Antifreeze Performance in Revolutionary Data Centers Analysis

Antifreeze Tech Evolution

The evolution of antifreeze technology in data centers has been driven by the increasing demand for energy efficiency and the need to maintain optimal operating conditions for sensitive electronic equipment. In the early days of data center cooling, traditional glycol-based antifreeze solutions were commonly used to prevent freezing in cooling systems. These solutions, while effective, often had limitations in terms of thermal conductivity and environmental impact.

As data centers grew in size and complexity, the focus shifted towards more advanced antifreeze technologies. The introduction of propylene glycol-based solutions marked a significant improvement, offering better thermal properties and reduced toxicity compared to their ethylene glycol counterparts. This transition aligned with the growing emphasis on environmental sustainability in data center operations.

The mid-2000s saw the emergence of nano-fluid antifreeze solutions, which incorporated nanoparticles to enhance heat transfer capabilities. These innovative formulations demonstrated superior thermal conductivity and heat capacity, allowing for more efficient cooling processes in data center environments. The adoption of nano-fluids represented a paradigm shift in antifreeze technology, paving the way for more compact and energy-efficient cooling systems.

In recent years, the development of bio-based antifreeze solutions has gained traction. Derived from renewable resources such as corn or soybean oils, these eco-friendly alternatives offer comparable performance to traditional petroleum-based products while reducing the carbon footprint of data center operations. The integration of bio-based antifreeze aligns with the industry's broader sustainability goals and regulatory requirements.

The latest advancements in antifreeze technology for data centers focus on smart, adaptive solutions. These systems utilize real-time monitoring and predictive algorithms to optimize antifreeze concentration and flow rates based on changing environmental conditions and workload demands. By dynamically adjusting the antifreeze properties, these intelligent systems maximize cooling efficiency while minimizing energy consumption.

Looking ahead, the future of antifreeze technology in data centers is likely to involve the integration of phase-change materials (PCMs) and advanced polymer technologies. These innovations promise to provide enhanced thermal management capabilities, potentially revolutionizing the approach to data center cooling. As the industry continues to push the boundaries of computing power and density, the evolution of antifreeze technology will play a crucial role in enabling the next generation of high-performance, sustainable data centers.

Data Center Cooling Demand

The demand for efficient cooling solutions in data centers has become increasingly critical as the digital landscape continues to expand rapidly. With the exponential growth of data processing and storage requirements, modern data centers are facing unprecedented challenges in managing heat generation and maintaining optimal operating temperatures. The traditional air-cooling methods are proving inadequate to meet the cooling demands of high-density server racks and advanced computing systems.

The primary driver behind the escalating cooling demand is the continuous increase in power density within data centers. As processors become more powerful and compact, the heat generated per square foot of data center space has risen dramatically. This trend is further exacerbated by the adoption of artificial intelligence and machine learning technologies, which require even more computational power and, consequently, generate more heat.

Energy efficiency has also become a paramount concern in data center operations. Cooling systems typically account for a significant portion of a data center's total energy consumption, often ranging between 30% to 50%. As organizations strive to reduce their carbon footprint and operational costs, there is a growing emphasis on developing more energy-efficient cooling solutions that can effectively manage higher heat loads while minimizing power usage.

The geographical distribution of data centers adds another layer of complexity to the cooling challenge. Data centers are being established in diverse climatic conditions, from arid deserts to humid tropical regions, each presenting unique cooling requirements. This variability necessitates the development of adaptive cooling technologies that can perform efficiently across different environmental conditions.

Moreover, the push towards edge computing is creating a new set of cooling challenges. As data processing moves closer to the point of data generation, cooling solutions need to be scalable and adaptable to smaller, distributed data center environments. These edge facilities often have limited space and resources, making traditional cooling methods impractical or cost-prohibitive.

Water scarcity is another critical factor influencing cooling demand in data centers. Many regions are experiencing water stress, leading to restrictions on water usage for industrial purposes. This has prompted the need for water-efficient cooling technologies or alternatives that can reduce or eliminate water consumption in data center cooling processes.

The reliability and uptime requirements of modern data centers further intensify the cooling demand. With businesses relying heavily on continuous data access and processing, even minor temperature fluctuations can lead to significant performance issues or system failures. This necessitates robust, redundant cooling systems that can maintain consistent temperatures under varying load conditions and potential equipment failures.

Current Antifreeze Challenges

The current antifreeze challenges in revolutionary data centers primarily revolve around the increasing power density and heat generation of modern computing equipment. As data centers evolve to accommodate more powerful and compact hardware, traditional cooling methods are becoming less effective and efficient. This has led to a growing need for innovative antifreeze solutions that can maintain optimal operating temperatures while minimizing energy consumption.

One of the main challenges is the limitation of conventional air-cooling systems in high-density server environments. As rack power densities continue to rise, air-cooling struggles to dissipate heat effectively, leading to hotspots and potential equipment failures. This issue is particularly pronounced in edge data centers and modular installations, where space constraints further complicate cooling strategies.

Liquid cooling technologies, while promising, present their own set of challenges. The implementation of direct-to-chip or immersion cooling systems requires significant infrastructure modifications and raises concerns about potential liquid leaks that could damage sensitive electronic components. Additionally, the chemical composition of antifreeze solutions used in these systems must be carefully balanced to ensure optimal heat transfer properties without causing corrosion or degradation of server components.

Another critical challenge is the environmental impact of antifreeze solutions. Many traditional antifreeze formulations contain toxic substances that pose risks to ecosystems if leaked or improperly disposed of. As data centers strive for greater sustainability, there is a pressing need to develop eco-friendly antifreeze alternatives that maintain high performance while minimizing environmental hazards.

The variability of climatic conditions across different geographical locations also presents a significant challenge for antifreeze performance. Data centers operating in extreme environments, such as arctic or desert regions, require specialized antifreeze solutions that can withstand a wide range of temperatures and maintain consistent performance under diverse conditions.

Furthermore, the integration of antifreeze systems with emerging technologies such as artificial intelligence and machine learning poses new challenges. These advanced computing applications often have dynamic workload patterns that result in fluctuating heat generation, requiring more adaptive and responsive antifreeze solutions.

Lastly, the cost-effectiveness of antifreeze implementations remains a significant hurdle. While more advanced cooling solutions can offer improved performance, they often come with higher initial investment and operational costs. Balancing the need for cutting-edge antifreeze technology with budget constraints is a ongoing challenge for data center operators, particularly as they seek to optimize total cost of ownership in an increasingly competitive market.

Existing Antifreeze Solutions

01 Composition of antifreeze solutions

Antifreeze solutions typically consist of a mixture of water and one or more glycols, such as ethylene glycol or propylene glycol. These solutions may also include additives like corrosion inhibitors, pH buffers, and anti-foaming agents to enhance performance and protect engine components.- Composition of antifreeze solutions: Antifreeze solutions typically consist of a mixture of water and glycols, such as ethylene glycol or propylene glycol. These solutions may also include additives like corrosion inhibitors, pH buffers, and anti-foaming agents to enhance their performance and protect engine components. The specific composition is tailored to provide optimal freezing point depression and heat transfer properties.

- Environmentally friendly antifreeze formulations: Development of eco-friendly antifreeze solutions using biodegradable materials and renewable resources. These formulations aim to reduce environmental impact while maintaining effective antifreeze performance. They may incorporate plant-based glycols, natural corrosion inhibitors, or other sustainable ingredients to achieve the desired antifreeze properties.

- Antifreeze performance testing methods: Various testing methods are employed to evaluate antifreeze performance, including freezing point depression tests, corrosion protection assessments, and heat transfer efficiency measurements. These tests help determine the effectiveness of antifreeze solutions under different operating conditions and ensure they meet industry standards and specifications.

- Antifreeze recycling and regeneration: Techniques for recycling and regenerating used antifreeze solutions to extend their lifespan and reduce waste. These processes may involve filtration, chemical treatment, or distillation to remove contaminants and restore the antifreeze properties. Recycling antifreeze helps conserve resources and minimize environmental impact.

- Antifreeze additives for enhanced performance: Development of specialized additives to improve antifreeze performance, such as nanoparticles for enhanced heat transfer, advanced corrosion inhibitors, or anti-scaling agents. These additives aim to enhance the overall efficiency and longevity of antifreeze solutions in various applications, including automotive, industrial, and HVAC systems.

02 Corrosion inhibition in antifreeze formulations

Corrosion inhibitors are crucial components in antifreeze formulations to protect metal surfaces in cooling systems. These inhibitors can include organic acids, inorganic salts, or combinations thereof. The selection and balance of inhibitors are essential for long-term protection against various types of corrosion.Expand Specific Solutions03 Environmental and safety considerations

Development of more environmentally friendly and less toxic antifreeze formulations is an ongoing trend. This includes the use of propylene glycol-based solutions instead of ethylene glycol, as well as the incorporation of biodegradable additives. Safety features such as bittering agents to prevent accidental ingestion are also considered.Expand Specific Solutions04 Performance enhancement techniques

Various techniques are employed to enhance antifreeze performance, including the use of nanoparticles to improve heat transfer properties, incorporation of polymeric additives for better freeze protection, and development of hybrid formulations that combine multiple functional components for overall improved performance.Expand Specific Solutions05 Testing and quality control methods

Rigorous testing and quality control methods are essential for ensuring antifreeze performance. This includes freeze point depression tests, boiling point elevation tests, corrosion tests, and long-term stability assessments. Advanced analytical techniques are used to monitor the composition and degradation of antifreeze solutions over time.Expand Specific Solutions

Key Data Center Cooling Players

The antifreeze performance analysis in revolutionary data centers is at a nascent stage, with the market showing significant growth potential. The industry is in its early development phase, characterized by rapid technological advancements and increasing demand for efficient cooling solutions. Major players like IBM, Microsoft, and Baidu are investing heavily in research and development to gain a competitive edge. The market size is expanding as data centers proliferate globally, driven by the surge in cloud computing and big data applications. While the technology is still evolving, companies such as Gree Electric Appliances and Chunjun New Materials are making strides in developing innovative antifreeze solutions, indicating a gradual increase in technological maturity.

International Business Machines Corp.

Beijing Baidu Netcom Science & Technology Co., Ltd.

Core Antifreeze Patents

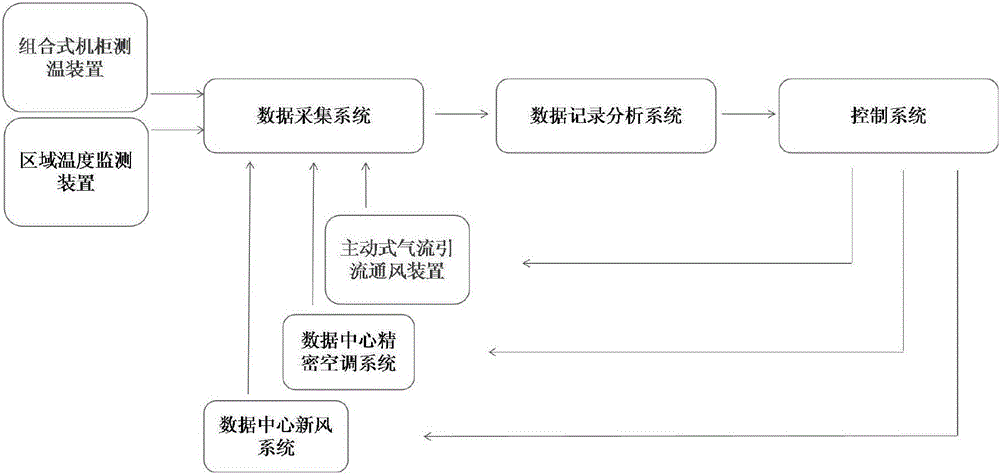

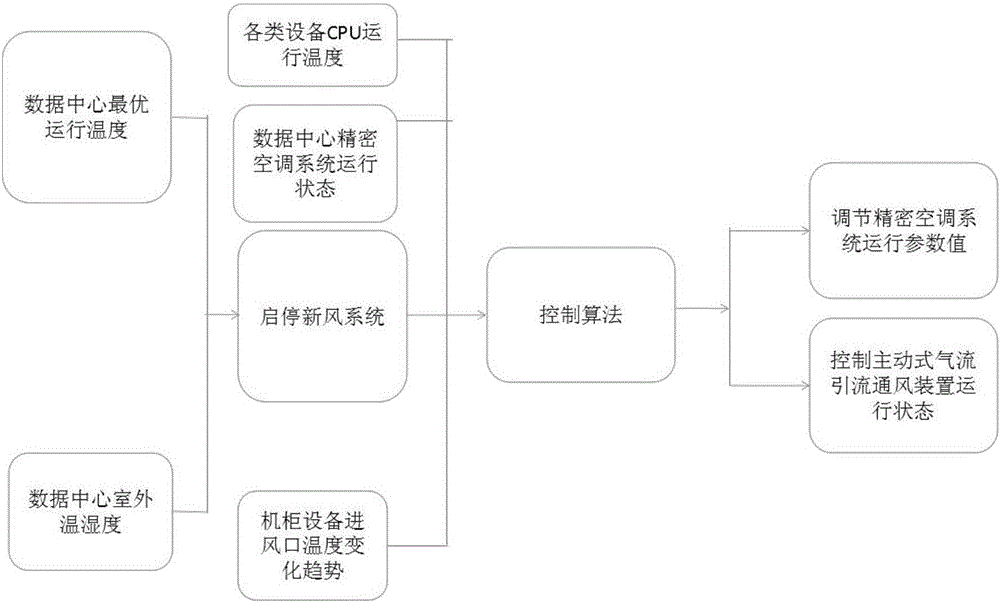

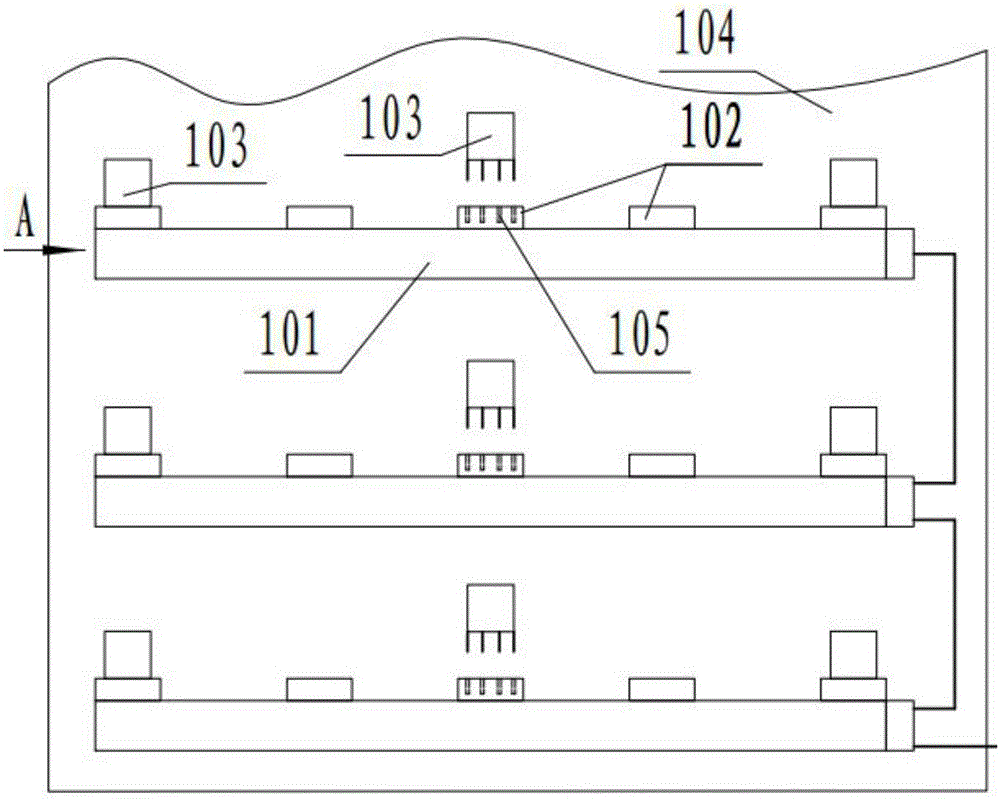

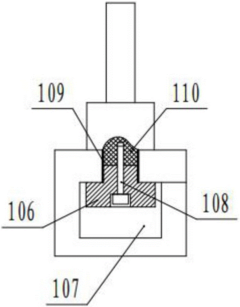

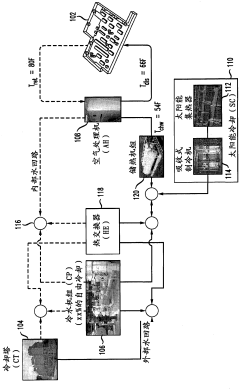

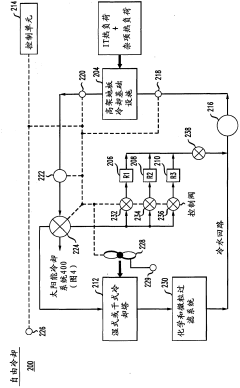

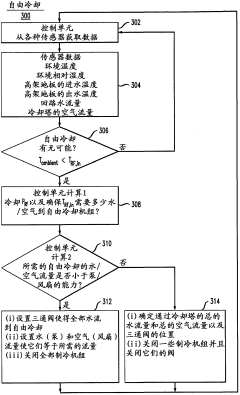

- An automated refrigeration analysis method is used to intelligently control the precision air conditioning system and fresh air system through data collection and control models, combined with the fresh air system and active air flow diversion and ventilation devices, and adjust the refrigeration parameters and ventilation volume in real time according to the cabinet temperature to ensure that the data center is in Maintain optimal operating temperature under any power supply conditions.

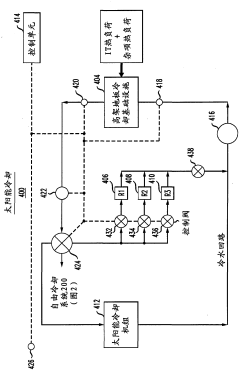

- Adopting a system that combines free cooling and solar cooling, through the combination of cooling towers, modular refrigeration units and solar cooling units, ambient air temperature and solar energy are used to selectively adjust the flow direction of the water loop, optimize cooling efficiency, and dynamically manage cooling through the control unit system components to save power.

Environmental Impact Analysis

The environmental impact of antifreeze performance in revolutionary data centers is a critical aspect that requires thorough analysis. As data centers continue to evolve and expand, their energy consumption and environmental footprint become increasingly significant. The use of antifreeze solutions in cooling systems plays a crucial role in maintaining optimal operating temperatures while potentially introducing environmental concerns.

One of the primary environmental considerations is the composition of antifreeze solutions. Traditional antifreeze formulations often contain ethylene glycol or propylene glycol, which can be toxic to wildlife and contaminate soil and water sources if not properly managed. Revolutionary data centers are exploring more environmentally friendly alternatives, such as biodegradable antifreeze solutions derived from plant-based sources. These eco-friendly options aim to reduce the potential harm to ecosystems in case of leaks or improper disposal.

Water consumption is another significant environmental factor associated with antifreeze performance in data centers. Cooling systems that utilize antifreeze solutions often require substantial amounts of water for heat exchange processes. This can strain local water resources, particularly in water-scarce regions. Advanced data center designs are incorporating closed-loop cooling systems and water recycling technologies to minimize freshwater consumption and reduce the overall environmental impact.

Energy efficiency is a key consideration when evaluating the environmental impact of antifreeze performance. The viscosity and thermal properties of antifreeze solutions can affect the energy required for pumping and heat transfer within cooling systems. Optimizing antifreeze formulations to enhance heat transfer efficiency can lead to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

The disposal and recycling of antifreeze solutions present additional environmental challenges. As data centers upgrade or decommission their cooling systems, proper handling and disposal of used antifreeze become critical to prevent environmental contamination. Implementing robust recycling programs and partnering with specialized waste management facilities can help mitigate the environmental risks associated with antifreeze disposal.

Climate change considerations also play a role in assessing the environmental impact of antifreeze performance. As global temperatures rise, the demand for cooling in data centers is expected to increase, potentially leading to greater reliance on antifreeze solutions. This underscores the importance of developing climate-resilient cooling strategies that balance performance requirements with environmental sustainability.

In conclusion, the environmental impact of antifreeze performance in revolutionary data centers encompasses various interconnected factors. From the chemical composition of antifreeze solutions to water and energy consumption, and from disposal practices to climate change adaptation, a holistic approach is necessary to minimize negative environmental consequences while maintaining optimal data center operations.

Energy Efficiency Metrics

Energy efficiency metrics play a crucial role in evaluating the performance of revolutionary data centers, particularly in the context of antifreeze capabilities. These metrics provide quantitative measures to assess the effectiveness of cooling systems and their impact on overall energy consumption. One of the primary metrics used is Power Usage Effectiveness (PUE), which compares the total energy consumed by a data center to the energy used solely by IT equipment.

In the realm of antifreeze performance, a modified version of PUE, known as Weather-normalized PUE (WnPUE), has gained prominence. This metric accounts for variations in external temperature and humidity, offering a more accurate representation of cooling system efficiency in cold climates. WnPUE allows for fair comparisons between data centers operating in different geographical locations and climatic conditions.

Another essential metric is the Cooling System Efficiency (CSE), which specifically measures the energy consumed by cooling systems relative to the total IT load. In antifreeze scenarios, CSE becomes particularly relevant as it directly reflects the effectiveness of cold weather adaptations. A lower CSE indicates better energy efficiency and improved antifreeze performance.

The Carbon Usage Effectiveness (CUE) metric has also gained traction in recent years. It measures the total CO2 emissions caused by a data center's energy consumption, divided by the energy consumption of IT equipment. This metric is especially pertinent when evaluating the environmental impact of antifreeze solutions in data centers located in cold regions, where energy sources may vary significantly.

Water Usage Effectiveness (WUE) is another critical metric, particularly relevant to antifreeze performance analysis. It measures the amount of water used for cooling and other purposes in relation to IT equipment energy consumption. In cold climates, where water-based cooling systems may be prone to freezing, innovative antifreeze solutions can significantly impact this metric.

The IT Thermal Conformance and IT Thermal Resilience metrics, introduced by The Green Grid, are particularly relevant to antifreeze performance. These metrics assess how well IT equipment operates within its specified temperature range and its ability to continue functioning during cooling system failures or extreme temperature events.

Lastly, the recently developed Performance Per Watt (PPW) metric provides insights into the computational efficiency of data centers in relation to energy consumption. In the context of antifreeze performance, PPW can help evaluate how cold weather adaptations impact overall system performance and energy efficiency.

These energy efficiency metrics, when applied to antifreeze performance analysis in revolutionary data centers, provide a comprehensive framework for evaluating the effectiveness of cooling strategies, energy consumption patterns, and overall system resilience in cold climates. They enable data center operators and designers to make informed decisions about implementing antifreeze technologies and optimizing energy usage in challenging environmental conditions.