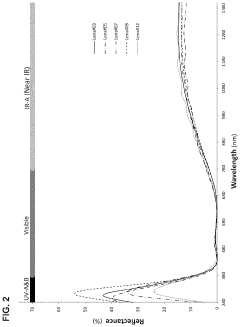

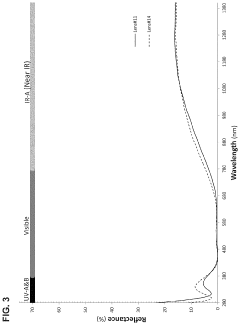

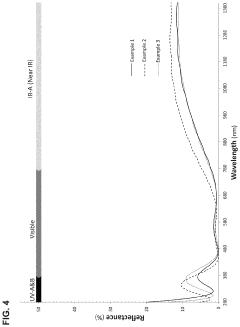

Visible Spectrum Anti-Reflective Coatings with Reduced Reflections in Ultraviolet and Infrared Spectral Bands

PatentPendingUS20220043186A1

Innovation

- A multilayer AR coating comprising high refractive index (HighIndex) and low refractive index (LowIndex) materials, specifically ZrO2 and SiO2, is applied to the backside of lenses, with a configuration that includes a final LowIndex layer and a penultimate HighIndex layer, along with additional layers for scratch resistance and hydrophobic properties, to minimize UV and IR reflectance while maintaining low visible light reflectance.

Anti-reflective and Anti-soiling coatings with self-cleaning properties

PatentInactiveUS20170141242A1

Innovation

- Development of silane-based coating compositions that form anti-reflective, anti-soiling, and abrasion-resistant films through a sol-gel process, using a combination of tetraalkoxysilane, organosilane, and organofluorosilane precursors, which are hydrolyzed and cured to create a stable, durable coating with enhanced mechanical and chemical resistance.

Standardization and Certification Requirements

The standardization and certification landscape for anti-reflective (AR) coatings is governed by a comprehensive framework of international, regional, and industry-specific standards. Organizations such as the International Organization for Standardization (ISO), American Society for Testing and Materials (ASTM), and Military Standards (MIL-STD) have established rigorous protocols for qualifying AR coatings against spectral targets and environmental conditions.

ISO 9211-4 specifically addresses the testing methods for optical coatings, providing standardized procedures for measuring spectral transmittance and reflectance. This standard ensures consistency in evaluating the optical performance of AR coatings across different laboratories and manufacturing facilities. Complementing this, ISO 9022 series outlines environmental testing methodologies that AR coatings must withstand, including temperature cycling, humidity exposure, and salt spray resistance.

In the United States, ASTM D1003 and ASTM F735 are frequently referenced for light transmittance and haze measurements, critical parameters for AR coating qualification. The military sector employs MIL-C-48497 and MIL-C-675, which specify stringent requirements for optical coatings used in defense applications, with particular emphasis on environmental durability.

Certification processes typically involve third-party testing laboratories that issue conformity certificates based on these standards. Notable certification bodies include Underwriters Laboratories (UL), TÜV, and SGS, which provide independent verification of AR coating performance claims. These certifications often serve as prerequisites for market entry in regulated industries such as aerospace, automotive, and medical devices.

Industry-specific standards have also emerged to address unique application requirements. The ophthalmic industry follows ISO 8980-4 for anti-reflection treatments on spectacle lenses, while the solar industry adheres to IEC 61215 for photovoltaic module qualification, which includes testing of AR coatings on solar panels.

Emerging trends in standardization include the development of accelerated testing protocols that can predict long-term performance in shorter timeframes, addressing the industry's need for faster qualification cycles. Additionally, there is growing emphasis on sustainability metrics within certification requirements, with standards beginning to incorporate criteria for environmental impact assessment of coating materials and processes.

Compliance with these standards and obtaining relevant certifications not only validates the technical performance of AR coatings but also facilitates market acceptance, reduces liability risks, and supports quality assurance programs throughout the supply chain. Manufacturers must carefully navigate this complex regulatory landscape to ensure their products meet both customer expectations and legal requirements across global markets.

ISO 9211-4 specifically addresses the testing methods for optical coatings, providing standardized procedures for measuring spectral transmittance and reflectance. This standard ensures consistency in evaluating the optical performance of AR coatings across different laboratories and manufacturing facilities. Complementing this, ISO 9022 series outlines environmental testing methodologies that AR coatings must withstand, including temperature cycling, humidity exposure, and salt spray resistance.

In the United States, ASTM D1003 and ASTM F735 are frequently referenced for light transmittance and haze measurements, critical parameters for AR coating qualification. The military sector employs MIL-C-48497 and MIL-C-675, which specify stringent requirements for optical coatings used in defense applications, with particular emphasis on environmental durability.

Certification processes typically involve third-party testing laboratories that issue conformity certificates based on these standards. Notable certification bodies include Underwriters Laboratories (UL), TÜV, and SGS, which provide independent verification of AR coating performance claims. These certifications often serve as prerequisites for market entry in regulated industries such as aerospace, automotive, and medical devices.

Industry-specific standards have also emerged to address unique application requirements. The ophthalmic industry follows ISO 8980-4 for anti-reflection treatments on spectacle lenses, while the solar industry adheres to IEC 61215 for photovoltaic module qualification, which includes testing of AR coatings on solar panels.

Emerging trends in standardization include the development of accelerated testing protocols that can predict long-term performance in shorter timeframes, addressing the industry's need for faster qualification cycles. Additionally, there is growing emphasis on sustainability metrics within certification requirements, with standards beginning to incorporate criteria for environmental impact assessment of coating materials and processes.

Compliance with these standards and obtaining relevant certifications not only validates the technical performance of AR coatings but also facilitates market acceptance, reduces liability risks, and supports quality assurance programs throughout the supply chain. Manufacturers must carefully navigate this complex regulatory landscape to ensure their products meet both customer expectations and legal requirements across global markets.

Cost-Benefit Analysis of Advanced Qualification Methods

When evaluating the implementation of advanced qualification methods for anti-reflective coatings, a comprehensive cost-benefit analysis reveals significant economic implications across the product lifecycle. Traditional qualification methods often rely on basic spectrophotometric measurements and limited environmental testing, resulting in lower initial costs but potentially higher long-term expenses due to field failures and customer returns.

Advanced qualification methods, including high-precision spectral mapping, accelerated environmental aging, and comprehensive adhesion testing, require substantial upfront investment. The initial capital expenditure for precision spectrophotometers with expanded wavelength capabilities typically ranges from $50,000 to $150,000, depending on measurement accuracy and spectral range requirements. Additionally, environmental test chambers capable of simulating multiple stress conditions simultaneously represent an investment of $30,000 to $100,000.

Personnel costs constitute another significant factor, as advanced qualification protocols require specialized expertise. Companies implementing comprehensive qualification systems report allocating 1.5 to 2 full-time equivalent positions to testing and qualification activities, representing an annual investment of approximately $120,000 to $200,000 in mature markets.

Despite these substantial initial investments, the return on investment analysis demonstrates compelling economic benefits. Field data from optical component manufacturers indicates that advanced qualification methods reduce coating-related field failures by 60-85% compared to basic qualification approaches. For high-volume consumer products, this translates to warranty cost reductions of $0.5-2.0 per unit, while for specialized industrial and scientific applications, the savings can exceed $500 per instance.

Production yield improvements represent another significant benefit. Manufacturers implementing comprehensive spectral target verification report average yield improvements of 8-12%, directly impacting production economics. The enhanced process control enabled by advanced qualification methods also reduces material waste and rework requirements, with documented savings of 5-15% in coating material consumption.

Time-to-market advantages further enhance the economic case for advanced qualification methods. By identifying potential environmental performance issues earlier in the development cycle, companies can avoid costly redesigns and market delays. Industry case studies suggest development cycle reductions of 15-30% when comprehensive qualification protocols are implemented from project inception.

The total cost of ownership analysis indicates that despite higher initial investments, advanced qualification methods typically achieve return on investment within 12-24 months for high-volume applications and 18-36 months for specialized, lower-volume products. This favorable economic profile has driven increasing adoption across the optical coating industry, particularly in applications where coating reliability directly impacts system performance and customer satisfaction.

Advanced qualification methods, including high-precision spectral mapping, accelerated environmental aging, and comprehensive adhesion testing, require substantial upfront investment. The initial capital expenditure for precision spectrophotometers with expanded wavelength capabilities typically ranges from $50,000 to $150,000, depending on measurement accuracy and spectral range requirements. Additionally, environmental test chambers capable of simulating multiple stress conditions simultaneously represent an investment of $30,000 to $100,000.

Personnel costs constitute another significant factor, as advanced qualification protocols require specialized expertise. Companies implementing comprehensive qualification systems report allocating 1.5 to 2 full-time equivalent positions to testing and qualification activities, representing an annual investment of approximately $120,000 to $200,000 in mature markets.

Despite these substantial initial investments, the return on investment analysis demonstrates compelling economic benefits. Field data from optical component manufacturers indicates that advanced qualification methods reduce coating-related field failures by 60-85% compared to basic qualification approaches. For high-volume consumer products, this translates to warranty cost reductions of $0.5-2.0 per unit, while for specialized industrial and scientific applications, the savings can exceed $500 per instance.

Production yield improvements represent another significant benefit. Manufacturers implementing comprehensive spectral target verification report average yield improvements of 8-12%, directly impacting production economics. The enhanced process control enabled by advanced qualification methods also reduces material waste and rework requirements, with documented savings of 5-15% in coating material consumption.

Time-to-market advantages further enhance the economic case for advanced qualification methods. By identifying potential environmental performance issues earlier in the development cycle, companies can avoid costly redesigns and market delays. Industry case studies suggest development cycle reductions of 15-30% when comprehensive qualification protocols are implemented from project inception.

The total cost of ownership analysis indicates that despite higher initial investments, advanced qualification methods typically achieve return on investment within 12-24 months for high-volume applications and 18-36 months for specialized, lower-volume products. This favorable economic profile has driven increasing adoption across the optical coating industry, particularly in applications where coating reliability directly impacts system performance and customer satisfaction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!